Patents

Literature

154results about How to "Low kinematic viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

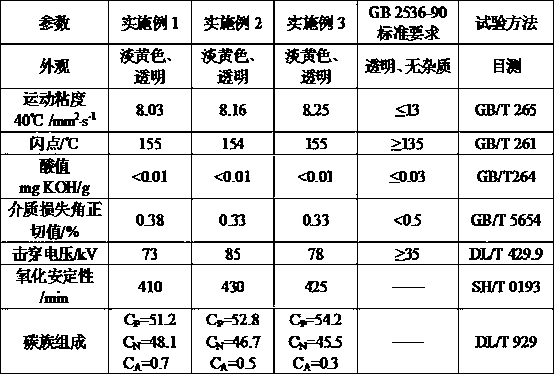

Extra-high voltage transformer oil and production process thereof

The invention relates to extra-high voltage transformer oil and a production process thereof. The extra-high voltage transformer oil comprises the following components in percentage by weight: 75wt%-85wt% of naphthenic-base base oil, 12wt%-22wt% of dodecyl benzene, 10ppm-200ppm of a metal de-activating agent and 0.1wt%-3wt% of a light stabilizer. Compared with the prior art, the extra-high voltage transformer oil is low in cost, simple in formula and production process, convenient to use, excellent in comprehensive performances and in particular suitable for being used as extra-high voltage transformer oil.

Owner:ANHUI KAIAO NEW ENERGY CO LTD

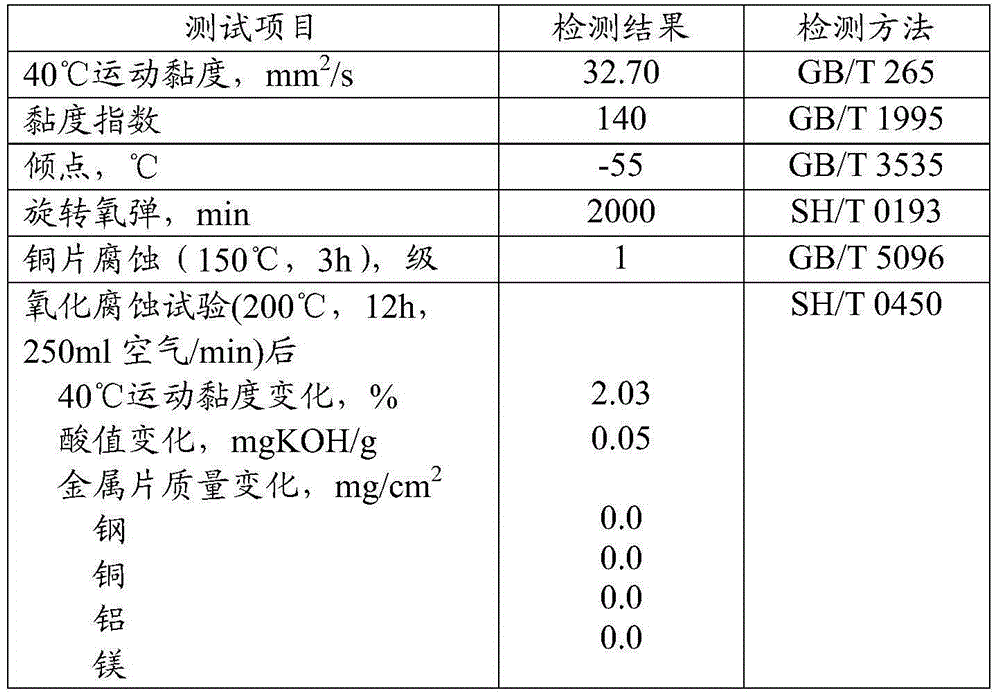

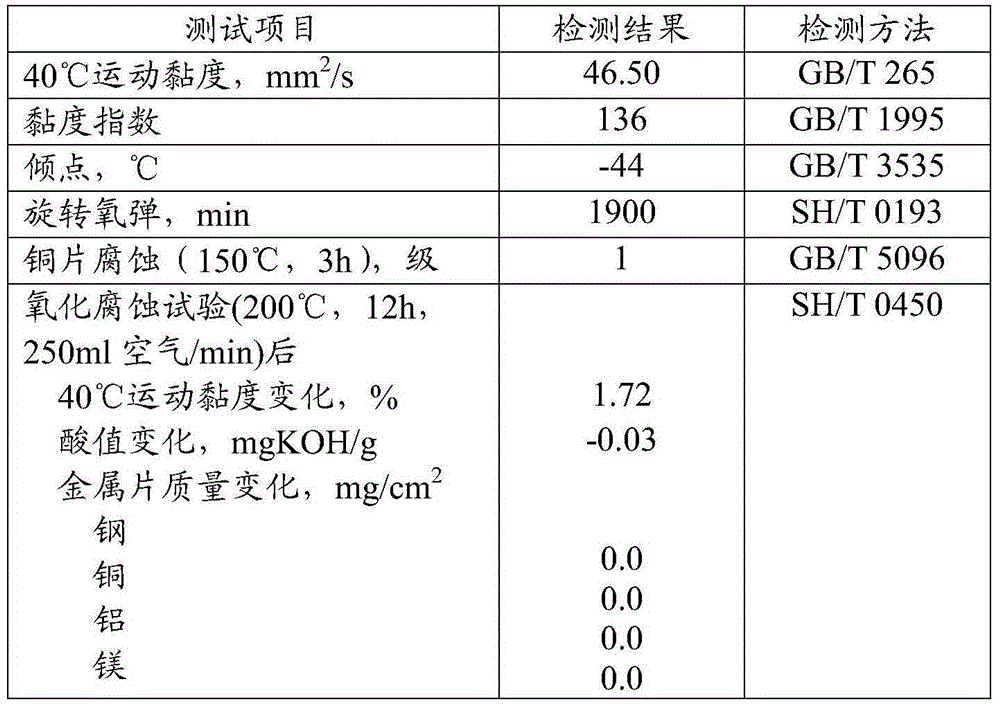

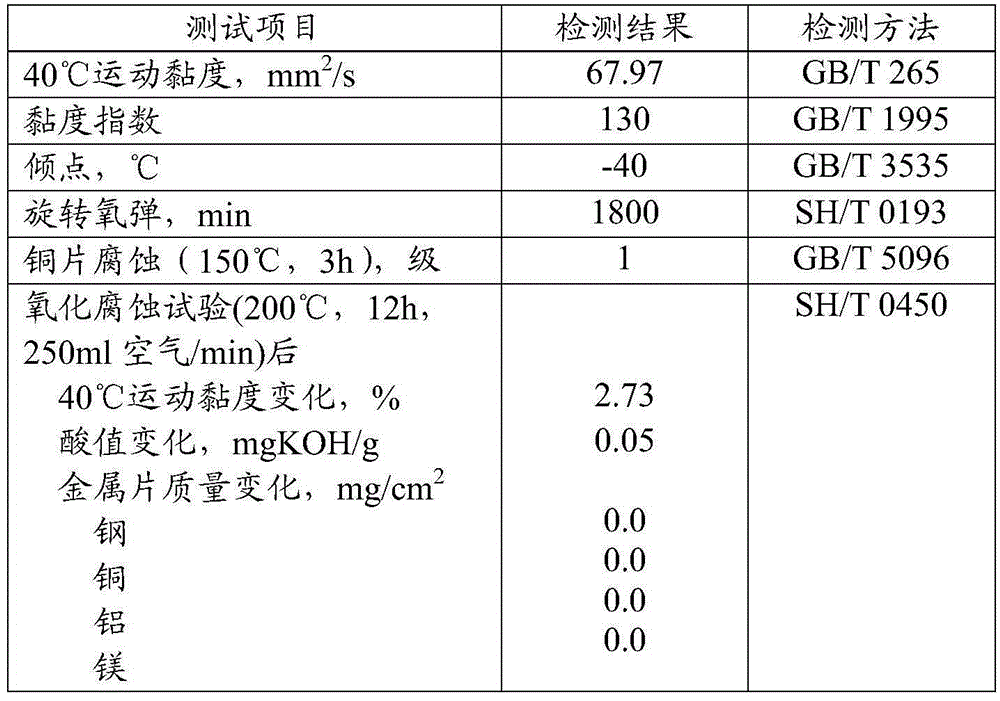

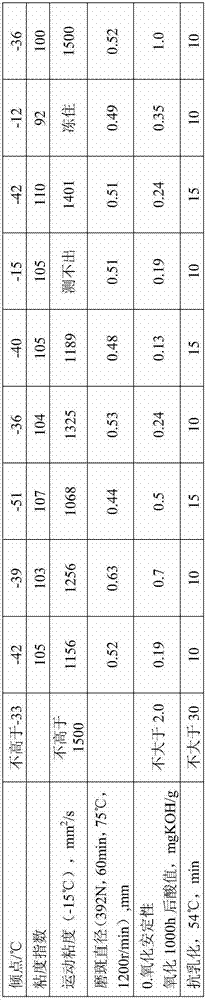

Screw air compressor oil composition and preparation method thereof

InactiveCN105176650AGuaranteed safe operationNot easy to oxidize and deteriorateLubricant compositionGas compressorAntioxidant

The invention provides a screw air compressor oil composition. The screw air compressor oil composition comprises the following components in percentage by weight: 75wt%-94wt% of synthetic hydrocarbon base oil, 5wt%-20wt% of synthetic ester base oil and 1wt%-5wt% of functional additives, wherein the functional additives include one or more of an anti-wear agent, a metal deactivator, a rust inhibitor, an antioxidant, a pour point depressant, a demulsifying agent, an anti-foaming agent and an acid scavenger. By taking mixed hydrocarbon oil of the synthetic hydrocarbon base oil and the synthetic ester base oil as the base oil and simultaneously adding functional additives, the obtained screw air compressor oil composition is not easily oxidized and degraded in a use process, and the changes of the dynamic viscosity and the acid value are relatively small, so that the corrosion to units of an air compressor can be reduced, and the safe operation of the screw air compressor is guaranteed.

