Waste oil based mud recycle and application method

An oil-based mud and oil phase technology, which is applied in earthwork drilling, wellbore/well components, flushing wellbore, etc., can solve the problem that solid phase resources are not fully utilized, material closed-loop recycling cannot be formed, and oil phase recycling Solve problems such as separation and treatment, and achieve the effect of low aromatic hydrocarbon content, fast filtration speed and easy filtration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for recycling waste oil-based mud. First, the solid phase, oil phase, and water phase in the waste oil-based mud are subjected to three-phase separation, and then the separated oil phase is subjected to three-phase separation again, and the three-phase separation is performed twice. The obtained oil phases are combined and then added with an adsorbent, and then rectified and separated to obtain white oil and mixed emulsified oil, including the following steps:

[0037] A. Heat the waste oil-based mud to 80°C, then add 2% aluminum sulfate of the weight of the waste oil-based mud, stir for 20 minutes, and centrifuge with a decanter centrifuge at a centrifugal speed of 800r / min to obtain a first-grade solid mud, Primary oil phase, primary water phase;

[0038] B. The primary oil phase is centrifuged with a disc centrifuge, and the centrifugal speed is 3000r / min to obtain secondary solid mud, secondary oil phase, and secondary water phase;

[0039] C. Combine the ...

Embodiment 2~5

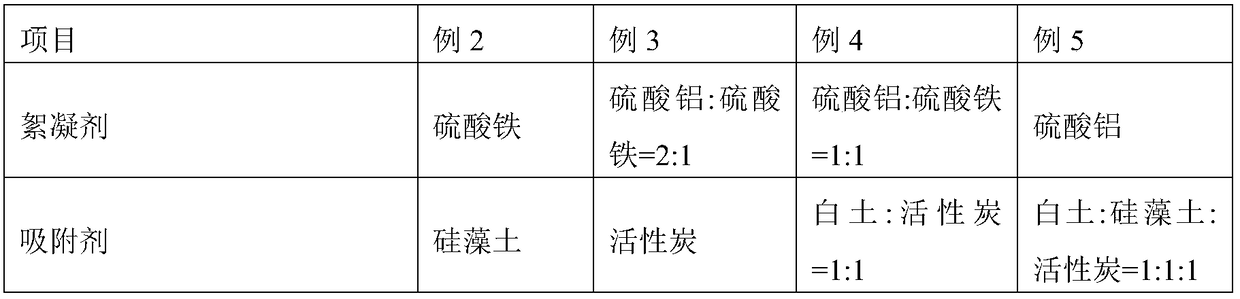

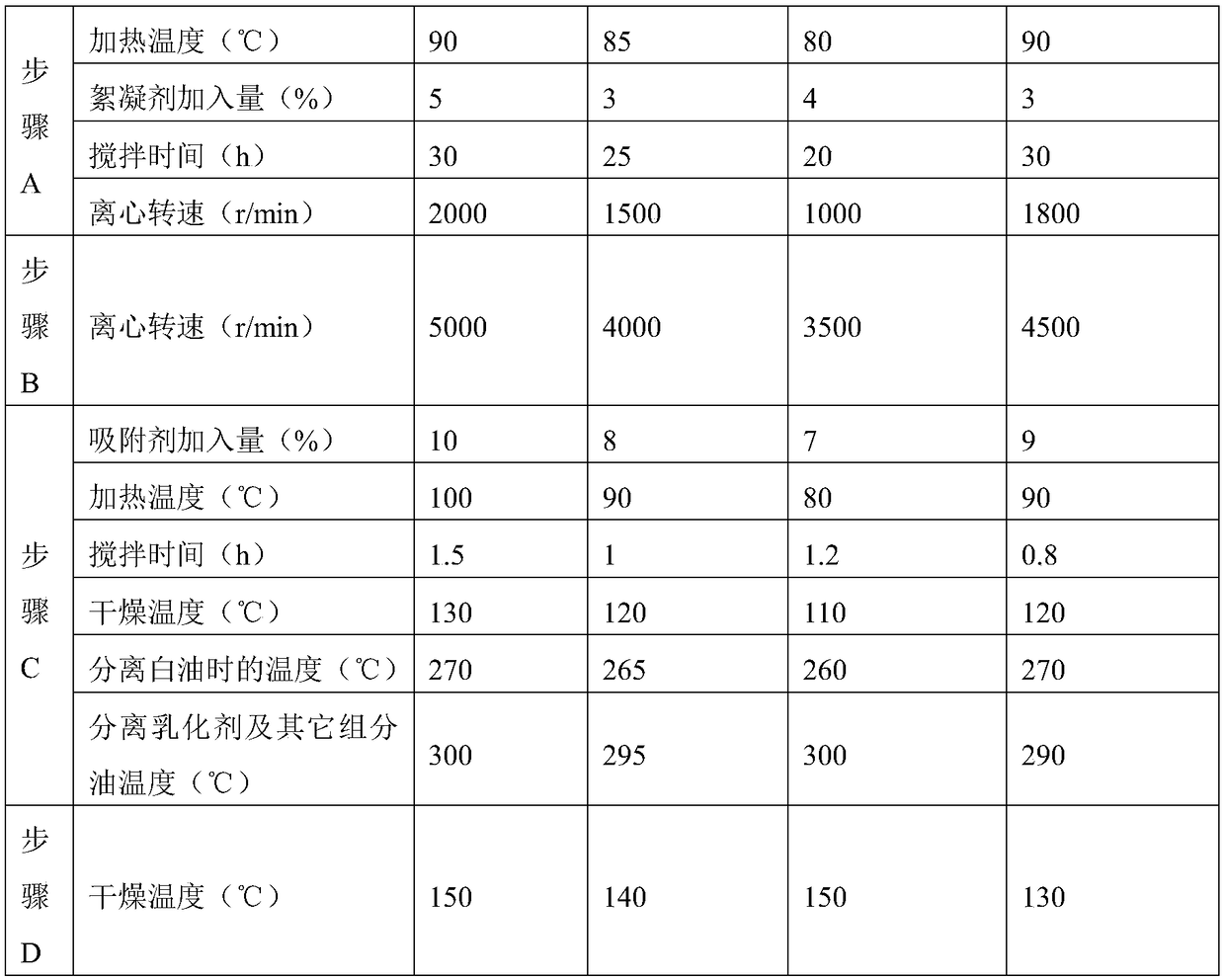

[0044] Embodiments 2 to 5 are the same as the above-mentioned production process steps, except that the process parameters, or the selected flocculant and adsorbent, are as shown in Table 1 below, wherein the flocculant addition (%) is the percentage of flocculant The percentage of waste oil-based mud weight, the amount of adsorbent added (%) is the percentage of adsorbent in the combined oil phase weight.

[0045] Table 1

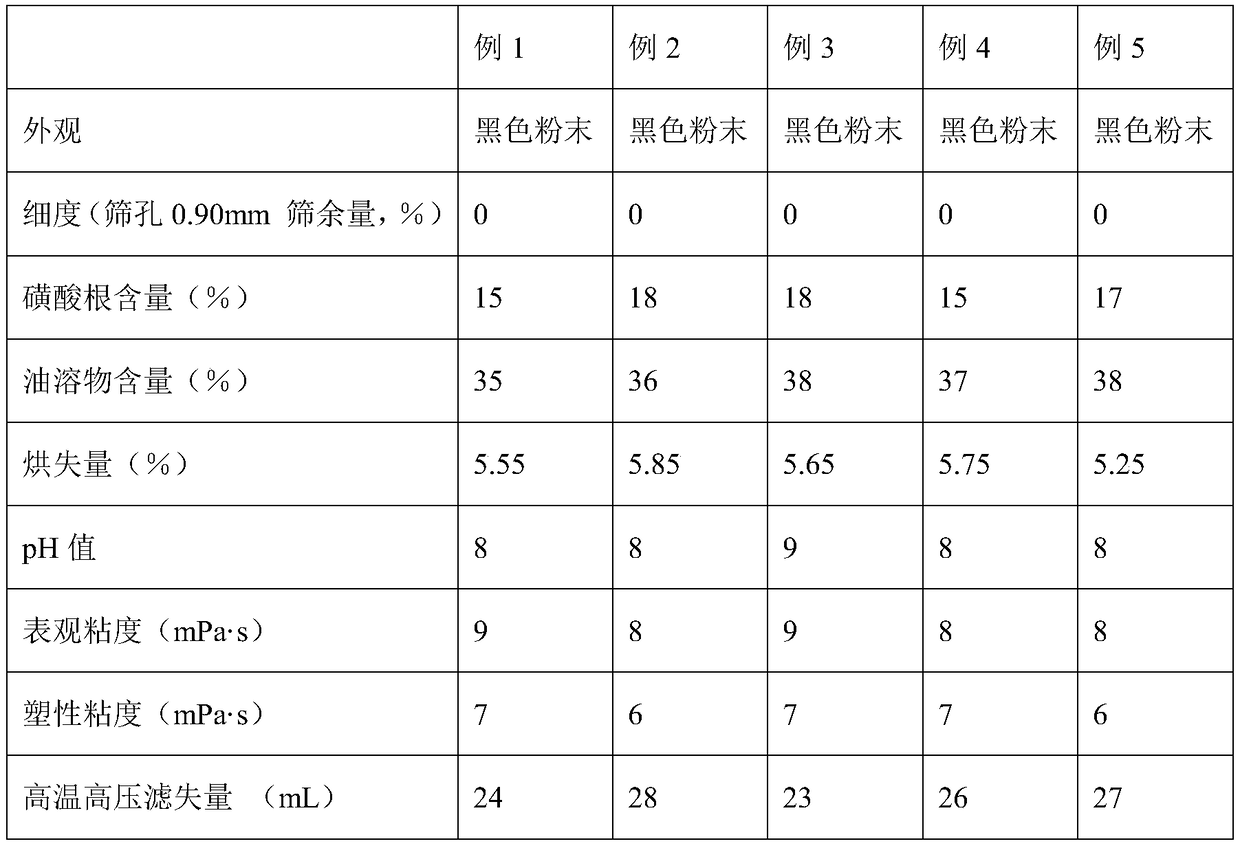

[0046]

[0047]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com