Patents

Literature

374results about How to "High volume resistivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

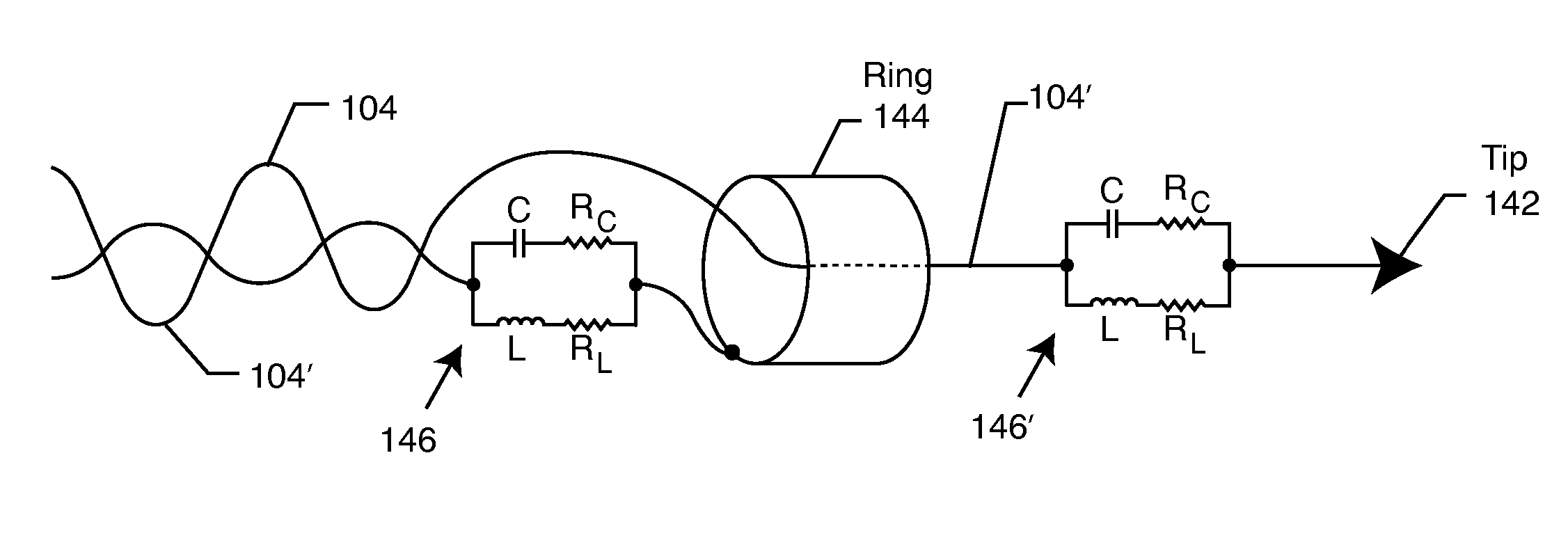

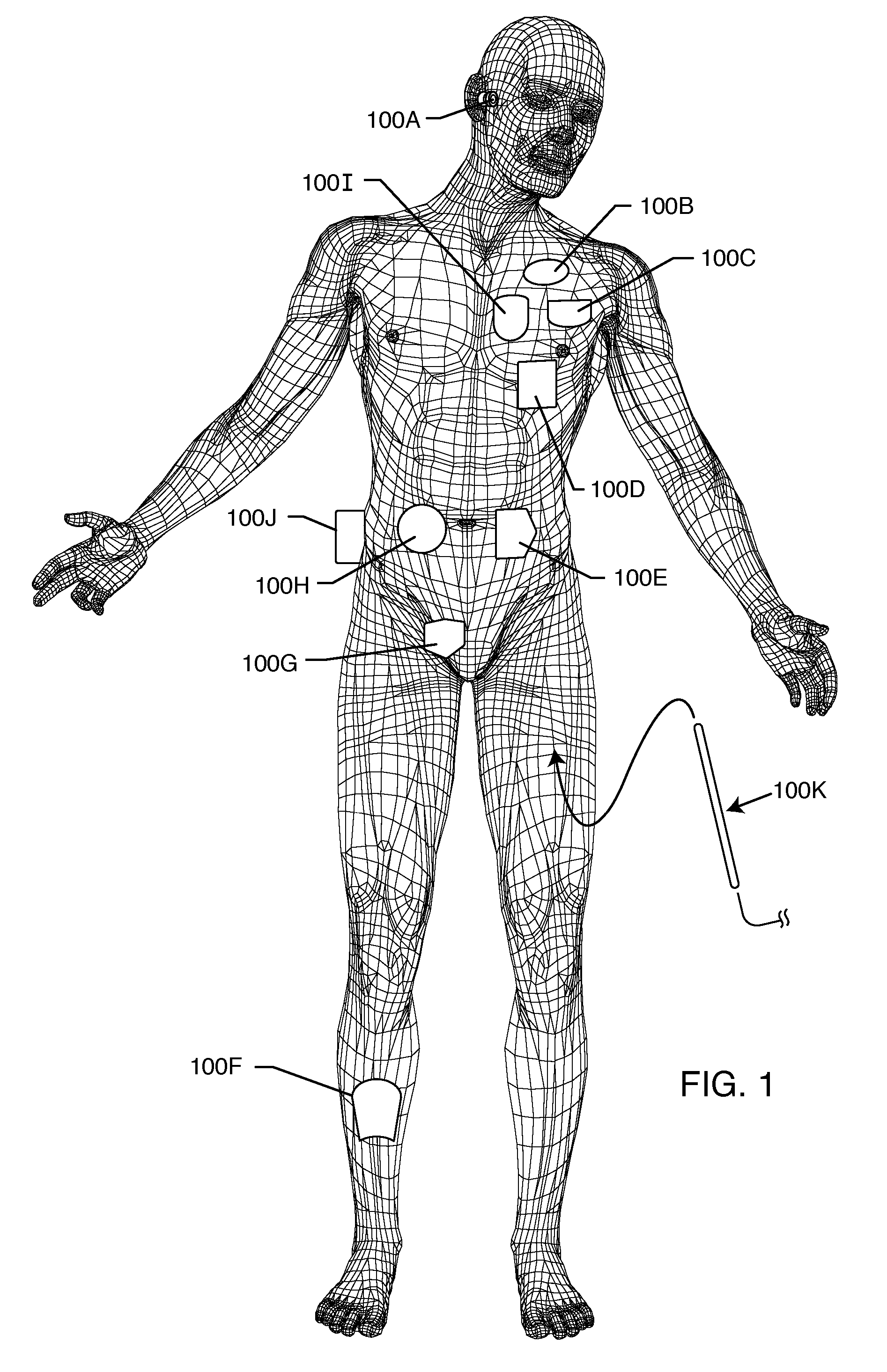

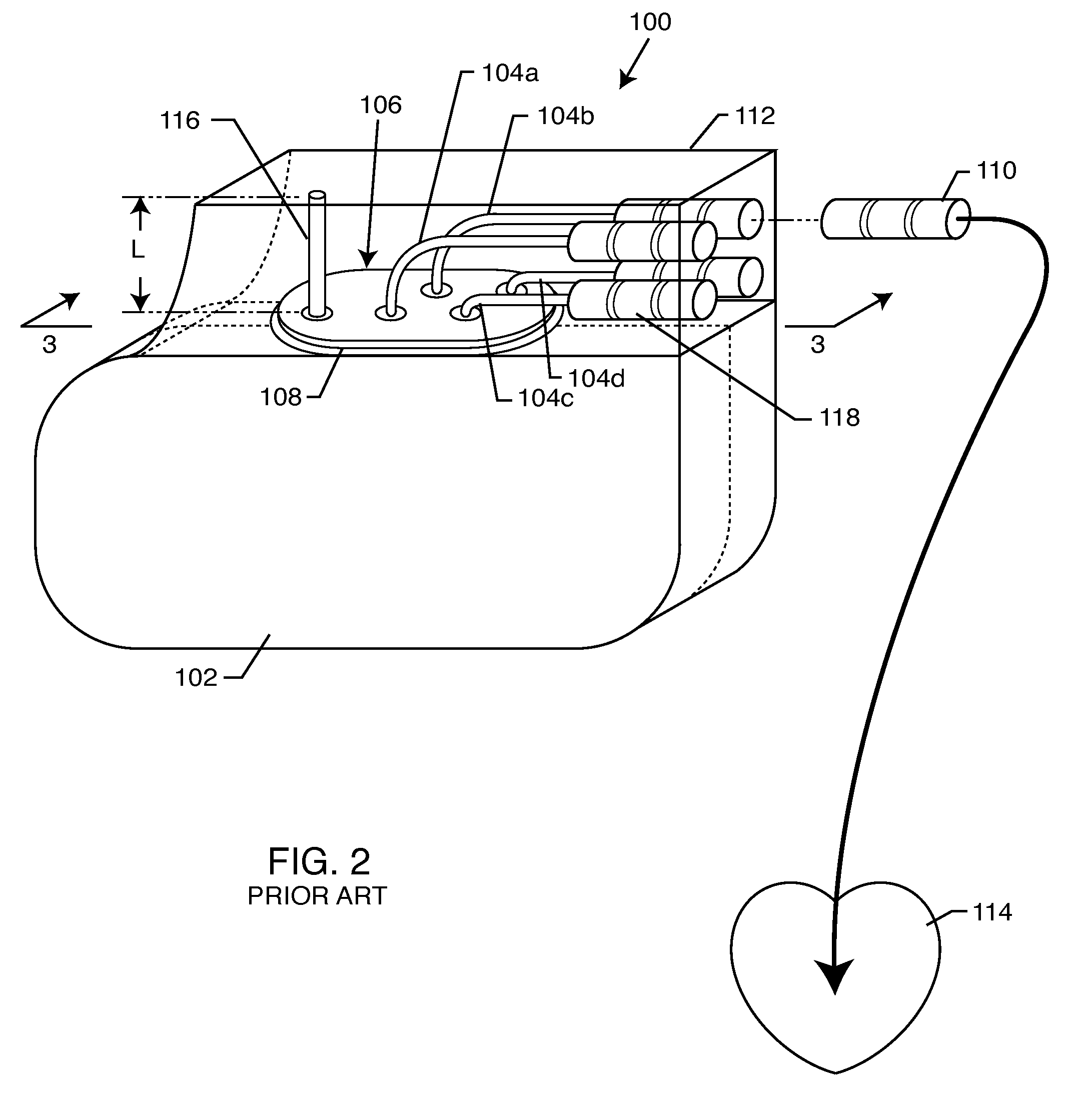

Band stop filter employing a capacitor and an inductor tank circuit to enhance MRI compatibility of active medical devices

InactiveUS20060247684A1Decrease QCapacitor is relatively minimizedMultiple-port networksInternal electrodesCapacitanceEngineering

A band stop filter is provided for a lead wire of an active medical device (AMD). The band stop filter includes a capacitor in parallel with an inductor. The parallel capacitor and inductor are placed in series with the lead wire of the AMD, wherein values of capacitance and inductance are selected such that the band stop filter is resonant at a selected frequency. The Q of the inductor may be relatively maximized and the Q of the capacitor may be relatively minimized to reduce the overall Q of the band stop filter to attenuate current flow through the lead wire along a range of selected frequencies. In a preferred form, the band stop filter is integrated into a TIP and / or RING electrode for an active implantable medical device.

Owner:WILSON GREATBATCH LTD

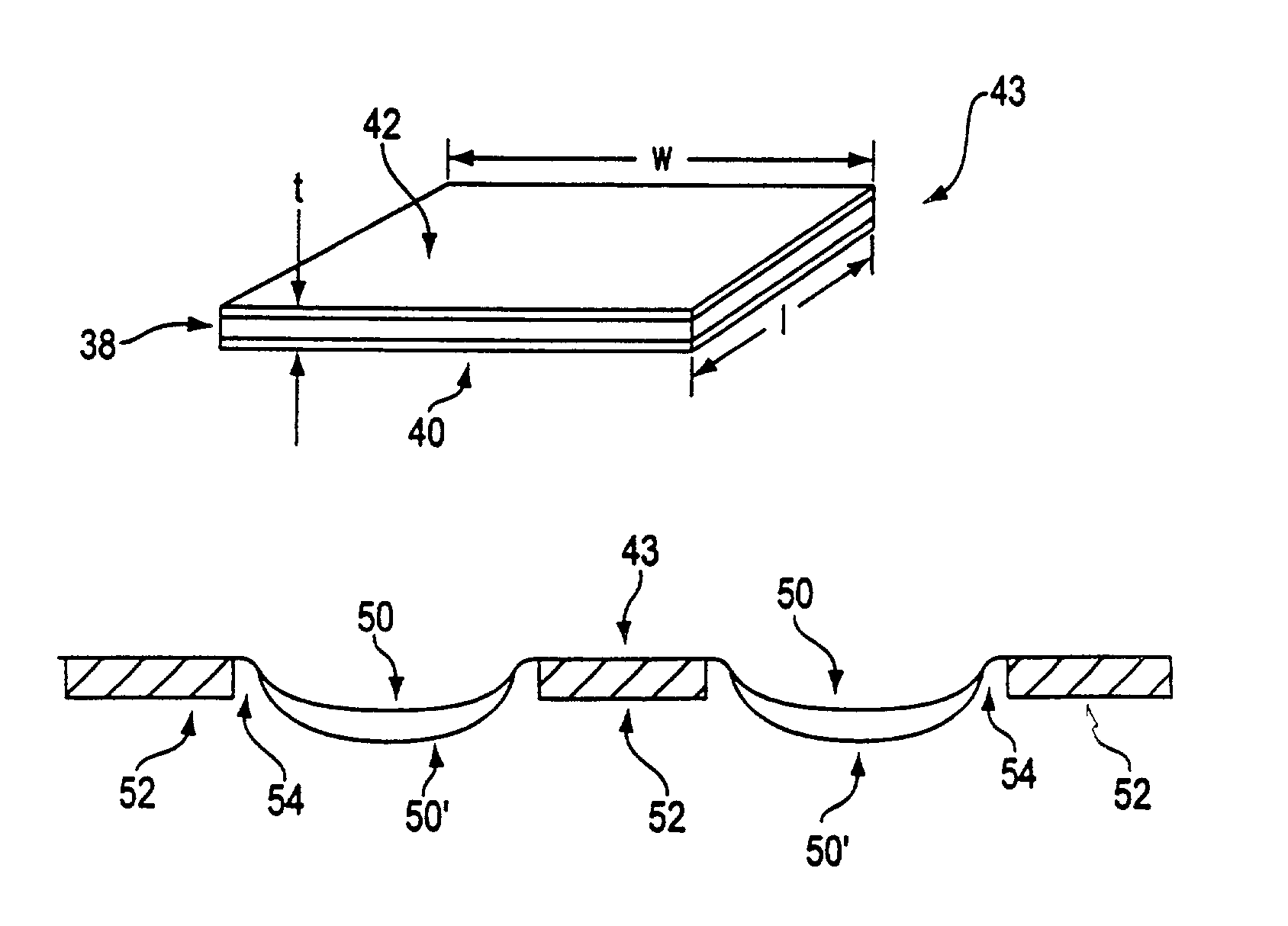

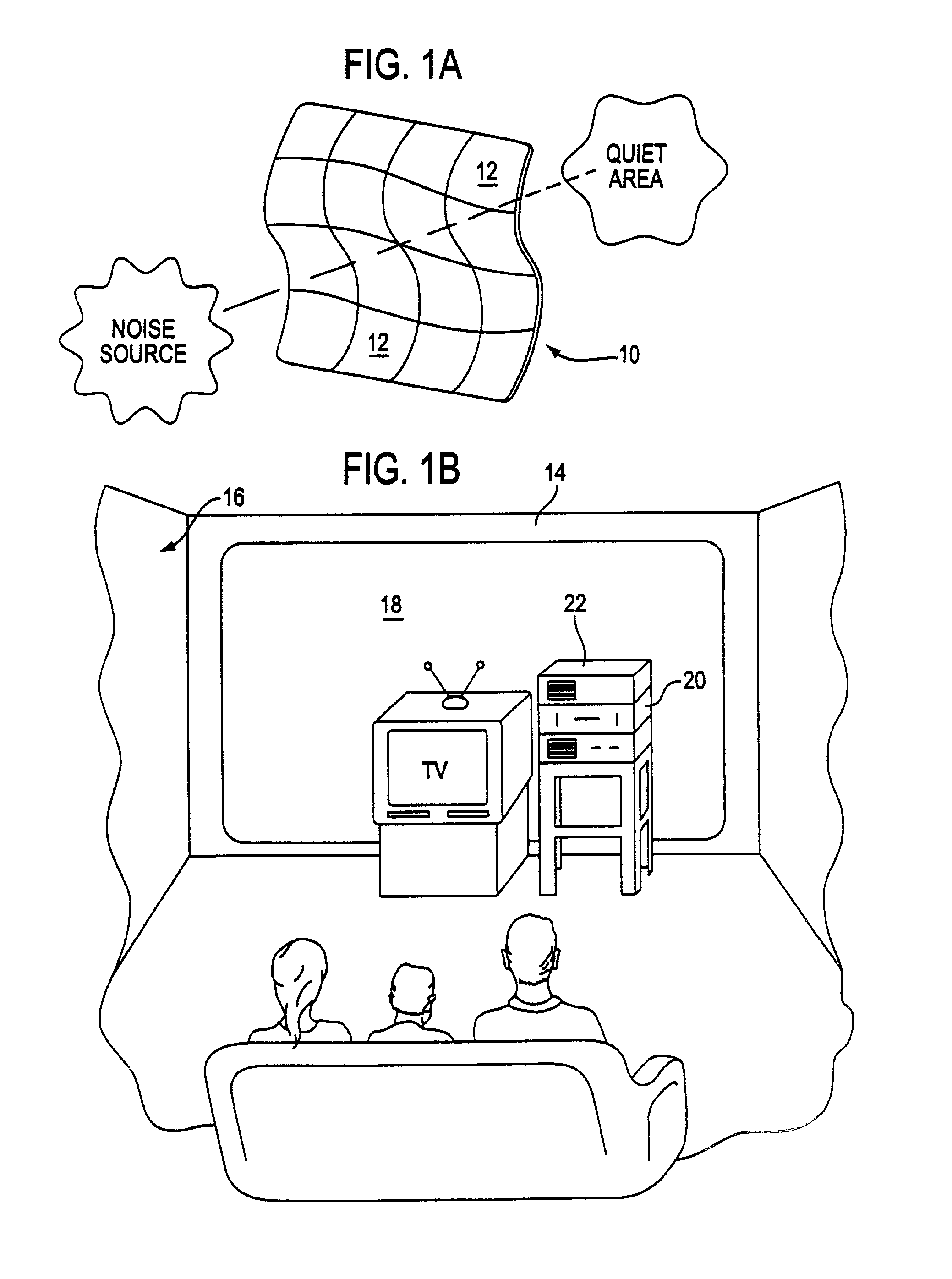

Elastomeric dielectric polymer film sonic actuator

InactiveUS7062055B2Optimize power outputLow working voltagePiezoelectric/electrostrictive gramophone pickupsStirling type enginesDielectricConductive polymer

A sonic actuator including a multi-layer membrane having a non-metallic elastomeric dielectric polymer layer with a first surface and a second surface, a first compliant electrode layer contacting the first surface of the polymer layer, and a second compliant electrode layer contacting the second surface of the polymer layer. The actuator further includes a support structure in contact with the sonic actuator film. Preferably, the non-metallic dielectric polymer is selected from the group consisting essentially of silicone, fluorosilicone, fluoroelastomer, natural rubber, polybutadiene, nitrile rubber, isoprene, and ethylene propylene diene. Also preferably, the compliant electrode layer is made from the group consisting essentially of graphite, carbon, and conductive polymers. The support structure can take the form of grid having a number of circular apertures. When a voltage is applied to the electrodes, portions of the film held at the aperture of the support structure can bulge due to the electrostriction phenomenon. The resultant “bubbles” can be modulated to generate sonic vibrations, or can be used to create a variable surface for airflow control.