Owner:CHINA PETROLEUM & CHEM CORP

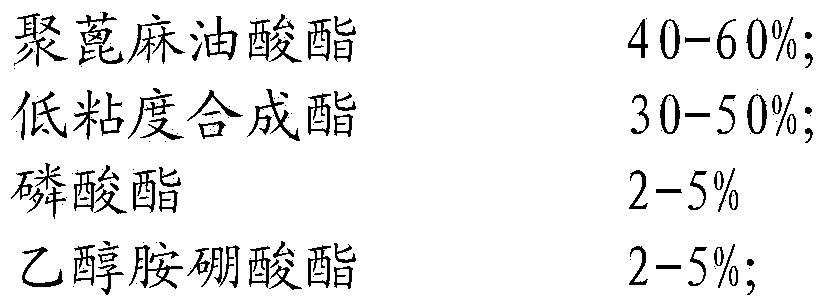

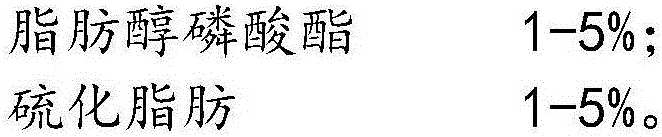

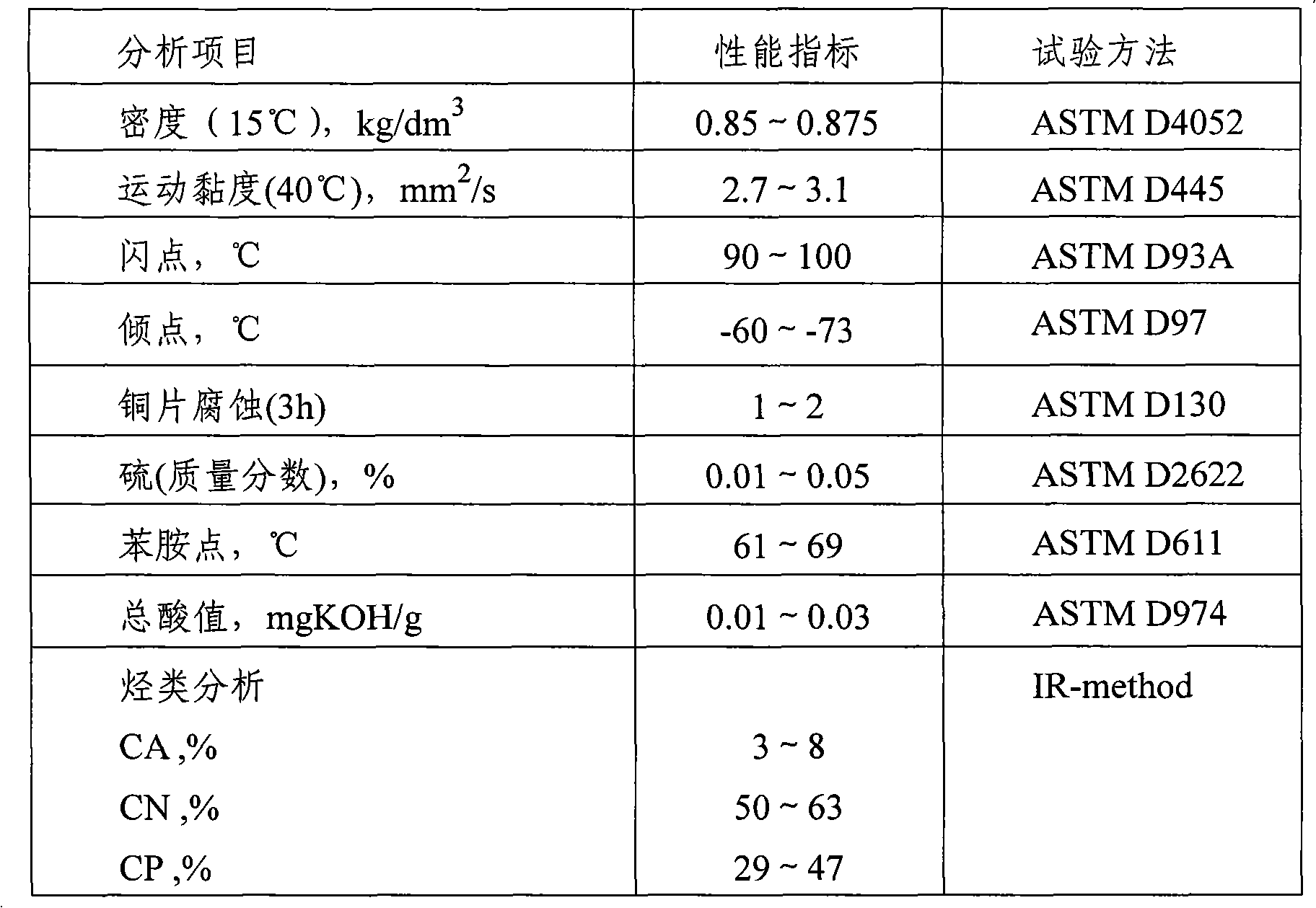

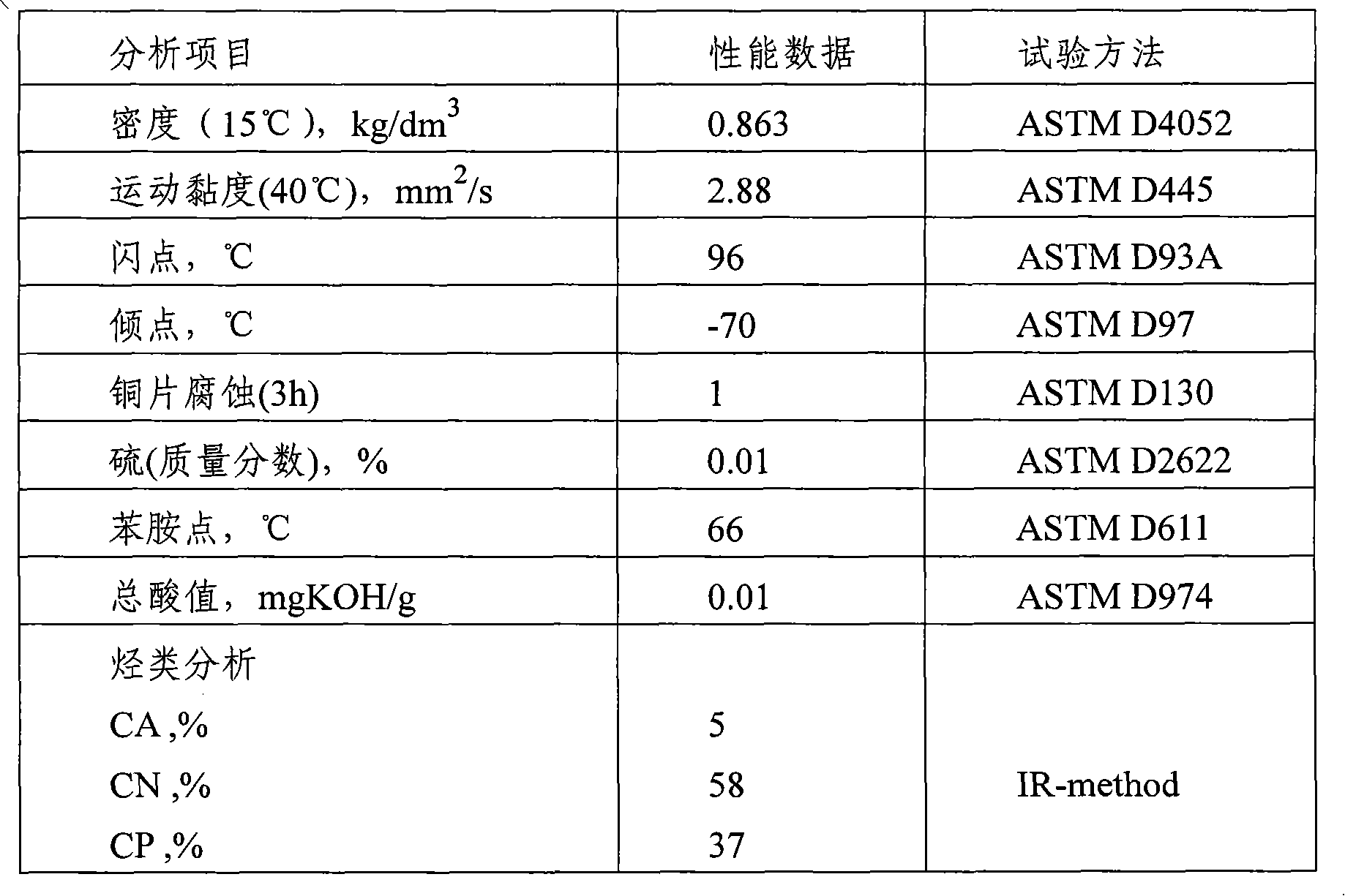

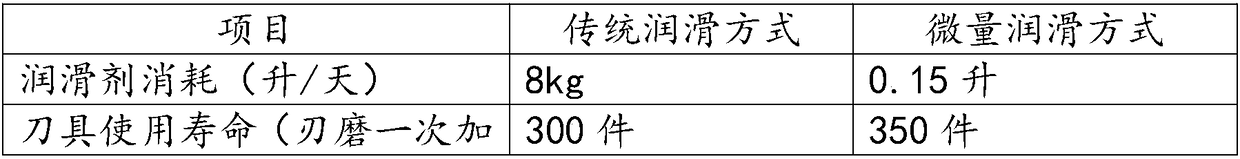

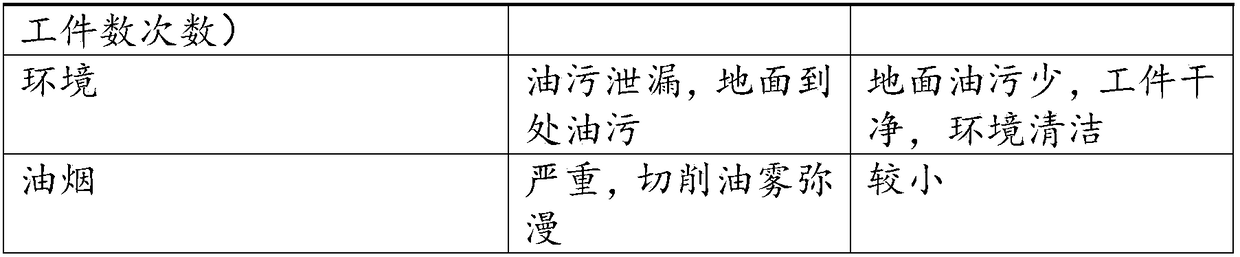

Special micro-lubricant for oil-water-gas-phase micro-lubricating system and preparation method of lubricant

ActiveCN104031732AImprove cooling effectGood extreme pressure and anti-wear propertiesLubricant compositionAlcoholMolybdate

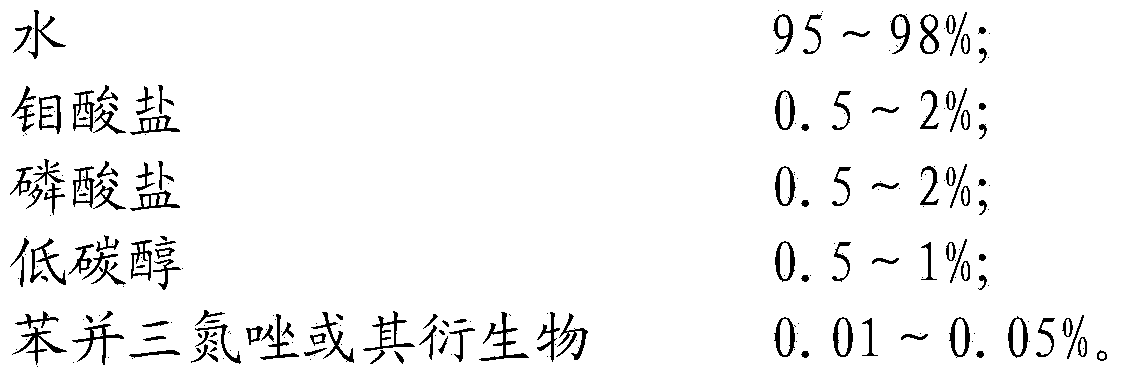

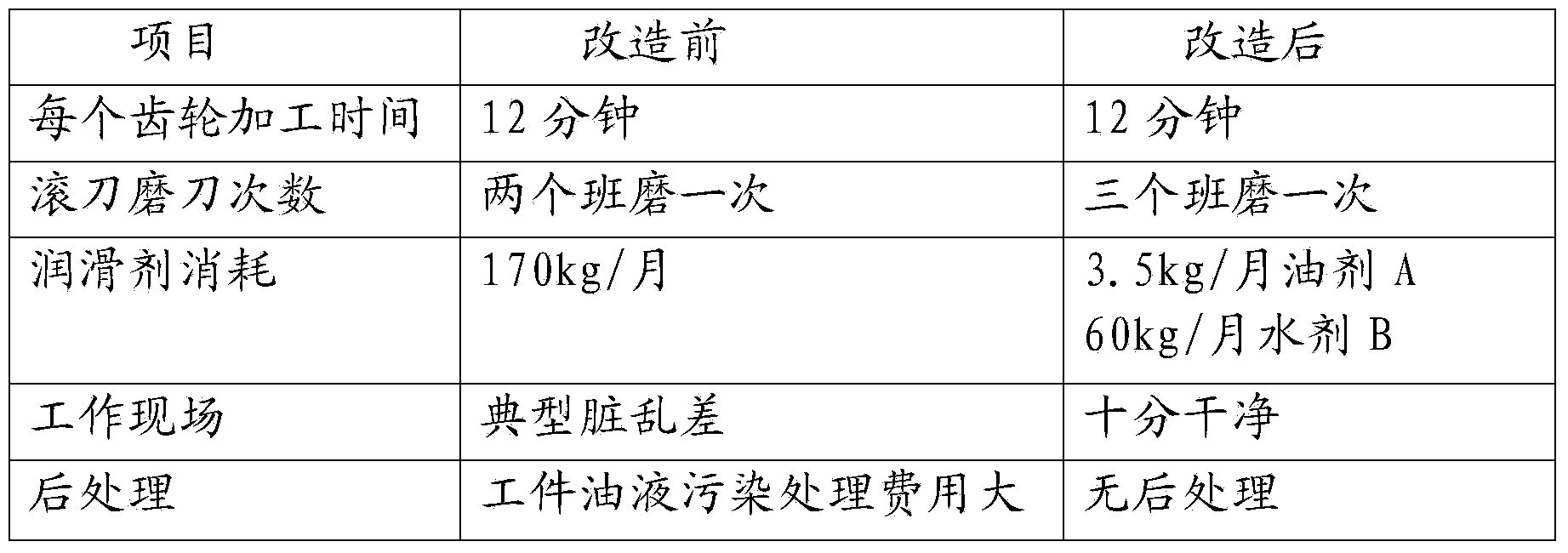

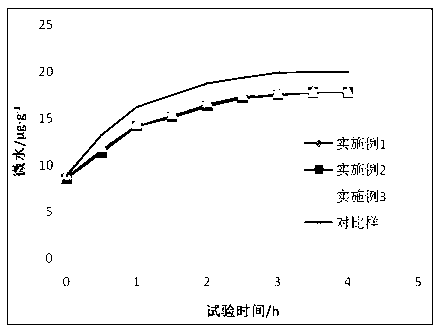

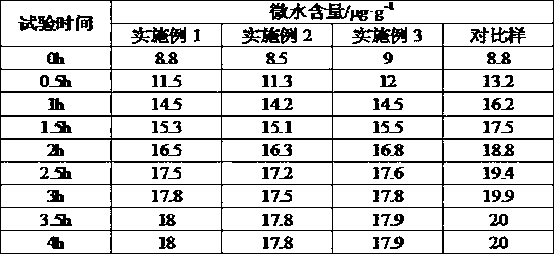

The invention relates to a special micro-lubricant for an oil-water-gas-phase micro-lubricating system. The lubricant is characterized by comprising an oiling agent A and water aqua B, wherein the oiling agent A is prepared from the following components in percentage by weight: 40-60% of polyricinoleate, 30-50% of low viscosity synthetic ester, 2-5% of phosphate and 2-5% of ethanolamine borate; the water aqua B is prepared from the following components in percentage by weight: 95-98% of water, 0.5-2% of molybdate, 0.5-2% of phosphate, 0.5-1% of lower alcohol and 0.01-0.05% of benzotriazole or derivatives. The special micro-lubricant for the oil-water-gas-phase micro-lubricating system, which is disclosed by the invention, is matched with a micro-lubricating device in use, so that the use level of a cutting liquid is saved by over 95%.

Owner:营口康如科技有限公司

Transformer oil with excellent cooling heat-radiating and moisture preventing properties and preparation method thereof

The invention discloses transformer oil with excellent cooling heat-radiating and moisture preventing properties. The transformer oil is mainly prepared from the following raw materials: hydrogenated stock oil, naphthene thickened oil, an antioxidant and a metal passivator, wherein the ratio of the hydrogenated stock oil to the naphthene thickened oil is (72-82):(18-28) in terms of parts by weight, the amount of the used antioxidant accounts for 0.3-0.5% relative to the total mass of the hydrogenated stock oil and the naphthene thickened oil, and the amount of the used metal pasivator accounts for 0.1-0.2% relative to the total mass of the hydrogenated stock oil and the naphthene thickened oil. The invention further discloses a preparation method of the transformer oil. The transformer oil has excellent cooling heat-radiating and moisture preventing properties, thus being very suitable for being used in southern areas of China.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

Lubricating Oil Composition For Lubricating Automotive Engines

ActiveUS20120132166A1High HTHS viscosityImprove fuel economyNon-fuel substance addition to fuelCombustion enginesAlkaline earth metalViscosity grade

A lubricating oil composition of SAE viscosity grade 0W20 which comprises a base oil and additive components comprising a nitrogen-containing ashless dispersant, an alkaline earth metal-containing detergent, a phosphorus-containing wear inhibitor, an oxidation inhibitor and a viscosity index improver and which shows a viscosity index of 200-240, a HTHS viscosity of not less than 2.9 mPa·s s at 150° C. and a Noack evaporation loss of not more than 13% favorably gives a high fuel economy and high wear inhibition to a four cycle gasoline engine of motorcycles and a diesel engine mounted on motor cars equipped with an exhaust gas post-processing apparatus.

