Special micro-lubricant for oil-water-gas-phase micro-lubricating system and preparation method of lubricant

A micro-quantity lubricant and micro-lubrication technology, applied in the field of lubrication, can solve the problems of processing places and environmental pollution, large amount of lubricant used, insufficient compressed air, etc., achieve good extreme pressure anti-wear and anti-rust performance, good extreme Good anti-wear and anti-rust properties, lubricity and biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

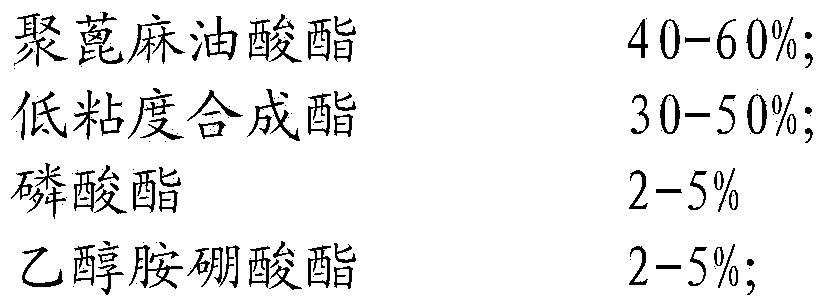

[0028] Oil A:

[0029] Put 100kg of ricinoleic acid in a polymerization kettle, add 0.2kg of 5% dilute sulfuric acid under the protection of nitrogen, polymerize at a temperature of 160°C for 12 hours, and drain the water under reduced pressure, which is a kind of polyricinoleic acid ester.

[0030] Weigh 40kg of the above-mentioned polyricinoleic acid ester; 50kg of methyl oleate; 5kg of dibutyl phosphite; Special micro-quantity lubricant A for oil-water-air three-phase micro-lubrication system.

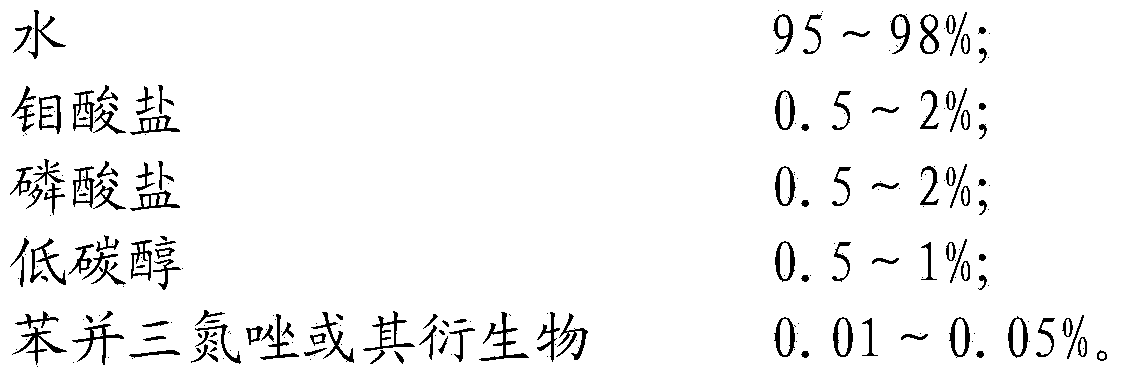

[0031] Liquid B:

[0032] Weigh 2kg of sodium molybdate; 0.5kg of sodium tripolyphosphate; dissolve 0.05kg of benzotriazole in 0.5kg of ethanol, and add it to 95.95kg of water in turn, and stir until completely dissolved, which is an oil-water-gas three-phase The special micro-quantity lubricant water agent B for the micro-quantity lubrication system can be used on the processing site.