Owner:SRI INTERNATIONAL

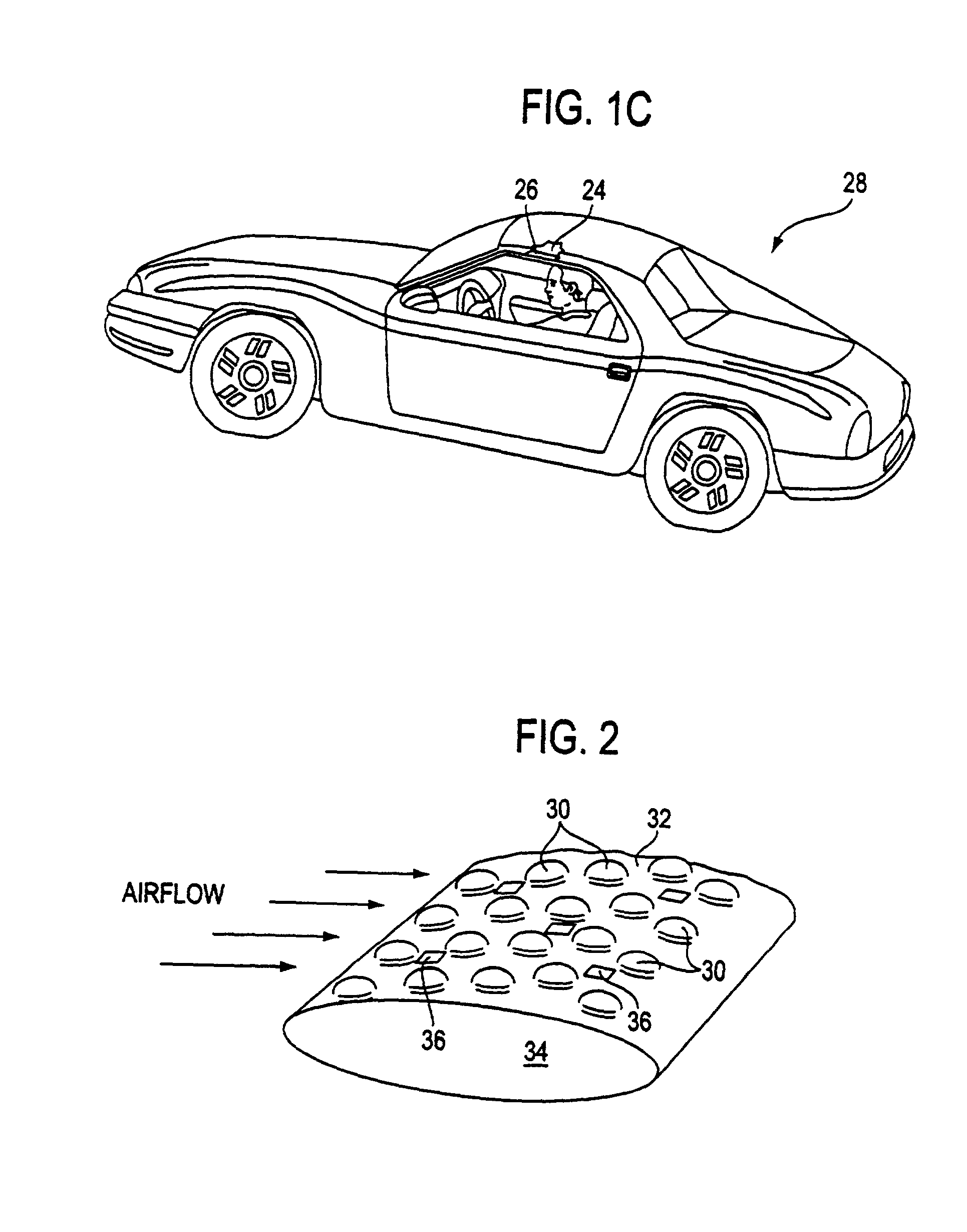

Positive electrode active material for non-aqueous electrolyte secondary battery and method for producing the same

ActiveUS20100112447A1High volume resistivityLow volume resistivityNon-aqueous electrolyte accumulatorsActive material electrodesComposite oxideMaterials science

A positive electrode active material for a non-aqueous electrolyte secondary battery is provided. The positive electrode active material includes a composite oxide containing lithium and metal M other than lithium, and M contains Ni, Mn, and Co. The molar ratio of Ni to the total of Ni, Mn, and Co is from 0.45 to 0.65, and the molar ratio of Mn to the total of Ni, Mn, and Co is from 0.15 to 0.35. The positive electrode active material has a pressed density under a compression of 60 MPa of 3.3 g / cm3 or more and 4.3 g / cm3 or less. The positive electrode active material has a volume resistivity under a compression of 60 MPa of 100 Ω·cm or more and less than 1000 Ω·cm.

Owner:PANASONIC CORP

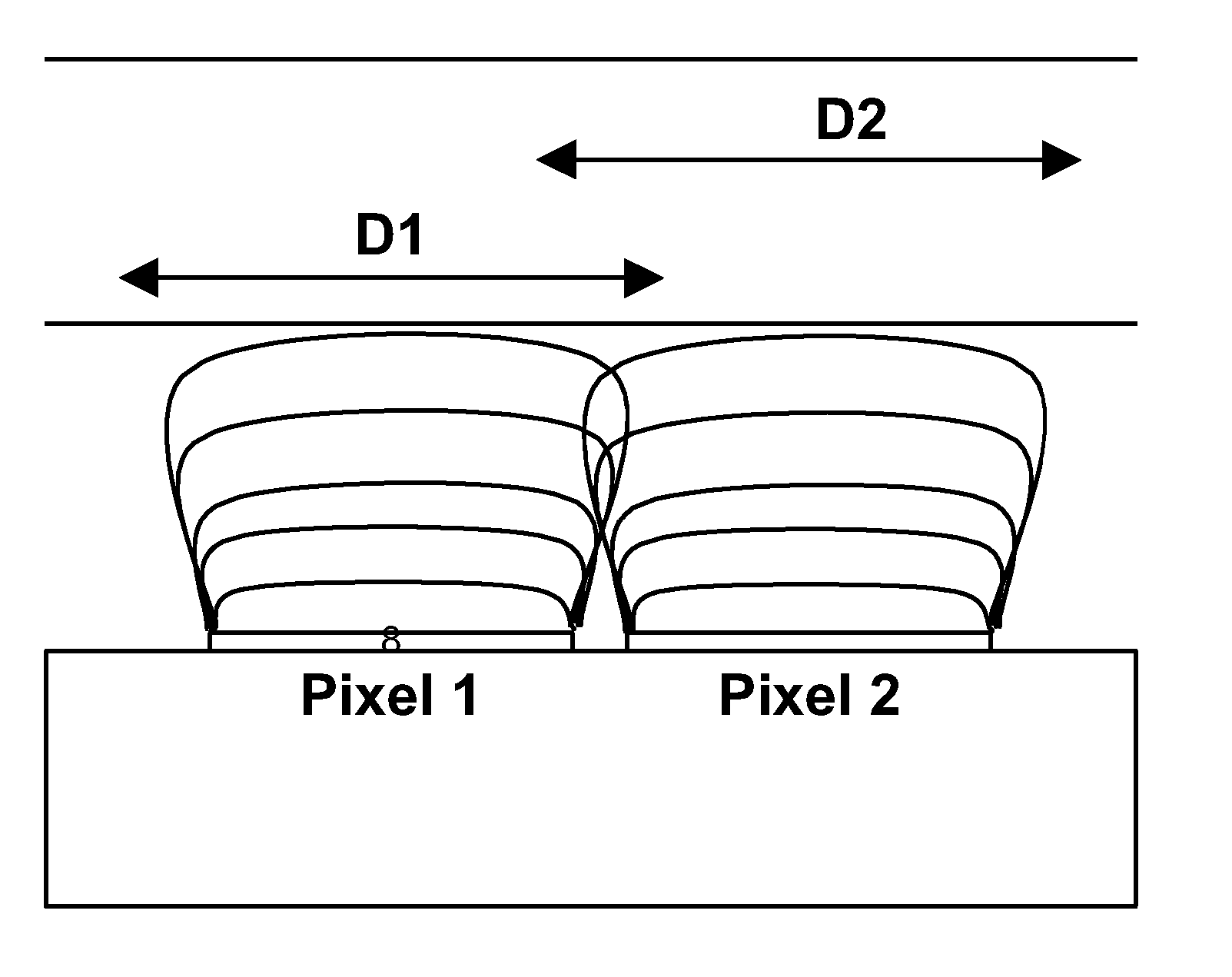

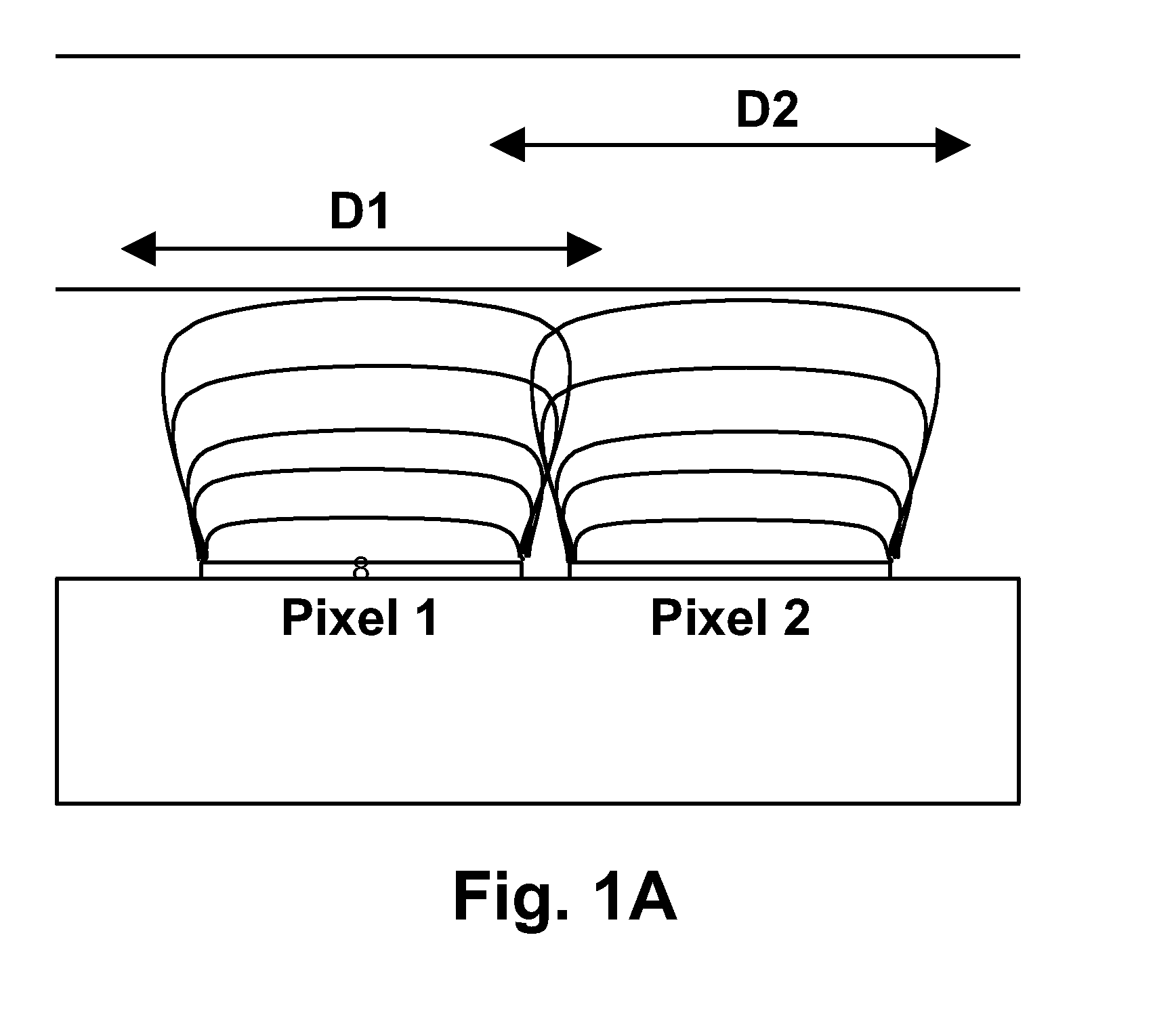

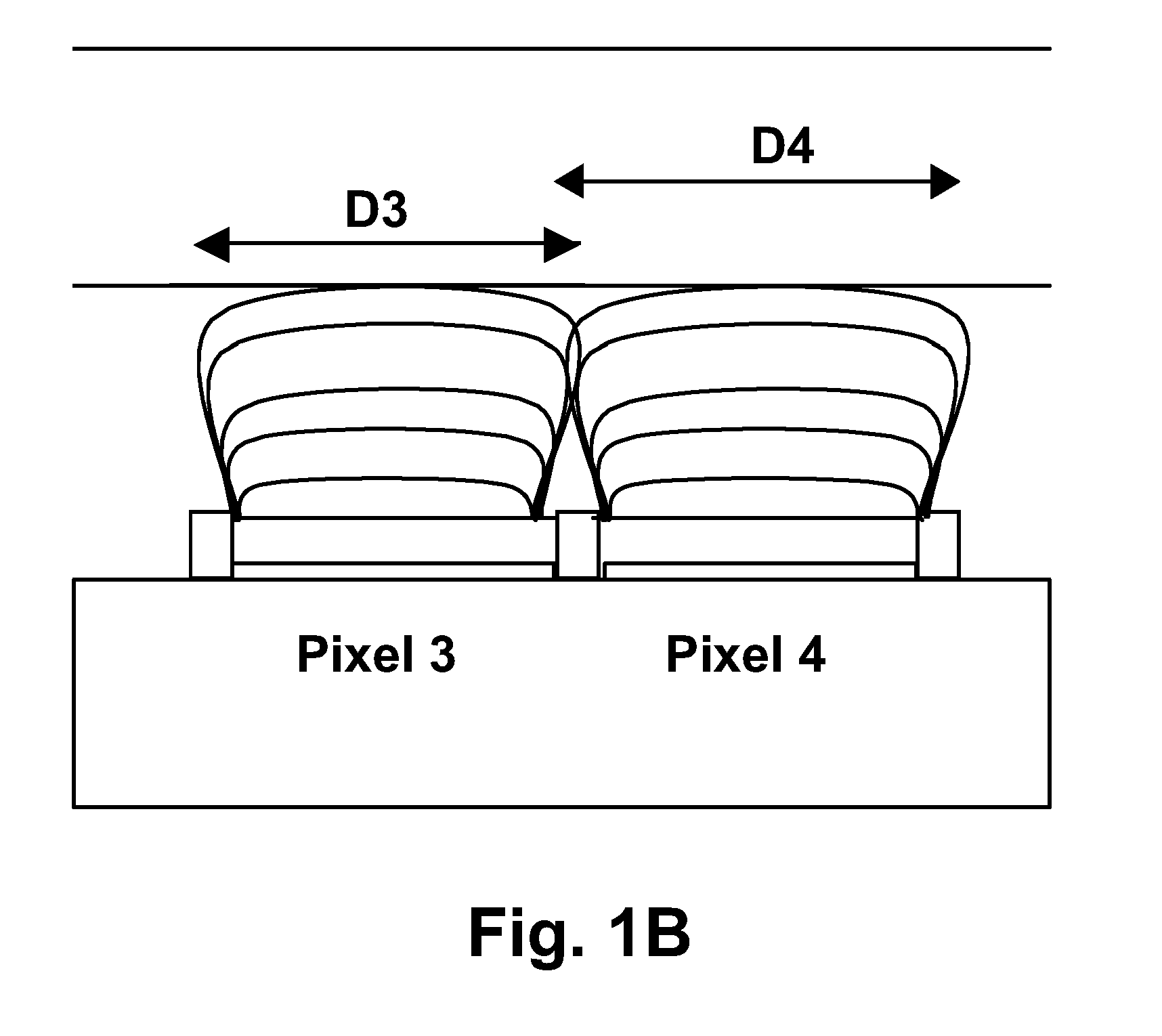

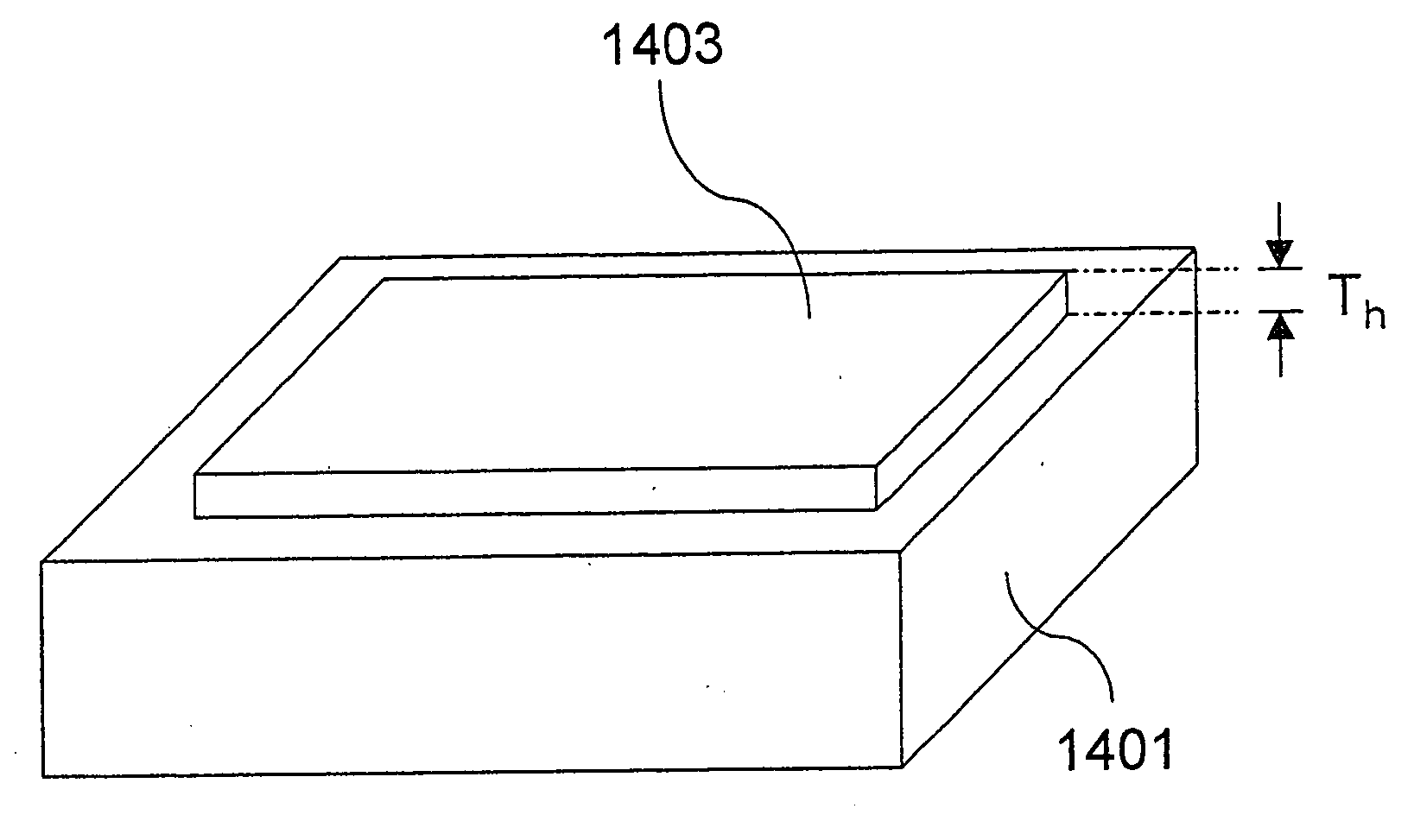

Backplanes for electro-optic displays

ActiveUS20050190137A1High volume resistivityDielectric constant be lowerStatic indicating devicesNon-linear opticsPhysicsBackplane

A backplane for an electro-optic display comprises a plurality of pixel electrodes, and an adhesive layer disposed adjacent the backplane, the adhesive layer comprising a plurality of pixel regions disposed adjacent the pixel electrodes of the backplane, and at least one inter-pixel region disposed between two pixels of the backplane, the at least one inter-pixel region having at least one of a lower dielectric constant and a higher volume resistivity than the pixel regions of the adhesive layer.

Owner:E INK CORPORATION

Heat-conducting wire cable electric-insulation material or sheath material

InactiveCN104017267AImprove thermal conductivityImprove insulation performanceRubber insulatorsPlastic/resin/waxes insulatorsElastomerHeat conducting

The invention discloses a heat-conducting wire cable electric-insulation material or sheath material which comprises the following components in parts by weight: 100 parts of ethylene and copolymer thereof and / or ethylene propylene diene monomer, 0-25 parts of compatilizer, 0-280 parts of flame retardant, 0.3-8 parts of antioxidant, 0.5-6 parts of lubricant, 0.01-10 parts of crosslinking assistant, 0-30 parts of polymer elastomer, 0-8 parts of coupling agent, 0-12 parts of color master batch and 1-35 parts of heat-conducting material. The heat-conducting wire cable electric-insulation material or sheath material has excellent heat conductivity and electric insulativity; and the cross network formed by piling the heat conducting material, the ethylene and copolymer thereof and other components can effectively perform heat conduction, so that the heat conductivity coefficient is up to 3.305-4.867 w / m.k, and the volume resistivity is 10<14> ohm*cm, thereby ensuring the electric-insulation effect and heat-conducting effect of the wire cable and the, and further ensuring the normal operation of the cable.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL +4