Owner:CHEVRON JAPAN

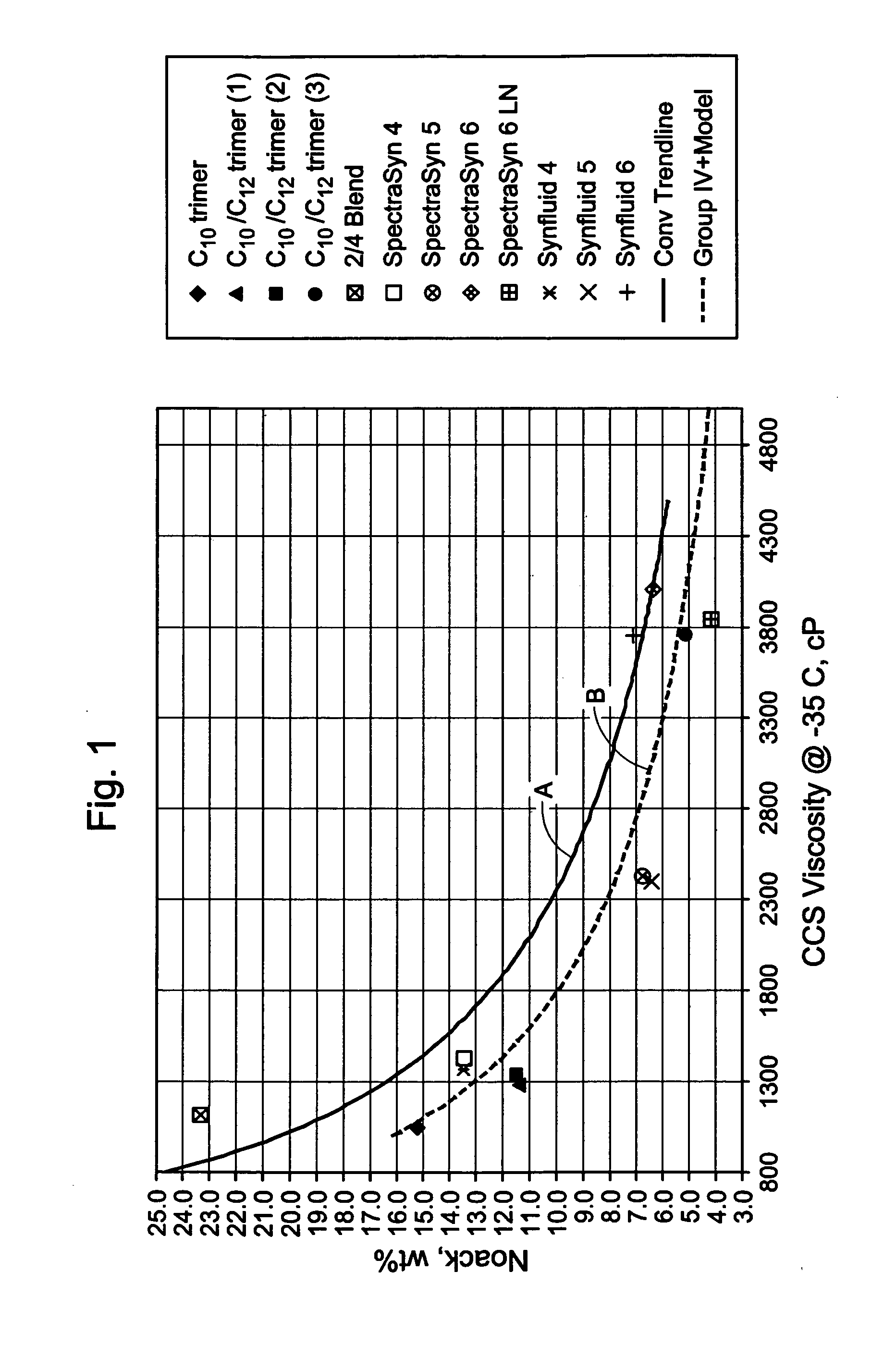

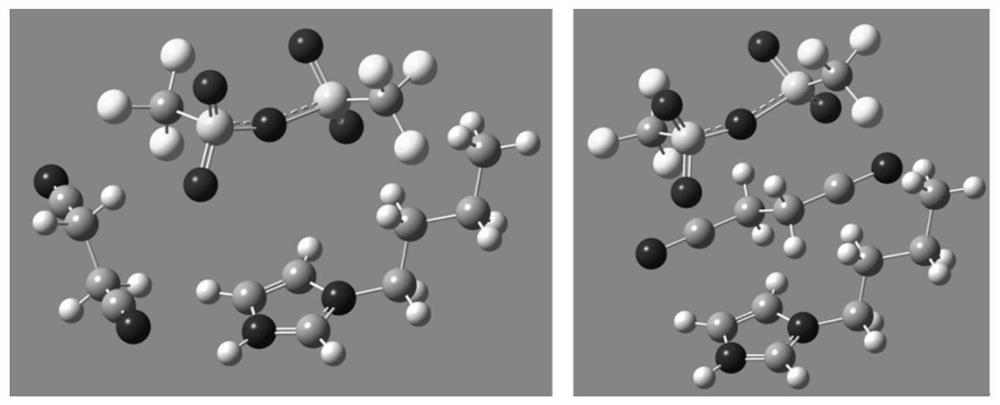

Use of a metallocene catalyst to produce a polyalpha-olefin

InactiveUS20150344598A1High catalytic activityLow kinematic viscosityHydrocarbon by hydrogenationOrganic-compounds/hydrides/coordination-complexes catalystsHalogenSilylene

A process may include contacting an olefin monomer and a racemic bridged metallocene catalyst at a temperature of 80° C. to 150° C. in the presence of hydrogen. The racemic bridged metallocene catalyst may include a metallocene compound (A) and an activator component (B). The process may include recovering an effluent containing polyalpha-olefins (PAOs). The metallocene compound (A) may be represented by the formula R(Cp1)(Cp2)MX1X2. In the formula, R may be a C1-C20 alkylene bridging group; Cp1 and Cp2 may be the same or different substituted or unsubstituted tetrahydroindenyl rings; M may be a transition metal; and X1 and X2 may be independently selected from hydrogen, halogen, hydride radicals, hydrocarbyl radicals, substituted hydrocarbyl radicals, halocarbyl radicals, substituted halocarbyl radicals, silylcarbyl radicals, substituted silylcarbyl radicals, germlcarbyl radicals, substituted germylcarbyl radicals.

Owner:TOTAL RES & TECH FELUY

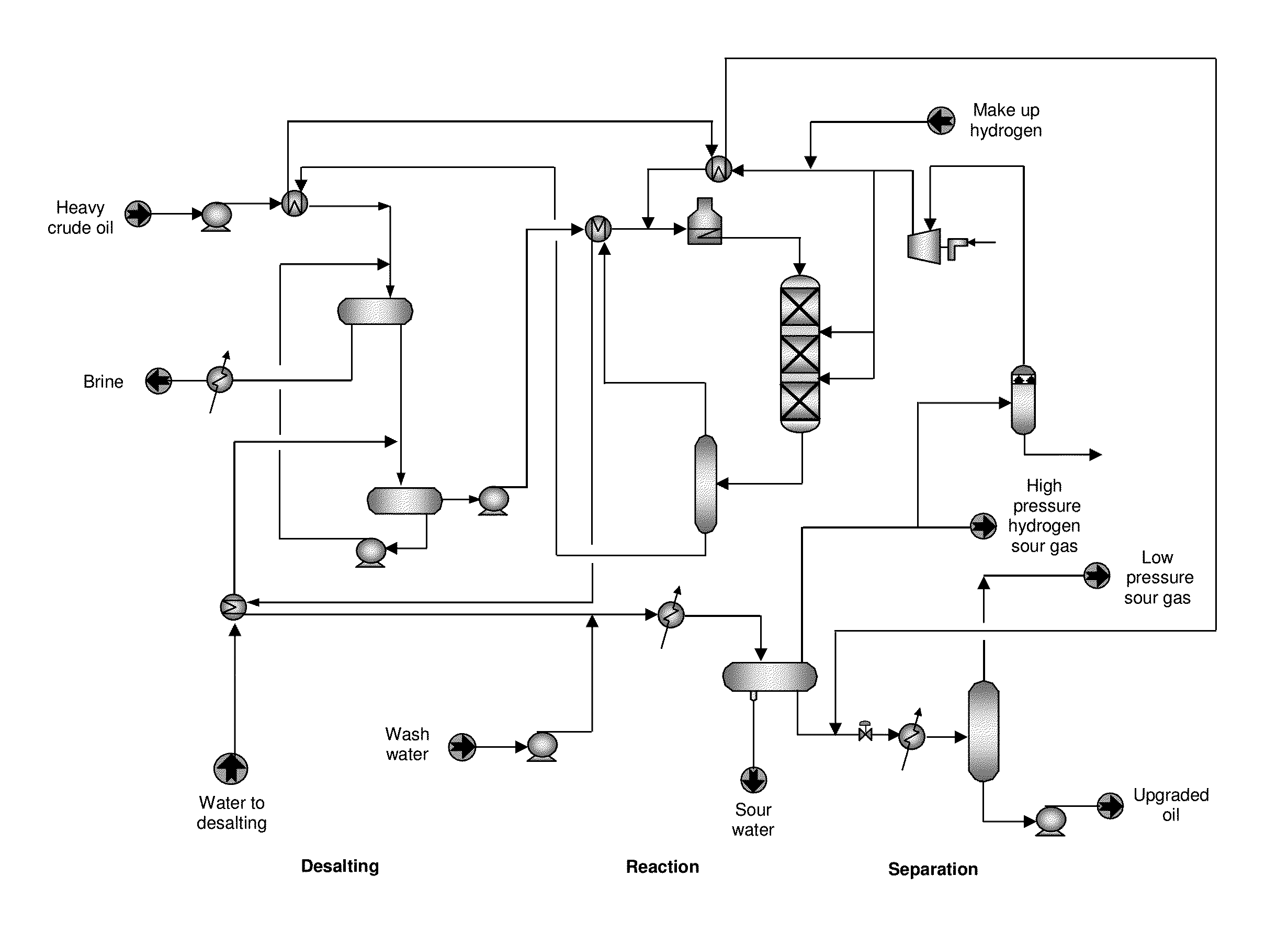

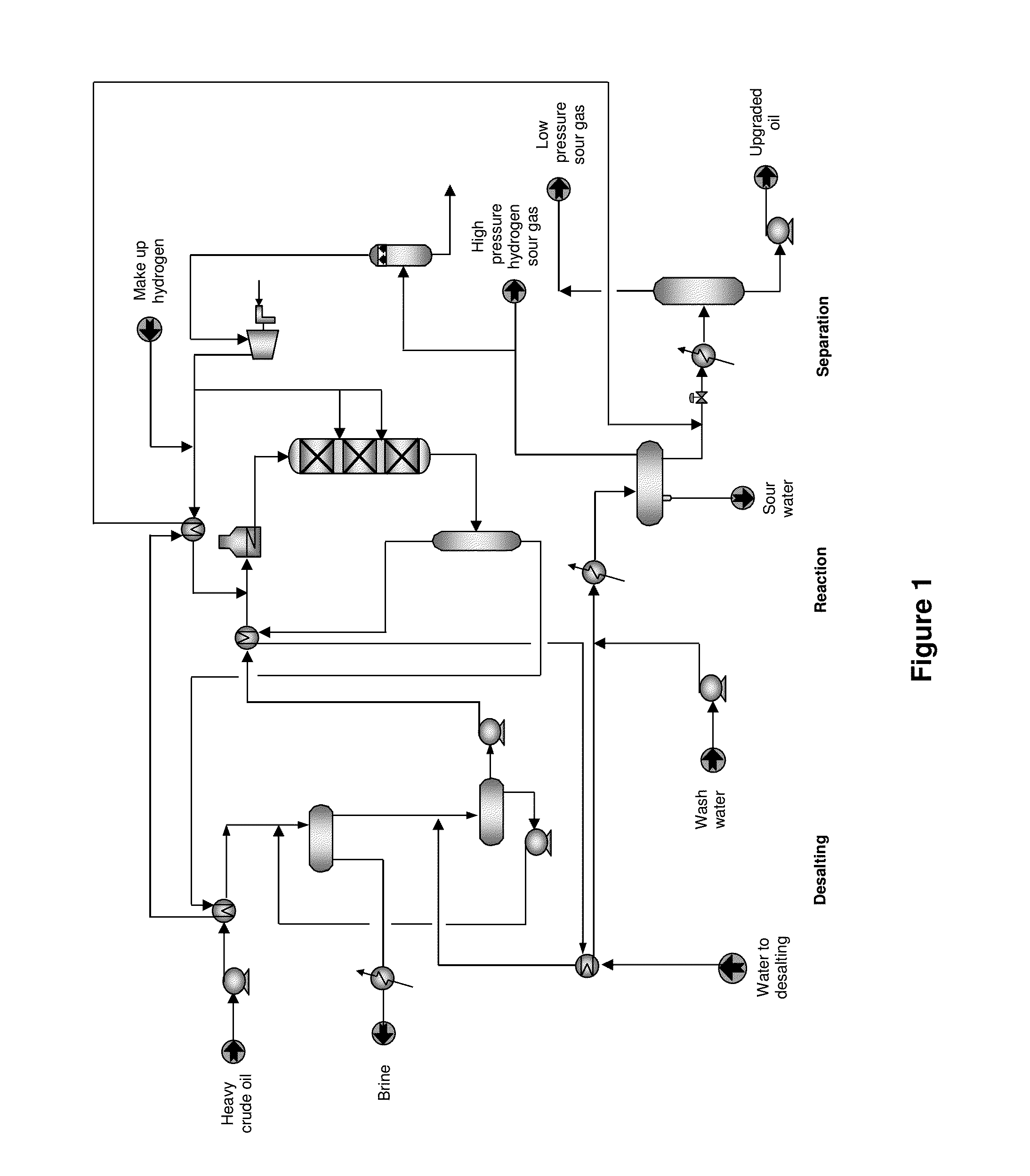

Process for partial upgrading of heavy and/or extra-heavy crude oils for transportation

ActiveUS20160060549A1Suitable propertyReduce viscosityLiquid hydrocarbon mixture recoveryHydrocarbon oil crackingNitrogenOil refinery

The present invention relates to a process for the partial upgrading of properties of heavy and / or extra-heavy crude oil by low severity catalytic hydrotreatment in only one reaction step. The process of the present invention is obtained upgraded oil with properties required for its transportation from offshore platforms either to maritime terminal or to refining centers. The process reduces the viscosity of heavy and / or extra-heavy crude oil, and decreases the concentration of impurities, such as sulfur, nitrogen, and metals, in such a way that heavy and / or extra-heavy crude oils can be transported to maritime terminals or to refining centers. The process increases the lifetime of the catalyst and decreased operating costs by reducing consumption of utilities because the operation of the process is carried out at lower severity. The partially upgraded oils obtained in this process can be transported directly to the maritime terminals or to existing refineries.