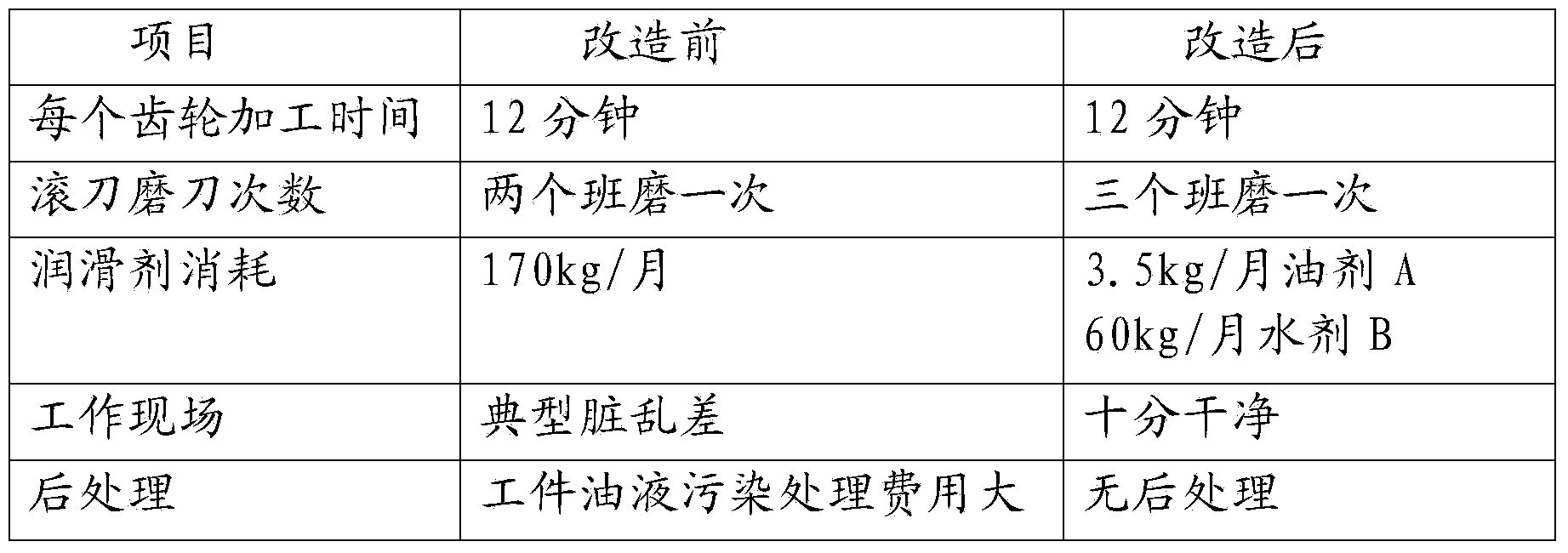

[0033] Effect and effect of embodiment one:

[0034] A kind of oil-water-air three-phase m...

Embodiment 2

[0043] Oil A:

[0044] Put 100kg of ricinoleic acid in a polymerization kettle, add 0.3kg of 5% dilute sulfuric acid under the protection of nitrogen, polymerize at a temperature of 150°C for 15 hours, and drain the water under reduced pressure, which is a kind of polyricinoleic acid ester.

[0045] Take by weighing 60kg of the above-mentioned polyricinoleic acid ester; 10kg of butyl stearate, 10kg of dioctyl sebacate, 10kg of ethyl caprate; 2kg of lauryl phosphate; 2kg of diethanolamine borate is placed in a container and heated to 30 ℃, stirring for 60 minutes, that is, a special microlubricant oil agent A for oil-water-air three-phase microlubrication system.

[0046] Liquid B:

[0047] Weigh 0.5kg of potassium molybdate; 2kg of dipotassium hydrogen phosphate; dissolve 0.01kg of benzotriazole in 1kg of ethylene glycol, and add it to 96.49kg of water in turn, and stir until completely dissolved, which is a kind of oil-water gas three The special micro-quantity lubricant w...

Embodiment 3

[0049] Oil A:

[0050] Put 100kg of ricinoleic acid in the polymerization kettle, under the protection of nitrogen, add 0.25kg of 5% dilute sulfuric acid, polymerize at a temperature of 155°C for 13 hours, and drain the water under reduced pressure, which is a kind of polyricinoleic acid ester.

[0051]Weigh 50kg of the above-mentioned polyricinoleic acid ester; 44kg of propylene glycol dioctyl ester; 3kg of dibutyl phosphite; Special micro-quantity lubricant A for oil-water-air three-phase micro-lubrication system.

[0052] Liquid B:

[0053] Weigh 1kg of ammonium molybdate; 1kg of disodium hydrogen phosphate; dissolve 0.03kg of benzotriazole in 0.7k n-butanol, and add it to 97.27kg of water in turn, and stir until completely dissolved, which is a kind of oil-water gas three The special micro-quantity lubricant water agent B for the micro-quantity lubrication system can be used on the processing site.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com