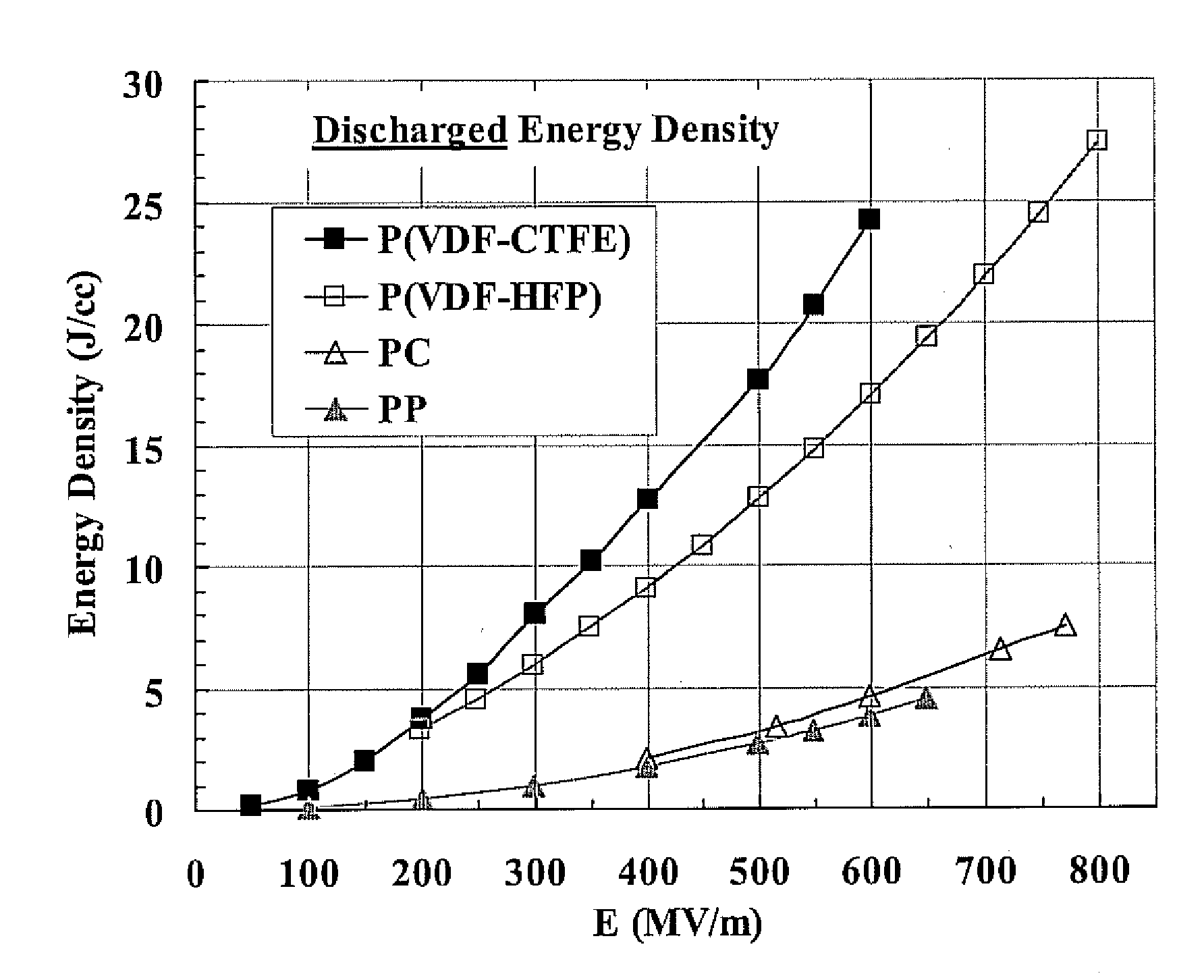

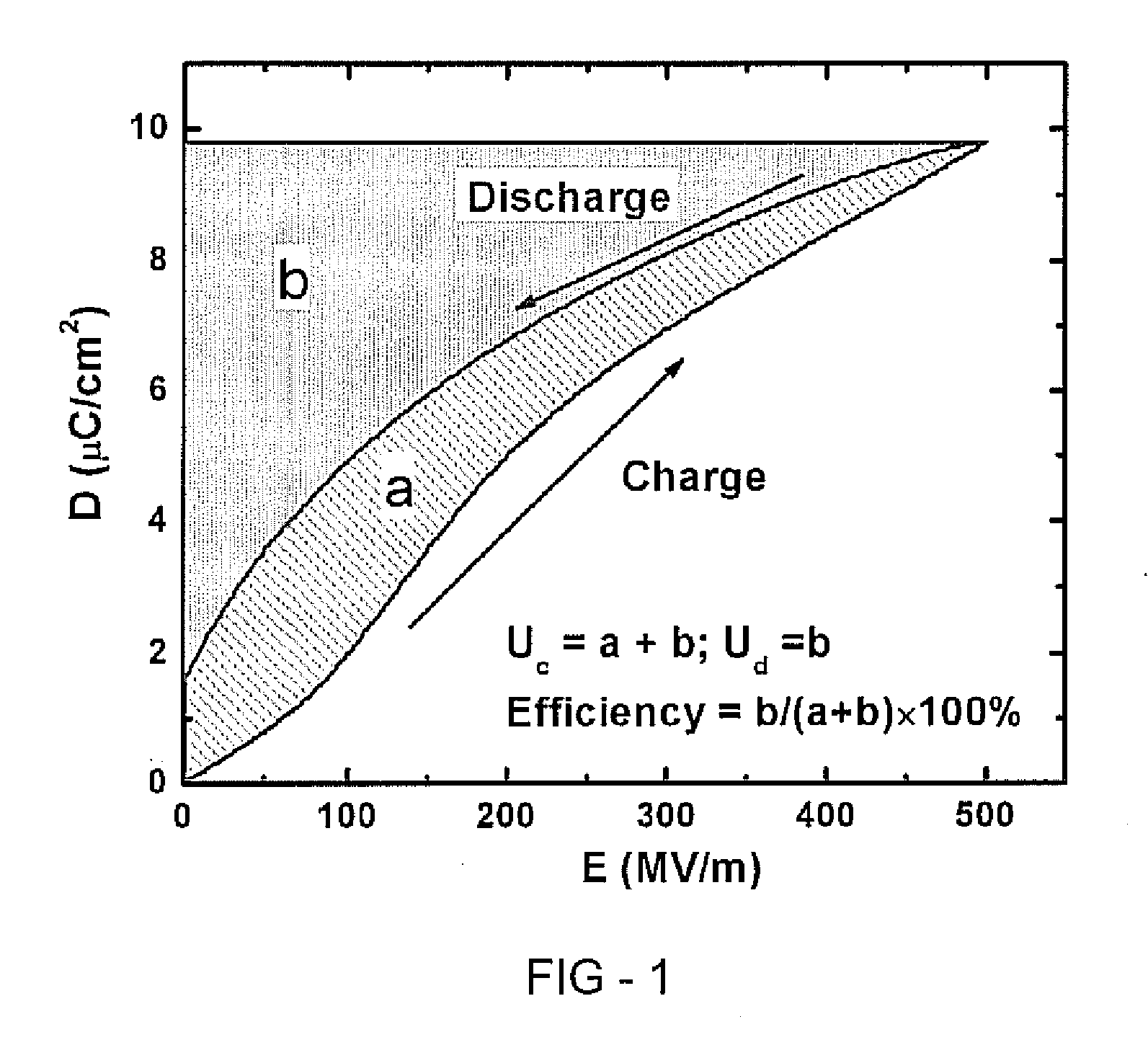

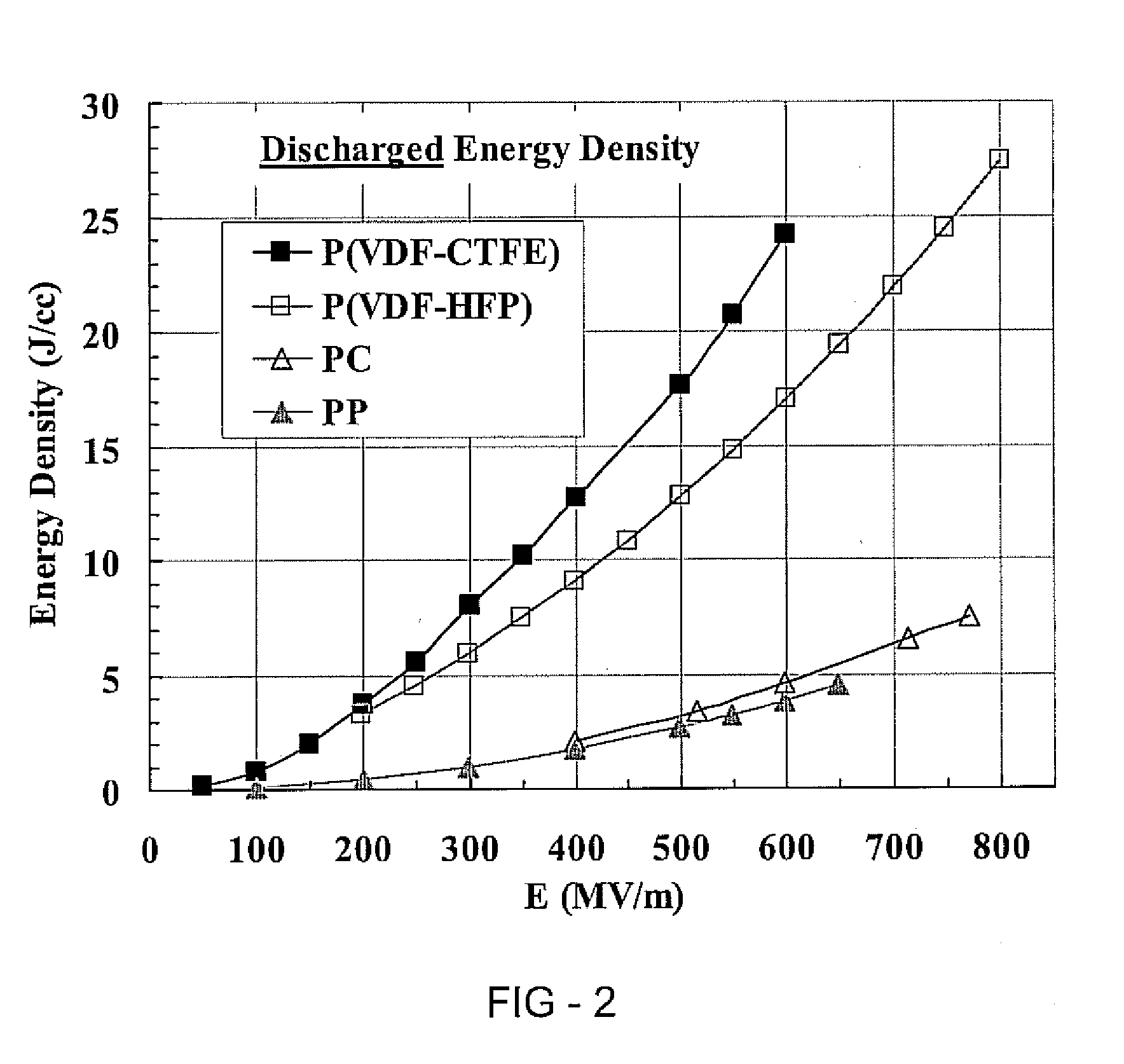

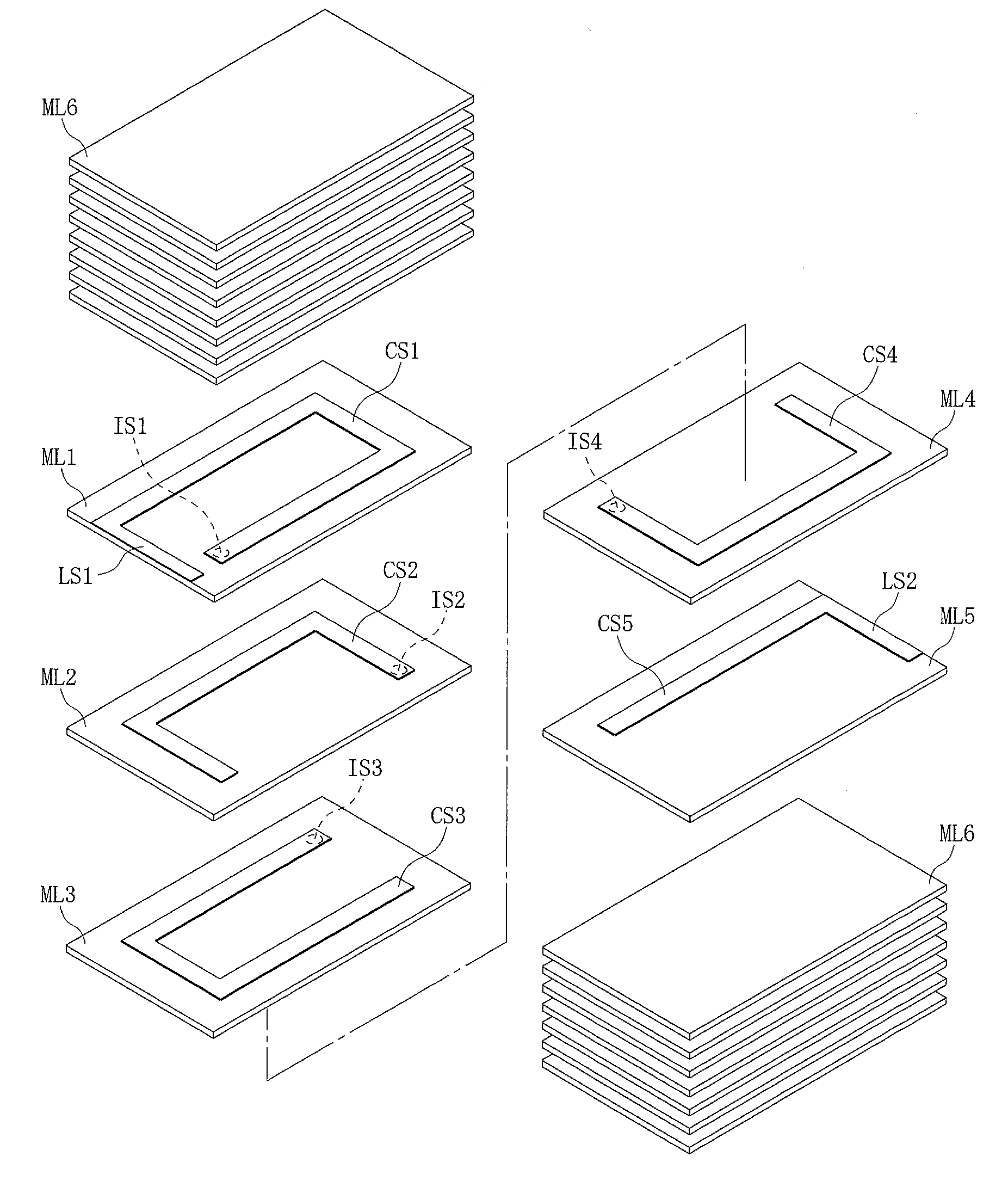

High electric energy density polymeric compositions, methods of the manufacture therefor, and articles comprising the same

InactiveUS20100067172A1Improve efficiencyFast dischargeFixed capacitor dielectricVehicular energy storagePolymer capacitorPolymer science

Examples of the present invention relate generally to high electric energy density polymer film capacitors with high charge-discharge efficiency and fast discharge speed. For example, a high energy density polymer capacitor may be fabricated using a polymer blend comprising one or more high dielectric constant PVDF-based polymers (including homopolymers, copolymers and / or terpolymers) and one or more other polymer with low dielectric loss and high volume resistivity compared to the one or more PVDF-based polymers. An example film capacitor may comprise a high temperature fluoropolymer with dielectric loss lower than 0.2% and good film manufacturability. Polymer films can be stretched and orientated at least in one direction to make thinner films with improved performance. Film capacitors can be made by winding metallized films, plain films with metal foils, or using a hybrid construction where the dielectric films comprise the new compositions. Capacitors can also have a multilayer construction where the films are metallized.

Owner:NOVASENTIS

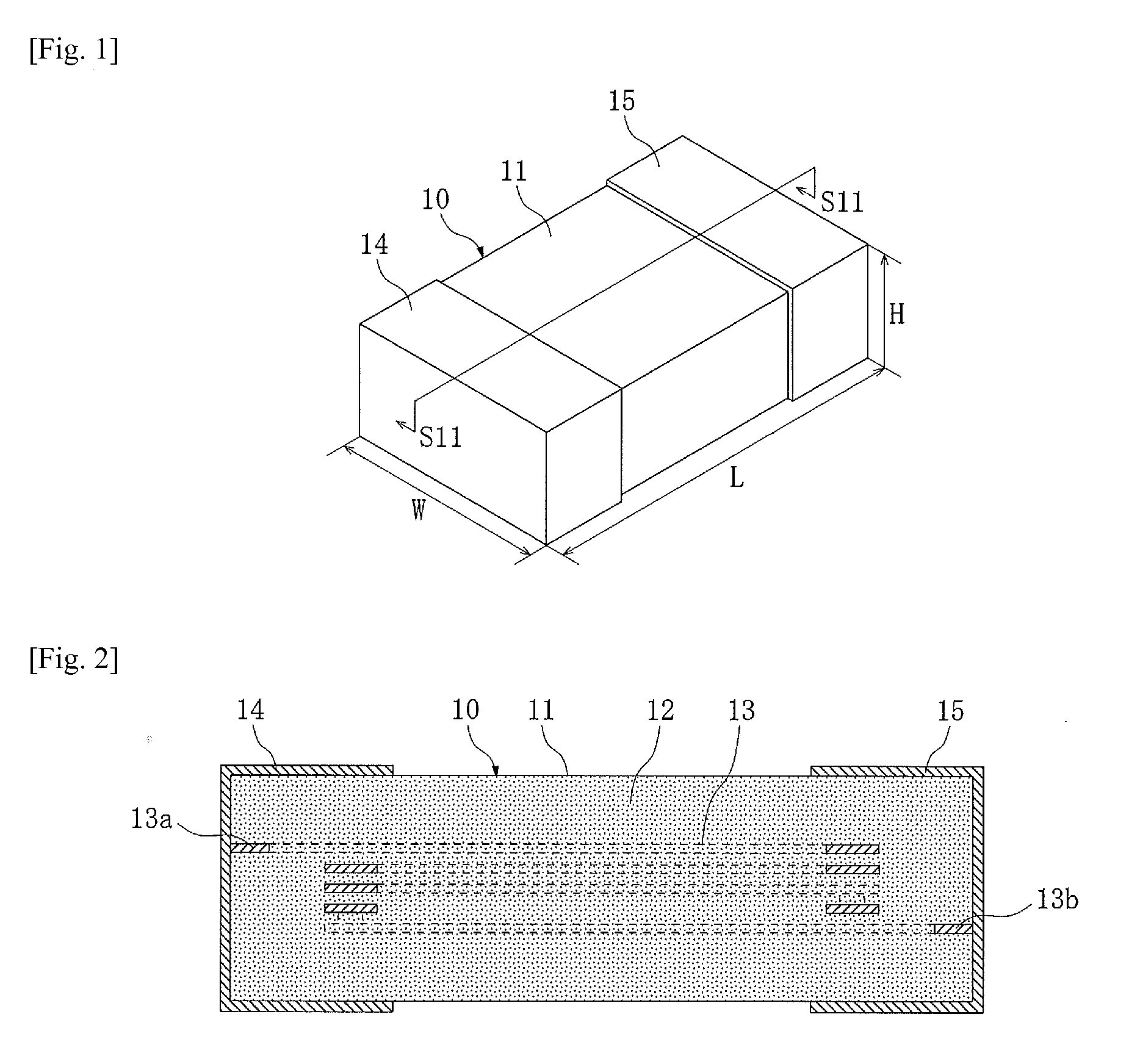

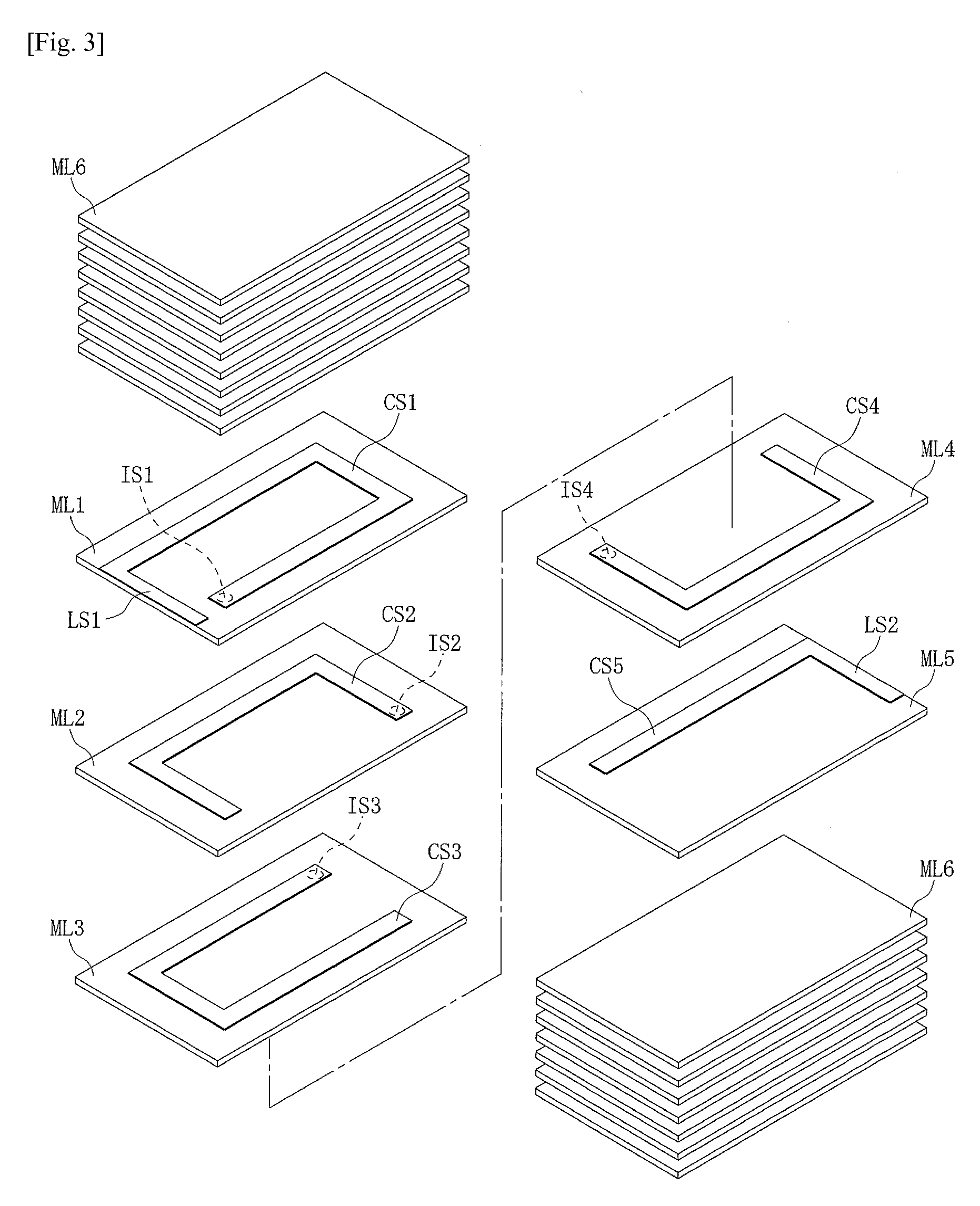

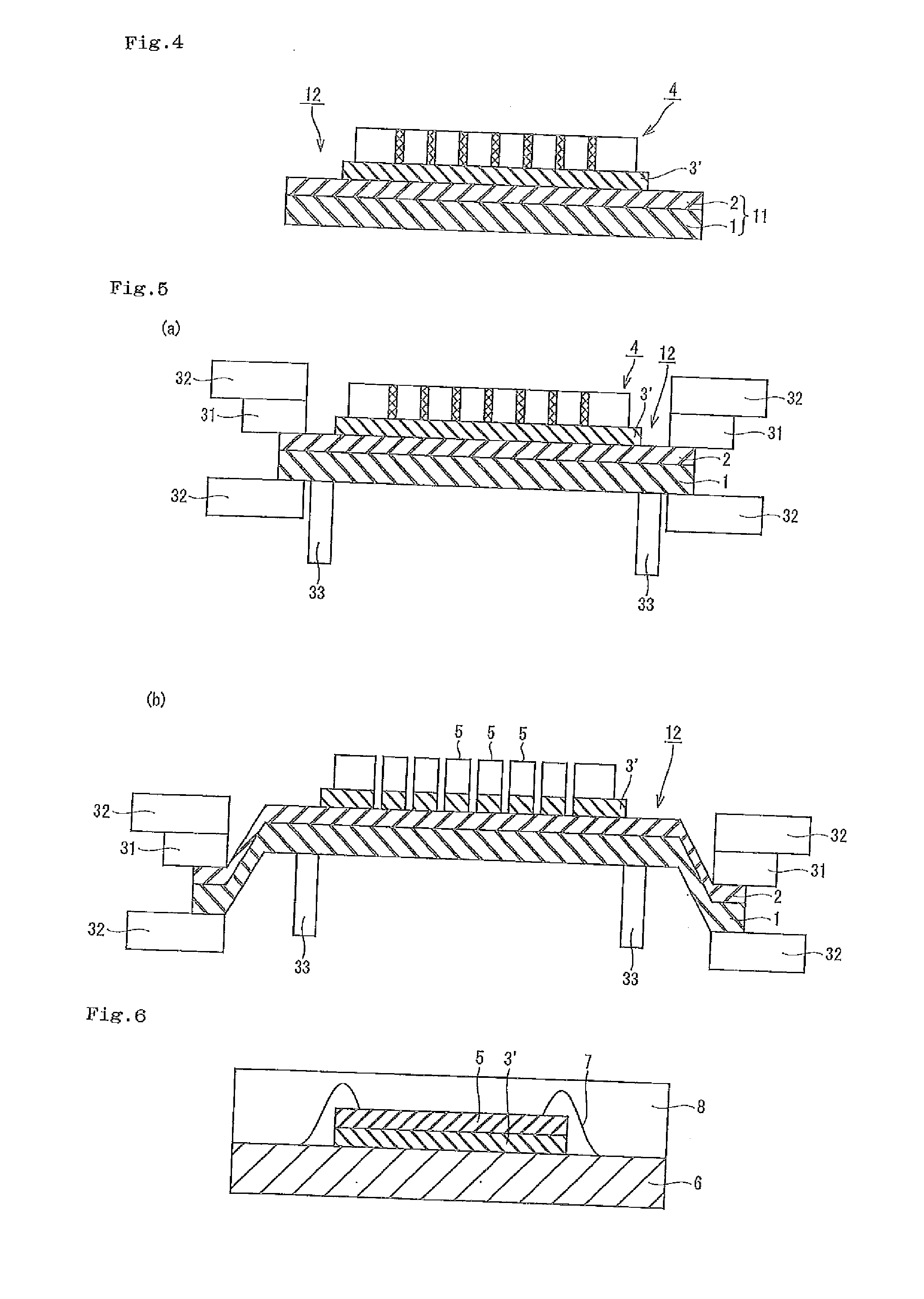

Coil component

ActiveUS20120188049A1High volume resistivityIncrease component densityTransportation and packagingMetal-working apparatusElectrical currentMaterials science

A coil component is of the type where a helical coil is directly contacting a magnetic body, which is still capable of meeting the demand for electrical current amplification. A coil component, comprising a magnetic body mainly constituted by magnetic alloy grains, and a coil formed on the magnetic body; wherein an oxide film of the magnetic alloy grains is present on the surface of each of the magnetic alloy grains, and based on grain size by volume standard, the magnetic alloy grains have a d50 in a range of 3.0 to 20.0 μm, d10 / d50 in a range of 0.1 to 0.7, and d90 / d50 in a range of 1.4 to 5.0.