Owner:INST MEXICANO DEL GASOLINEEO

Blend comprising group II and group IV basestocks

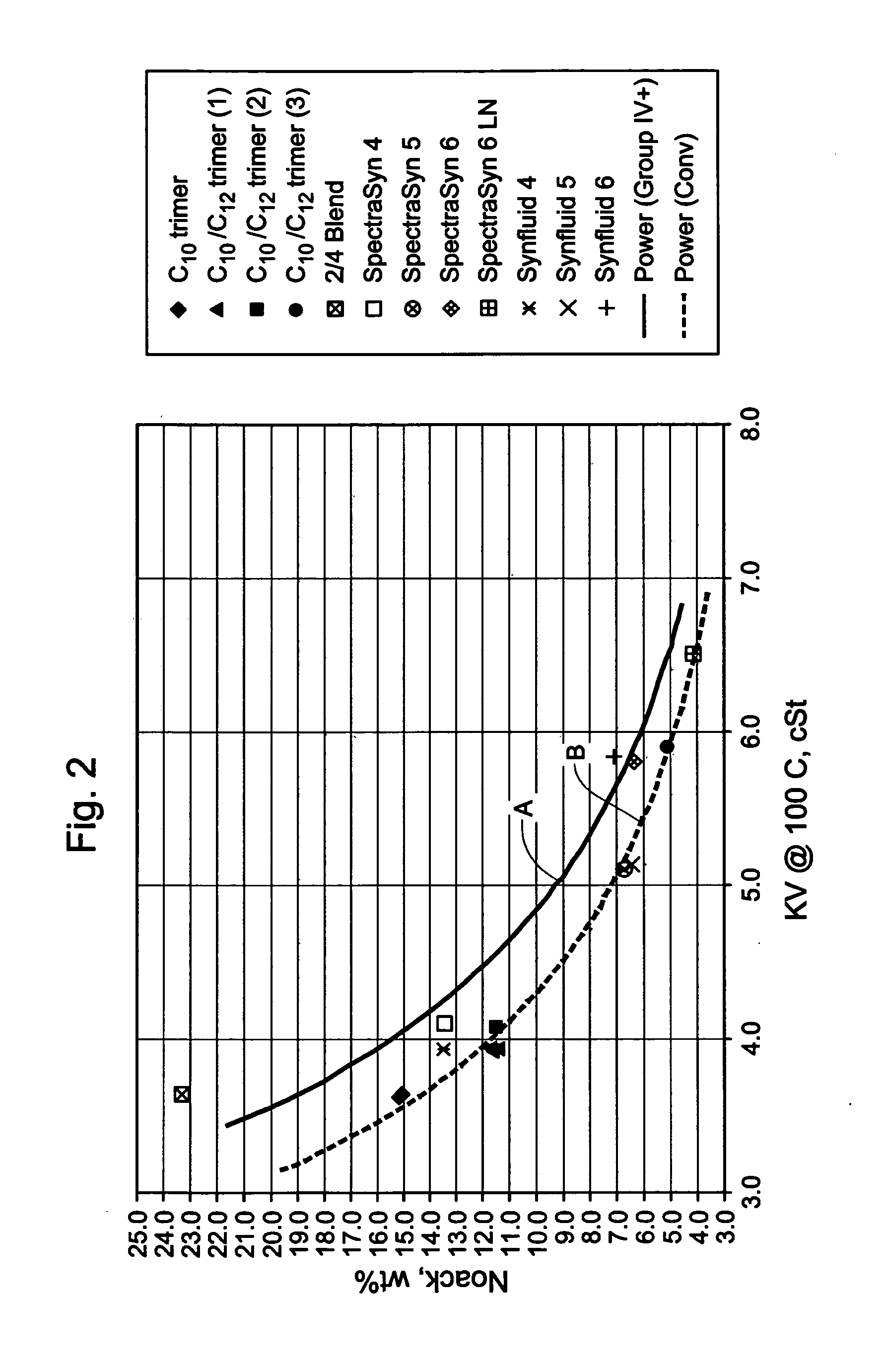

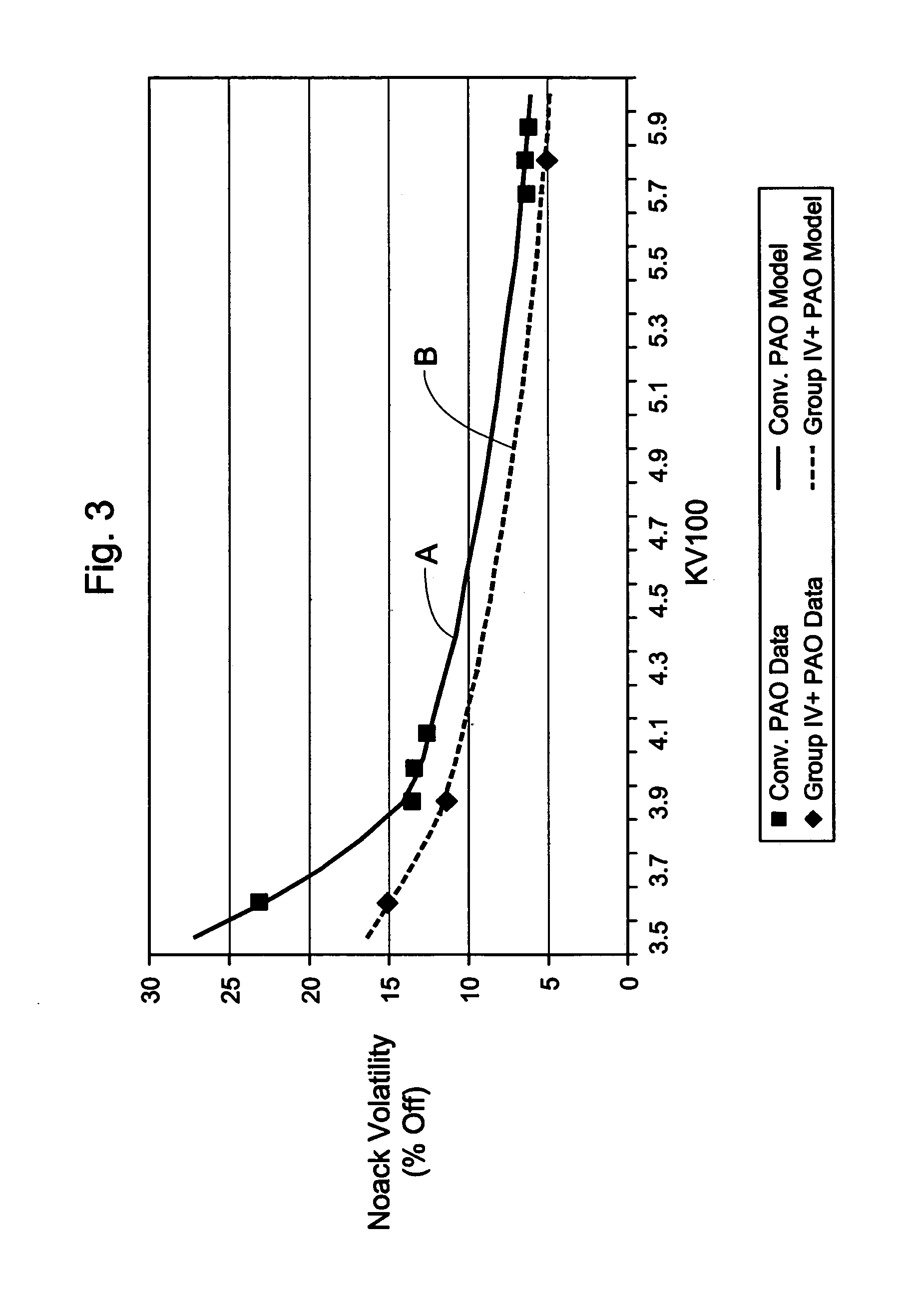

InactiveUS20070078070A1Low kinematic viscosityLow Noack volatilityLiquid hydrocarbon mixtures productionLiquid carbonaceous fuelsBase oilHydraulic fluid

The invention relates to compositions comprising a blend of Group II basestocks and low volatility, low viscosity PAO basestocks. The blend is particularly useful for preparing finished lubricants that meet or even exceed the criteria for SAE Grade 0W multi-grade engine oils. The combination of these low volatility, low viscosity PAOs with Group II basestocks provide, in embodiments, the necessary performance criteria in automatic transmission fluids, automotive or industrial gear oils, hydraulic fluids, or any other high performance lubricant requiring a combination of excellent low fluidity and low volatility.

Owner:EXXONMOBIL CHEM PAT INC

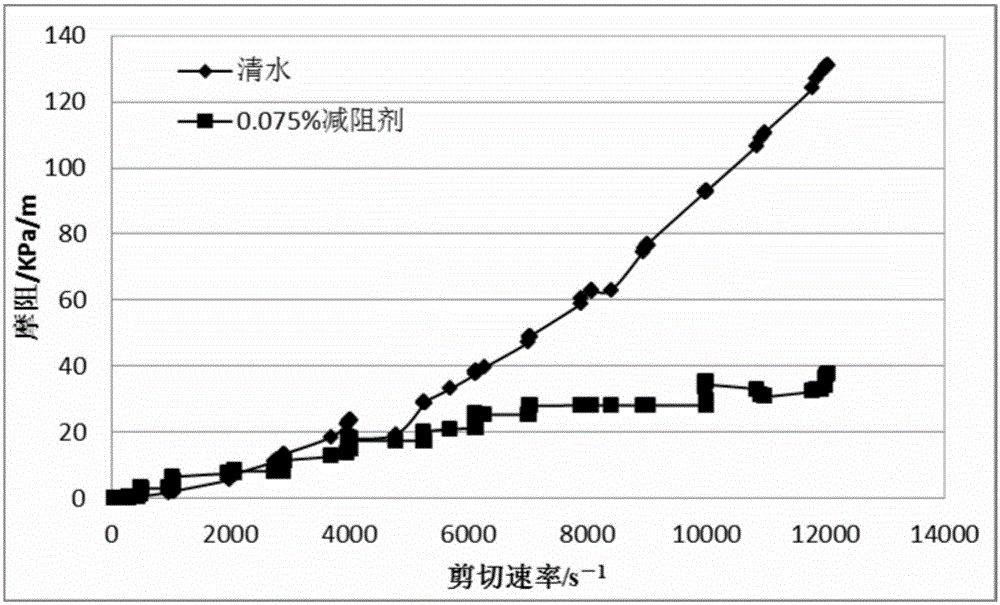

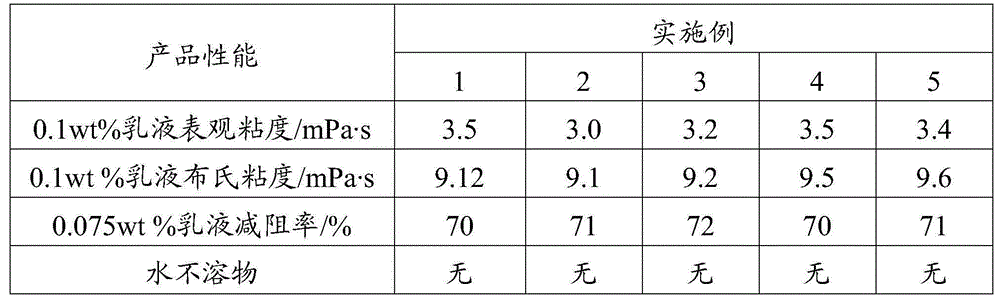

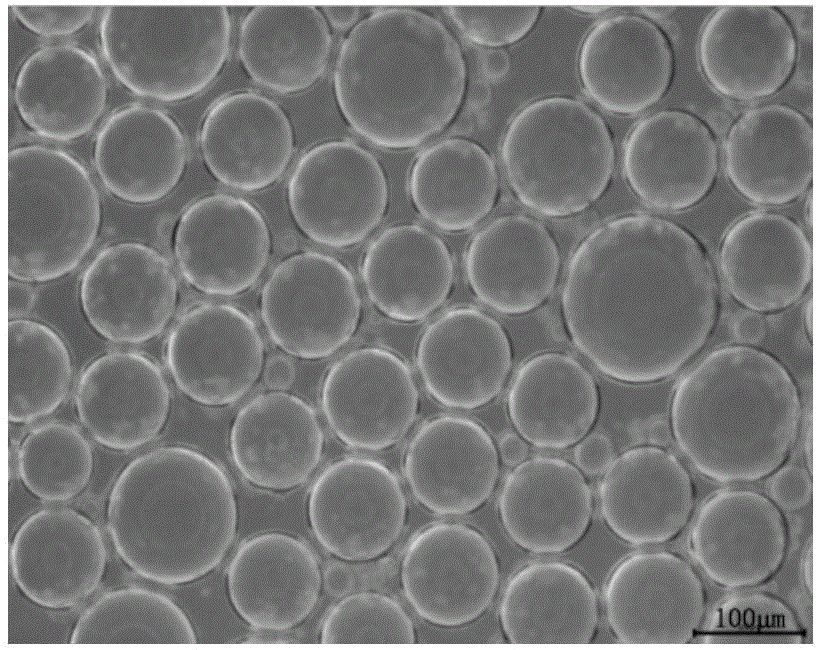

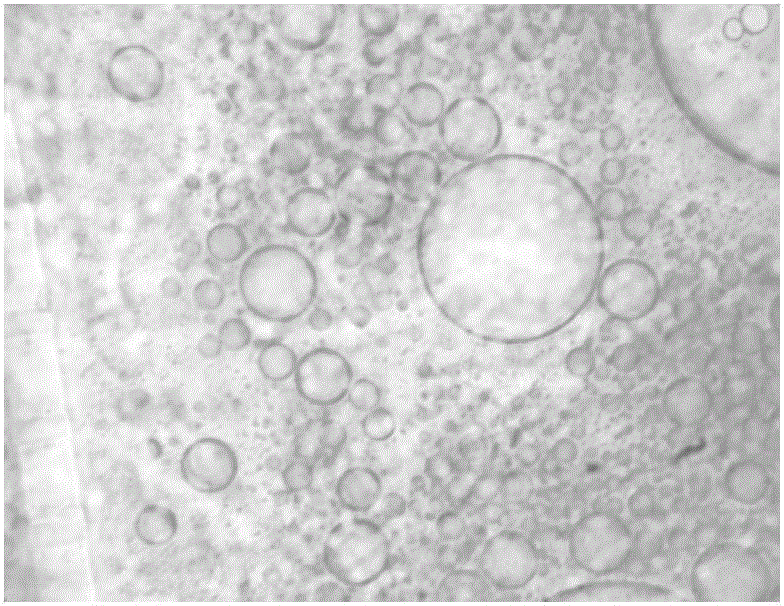

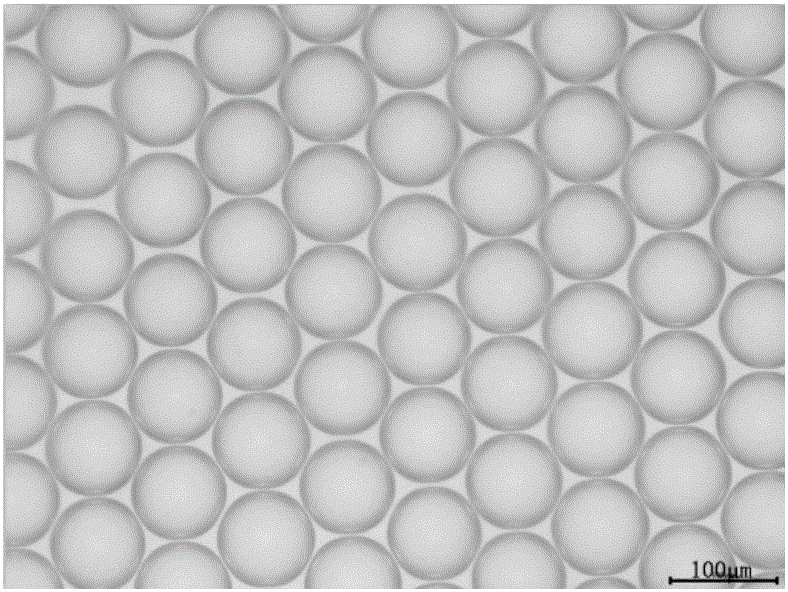

Inverse emulsion polymer drag reducer, and preparation method and application thereof

InactiveCN106565900AGood temperature and salt resistanceFast dispersionDrilling compositionPolymer scienceEmulsion polymerization

The invention provides an inverse emulsion polymer drag reducer, and a preparation method and an application thereof. The method comprises the following steps: adding an aqueous-phase material into an oil-phase material, and carrying out emulsifying so as to obtain a monomer emulsion, wherein the aqueous-phase material comprises 130 to 165 parts by mass of water, 6 to 36 parts by mass of acrylic acid, 24 to 77 parts by mass of 2-acrylamido-2-methyl propane sulfonic acid, 32 to 82 parts by mass of an organic amide monomer and 0.5 to 0.9 part by mass of a hydrophilic emulsifier, and the oil-phase material comprises 104 to 120 parts by mass of base oil with a specific viscosity and 4 to 8 parts by mass of a lipophilic emulsifier; and mixing the monomer emulsion with an initiator at 20 DEG C to 30 DEG C, then carrying out standing, and carrying out a polymerization reaction under the condition of 50 DEG C to 55 DEG C for 1 h to 2 h so as to obtain the inverse emulsion polymer drag reducer. The inverse emulsion polymer drag reducer prepared by using the method provided by the invention has high drag reducing rate and low cost under the condition of small addition amount.

