Transformer oil with excellent cooling heat-radiating and moisture preventing properties and preparation method thereof

A transformer oil and moisture-proof performance technology, which is applied in the field of transformer oil, can solve problems such as overall excellent indicators, shorten the service life of equipment, and affect the safe operation of equipment, and achieve high safe operation, good electrical and physical and chemical properties, and superior cooling and heat dissipation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

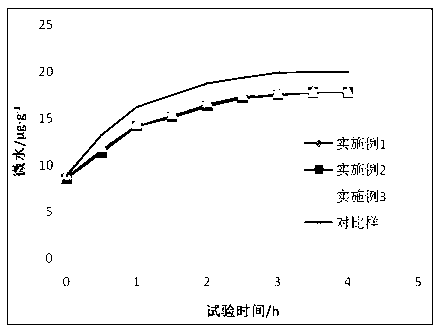

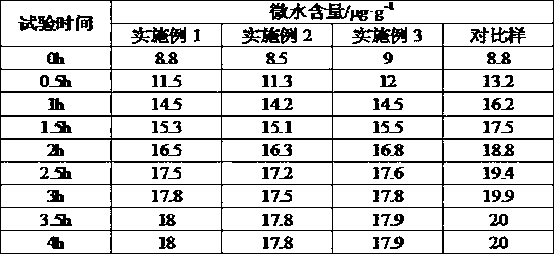

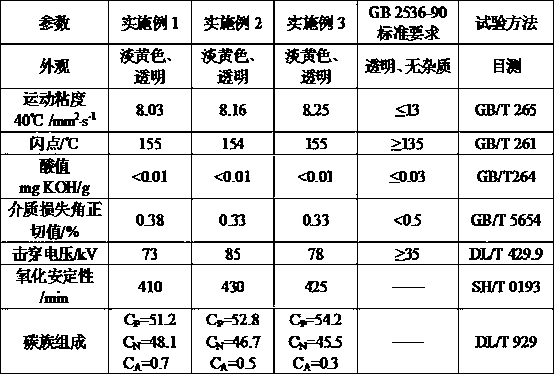

Image

Examples

Embodiment 1

[0029] The transformer oil with excellent cooling and heat dissipation and moisture-proof properties provided in this example is mainly prepared from the following raw materials: hydrogenated base oil, naphthenic heavy oil, antioxidant and metal deactivator, wherein hydrogenated base oil and naphthenic The weight ratio of heavy oil is 72: 28, the consumption of antioxidant accounts for 0.5% of the total weight of hydrogenated base oil and naphthenic heavy oil, and the consumption of metal deactivator accounts for the total weight of hydrogenated base oil and naphthenic heavy oil. 0.2% by weight.

[0030] Among them, the hydrogenated base oil is prepared by the following method: the intermediate base heavy oil fraction with a distillation range of 253°C-433°C is hydrotreated with tungsten-molybdenum-nickel / (alumina+silica) as a catalyst to obtain hydrogenation base oil, and make the paraffin component content in the hydrogenated base oil be 50%-60%, and the aromatic component c...

Embodiment 2

[0036] The transformer oil with excellent cooling and heat dissipation and moisture-proof properties provided in this example is mainly prepared from the following raw materials: hydrogenated base oil, naphthenic heavy oil, antioxidant and metal deactivator, wherein hydrogenated base oil and naphthenic The weight ratio of heavy oil is 75: 25, the consumption of antioxidant accounts for 0.5% of the total weight of hydrogenated base oil and naphthenic heavy oil, and the consumption of metal deactivator accounts for the total weight of hydrogenated base oil and naphthenic heavy oil. 0.1% by weight.

[0037] Among them, the hydrogenated base oil is prepared by the following method: the intermediate base heavy oil fraction with a distillation range of 253°C-433°C is hydrotreated with tungsten-molybdenum-nickel / (alumina+silica) as a catalyst to obtain hydrogenation base oil, and make the paraffin component content in the hydrogenated base oil be 50%-60%, and the aromatic component c...

Embodiment 3

[0043] The transformer oil with excellent cooling and heat dissipation and moisture-proof properties provided in this example is mainly prepared from the following raw materials: hydrogenated base oil, naphthenic heavy oil, antioxidant and metal deactivator, wherein hydrogenated base oil and naphthenic The weight ratio of heavy oil is 82: 18, and the consumption of antioxidant accounts for 0.4% of the total weight of hydrogenated base oil and naphthenic heavy oil, and the consumption of metal deactivator accounts for the total weight of hydrogenated base oil and naphthenic heavy oil. 0.1% by weight.

[0044] Among them, the hydrogenated base oil is prepared by the following method: the intermediate base heavy oil fraction with a distillation range of 253°C-433°C is hydrotreated with tungsten-molybdenum-nickel / (alumina+silica) as a catalyst to obtain hydrogenation base oil, and make the paraffin component content in the hydrogenated base oil be 50%-60%, and the aromatic compone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com