Hydraulic oil composition with low viscosity and low solidifying point

A technology of hydraulic oil composition and low freezing point, which is applied in the direction of lubricating composition and petroleum industry, can solve the problems of not being able to meet the oil requirements of the equipment hydraulic system, and achieve the advantages of wide application range, simple preparation method and reasonable raw material compatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Get neutral barium dinonylnaphthalene sulfonate (purchased from T705A of Suzhou Hushuguan Chemical Additive Factory) 0.01kg, 2,6-di-tert-butyl p-cresol (purchased from Nanjing Runyou Chemical Additive Co., Ltd.) 0.1kg , polymethacrylate (purchased from RohMax Additives 8-200) 5kg, and then sequentially added to 94.89kg of 40 ℃ kinematic viscosity of 2.5mm 2 / s deeply hydrogenated base oil (purchased from Ninas Company), mixed and stirred at 65°C for 1.5 hours to prepare a low-viscosity and low-freezing-point hydraulic oil composition.

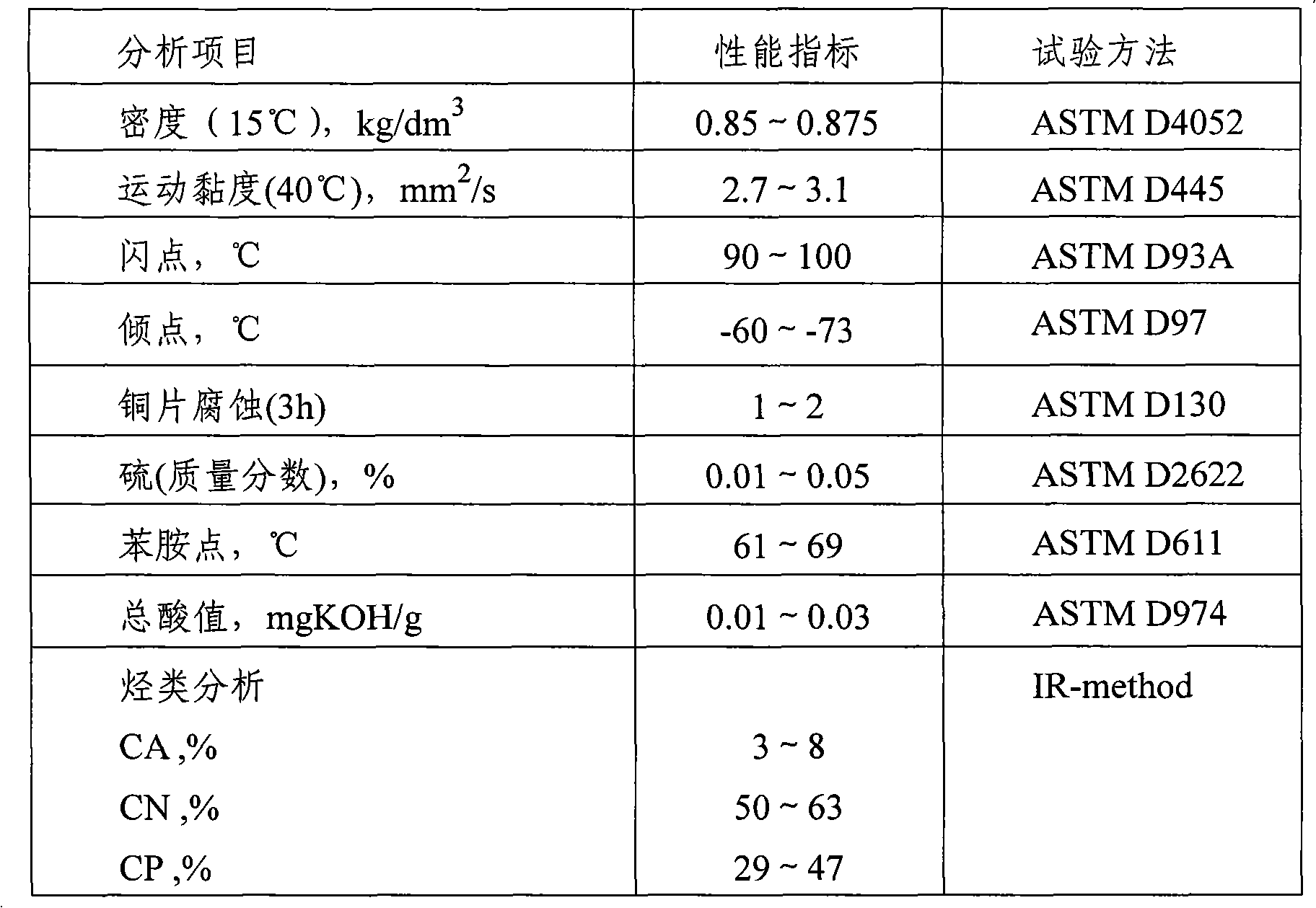

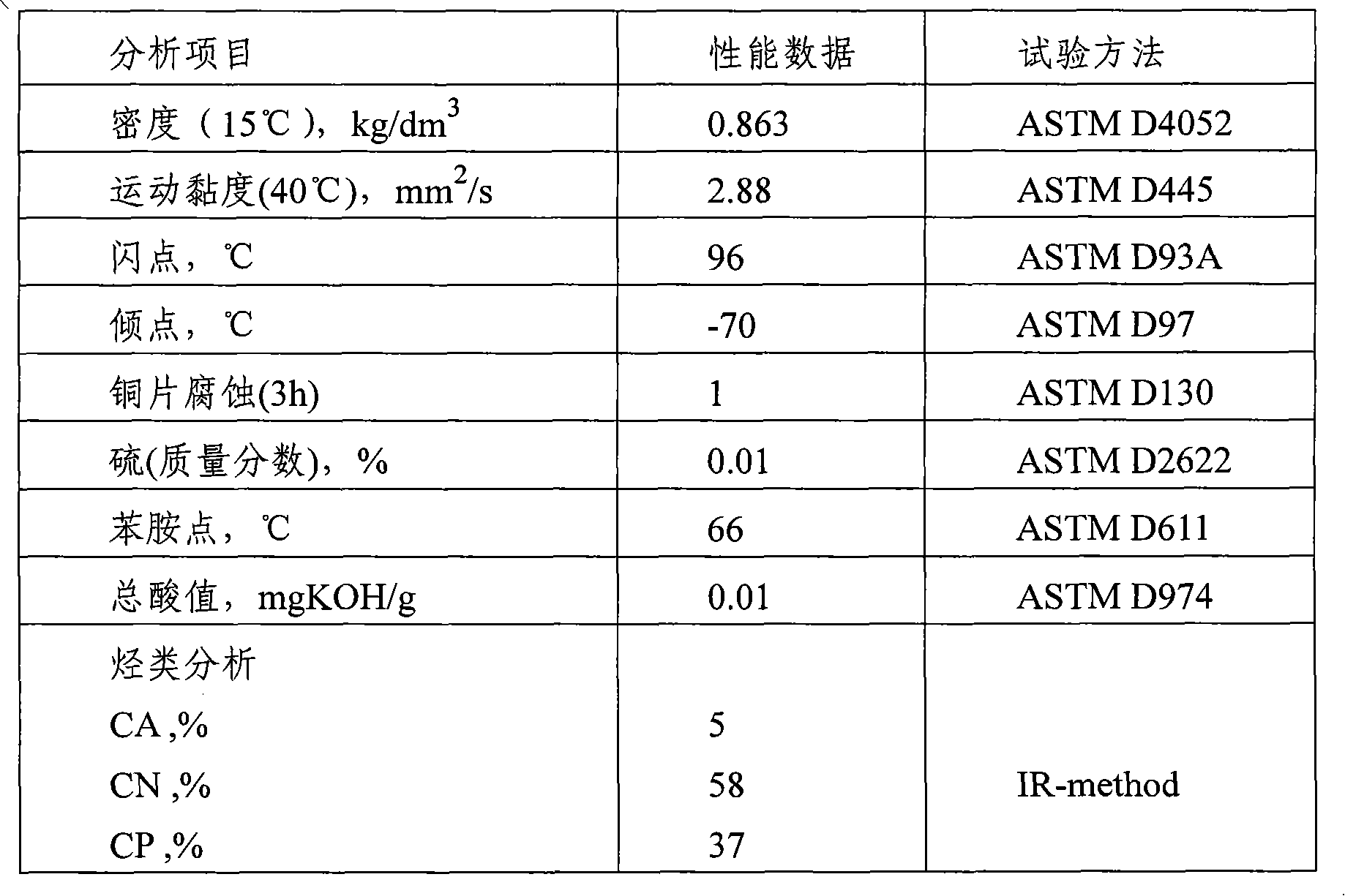

[0028] Among them, the performance data of the base oil are as follows:

[0029] Table 2

[0030]

Embodiment 2