Owner:中石化石油工程技术服务有限公司 +1

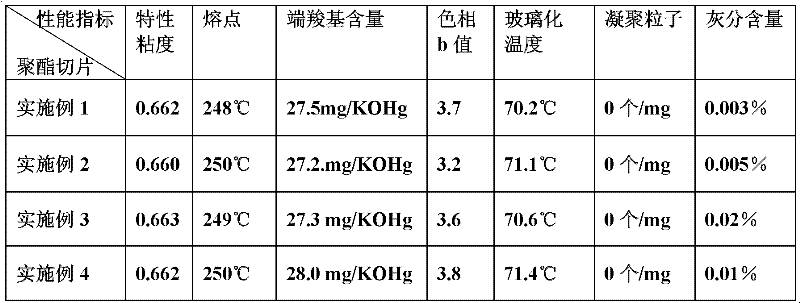

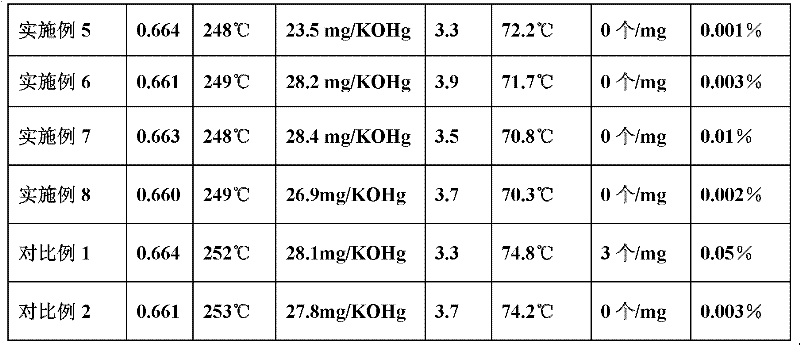

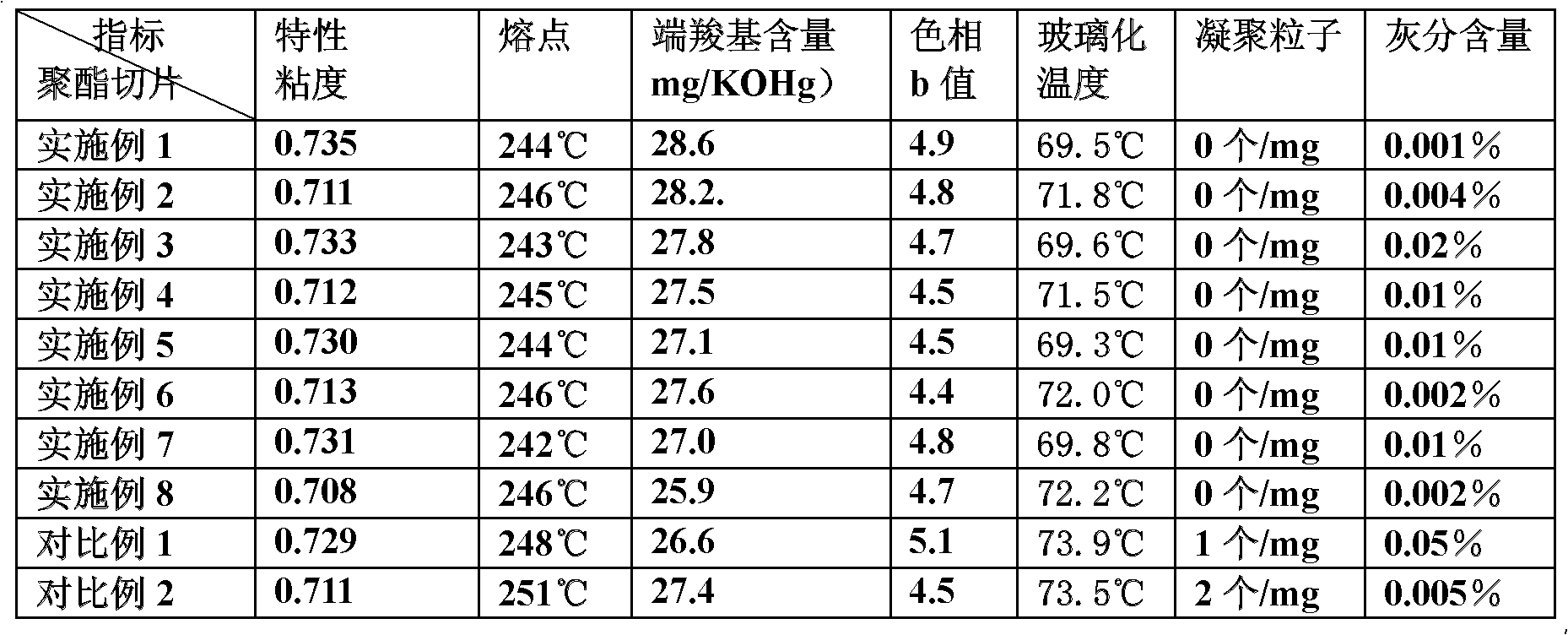

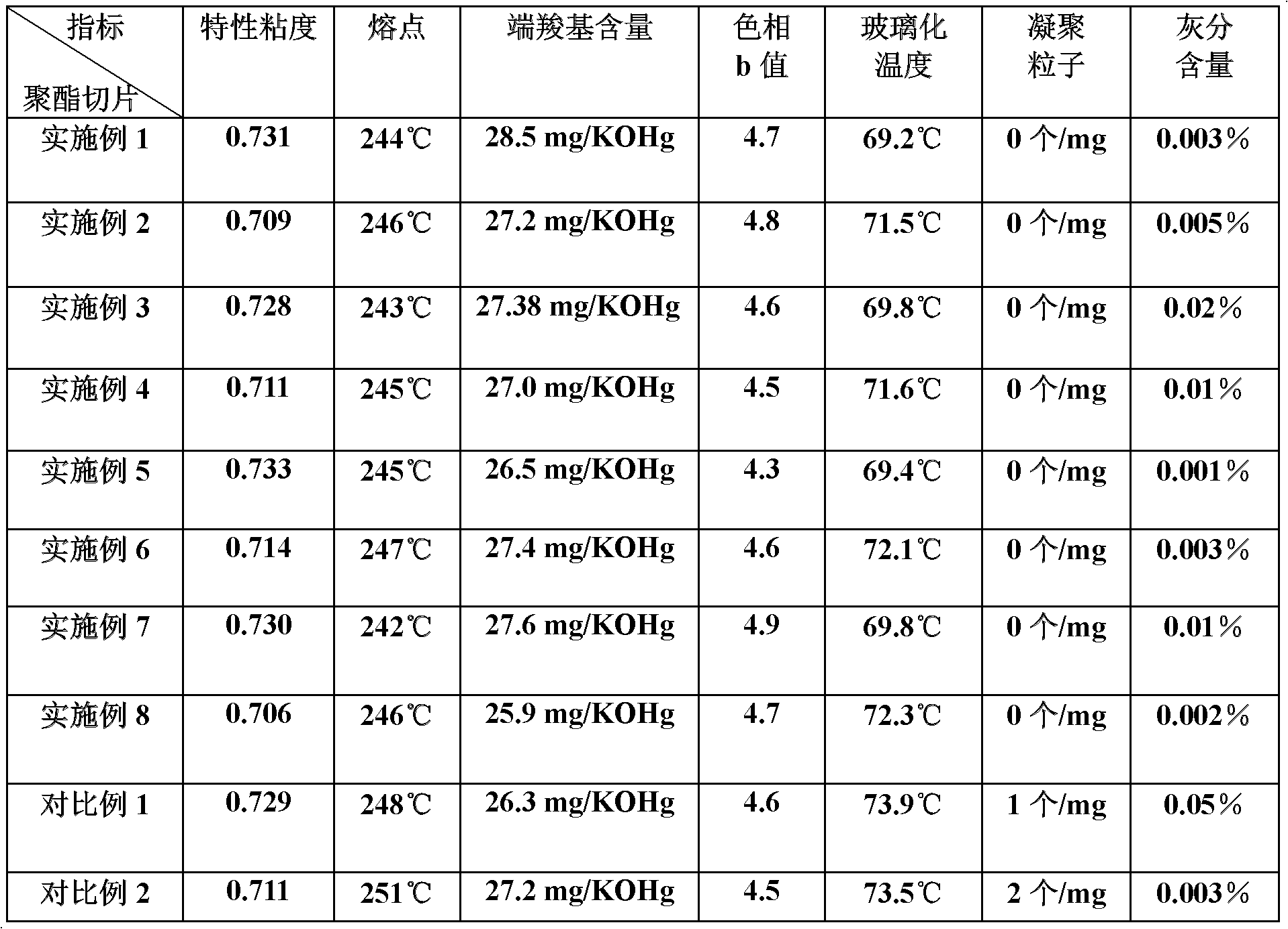

Preparation method for polyester fiber with compound ultraviolet ray resisting, aging resisting, moisture absorbing and quick drying functions

ActiveCN102443876AImproves UV resistanceReduce permeationMonocomponent polyesters artificial filamentPolyesterFiber

The invention relates to a preparation method for a polyester fiber with compound ultraviolet ray resisting, aging resisting, moisture absorbing and quick drying functions. The method comprises an esterification reaction process, a polymerization reaction process and a spinning process in sequence, and comprises the following specific steps of: in an esterification reaction, introducing a third monomer with relatively large steric hindrance; after the esterification reaction and before a pre-polymerization reaction, adding titanium dioxide serving as a high-content delustering agent, a hindered amine light stabilizer and a hindered phenol antioxidant; after the pre-polymerization of polymerization reaction process and before final polymerization, adding an ultraviolet absorber; and beforethe spinning process, pre-crystallizing and drying polyester slices obtained in the polymerization reaction process, and designing a special-shaped section for the fiber. The polyester fiber obtainedby using the method has superior ultraviolet ray resisting, aging resisting, moisture absorbing and quick drying functions. As provided by testing, relevant technical indexes are that: the ultraviolet transmission is less than or equal to 5.0 percent, the wicking height is more than or equal to 120 millimeters, and the evaporation rate is more than or equal to 0.20g / hr after the polyester fiber is woven into a knitted fabric and a woven fabric.

Owner:JIANGSU GUOWANG HIGH TECH FIBER CO LTD

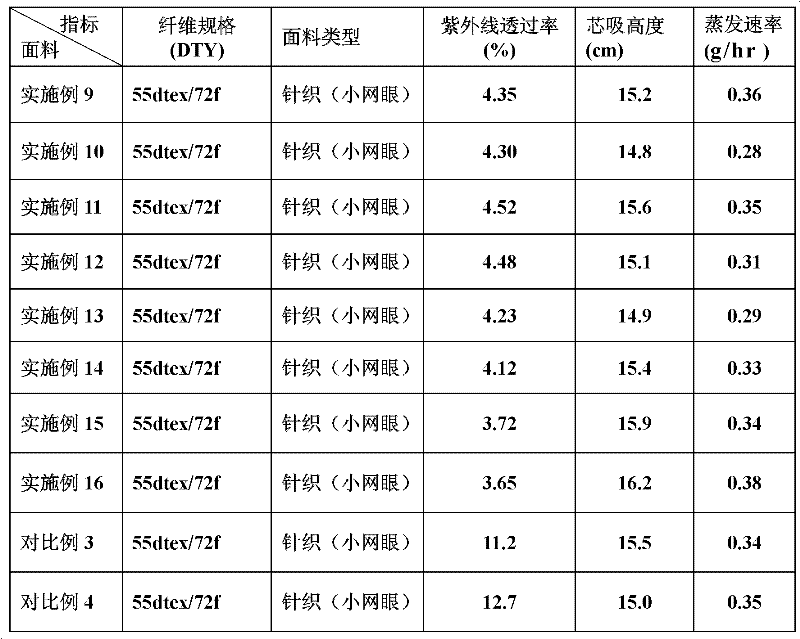

Concentrated emulsified diesel fuel and preparation method thereof

The invention relates to concentrated emulsified diesel fuel and a preparation method thereof, wherein the concentrated emulsified diesel fuel is long in shelf life and low in cost and is prepared by the following raw materials by weight parts: 50-80 of diesel, 0.5-1 of cyclohexylamine, 0.5-2 of ethanolamine, 0.03-0.08 of water and hydrazine, 8-17 of oleic acid or fatty acid, 0.01-0.08 of ferrocene, 0.1-1 of isooctyl nitrate or amyl nitrate, 5-10 of ethanol, 4-15 of solvent oil and 10-30 of water. The concentrated emulsified diesel fuel is long in service life which is 6 years, has no emulsion breaking, is good in stability, can be used directly, also can be used by being mixed with national-standard diesel in any proportion, and further has the advantages of being simple in production process, easy to control, low in sulphur content and good in flowability, and the quality of the diesel is free of influence caused by secondary water adding.