Owner:TAIYO YUDEN KK

Dicing die bond film

InactiveUS20120061805A1Good tackinessImprove workabilitySemiconductor/solid-state device detailsSolid-state devicesDie bondingPolymer chemistry

The present invention provides a dicing die bond film in which peeling electrification hardly occurs and which has good tackiness and workability. The dicing die bond film of the present invention is a dicing die bond film including a dicing film and a thermosetting type die bond film provided thereon, wherein the thermosetting type die bond film contains conductive particles, the volume resistivity of the thermosetting type die bond film is 1×10−6 Ω·cm or more and 1×10−3 Ω·cm or less, and the tensile storage modulus of the thermosetting type die bond film at −20° C. before thermal curing is 0.1 to 10 GPa.

Owner:NITTO DENKO CORP

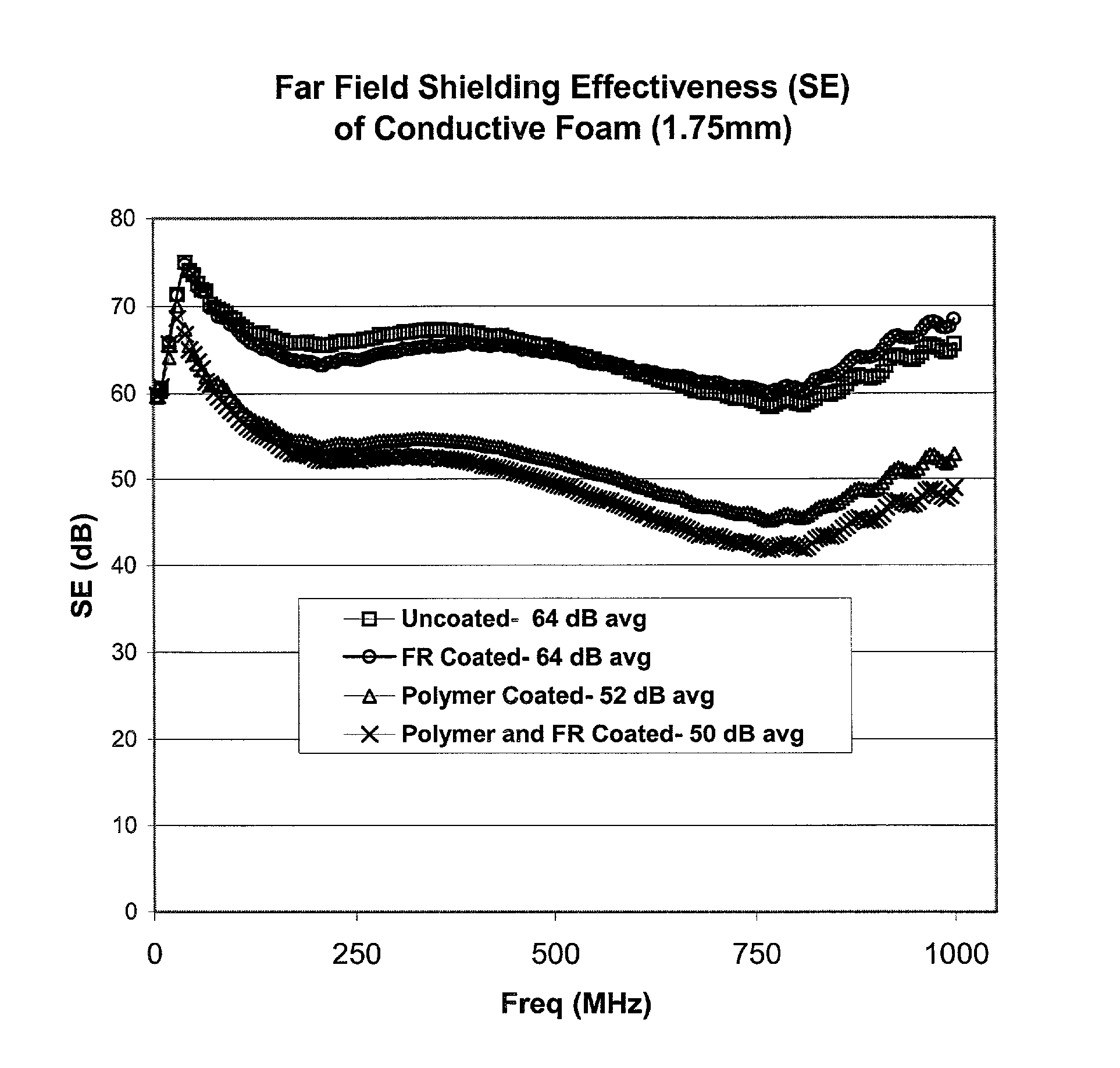

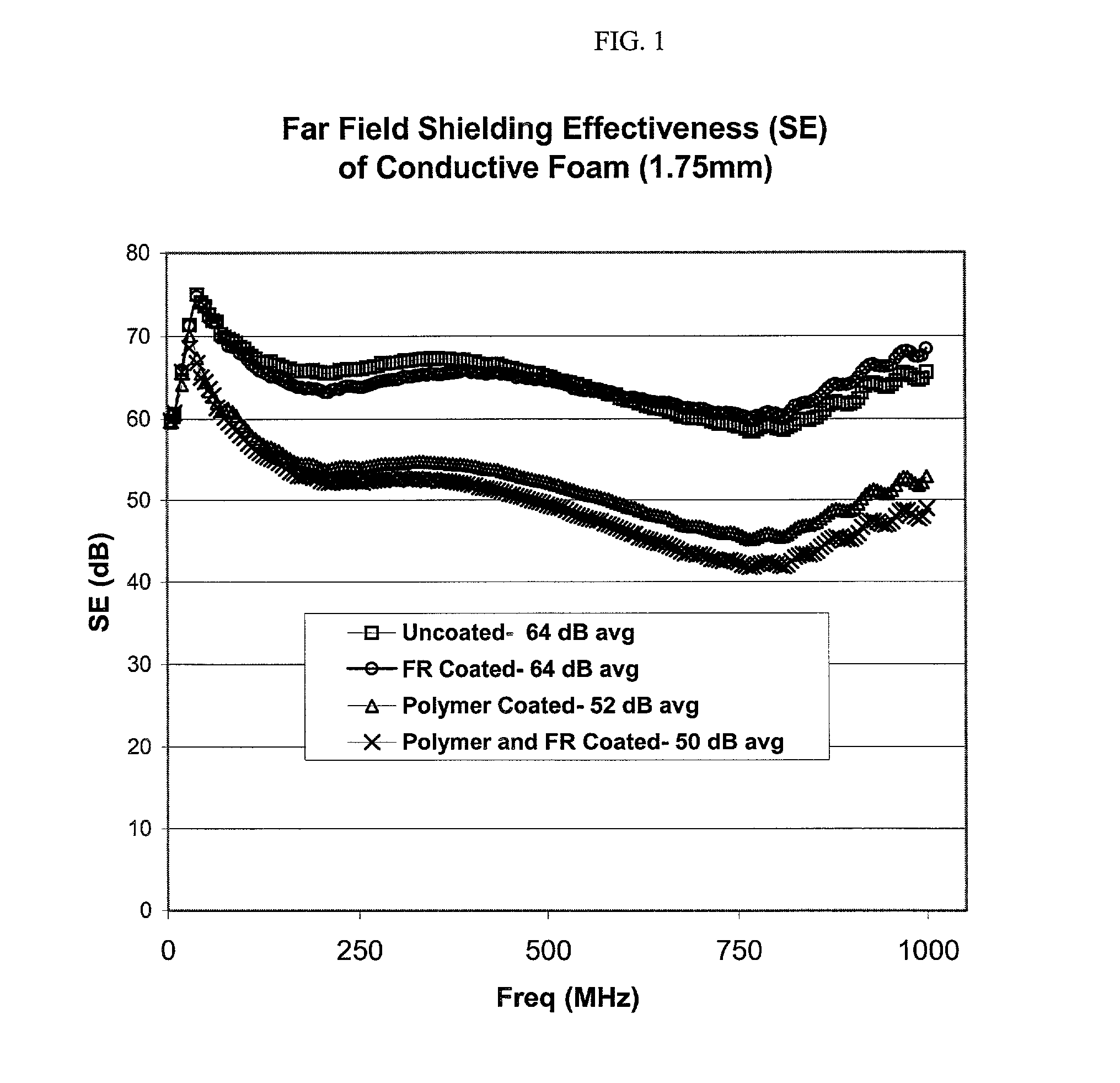

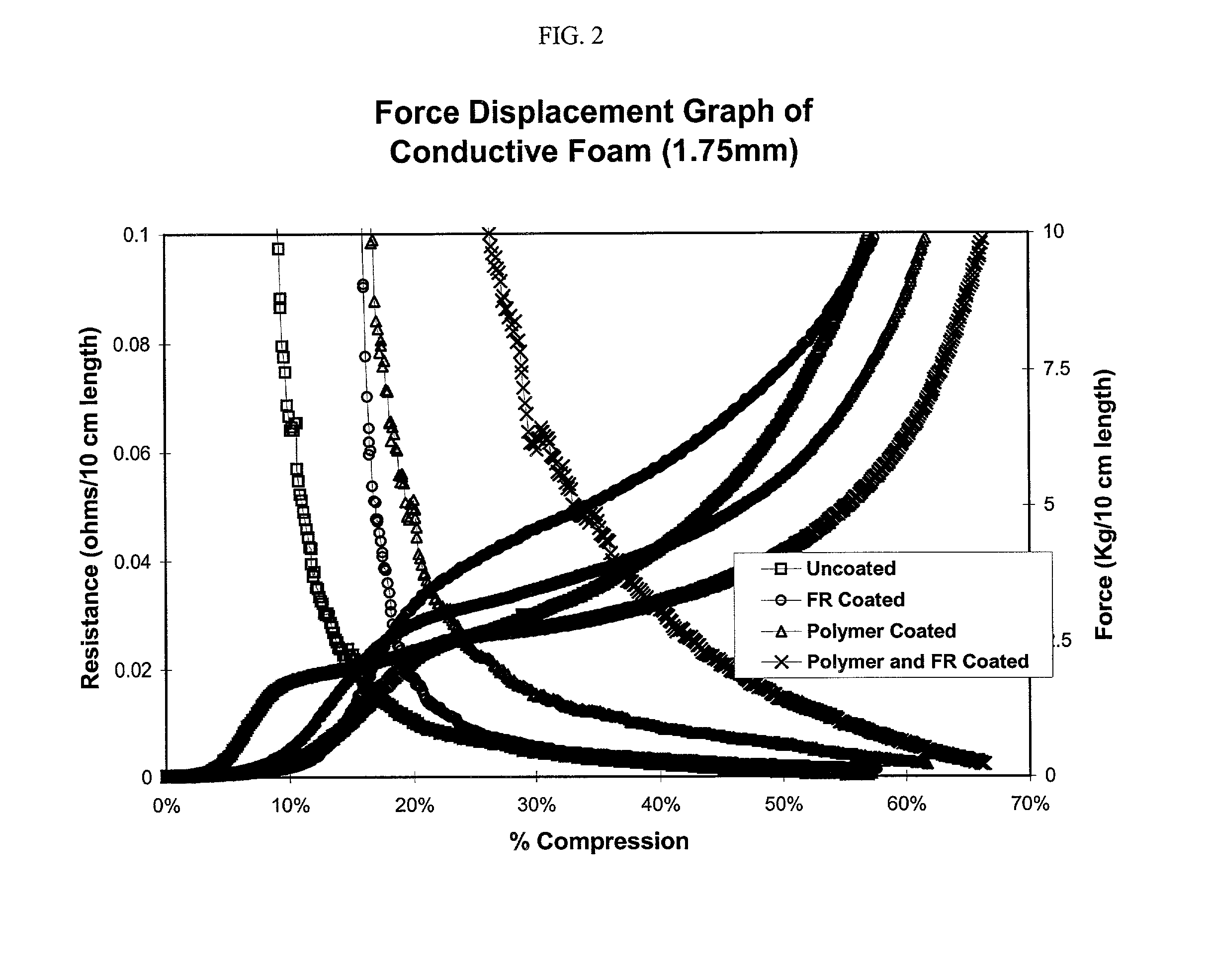

Flame retardant, electrically conductive shielding materials and methods of making the same

ActiveUS7060348B2High volume resistivityMaintain good propertiesRadiation/particle handlingMagnetic/electric field screeningEngineeringFire retardant

Owner:LAIRD TECH INC

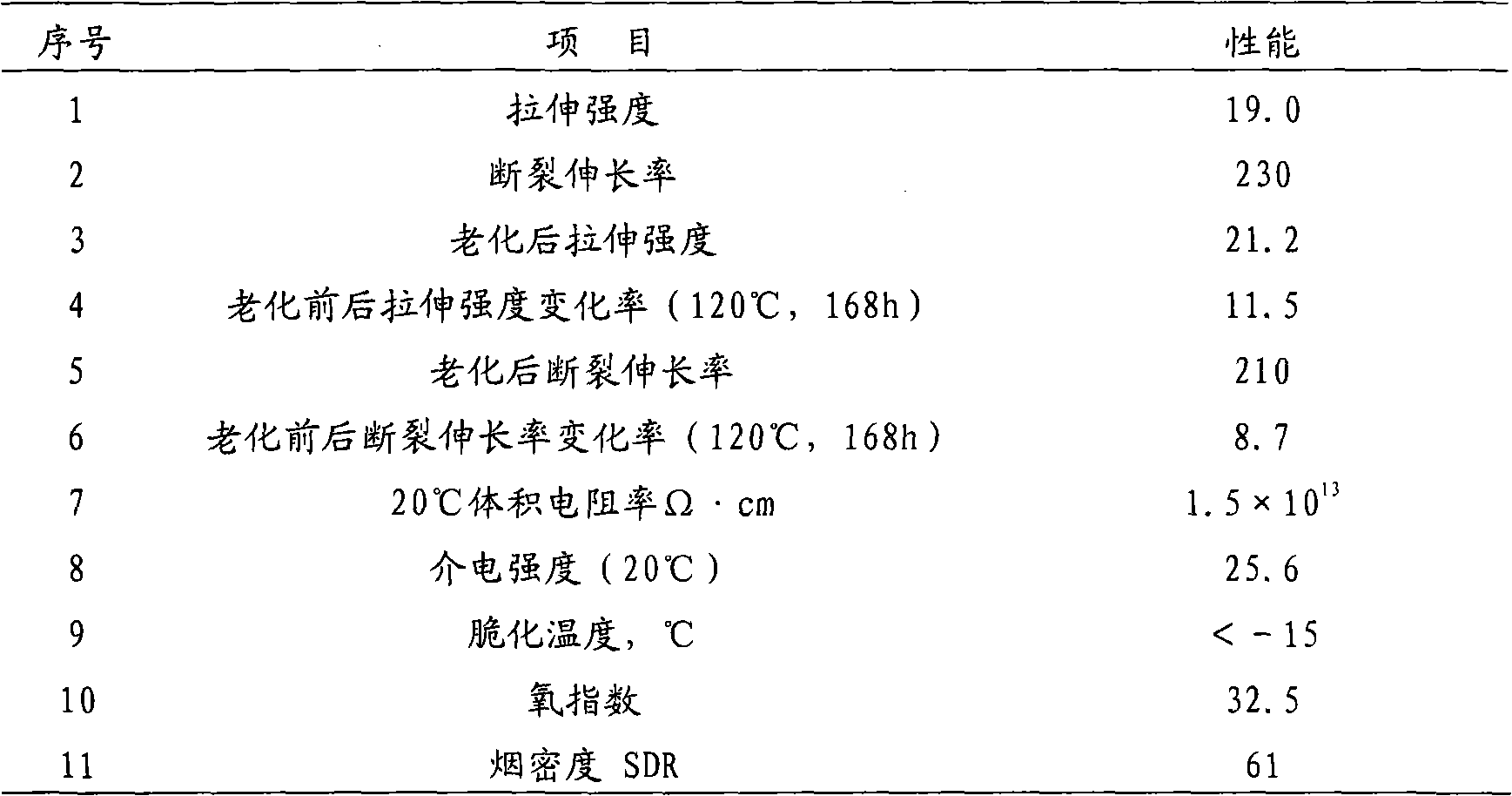

Silicone hydride crosslinked non-halogen flame-proof smoke-restraining polyvinyl chloride cable material and manufacturing process thereof

InactiveCN101319079AEasy to processPromote degradationInsulated cablesInsulated conductorsPolyvinyl chlorideFire retardant

The invention discloses a silane crosslinking HFFR flame retardant polyvinyl chloride cable material and a preparation technique thereof. The compositions by weight portion of the cable material are: 100 portions of polyvinyl chloride resin, 10 to 100 portions of a plasticizer, 0.5 to 10 portions of a silane cross-linking agent, 0.5 to 6 portions of a heat stabilizer, 30 to 100 portions of a metal hydroxide flame retardant, 1 to 10 portions of a metallic compound flame retardant synergist, 0.1 to 5 portions of a preventing cross-linking agent, 0.1 to 5 portions of a lubricant, 0.1 to 0.5 portion of an antioxidizer, 0.05 to 0.1 portion of dibutyl tin dilaurate and appropriate amount of a colorant. The cable material has the characteristics that the mechanical property is good, the mechanical intensity is increased by 20 to 30 percent compared with the uncrosslinked PVC cable material, the heat resistance is good, the electrical property is good, the specific volume resistance is increased by 3 to 5 times compared with the uncrosslinked PVC cable material, the insulating property of the cable is improved and the aging property is good.