[0032] Get neutral barium dinonylnaphthalenesulfonate (purchased from T705A of Liaoning Tianhe Fine Chemical Co., Ltd.) 0.05kg, 2,6-di-tert-butyl p-cresol (purchased from Langfang Fuhai Fine Chemical Co., Ltd.) 0.5kg , polymethacrylate (purchased from RohMax Additives 8-310) 15kg, and then sequentially added to 84.45kg of 40 ℃ kinematic viscosity of 3mm 2 / s deep hydrogenated base oil (purchased from Ninas Company), mixed and stirred at 60°C for 2 hours to prepare a low-viscosity and low-freezing-point hydraulic oil composition.

Embodiment 3

[0034] Get neutral barium dinonylnaphthalene sulfonate (purchased from T705A of Suzhou Specialty Chemical Co., Ltd.) 1kg, 2,6-di-tert-butyl p-cresol (purchased from Liaoning Tianhe Fine Chemical Co., Ltd.) 1.5kg, Polymethacrylate (purchased from RohMax Additives Co. 7-310) 25kg, and then sequentially added to 72.5kg of 40 ℃ kinematic viscosity of 4.0mm 2 / s deeply hydrogenated base oil (purchased from Ninas Company), mixed and stirred at 70°C for 3 hours to prepare a low-viscosity and low-freezing-point hydraulic oil composition.

[0035] The freezing point comparison of table 3 embodiment and comparative example

[0036] components

[0037] The comparative example is a commercially available hydraulic oil with a viscosity grade of L-HS of 10.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com