Owner:易信三农(沈阳)石化有限公司

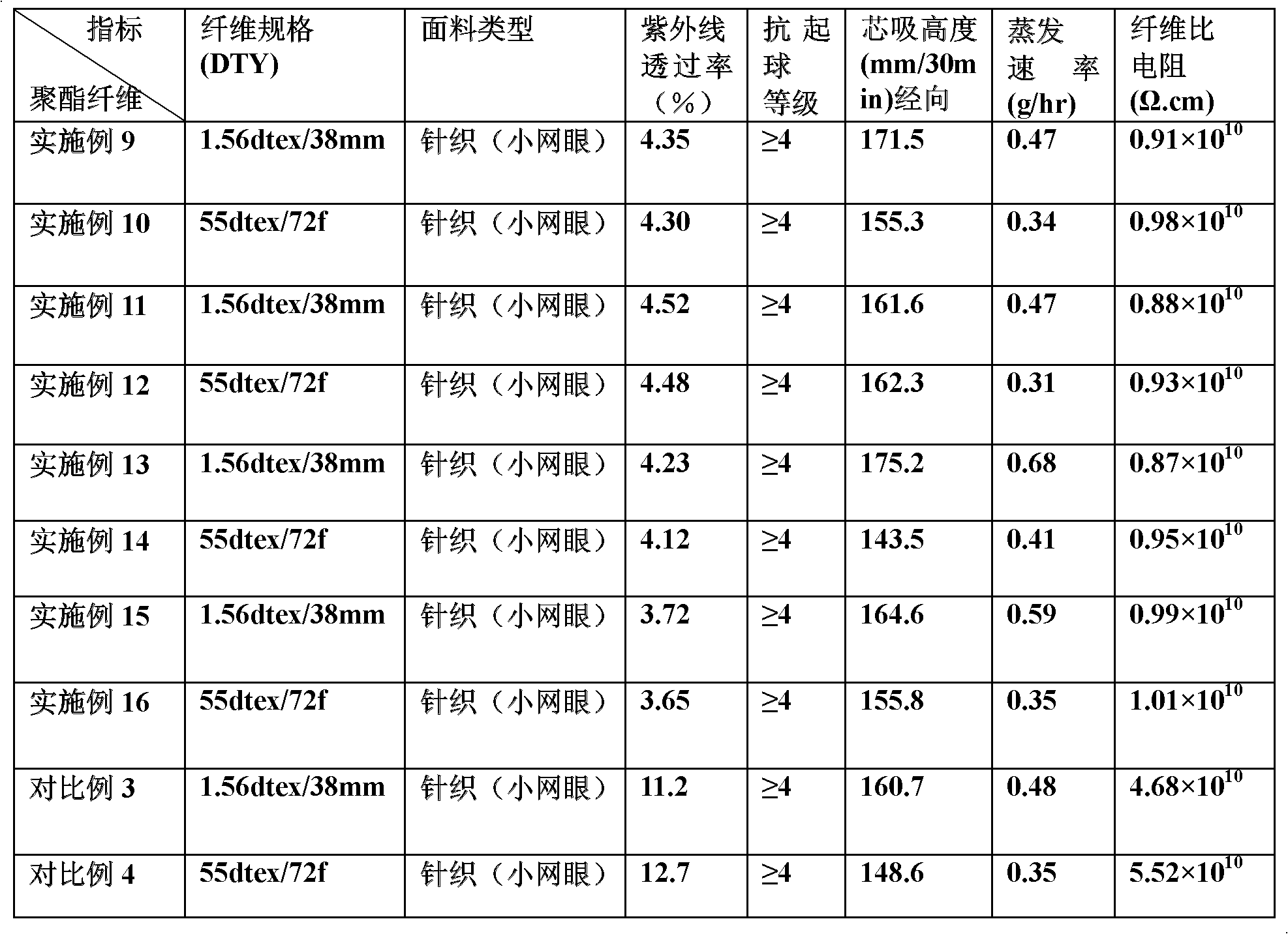

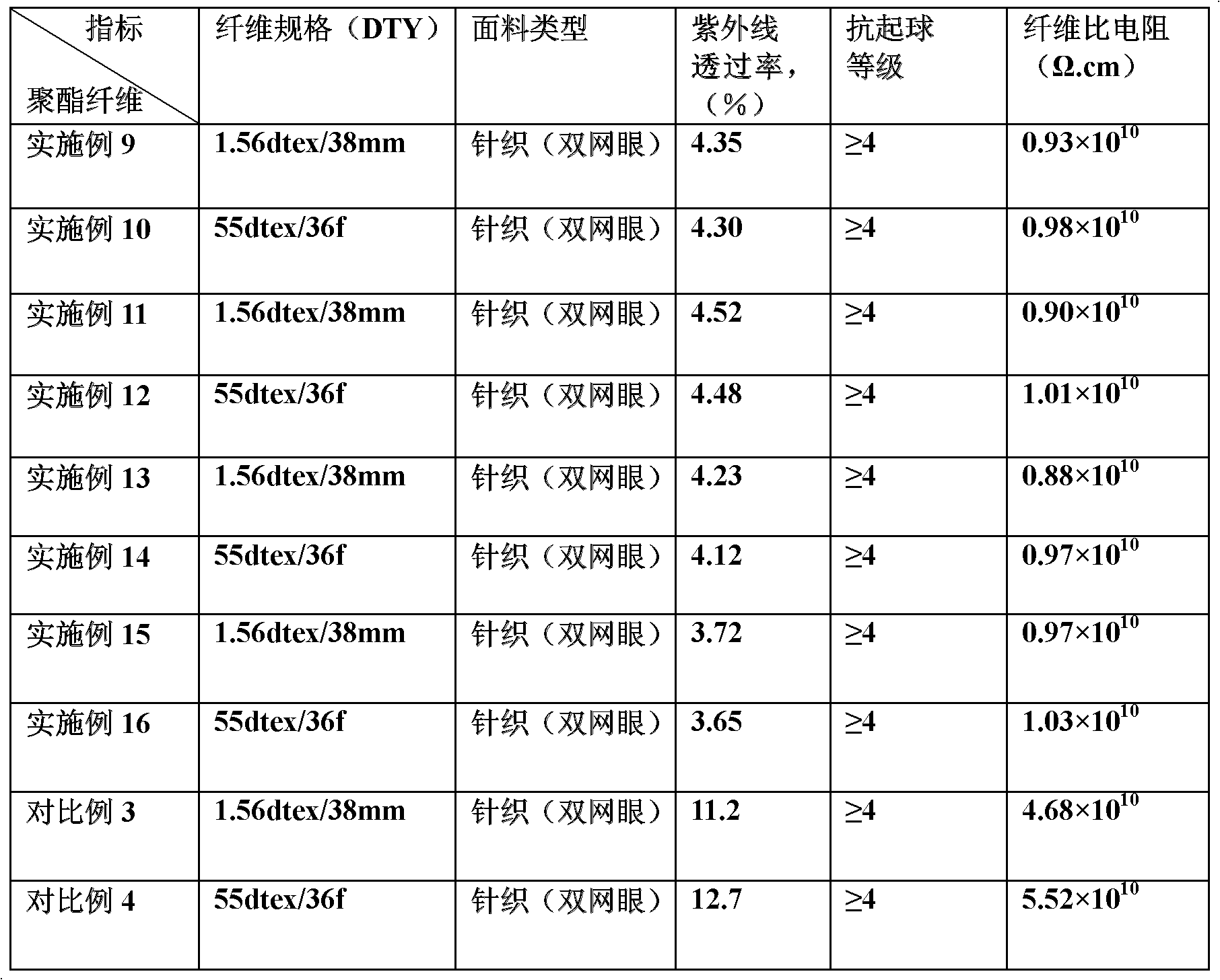

Method for preparing high-comfortable composite functional polyester fiber

ActiveCN102409429AReduce harmImproves UV resistanceElectroconductive/antistatic filament manufactureMonocomponent polyesters artificial filamentSolventAntistatic agent

The invention relates to a method for preparing a high-comfortable composite functional polyester fiber, comprising the steps of: first esterification reaction section, secondary esterification reaction section, polymerization reaction process and spinning process, wherein aliphatic dicarboxylic acid and / or non-centrosymmetrically aromatic dicarboxylic acid is led into the first esterification reaction section to serve as a third monomer; flexible polyethylene glycol is led into the secondary esterification reaction section to serve as a fourth monomer; after finishing the esterification reactions, hindered amine light stabilizer and hindered phenolic antioxidant which are respectively prepared by taking acetic acid and ethylene glycol as solvents and hydroxyl silicone oil are added; after finishing pre-polymerization and before final polymerization of the polymerization reaction process, ultraviolet light absorber and antistatic agent are added; and before finishing the spinning process, polyester slices are performed pre-crystallization and drying; fibers with odd-shaped cross sections of three-leaf, cross, five-leaf and the like are prepared by melt spinning. The obtained polyester fiber is anti-ultraviolet light, antistatic, anti-pilling and has wet-absorbing quick-drying performance; and the fabric has high comfort.

Owner:JIANGSU ZHONGLU TECH DEV +1

Preparation method for polyester fiber with composite ultraviolet, static electricity and pilling resisting functions

ActiveCN102409427AReduce harmImproves UV resistanceElectroconductive/antistatic filament manufactureArtificial filament heat treatmentSolventTransmittance

The invention relates to a preparation method for a polyester fiber with a composite ultraviolet, static electricity and pilling resisting function. The preparation method comprises an esterification reaction procedure, a polymerization reaction procedure and a spinning procedure. The esterification reaction procedure comprises a primary esterification reaction stage and a secondary esterification reaction stage, flexible polyethylene glycol is introduced as a third monomer in the secondary esterification reaction stage, and after esterification is finished, a hindered amine light stabilizer,a hindered phenol anti-oxidant and hydroxyl silicone oil are added, wherein the hindered amine light stabilizer and the hindered phenol anti-oxidant are prepared by taking an acetic acid and ethyleneglycol as solvents. In the polymerization reaction procedure, after prepolymerization and before final polymerization, an ultraviolet absorbent and an antistatic agent are added. Before the spinning procedure, polyester is sliced for pre-crystallization and drying. The polyester fiber obtained by the method has the outstanding ultraviolet, static electricity and pilling resisting functions, and after being woven into knitted machine-made fabrics, is tested to have related technical indexes comprising the ultraviolet light transmittance of less than or equal to 5.0%, the pilling resistance of more than or equal to level 4 and the fiber volume specific resistance of less than or equal to 10*10<10> ohm.cm.

Owner:JIANGSU ZHONGLU TECH DEV +1

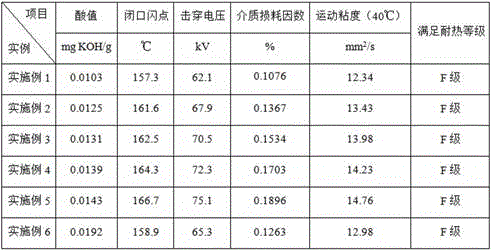

High-overload transformer oil and preparation process thereof

ActiveCN106635246AIncrease the breakdown voltage valueImprove overload capacityBase-materialsTransformer oilUltrasonic oscillation

The invention belongs to the technical field of insulating oil for power transformers with high overload capacity, and particularly relates to high-overload transformer oil and a preparation process thereof. The high-overload transformer oil is prepared from natural ester insulating oil and mineral insulating oil according to the volume percentage of (40%-50%):(60%-43%). The preparation process comprises the following steps: firstly, heating the natural ester insulating oil to 80 to 95 DEG C under a vacuum stirring condition; then under a vacuum condition, adding the mineral insulating oil into the natural ester insulating oil, and carrying out mechanical stirring and then ultrasonic oscillation; finally, carrying out two-stage vacuum filtering treatment on treated transformer oil, wherein the closed-cup flash point of a treated oil product is greater than or equal to 155 DEG C. The transformer oil disclosed by the invention is high in physical, chemical and electrical properties, low in kinematic viscosity, high in flowability and long in service life; the transformer with high overload capacity is high in overload capacity; faults of the transformer are reduced, and the problem of 'load returning' is effectively solved; the safety stability of the transformer is improved; the high-overload transformer oil has a high popularization and application value.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +1

Oil phase composition for preparing droplet digital PCR liquid drops

The invention discloses an oil phase composition for preparing droplet digital PCR liquid drops. The oil phase composition comprises main constituents and surfactants. The main constituents include mineral oil and alkane, and the surfactants include EM90 and TritonX-100, wherein the alkane is one of 12-16 alkane or a mixture of 12-16 alkane. Fluorinated oil is replaced by mineral oil, and the oil phase composition has the advantages that the oil phase composition is nonpolar, insoluble in water, not prone to volatilization, stable in property and free of inhibiting effect on PCR amplification, and the kinematic viscosity of light oil is low; meanwhile, kinematic viscosity is further reduced by adding proper alkane, then the proper surfactants EM90 and TritonX-100 are added, and finally, the oil phase composition is used for preparing liquid drops. The obtained liquid drops have the advantages that sizes are uniform, thermal stability is high, volatilization and foam generation do not occur easily, and amplification inhibition is avoided.

Owner:领航医学科技(深圳)有限公司

Hydraulic oil composition and uses thereof

ActiveCN103710082ALow kinematic viscosityImprove Oxidation StabilityLubricant compositionNitrogenViscosity index

The invention relates to a hydraulic oil composition and uses thereof, mainly solves the problems that in the prior art, HM anti-wear hydraulic oil is poor in low temperature performance, and cannot meet the requirements of low temperature operation equipment. The hydraulic oil composition comprises the following components: by weight, a) 100 parts of mineral base oil; and b) 0.1-2 parts of an anti-wear hydraulic oil compound agent; wherein the characteristics of the mineral base oil are that: a1) the kinematic viscosity at 40 DEG C is 28.8-35.2mm<2> / s; a2) the pour point is below -30 DEG C; a3) the viscosity index is higher than 100; a4) the sulfur content is less than or equal to 0.03 wt.%; a5) the nitrogen content is less than or equal to 0.005 wt.%; the anti-wear hydraulic oil compound agent is selected from at least one from HiTEC521 and HiTEC543 of AFTON corporation, LZ5703 of LUBRIZOL corporation, OLA4994 of CHEVRON corporation, and IR5010 of BASF corporation, and the technical scheme well solves the problems, and can be used in industrial production of low pour point anti-wear hydraulic oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

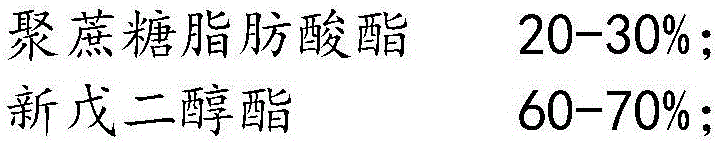

Polysucrose fatty acid ester, preparation method thereof and application thereof to preparation of micro-scale lubricating oil

ActiveCN105732968AReduce usageImprove the lubrication effectLubricant compositionSucroseMetalworking

The invention provides polysucrose fatty acid ester which is characterized by comprising or being prepared from sucrose, dicarboxylic acid and fatty acid at a mole ratio of 1:(1-1.5):(1-2). Due to the rich vacancy-OH, the polysucrose fatty acid ester provided by the invention can be effectively adhered to surfaces of processed metals, is excellent in lubrication property, extreme pressure antiwear property and rusting resistance, and can completely or partially replace conventional extreme pressure antiwear agents used in micro-scale lubricating oil, and only the micro-scale lubricating oil can meet the requirements of lubrication cooling, extreme pressure antiwear property and rusting resistance in metal processing, and when the polysucrose fatty acid ester is used with a micro-scale lubricating device, the use amount of cutting fluid can be reduced by more than 95%, and remarkable effects of energy conservation, emission reduction and environmental protection can be achieved.

Owner:SHANGHAI JINZHAO ENERGY SAVING TECH

Hydraulic oil composition with low viscosity and low solidifying point

ActiveCN102337176ACompatibility is reasonableLow viscosityLubricant compositionDepressantHydraulic equipment

The invention provides a hydraulic oil composition with low viscosity and low solidifying point, which comprises the following ingredients by weight percentage: 0.01-1% of neutral dinonyl naphthalene sulfonic acid barium, 0.1-1.5% of 2,6-di-tert-butyl p-cresol, 5-25% of polymethacrylate and 72-95% of deeply hydrodearomatized base oil. The hydraulic oil composition with low viscosity and low solidifying point has excellent low temperature performance which comprises low pour point and low kinematic viscosity. Without adding a pour point depressant, the pour point is -76 DEG C (GB / T 1995), the kinematic viscosity at the temperature of -40 DEG C is 367 mm<2> / s, and the kinematic viscosity at the temperature of 40 DEG C is 12.47 mm<2> / s (GB / T 265). Besides the excellent low temperature performance, the hydraulic oil composition has antioxidant and antirust functions and can used for various hydraulic equipments in severe cold regions, the hydraulic oil composition has the advantages of reasonable raw materials compatibility, simple preparation method and wide application scope.

Owner:CHINA PETROLEUM & CHEM CORP

Fuel additive for heavy oil, and fuel oil comprising same

InactiveUS20140000156A1Low kinematic viscosityLightweight productionLiquid carbonaceous fuelsAdditivesParaffin waxKerosene

Provided in a fuel additive for heavy oil, made using a composition comprising: an oil-soluble metallic compound containing any one metal selected from calcium, barium, manganese, and iron; alcohol; hydrotreated light distillate; paraffin (kerosene); mineral oil; and a nonionic surfactant. The fuel additive for heavy oil, when added in a small amount to a heavy oil, can lower the kinematic viscosity and the flash point of the heavy oil, minimize the occurrence of a residual carbon fraction, dust, a sulfur fraction, or the like, increase the caloric value of the heavy oil, and improve the combustion efficiency during the combustion of the heavy oil.

Owner:LEE IN OK +1

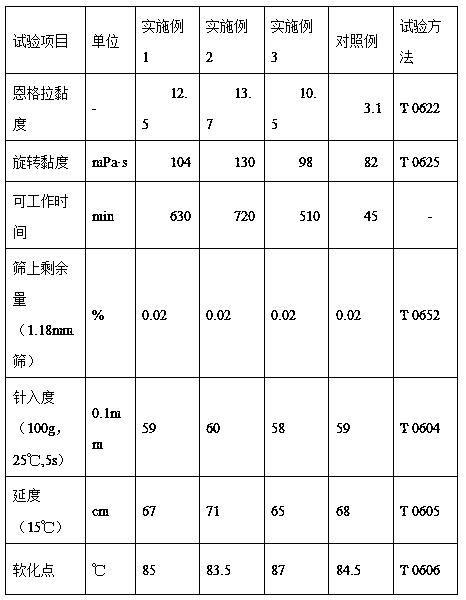

Special modified cold-mixing asphalt for cold-region normal-temperature mixing-type asphalt concrete

InactiveCN101735625ALow kinematic viscosityReduce internal friction angleBuilding insulationsEvaporationRoom temperature

The invention provides special modified cold-mixing asphalt for cold-region normal-temperature mixing-type asphalt concrete, which comprises linear liquid SBS, heavy traffic asphalt, surfactant, organic additives and water. The weight percentages of the components are: 50 to 70 percent of heavy traffic asphalt, 2.5 to 15 percent of linear liquid SBS, 1.2 to 11 percent of cationic surfactant, 3 to 6 percent of organic additives, and 20 to 30 percent of water. The water and the cationic surfactant are mixed pro rata and then are fully mixed through an emulsifier to form soap liquid; the heavy traffic asphalt is heated to between 100 and 170 DEG C; the soap liquid is heated to between 45 and 80 DEG C; the heavy traffic asphalt, the soap liquid, the linear liquid SBS and the organic additives are rapidly mixed in a mixing-melting device; and a uniform stable suspended substance is formed through a grinding machine, fully stirred, cooled to normal temperature and stored, thus the asphalt can be obtained. The problem that cold-mixing asphalt is too fast to demulsify, unstable in performance, short in storage time and poor in regional adaptability is solved. Evaporation residue of the asphalt mixture can greatly improve pavement performance. In addition, the asphalt has the advantages of simple process, stable performance and wide use.