Owner:LIAOCHENG UNIV

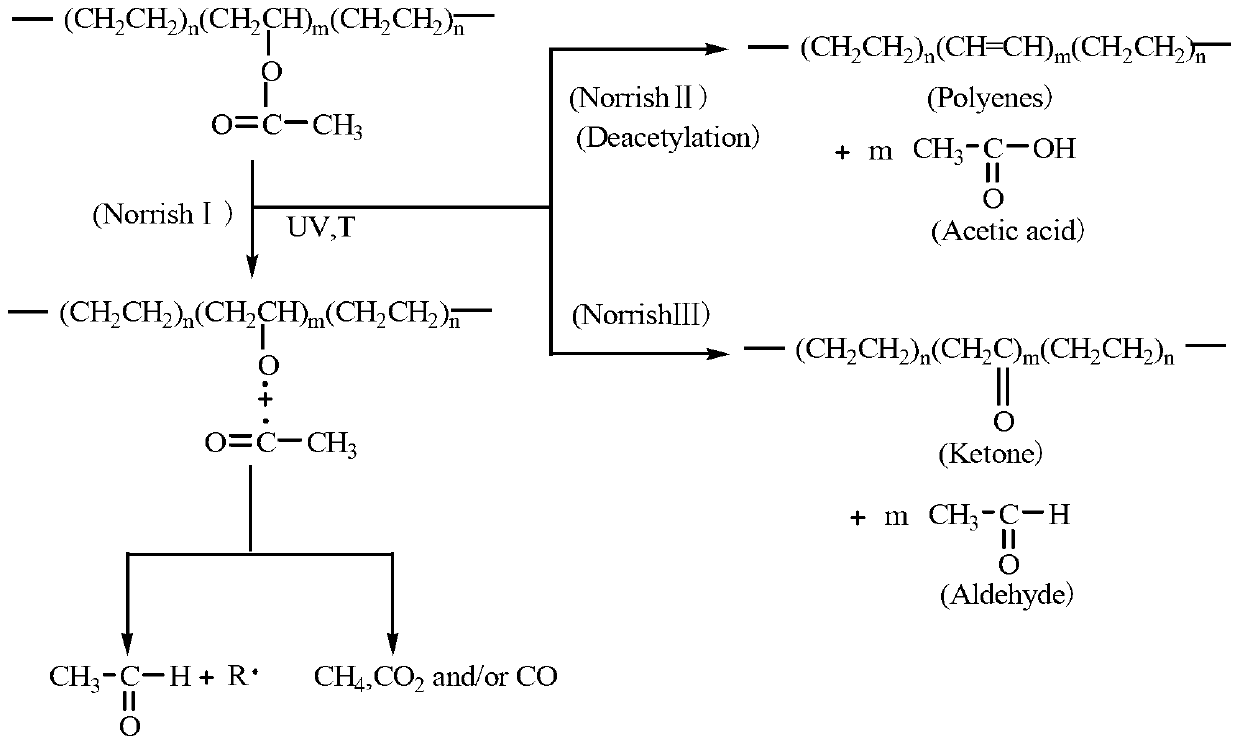

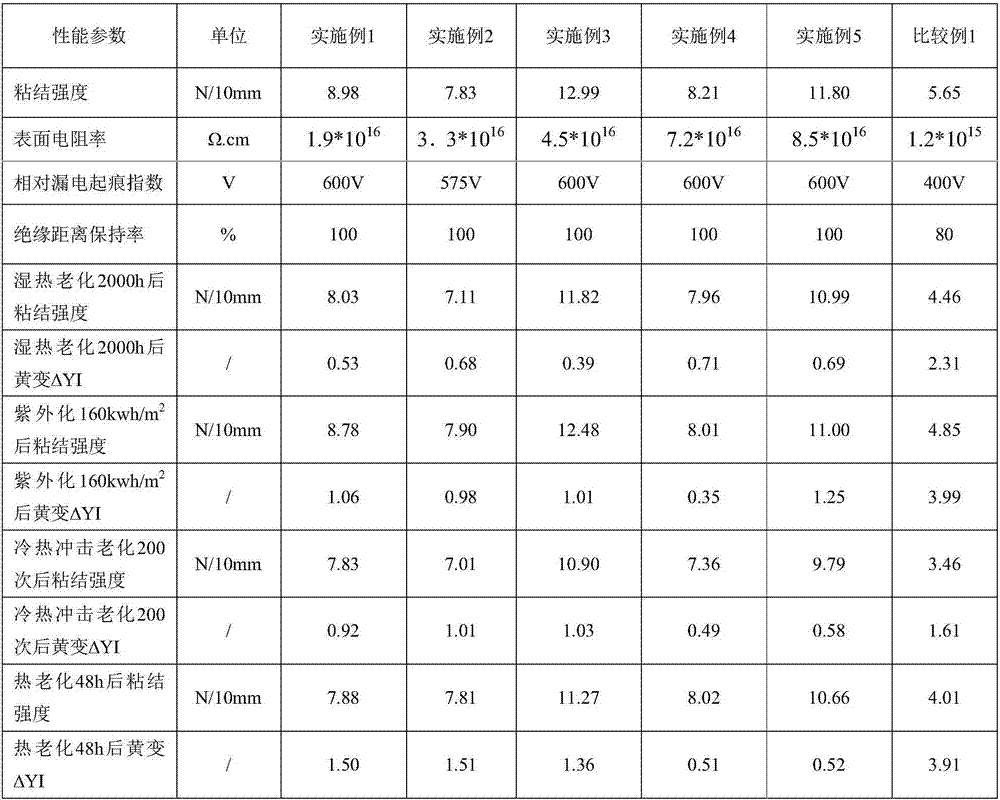

High-volume resistivity EVA (Ethylene Vinyl-acetate Copolymer) rubber film and preparation process thereof

ActiveCN103146315AHigh volume resistivityImprove aging resistanceNon-macromolecular adhesive additivesFilm/foil adhesivesElastomerPolymer science

The invention relates to a packaging material of a photovoltaic module, in particular to a high-volume resistivity EVA (Ethylene Vinyl-acetate Copolymer) rubber film and a preparation process of the rubber film. The EVA rubber film comprises the following components in percentage by weight: 82%-94% of EVA resin, 5%-15% of polyolefin elastomer (POE), 0.1%-0.5% of ultraviolet aging resisting additive, 0.3%-1.5% of liquid peroxide cross-linking agent and 0.1%-1.0% of liquid silane coupling agent. The high-volume resistivity EVA rubber film disclosed by the invention reduces the VA content, reduces generation of conductive ions, and can increase the resistivity. The polyolefin elastomer is easy to be cross-linked by the effect of an initiating agent, and a plurality of positions are cross-linked with the EVA molecule, thereby realizing high cross-linking density, firmer molecular chain, smaller free volume, higher resistivity, difficulty in conduction, so the EVA rubber film disclosed by the invention has higher volume resistivity which is as high as 1x1015 ohm.cm or higher.

Owner:浙江利昌科技有限公司

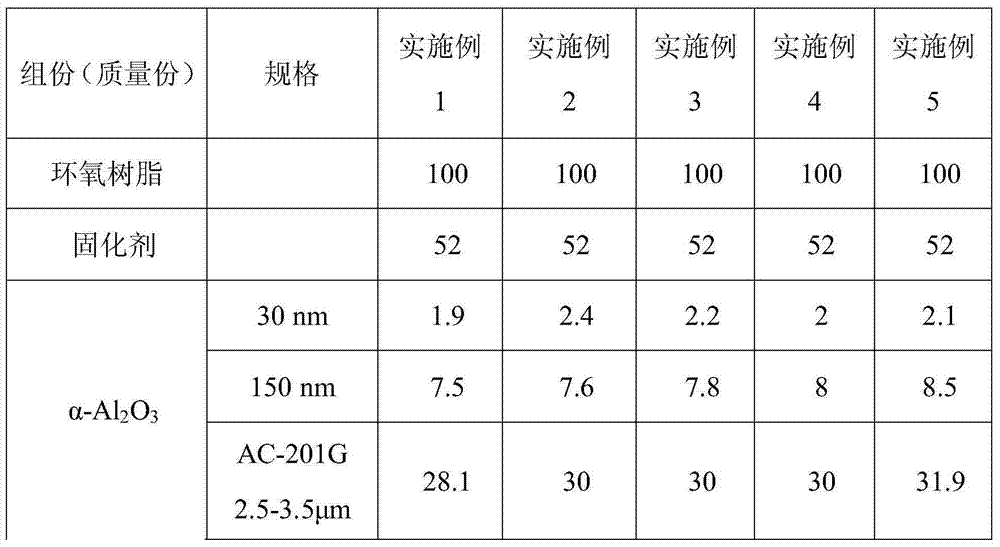

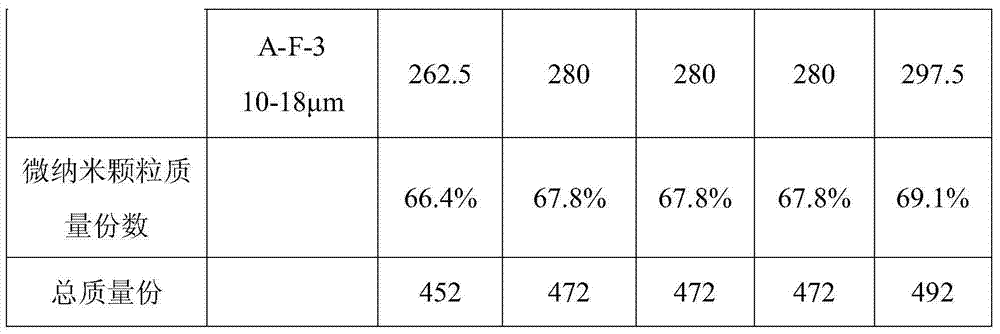

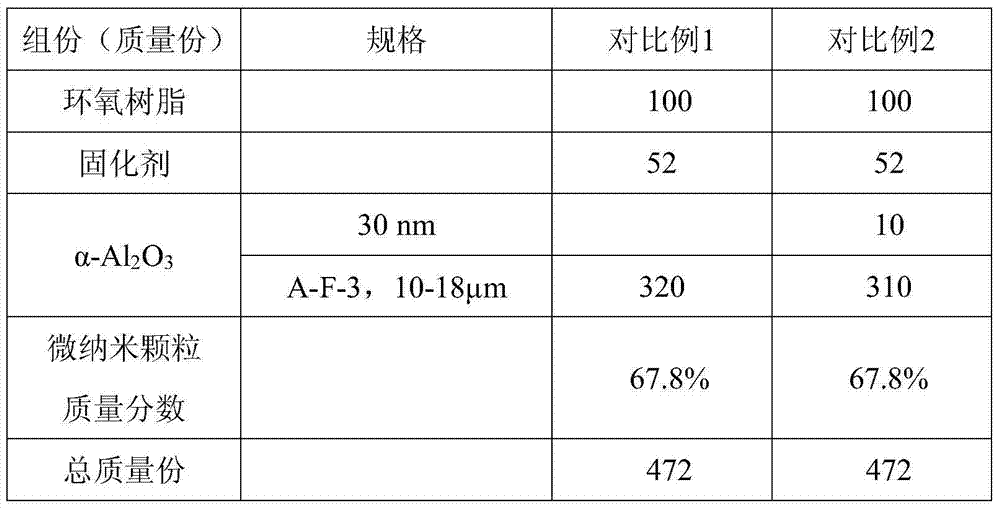

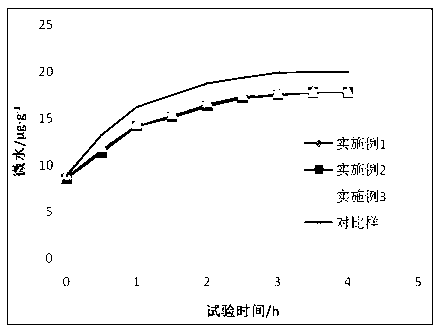

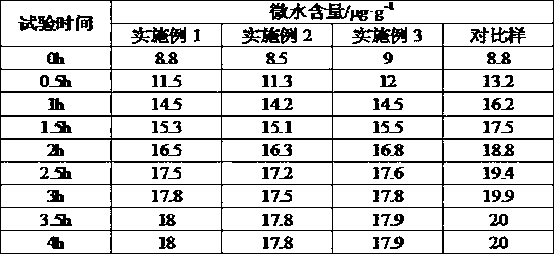

Electric insulating epoxy resin composition, preparation method and use of composition

The invention discloses an electric insulating epoxy resin composition which comprises the following components: (A) a mixture of at least two epoxy resins; (B) a mixture of at least two anhydride curing agents; and (C) a micro-nano inorganic particle composition, wherein the micro-nano inorganic particle composition accounts for 63-73wt% of the electric insulating epoxy resin composition. The electric insulating epoxy resin composition disclosed by the invention has high volume resistivity and meanwhile has excellent electric performances such as breakdown strength, heat resistance, mechanical property and machinable property, so that the composition can be used for preparing insulating parts in electric transmission and transformation equipment of a power grid, and is particularly used for preparing insulating parts in electric transmission and transformation equipment of a direct current ultra-high voltage grid.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +3

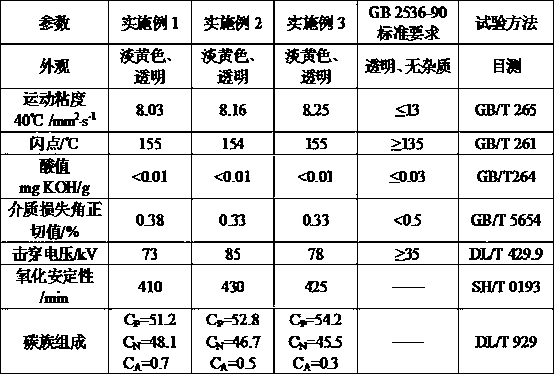

Transformer oil with excellent cooling heat-radiating and moisture preventing properties and preparation method thereof

The invention discloses transformer oil with excellent cooling heat-radiating and moisture preventing properties. The transformer oil is mainly prepared from the following raw materials: hydrogenated stock oil, naphthene thickened oil, an antioxidant and a metal passivator, wherein the ratio of the hydrogenated stock oil to the naphthene thickened oil is (72-82):(18-28) in terms of parts by weight, the amount of the used antioxidant accounts for 0.3-0.5% relative to the total mass of the hydrogenated stock oil and the naphthene thickened oil, and the amount of the used metal pasivator accounts for 0.1-0.2% relative to the total mass of the hydrogenated stock oil and the naphthene thickened oil. The invention further discloses a preparation method of the transformer oil. The transformer oil has excellent cooling heat-radiating and moisture preventing properties, thus being very suitable for being used in southern areas of China.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

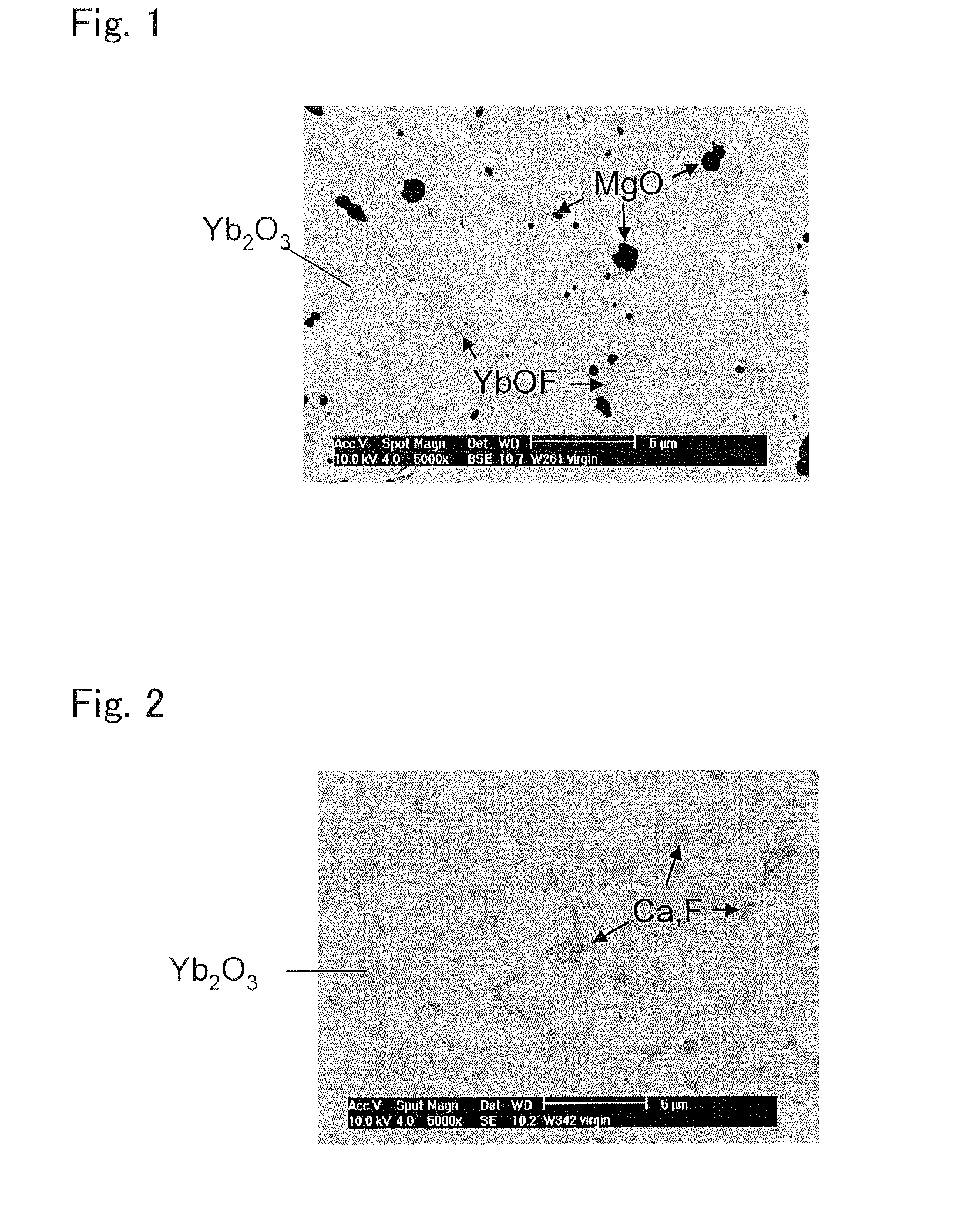

Corrosion-resistant member for semiconductor manufacturing apparatus and method for manufacturing the same

ActiveUS20130023401A1Reduce etch rateReduce the amount requiredSemiconductor/solid-state device manufacturingCeramic shaping apparatusManufactured apparatusManufactured material

Initially, an Yb2O3 raw material was subjected to uniaxial pressure forming at a pressure of 200 kgf / cm2, so that a disc-shaped compact having a diameter of about 35 mm and a thickness of about 10 mm was produced, and was stored into a graphite mold for firing. Subsequently, firing was performed by using a hot-press method at a predetermined firing temperature (1,500° C.), so as to obtain a corrosion-resistant member for semiconductor manufacturing apparatus. The press pressure during firing was specified to be 200 kgf / cm2 and an Ar atmosphere was kept until the firing was finished. The retention time at the firing temperature (maximum temperature) was specified to be 4 hours. In this manner, the corrosion-resistant member for semiconductor manufacturing apparatus made from an Yb2O3 sintered body having an open porosity of 0.2% was obtained.

Owner:NGK INSULATORS LTD

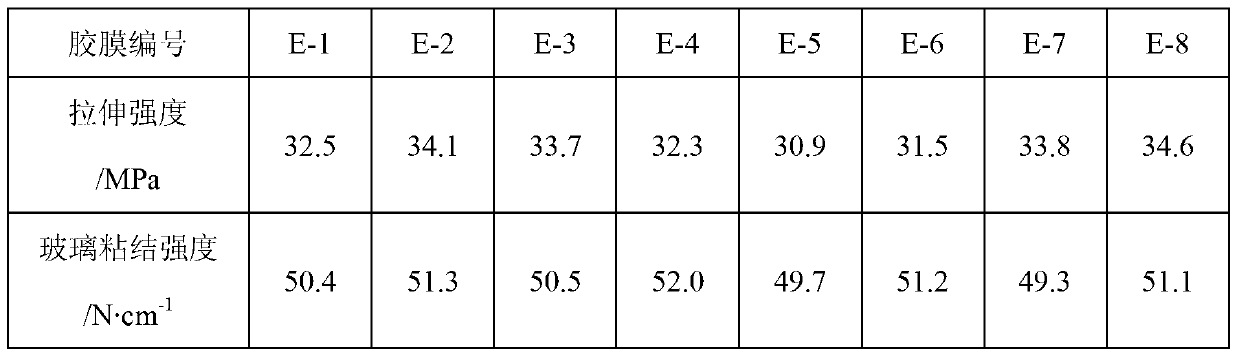

Production processes of packaging adhesive film with ultra-low ionic mobility and photovoltaic component

InactiveCN103342968AImprove insulation performanceImprove the phenomenon of poor mechanical propertiesFilm/foil adhesivesOrganic non-macromolecular adhesiveElastomerPolyolefin

The invention relates to a solar cell packaging adhesive film having low ionic mobility and belongs to the technical field of photovoltaic power generation fittings. The solar cell packaging adhesive film with low ionic mobility is formed by compounding a bonding layer adhesive film with an ion isolation layer in a certain proportion; the thickness proportion of the bonding layer to the ion isolation layer is (1:1)-(1:5); the thickness of the packaging adhesive film is 0.5-0.8 mm. According to the invention, the ion isolation layer is innovatively introduced; on one hand, the isolation layer has high insulativity of polyolefin elastomers, such as POE (Polyolefin Elastomer) and EPDM (Ethylene-Propylene-Diene Monomer); on the other hand, because of a hydrogen bond in a siloxane structure, the blending compatibility of the packaging adhesive film with other high-molecular polymers is greatly increased; meanwhile polymer linear polysiloxane is modified by using an ethylene-acrylate polymer; the poor mechanical property phenomenon of polysiloxane can be greatly improved.

Owner:CHANGZHOU UNIV +1

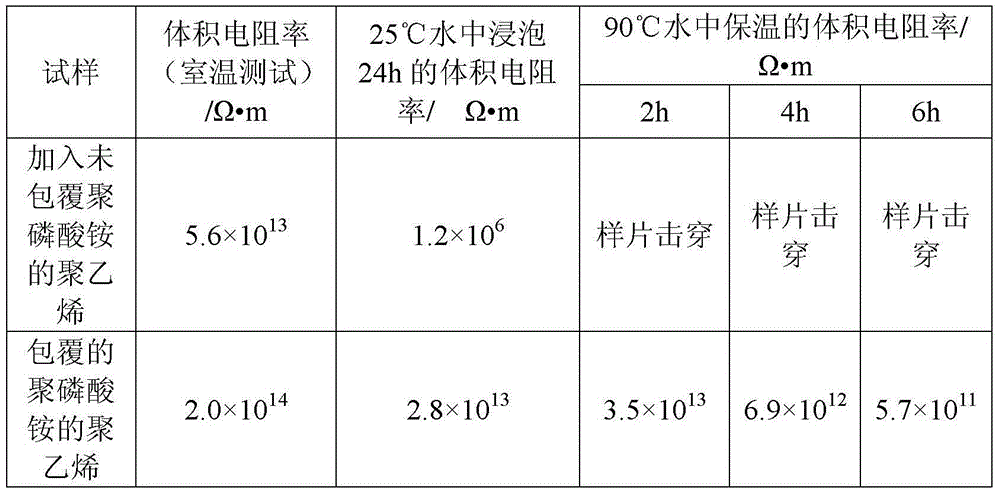

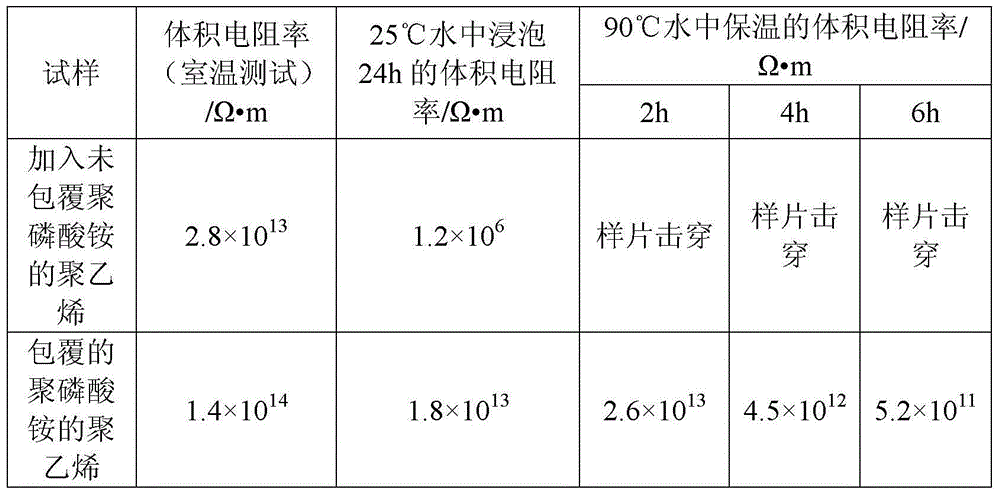

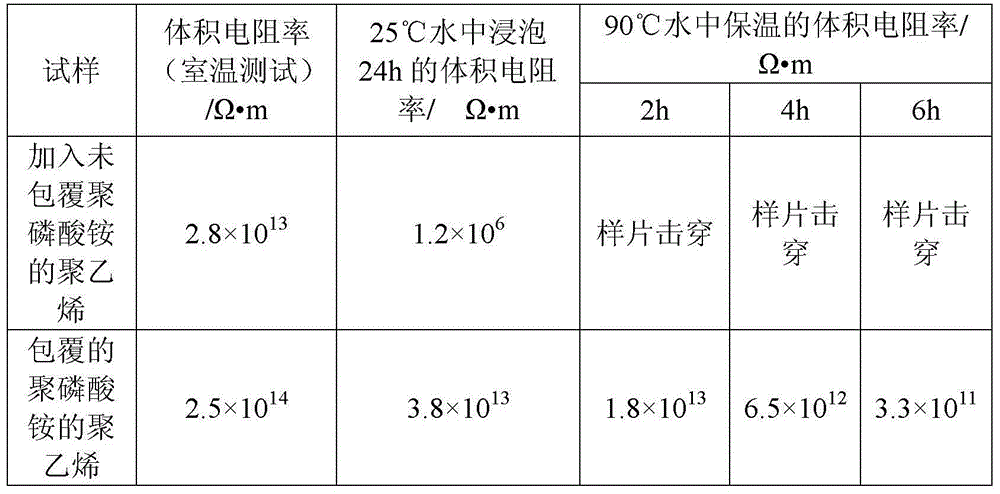

Preparation method of ammonium polyphosphate wrapped with fluorine-containing silicone oil on surface

ActiveCN104479172AReduce solubilityHigh volume resistivityPigment treatment with organosilicon compoundsSolubilityRoom temperature

The invention discloses a preparation method of ammonium polyphosphate wrapped with fluorine-containing silicone oil on the surface, relates to a preparation method of ammonium polyphosphate, and aims at solving the technical problems that existing modified ammonium polyphosphate as a fire retardant is easy to hydrolyze, so that the flame retardant property is reduced and the fire retardant in the material is easy to separate out. The method disclosed by the invention comprises the following steps: 1 heating ammonium polyphosphate; and 2 wrapping the surface of the ammonium polyphosphate with the fluorine-containing silicone oil. The method has the advantages that 1 the solubility of ammonium polyphosphate wrapped with the fluorine-containing silicone oil on the surface prepared by the method at a room temperature is greatly reduced in comparison with that of unwrapped ammonium polyphosphate at the room temperature; 2 the volume resistivity of a polyethylene material added with ammonium polyphosphate wrapped with the fluorine-containing silicone oil on the surface prepared by the method at the room temperature is greatly improved in compression with that of the polyethylene material added with the unwrapped ammonium polyphosphate; and 3 the hydrophobicity of ammonium polyphosphate wrapped with the fluorine-containing silicone oil on the surface prepared by the method is obviously improved, and the material compatibility and insulativity are also obviously improved.

Owner:HONGLONGJIANG ORIENT SCI & TECH

Special insulating material for electrical equipment and preparation method for special insulating material

InactiveCN105348739AGood compatibilityGood dispersionPlastic/resin/waxes insulatorsEpoxyPower equipment

The invention discloses a special insulating material for electrical equipment and a preparation method for the special insulating material. The special insulating material for the electrical equipment comprises the following components in parts by weight: 90-100 parts of epoxy resin, 15-25 parts of methyl vinyl silicone rubber, 20-25 parts of fluorosilicon resin, 15-20 parts of polytetrafluoroethylene, 10-15 parts of glass fiber, 15-20 parts of nano inorganic powders, 0.2-1 part of butyl titanate, 20-40 parts of distilled water, 1-6 parts of a compatilizer, 1-5 parts of a flame retardant, 0.3-1.2 parts of an antioxidant and 1-10 parts of a crosslinking agent. The special insulating material for the electrical equipment prepared by the invention can inhibit the space charge accumulation in the cable insulating material, improve the anti-aging property, the anti-flashover property and the anti-acidic and alkaline water-resistent property of the material, has good mechanical properties, electrical property and thermal property, and is excellent in comprehensive properties.

Owner:国网河南唐河县供电公司

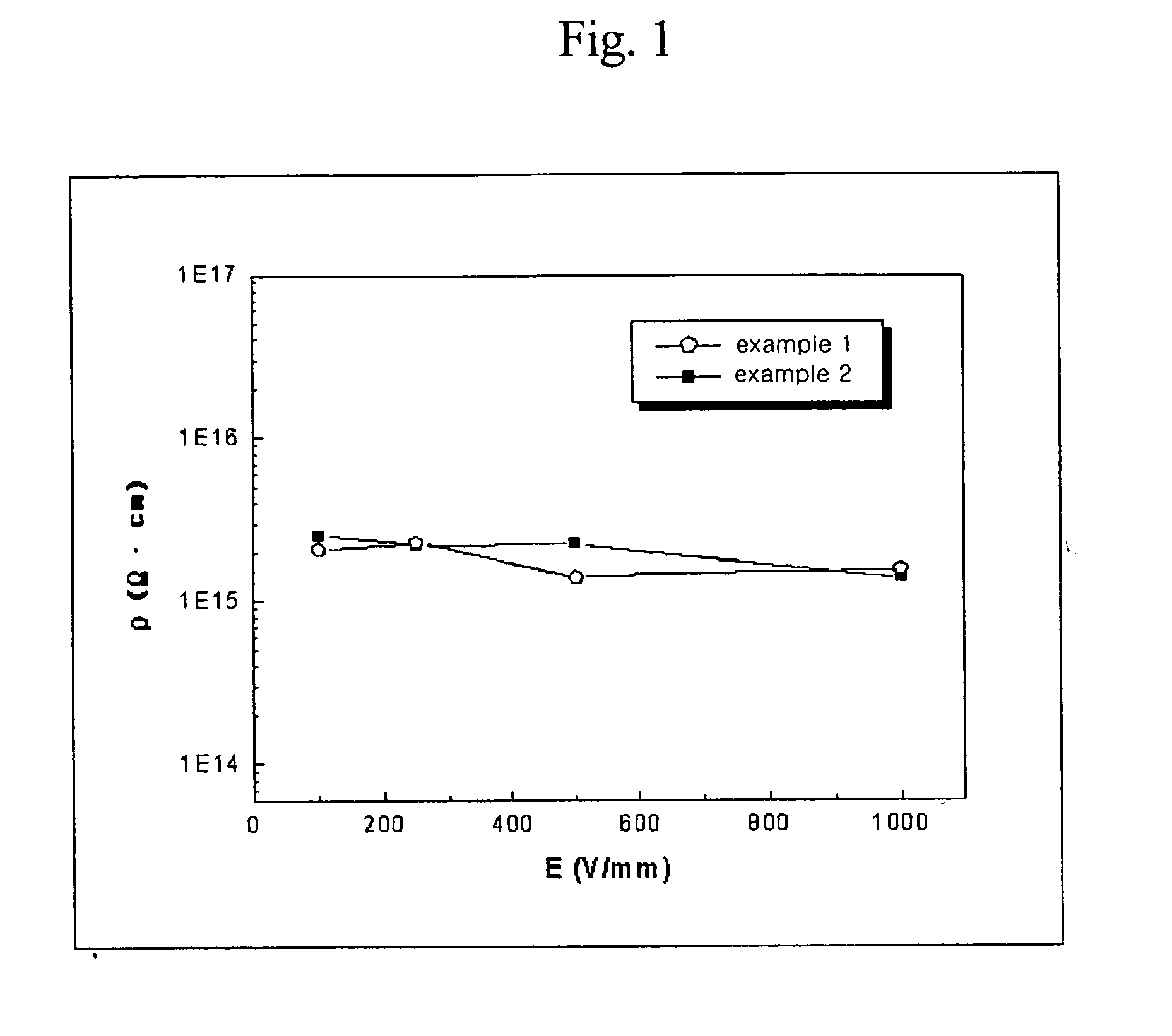

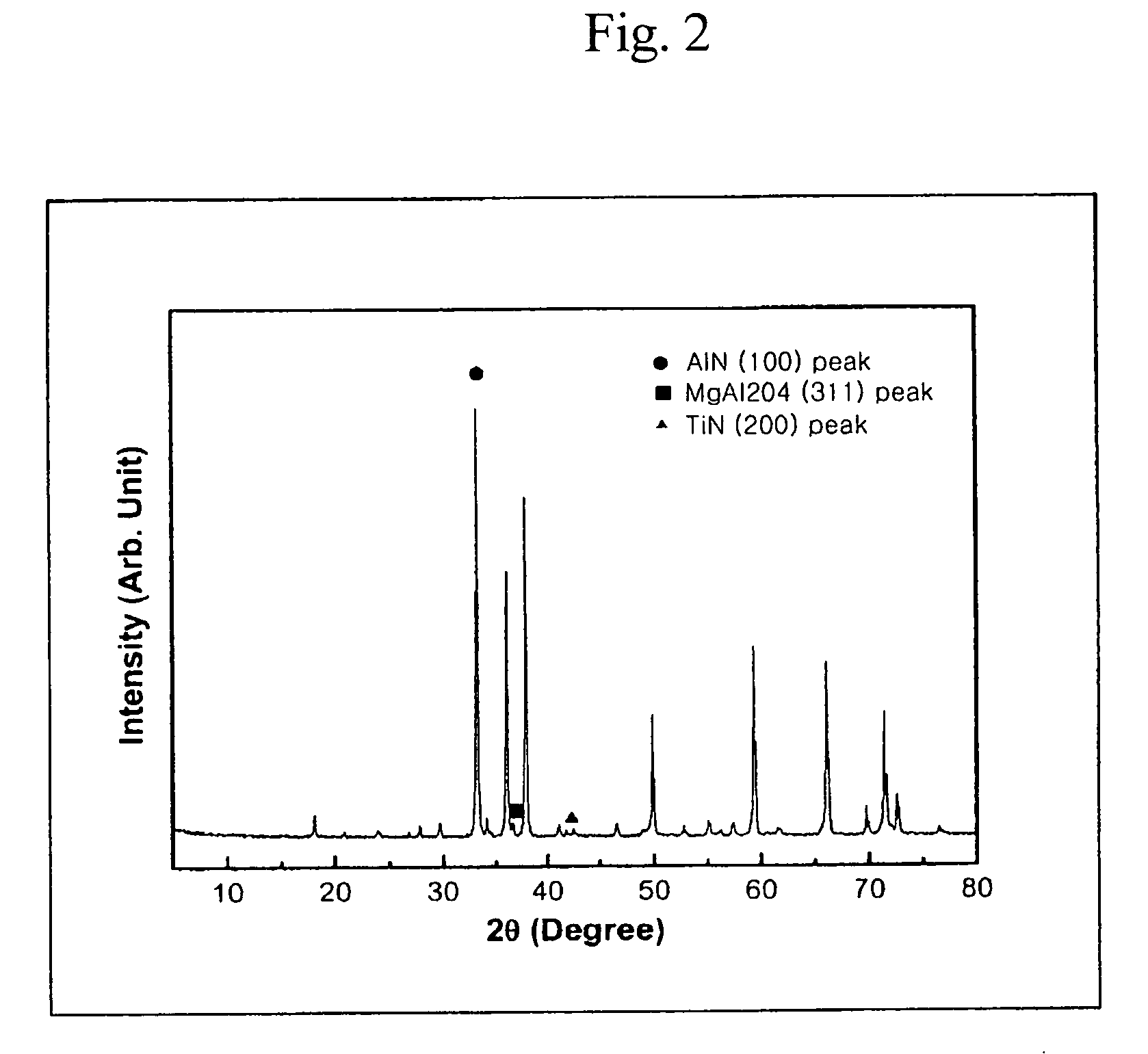

High dense sintered body of aluminum nitride, method for preparing the same and member for manufacturing semiconductor using the sintered body

ActiveUS20060240972A1High currentMaintain good propertiesSemiconductor/solid-state device manufacturingNitrideSemiconductor

The present invention provide a high dense aluminum nitride sintered body, a preparing method thereof, and a member for manufacturing semiconductor using the sintered body which has excellent leakage current characteristic, enough adsorbing property, good detachment property and excellent thermal conductivity and so can be applied to even a member for manufacturing semiconductor requiring high volume resistivity like the coulomb type electrostatic chucks as well as the Johnsen-Rahbek type electrostatic chucks.

Owner:MICOCERAMICS LTD

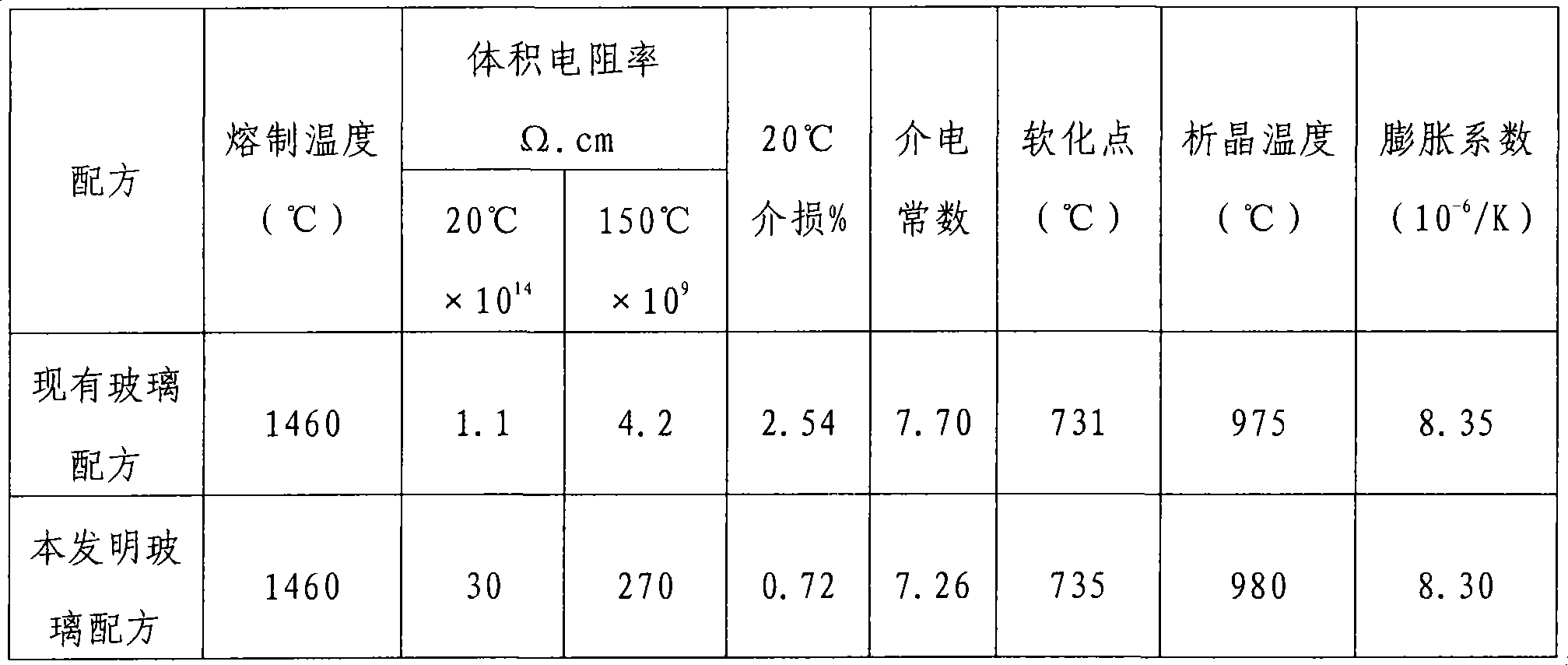

Glass formula for producing direct current glass insulator

The invention discloses a formulation of glass for producing a direct current glass insulator. The formulation is characterized in that the glass comprises the following compositions in percentage by weight: 65 to 72 percent of SiO2, 1.5 to 3.5 percent of Al2O3, 0.05 to 0.4 percent of Fe2O3, 5 to 8 percent of CaO, 2 to 4 percent of MgO, 5 to 9 percent of K2O, 0.1 to 3 percent of BaO and 6 to 9 percent of Na2O; and simultaneously, the glass also comprises 0.1 to 1 percent of Li2O and 0.1 to 2 percent of SrO. The formulation can effectively reduce the transfer of sodions, improve volume resistivity of the glass, reduce dielectric loss and improve electrical performance of the glass insulator.

Owner:南京电气绝缘子有限公司

Extra-high-voltage heat-resistant insulating material and preparation method thereof

The invention belongs to the technical field of electrical equipment and particularly relates to an extra-high-voltage heat-resistant insulating material and a preparation method thereof. The extra-high-voltage heat-resistant insulating material comprises components in parts by weight as follows: 80-100 parts of epoxy resin, 15-30 parts of polytetrafluoroethylene, 2-6 parts of nano-silica, 0.1-1 part of butyl titanate, 10-50 parts of distilled water, 2-10 parts of a mixture of nano silicon carbide, nano boron nitride and nano titanium dioxide, 5-15 parts of a diluent, 2-5 parts of a compatilizer, 0.2-2 parts of an antioxidant and 2-8 parts of a cross-linking agent. The prepared extra-high-voltage heat-resistant insulating material can effectively inhibit space charge accumulation in cable insulation materials and has good mechanical properties, electrical properties, thermal properties and physical properties and excellent comprehensive properties.