Owner:李国涛

Quenching medium preparing method in production technique of suspension insulator ultralow temperature steel pins

ActiveCN103589831AEasy to cleanClean working environmentQuenching agentsAging resistanceWorking environment

The invention discloses a quenching medium preparing method in a production technique of suspension insulator ultralow temperature steel pins. The specific preparation is as follows: firstly, 25% of a PAG stock solution and 75% of running water are fully mixed; the concentration of PAG is regulated within 10-13%; then 5% of a W901 antirust agent, 0.5% of an XJ-103 defoaming agent, 1.5% of a G801 antiseptic bactericide and 3% of an RQ-322H surface active agent are added in the mixed liquid. Compared with the traditional PAG quenching liquid, the quenching medium used by the embodiment has the advantages of no oil, no smoke, no poison, more ageing resistance, clean working environment, low movement viscosity, easy workpiece cleaning and no accumulation of carbon, oil and mud on equipment; the cooling capacity different from that of the traditional quenching liquid can be obtained by assisting to regulate concentration, temperature and stirring degree; for the low-temperature products of the embodiment, more pertinence is achieved on the quenching technique.

Owner:DALIAN SAIRUI METAL PROD

Trace lubricating oil and preparation method thereof

InactiveCN108165345AGood anti-frictionImprove rust resistanceAdditivesEnvironmental resistanceSulfur

The invention provides trace lubricating oil which is prepared from the following components in percentage by weight: 5-10% of a trace lubricating oil precursor, 70-85% of diesters and 10-20% of polycaster oleate. By adopting the trace lubricating oil provided by the invention, the problems of workpiece lubrication and cooling in the processing process can be well solved; in addition, the oil product provided by the invention is still very good in extreme pressure abrasion resistance under the condition that additives with sulfur, chlorine and the like which are relatively large in pressure to the environment are not used, in addition, a degradation effect can be achieved, and the lubricating oil is not only environmentally friendly, but also capable of effectively prolonging the servicelives of tools.

Owner:SHANGHAI JINZHAO ENERGY SAVING TECH

High-stability waterborne epoxy resin modified emulsified asphalt and preparation method thereof

ActiveCN111363373AGood thickening effectSlow reaction speedIn situ pavingsBuilding insulationsPolymer scienceBitumen emulsion

The invention discloses high-stability waterborne epoxy resin modified emulsified asphalt and a preparation method thereof, belonging to the technical field of road materials. The high-stability waterborne epoxy resin modified emulsified asphalt comprises the following raw materials in percentage by mass: 35%-45% of matrix asphalt, 0.9%-3% of an emulsifier, 3%-5% of a bentonite thixotropic agent,4%-27% of water-borne epoxy resin, 3%-10% of a water-borne epoxy curing agent, 0.1%-0.5% of an anti-stripping agent, 0.02%-0.2% of a thickening agent, 0.5%-2% of a pH regulator and 28%-38% of water. The raw materials are subjected to shearing and emulsifying at a high speed via a colloid mill to obtain the asphalt. Through the thickening effect of the bentonite thixotropic agent and the thickeningagent, the workable time of a cementing material is greatly prolonged, and the risk of thickening and segregation of the cementing material in the process of storage and transportation is reduced; and meanwhile, the water-borne epoxy resin modified emulsified asphalt keeps low kinematic viscosity, so spraying construction can be smoothly carried out, and traffic can be rapidly recovered.

Owner:福建省交通科研院有限公司 +1

Nanometer lubricant for drilling fluid and preparation method of nanometer lubricant

InactiveCN108753269AGood dispersionLarge specific surface areaMaterial nanotechnologyDrilling compositionWater in oil emulsionSURFACTANT BLEND

The invention discloses a nanometer lubricant for a drilling fluid and a preparation method of the nanometer lubricant in the petroleum industry. The lubricant is added to the drilling fluid to improve the lubricity of the drilling fluid, and then the friction and the torque in the drilling process are reduced. The nanometer lubricant for the drilling fluid comprises linear alpha-olefin, nanosilicon dioxide, sulfide fatty acid ester, a surfactant and water, the preparation method comprises putting the linear alpha-olefin into a stirring kettle, controlling the temperature of the kettle to 25-30 DEG C, then proportionally adding the surfactant, stirring for 4 hours, proportionally adding the nanosilicon dioxide, stirring for 2 hours, then proportionally adding the sulfide fatty acid ester,stirring for 2 hours, proportionally adding water, controlling the water addition speed to be lower than or equal to 2 m<3> / h, and continuously stirring for 4 hours until an even water-in-oil emulsionis formed, wherein the water-in-oil emulsion is the nanometer lubricant for the drilling fluid.

Owner:CHINA PETROLEUM & CHEM CORP +1

Textile fabric treating fluid

A textile fabric treating fluid comprises raw materials in parts by weight as follows: 35-40 parts of glycerin, 10-12 parts of ethylenediaminetetraacetic acid disodium salt, 12-16 parts of nano activated carbon, 5-8 parts of fatty alcohol polyoxyethylene ether, 2-3 parts of isopropyl myristate, 2-3 parts of chloramphenicol palmitate and 11-17 parts of a modification preparation. The textile fabric treating fluid contains no irritant chemicals, is safe, non-toxic and low in kinematic viscosity, fabric cannot be snapped when treated with the treating fluid, and the treating fluid can remove formaldehyde and other chemical substances carried by the fabric quite effectively, can enhance the fabric elasticity, is good in self-cleaning capacity, can be used repeatedly 15-20 times and cannot react with the substances in the fabric or damage the fabric structure.

Owner:广德毅维纺织有限公司

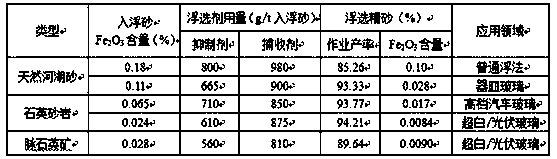

Preparation method of neutral flotation agent for purifying quartz minerals

The invention relates to a preparation method of a neutral flotation agent for purifying quartz minerals. The preparation method comprises the following steps of mixing raw materials, namely amines, an organic halogenated acid or a halogenated acid salt according to the molar ratio greater than or equal to 1, putting the mixture into a reaction kettle so as to prepare a crude flotation agent through reaction, and adjusting the pH value to obtain the neutral flotation agent. The preparation method of the neutral flotation agent for purifying the quartz minerals has the advantages that the prepared flotation agent has the functions of collecting and foaming, and is relatively low in kinematic viscosity, relatively good in hard water resistance and relatively low in freezing point; and directflotation of quartz sand can be realized without acids under the neutral conditions, so that the investment cost and the maintenance cost of ore dressing corrosion-resistant equipment are reduced, and the wastewater treatment cost of an ore dressing plant is reduced; the prepared floatation agent is used in coordination with an inhibitor, so that effective separation of the quartz sand from ironoxide disseminated type quartz sand and iron-containing aluminosilicate minerals is realized, and flotation and purification of the quartz minerals are realized; and the quartz fine sand can meet therequirements of glass, ceramic, plates and chemical industries for high-quality quartz raw materials.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD

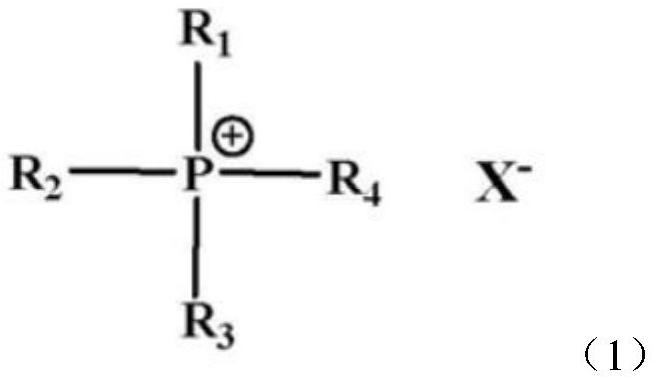

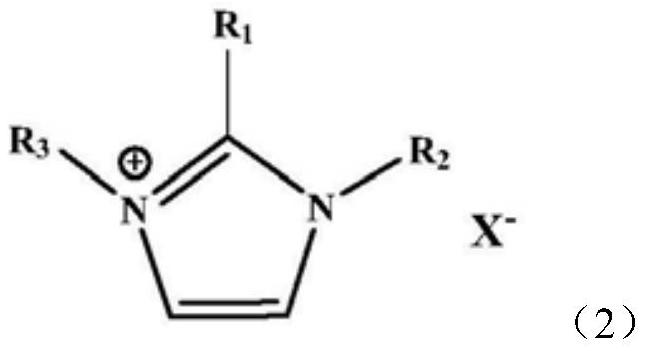

New ionic liquid-based organic heat carrier material and preparation method thereof

InactiveCN113429944ALow viscosityLow kinematic viscosityHeat-exchange elementsBulk chemical productionTemperature controlHeat carrier

The invention provides an ionic liquid-based organic heat carrier material. The main component of the novel organic heat carrier material is an ionic liquid material with high thermal stability, the problems that synthetic heat-conducting oil is not environmentally friendly in the using process and mineral heat-conducting oil is poor in thermal stability are solved, the material has the advantages of high calorific value, high heat conduction efficiency, uniform heat conduction rate, high temperature control precision, odorlessness, low-pressure operation, safety, convenience and the like, the service life exceeds the market standard, and the material is low in price, environment-friendly and energy-saving; and meanwhile, aiming at the problems that the motor is burnt down due to overlarge power during cold start of the motor and the energy consumption of the motor is greatly increased in a low-temperature environment, the invention further provides an ionic liquid-based efficient energy-saving organic heat carrier material suitable for the low-temperature environment by adding an organic solvent into the ionic liquid-based organic heat carrier material, and the problems of starting and running of the organic heat carrier material in a low-temperature environment are solved.

Owner:绍兴七轩新材料科技有限公司

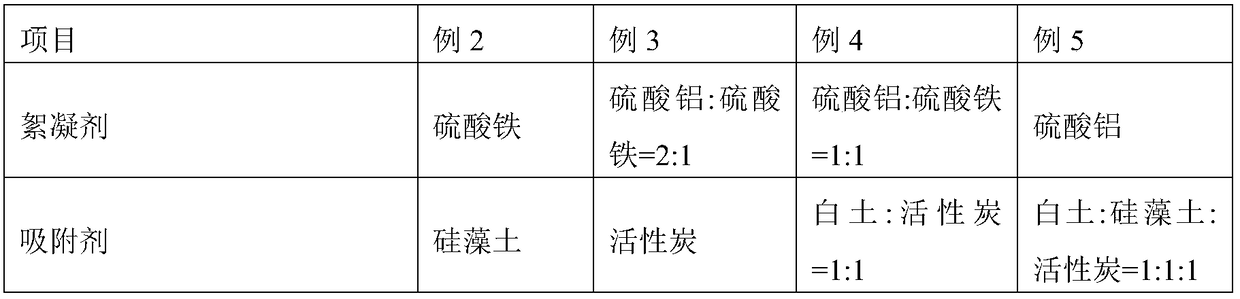

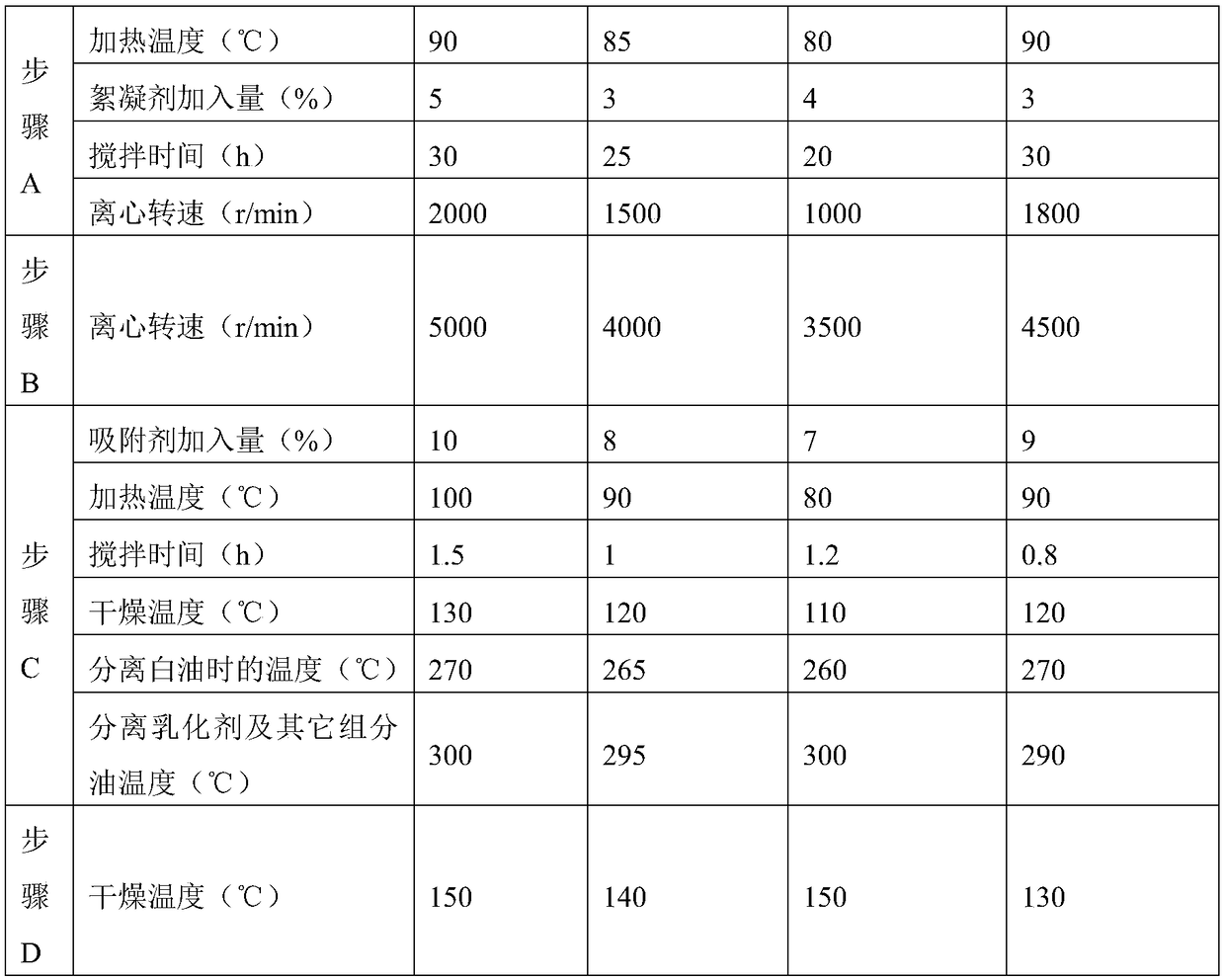

Waste oil based mud recycle and application method

The invention discloses a waste oil based mud recycle and application method. Solid, oil and water three-phase separation is conducted to waste oil based mud; three-phase separation is carried out onthe oil phase; an absorbing agent is added into combined oil to conduct decolorization and deodorization; and distillation separation is carried out to obtain white oil and mixed emulsified oil. The oil phase, the solid phase and the water phase can be separated at the same time, and the white oil and the mixed emulsified oil can be obtained through the oil phase after absorption, the decolorization and the distillation separation. The oil phase is fully recycled. The whole processing procedure of the waste oil based mud is free of waste and secondary pollution, and harmless treatment and resource recycling of the waste oil based mud are achieved.