Owner:STATE GRID HENAN ELECTRIC ZHOUKOU POWER SUPPLY

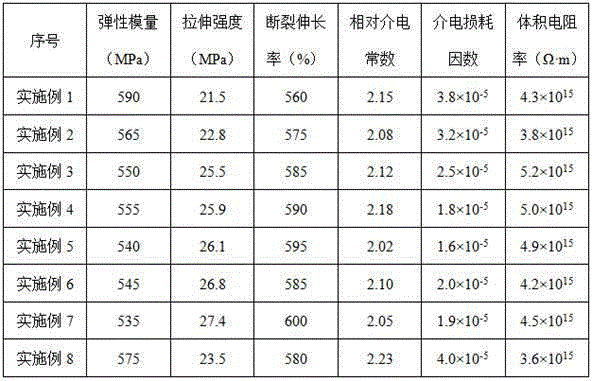

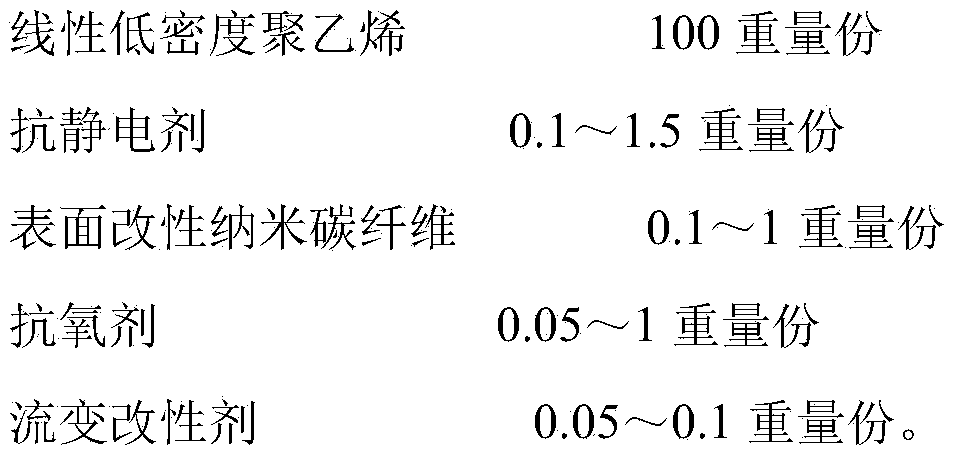

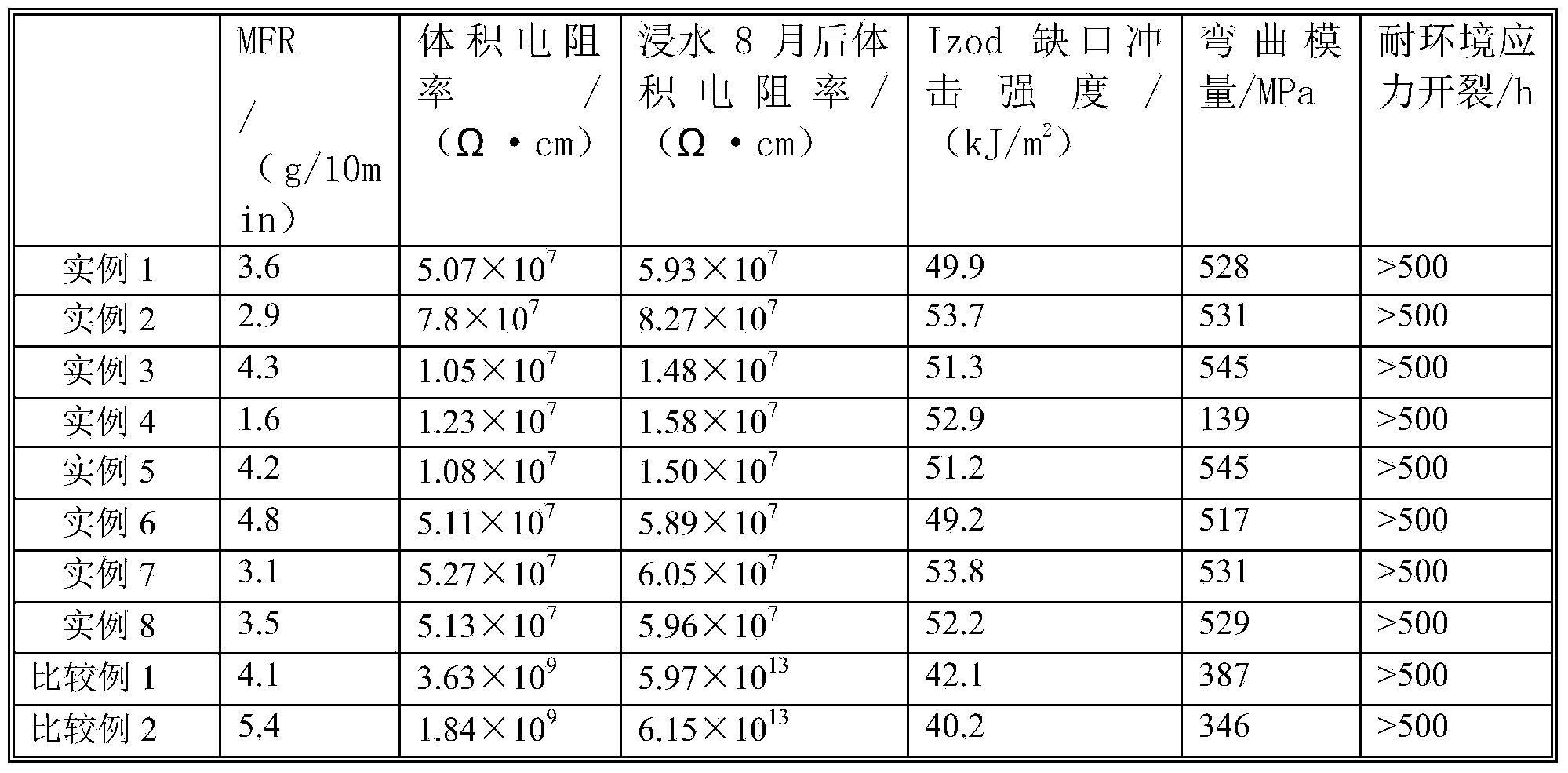

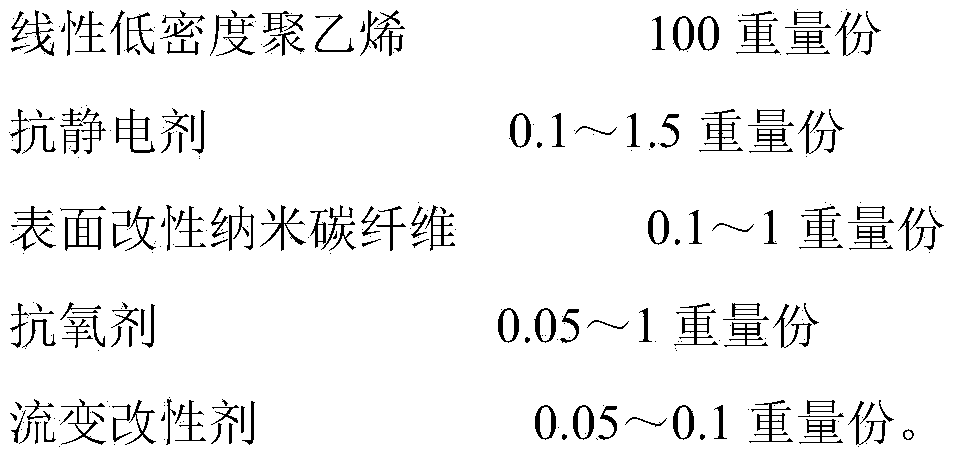

Antistatic high-rigidity rotational-moulded polyethylene composition and preparation method thereof

The invention discloses an antistatic high-rigidity rotational-moulded polyethylene composition. The antistatic high-rigidity rotational-moulded polyethylene composition comprises the following components: 100 parts by weight of linear low-density polyethylene, 0.1-1.5 parts by weight of antistatic agent, 0.1-1 part by weight of surface modified carbon nanofibers, 0.05-1 part by weight of antioxidant and 0.05-0.10 part by weight of rheology modifier. The invention also provides the preparation method of the composition. The antistatic high-rigidity rotational-moulded polyethylene composition provided by the invention has an outstanding antistatic function; the volume resistivity of the antistatic high-rigidity rotational-moulded polyethylene composition is less than 1*10<8> ohm.cm; the antistatic effect of the antistatic high-rigidity rotational-moulded polyethylene composition is lasting; the volume resistivity of the antistatic high-rigidity rotational-moulded polyethylene composition almost has no change after being soaked in water for 8 months; in addition, the composition also has better rigidity-tenacity balance; the impact strength of the composition is improved by at least 20% and the bending modulus of the composition is improved by more than 30%; simultaneously, the composition is good in environmental stress crack resistance, resin homogeneity and processability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for preparing low temperature, high heat conducting and electrical insulation epoxy resin nano composite material

InactiveCN101423651AGood low temperatureImprove thermal conductivityPlastic/resin/waxes insulatorsHeat-exchange elementsEpoxyNanoparticle

The invention provides a process for preparing a low-temperature, high-heat conduction and electric insulation epoxy resin nano composite material. In the process, by the filling method, nano ceramic grains with high heat conduction ratio are filled in an epoxy resin matrix, and the problem of easy agglomeration of the nano grains is solved by surface modifying the nano ceramic grains, and by the high-speed stirring and the ultrasonic wave vibration methods, the nano ceramic grains are evenly dispersed in the epoxy resin, so that the problem of the sedimentation of the nano ceramic grains in the resin is also solved; moreover, because the nano ceramic grains have pinning effect on micro cracks, thereby the impact toughness of the composite material system is improved; at the same time, the filled nano ceramic grains also have relative high volume resistivity, thereby the volume resistivity of the composite material system is still kept high.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

High-power high-stability cable material and preparation method thereof

InactiveCN104559203AStable chemical propertiesGood physical and mechanical propertiesRubber insulatorsFiberPolyvinyl chloride

The invention discloses a high-power high-stability cable material which is prepared from the following raw materials in parts by weight: 6-8 parts of oxidized polyethylene wax, 15-25 parts of PVC (polyvinyl chloride) resin, 3-4 parts of epoxy soybean oil, 3-5 parts of soluble polytetrafluoroethylene, 2-4 parts of nano titanium dioxide, 5-7 parts of ethylene-octylene copolymer, 3-4 parts of carbon fiber, 2-3 parts of benzotriazole, 4-5 parts of red phosphorus, 2-3 parts of nano graphite, 1-2 parts of accelerator CZ, 45-55 parts of nitrile silicone rubber, 6-7 parts of nano calcium carbonate, 2-5 parts of maleic anhydride grafted polypropylene and 8-12 parts of filler. The cable material has favorable chemical property stability, physical and mechanical properties, electrical insulation properties, aging resistance and flame retardancy, and can satisfy the demands for cable manufacturing industry.

Owner:HUAINAN WENFENG AEROSPACE CABLE CO LTD

Preparation method and usage method of low-viscosity flame-retardant heat-conducting solvent-free polyurethane electronic-pouring sealant

ActiveCN107216846AImprove flame retardant performanceLow viscosityNon-macromolecular adhesive additivesSemiconductor/solid-state device detailsPolymer scienceIn situ polymerization

The invention discloses a preparation method and a usage method of a low-viscosity flame-retardant heat-conducting solvent-free polyurethane electronic-pouring sealant. The electronic-pouring sealant comprises a component A and a component B, wherein the component A is prepared by means of the following process: adding 100 parts of castor oil, 5 to 15 parts of flame retardant, 1 to 5 parts of high heat conductive insulation composite powder and 0.05 to 3 parts of an anti-foaming agent into a reaction kettle in parts by mass, performing uniform mixing and vacuum dehydration, then adding 0.05 to 0.3 part of a catalyst, and performing uniform mixing to obtain the component A; and the component B is liquefied diphenylmethylene diisocyanate. In the invention, a high heat conductive insulation composite powder heat conduction technology, a polyurethane in-situ polymerization self-flame-retardant technology and a thermal sensitive catalyst asynchronous catalysis technology are adopted, the product viscosity is smaller than 6000mPa.s, the heat conduction coefficient is greater than 1.85W / MK, the volume resistivity is greater than 4.2*10<12>omega.m, and the flame retardant property can be up to the American FMVSS302 standard.

Owner:SHAANXI UNIV OF SCI & TECH

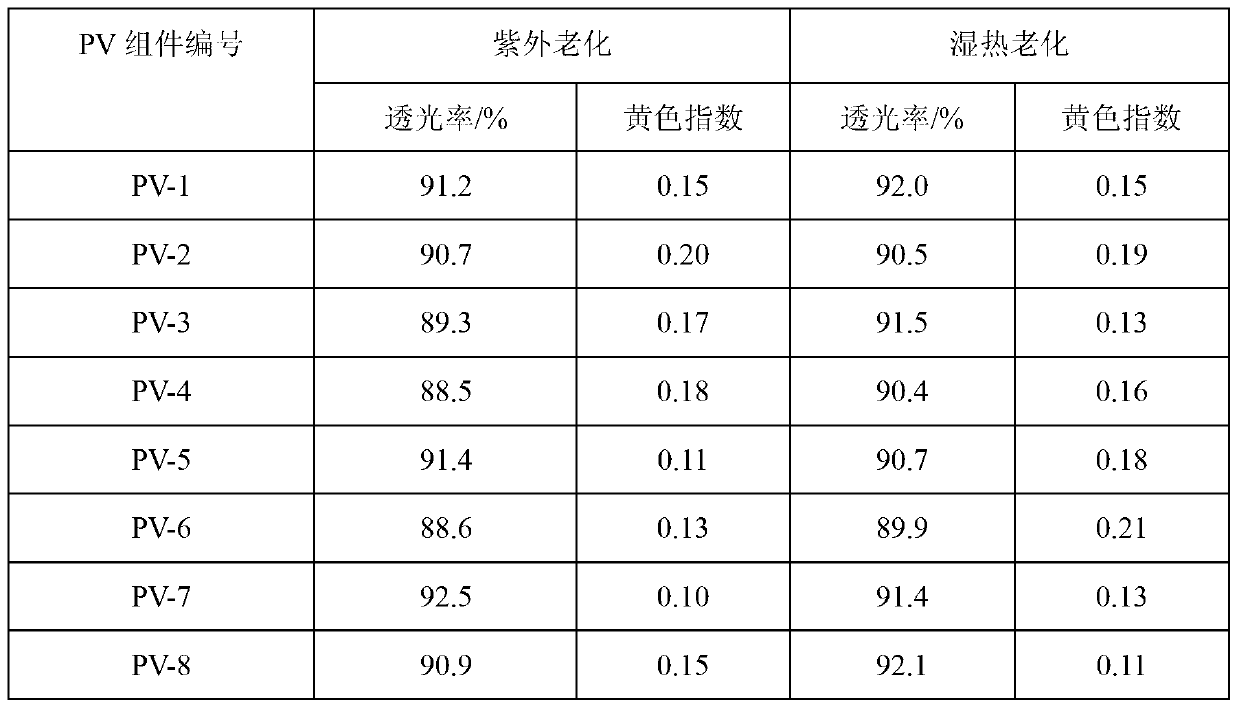

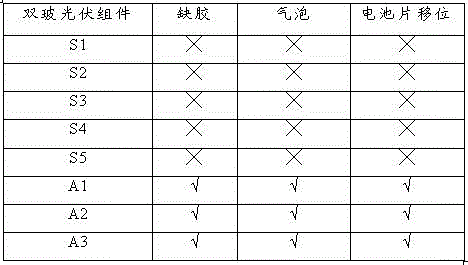

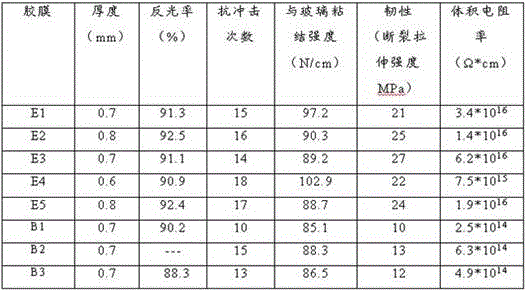

White packaging film for double-glazed photovoltaic module and preparation method thereof

ActiveCN105802548AIncrease profitImprove photoelectric conversion efficiencyNon-macromolecular adhesive additivesFilm/foil adhesivesMooney viscosityCarvacryl acetate

The invention discloses a white packaging film for a double-glazed photovoltaic module. The white packaging film comprises, by weight, 45-65 parts of ethylene-vinyl acetate, 25-50 parts of ethylene propylene rubber, 1-7 parts of white pigment and 0.5-10 parts of aids, wherein the ethylene-vinyl acetate comprises, by weight, 14-33% of vinyl acetate and 15-55% of ethylene propylene rubber; and the ethylene propylene rubber has a density of 0.80-0.91g / cm<3> and Mooney viscosity of 20-40. The dedicated white EVA film for the double-glazed photovoltaic module has high reflection rate, tenacity, volume resistivity and impact resistance, and the double-glazed photovoltaic module made of the film does not cause starved joints, bubbles or the like.