Owner:河北华运鸿业化工有限公司

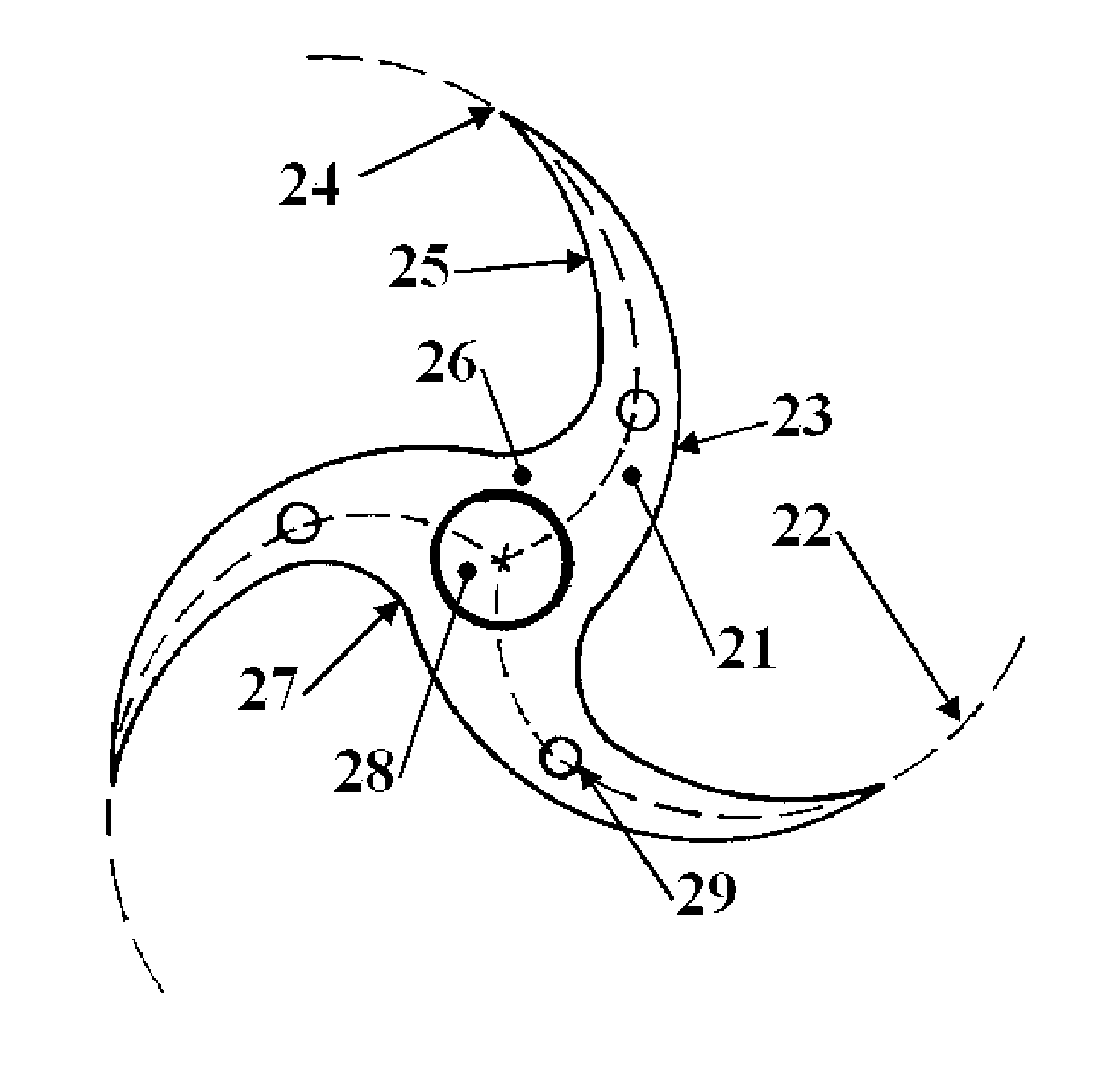

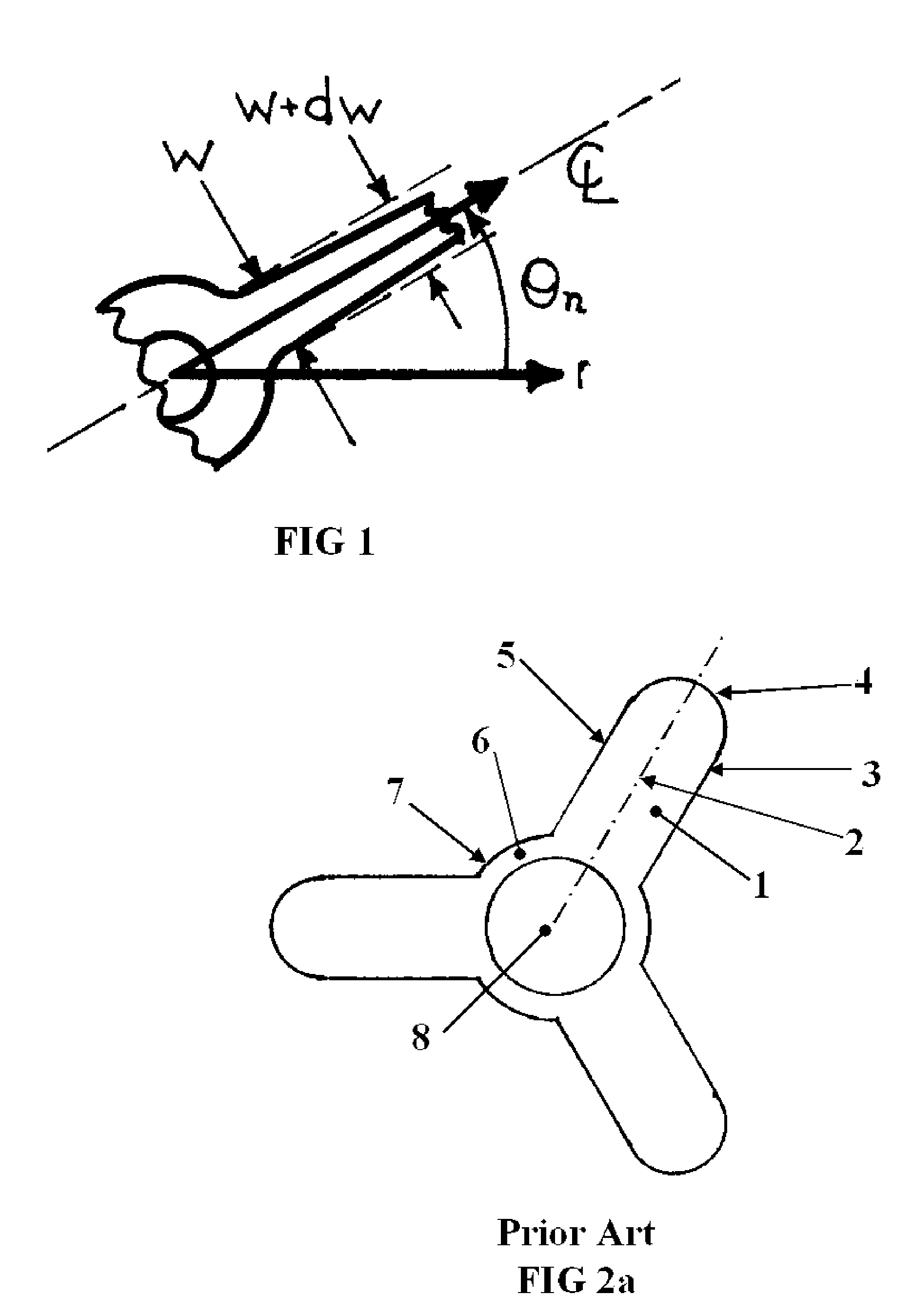

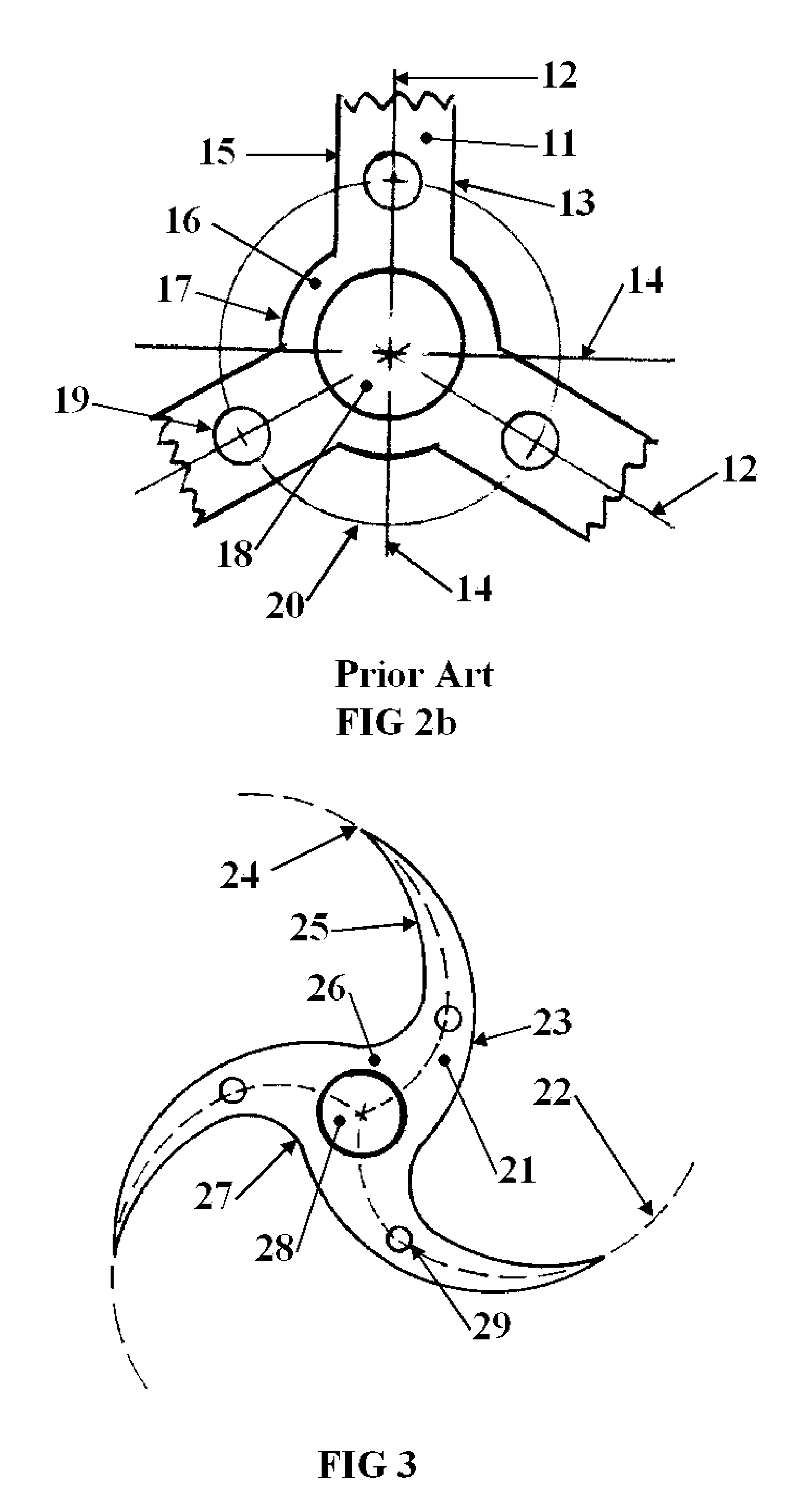

Bracket/spacer optimization in bladeless turbines, compressors and pumps

InactiveUS7478990B2Low kinematic viscosityAbility of to decreasedPropellersEngine manufactureEngineeringTurbine

A bracket / spacer design in a bladeless turbine, compressor or pump comprising of a hub for axial mounting and one or more arms connected to the hub. This bracket / spacer configuration contributes in part or completely to form one or more fluid flow chambers along with coinciding geometry of the neighboring disk or disks facilitating the entrance or exit of fluid for the purpose of extracting or infusing energy into or from the fluid. Furthermore, this invention includes a precise description of non-constant angular and axial geometry of the bracket / spacer arm or arms.

Owner:WILSON ERICH A

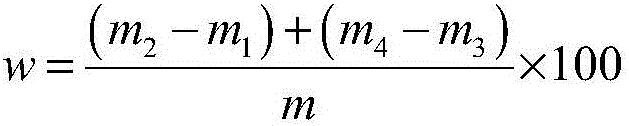

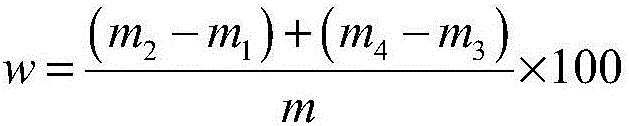

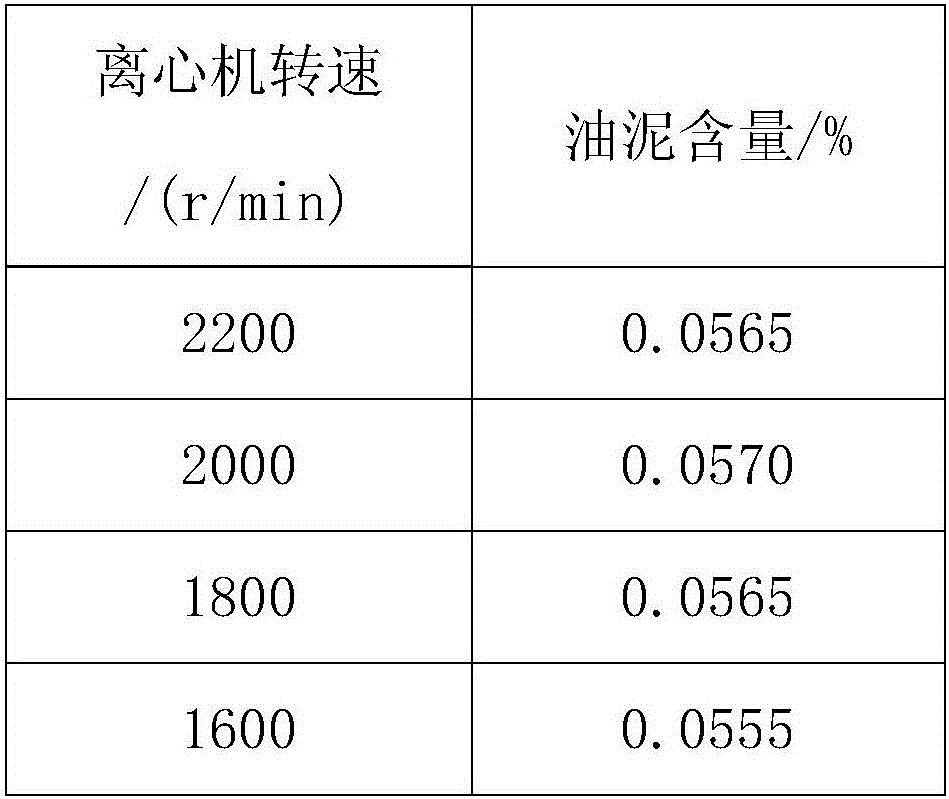

Method for testing content of oil sludge in phosphate fire-resistant oil

ActiveCN105891042ALow kinematic viscosityEasy to separateWeighing by removing componentCentrifugationOil sludge

The invention discloses a method for testing the content of oil sludge in phosphate fire-resistant oil. The method includes the following steps that 20 g of the to-be-tested phosphate fire-resistant oil is added into a constant-weight centrifugal tube, n-pentane is added into the centrifugal tube, an opening of the centrifugal tube is plugged through a first plug, and then the material is mixed to be uniform; 50 mL of n-pentane is added into the centrifugal tube, after a second plug is plugged into the opening of the centrifugal tube, shaking is conducted, the centrifugal tube is put in a centrifuge for centrifugation, and after centrifugation, an upper solution of liquid in the centrifugal tube is poured into filter paper for filtering; the liquid in the centrifugal tube is put in a flask; the filter paper is washed with petroleum ether till no oil sample trace exists on the filter paper, and then the filter paper is put in a weighing bottle; the flask and the weighing bottle are dried and then cooled, the cooled flask and the cooled weighing bottle are weighed, and the content w of the oil sludge in the to-be-tested phosphate fire-resistant oil is obtained. The content of the oil sludge in the phosphate fire-resistant oil can be accurately tested.

Owner:XIAN THERMAL POWER RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com