Owner:SUZHOU DUCHAMPS ADVANCED MATERIALS CO LTD

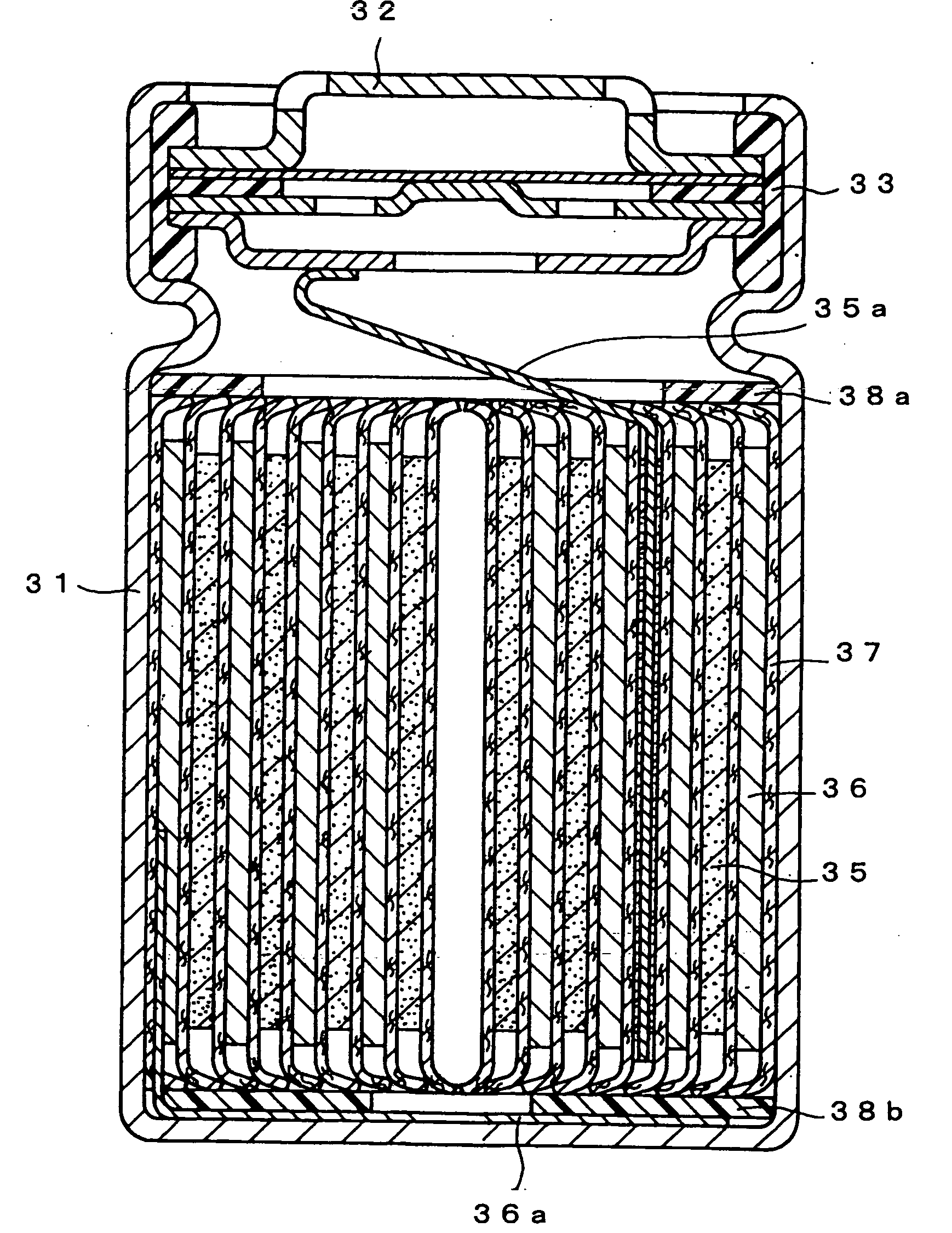

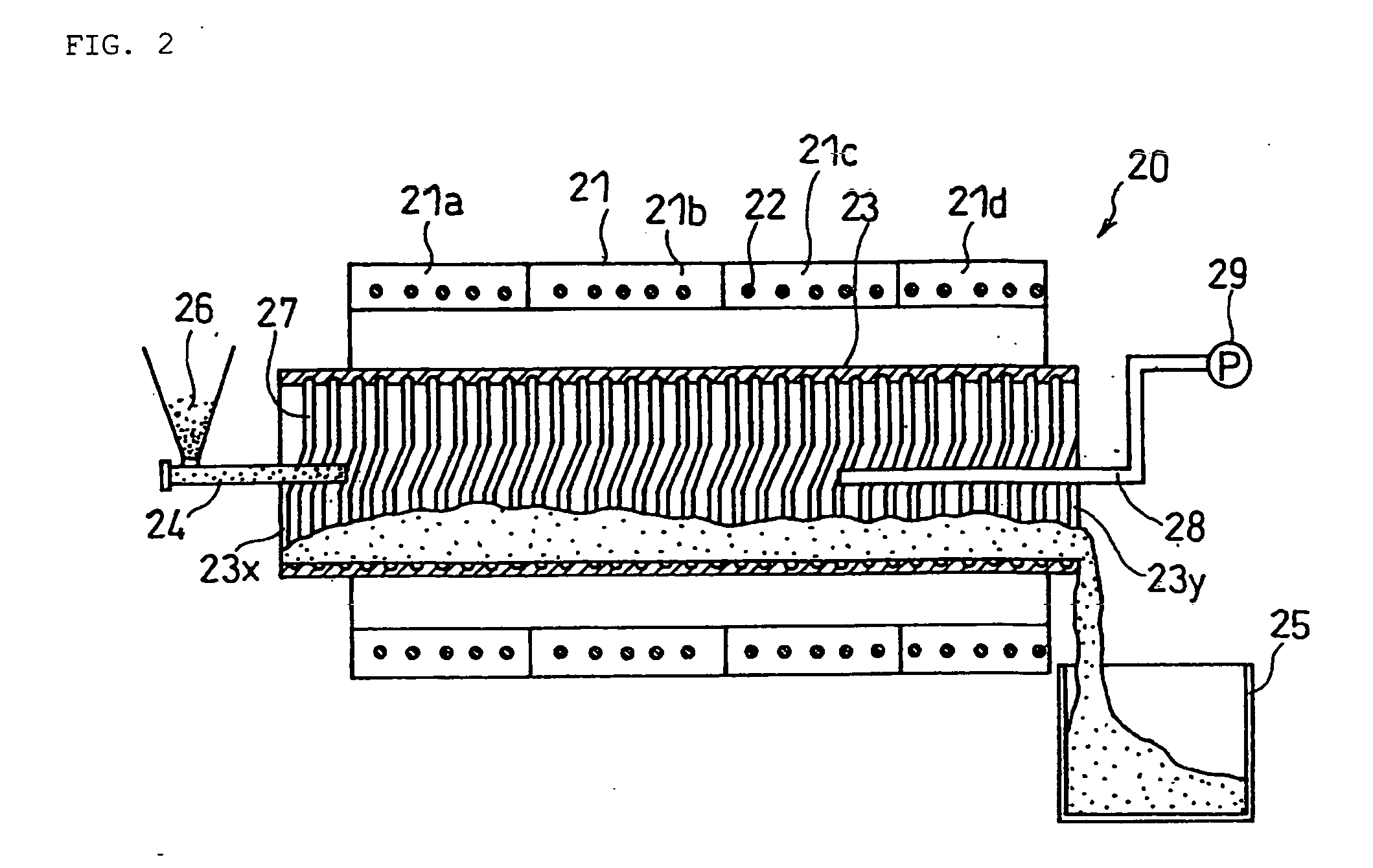

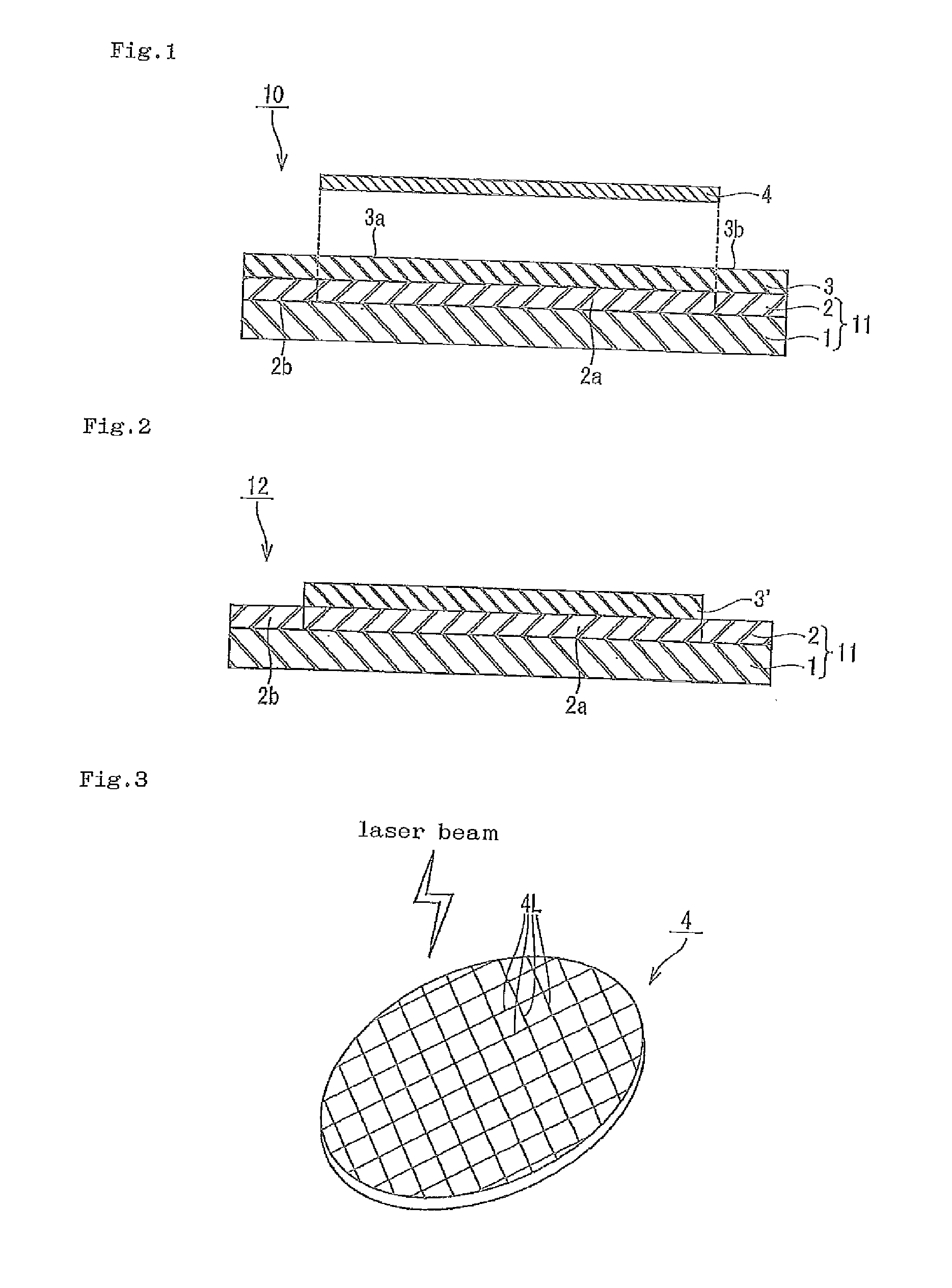

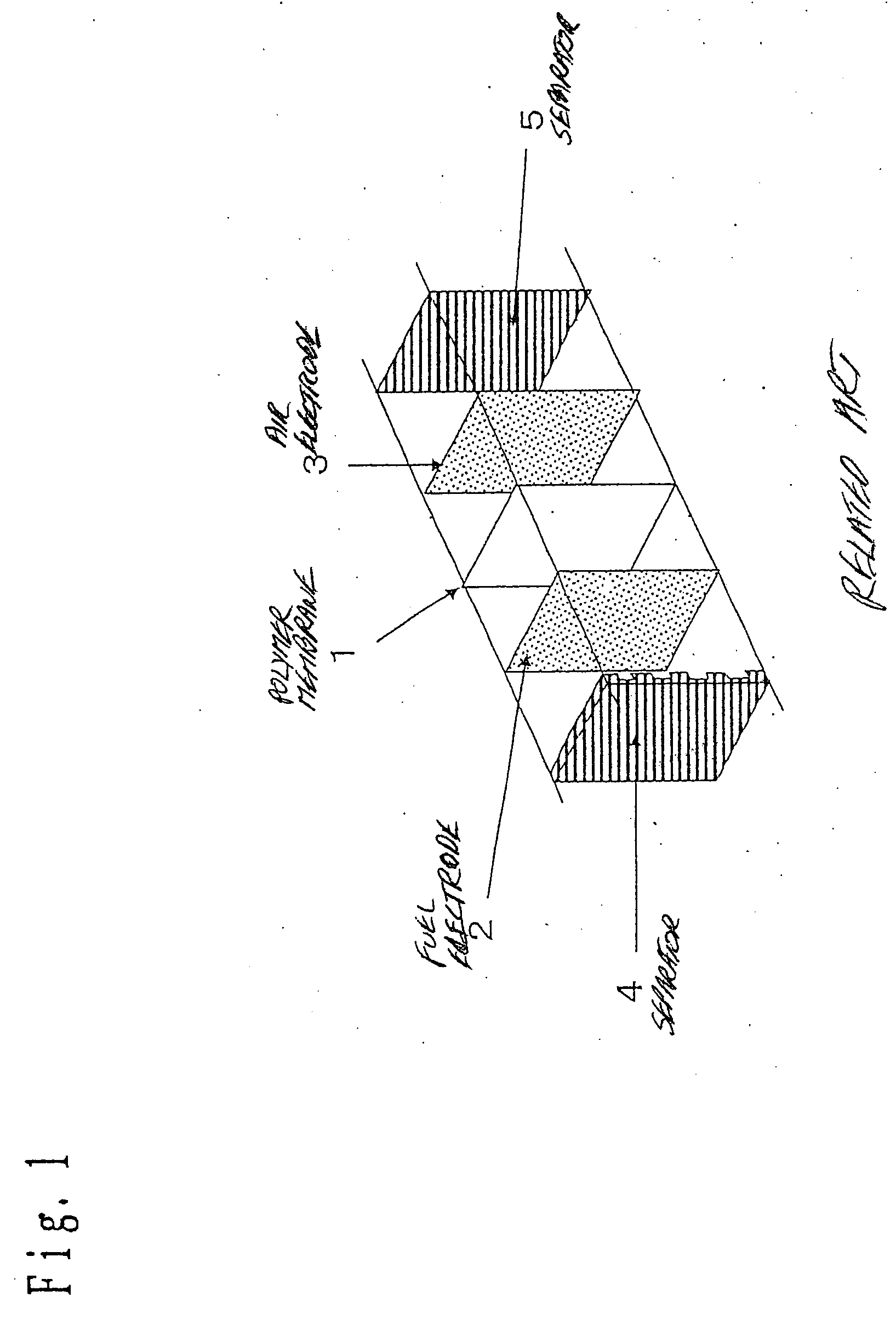

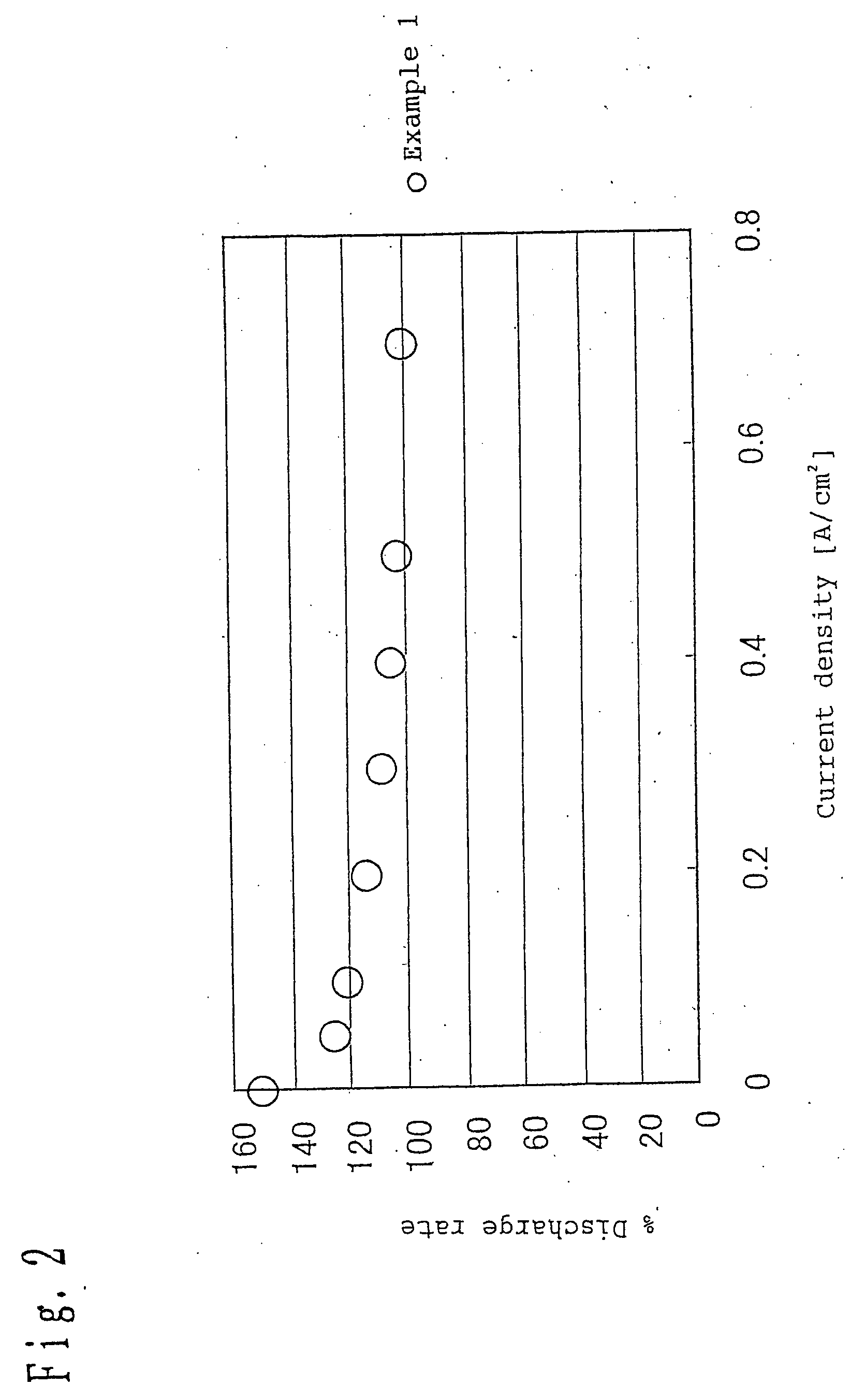

Polymer electrolyte fuel cell, fuel cell electrode, method for producing electrode catalyst layer, and method for producing polymer electrolyte fuel cell

InactiveUS20040209138A1Little and no crackingHigh volume resistivityFinal product manufactureActive material electrodesPolymer electrolytesFuel cells

A method for producing a polymer electrolyte membrane type fuel cell including a polymer electrolyte membrane, fuel and air electrodes that sandwich therebetween the polymer electrolyte membrane and that each include a gas diffusion layer and a catalyst layer provided in contact with the polymer electrolyte membrane, and separators provided in contact with the gas diffusion layers. A paste containing at least a carbon powder having a catalyst supported thereon is spread over a predetermined support, and the coated support is dried to form the catalyst layer. A cracking occupation area on the electrodes is controlled to a predetermined tolerance by controlling at least one of (1) a thickness of the catalyst layer, (2) a kind of carbon having the catalyst supported thereon, and (3) a drying rate of a solvent of the paste.

Owner:PANASONIC CORP

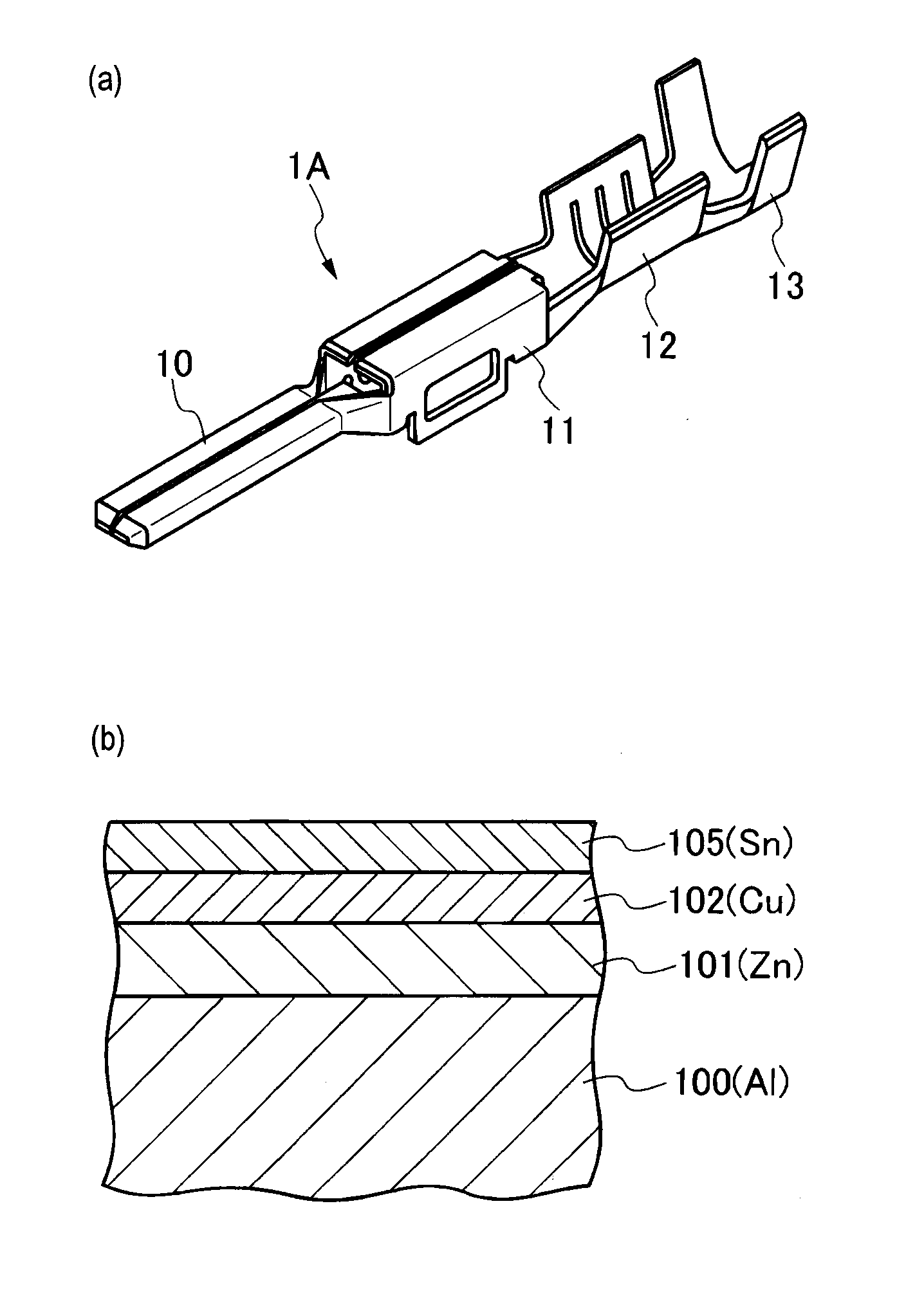

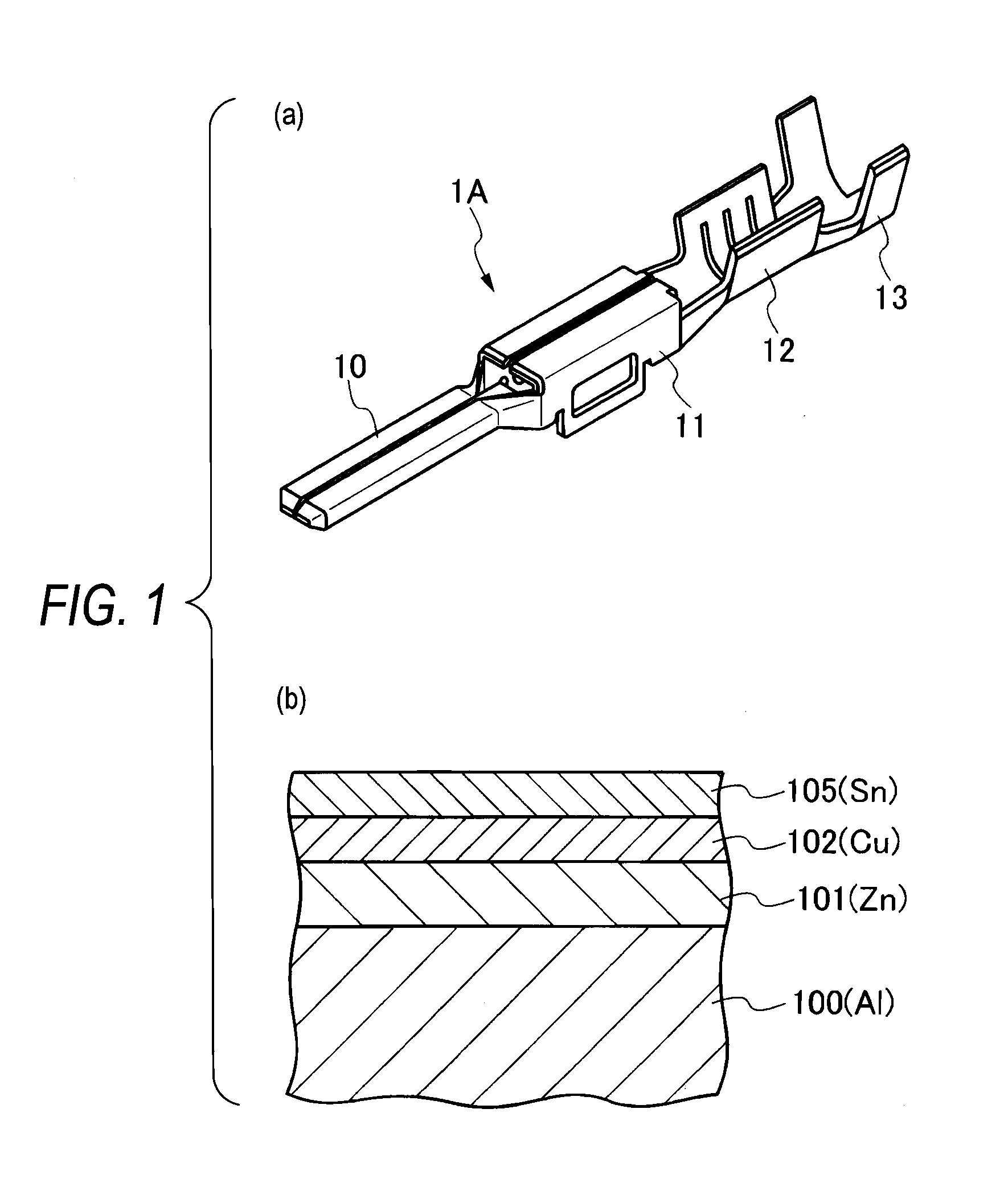

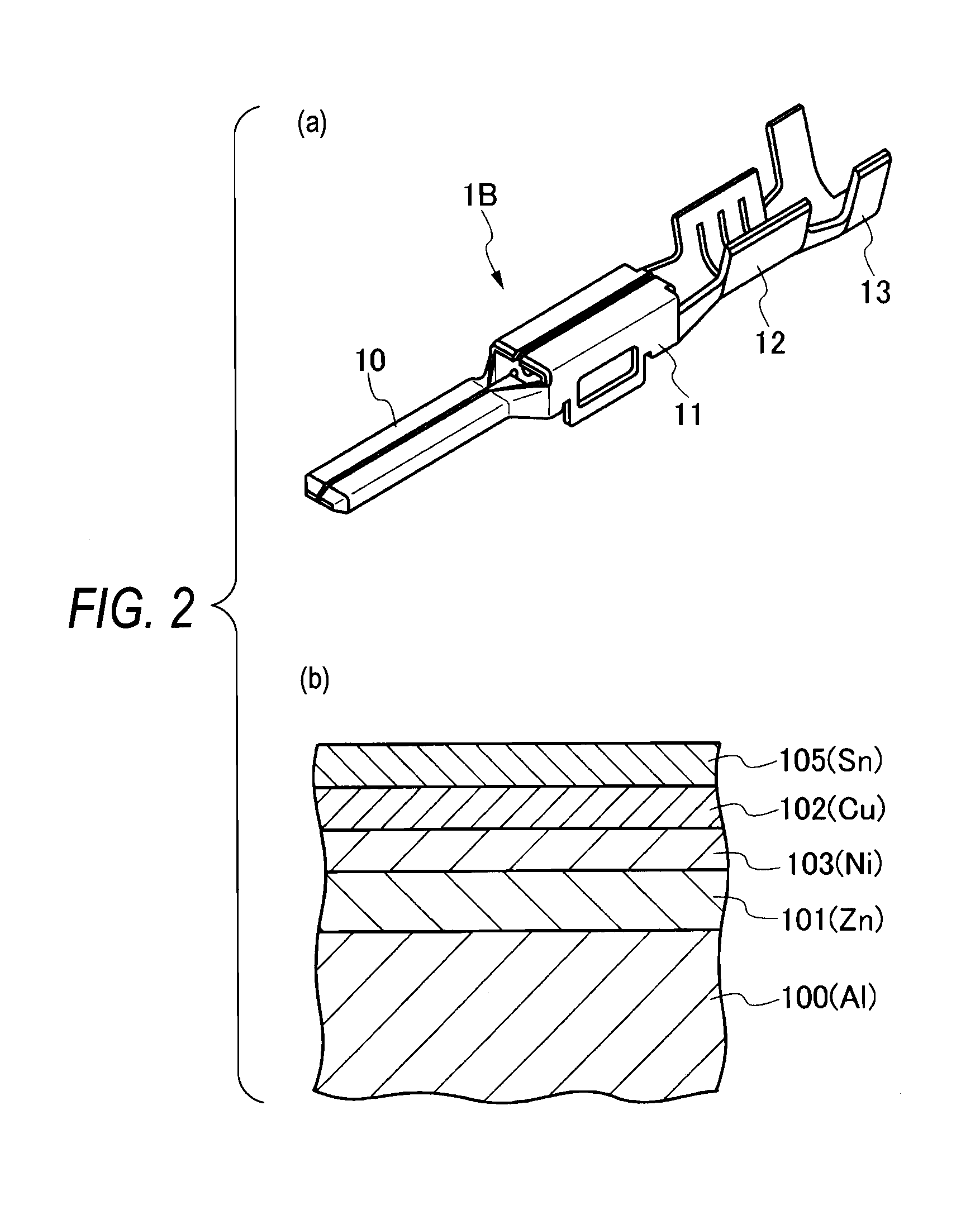

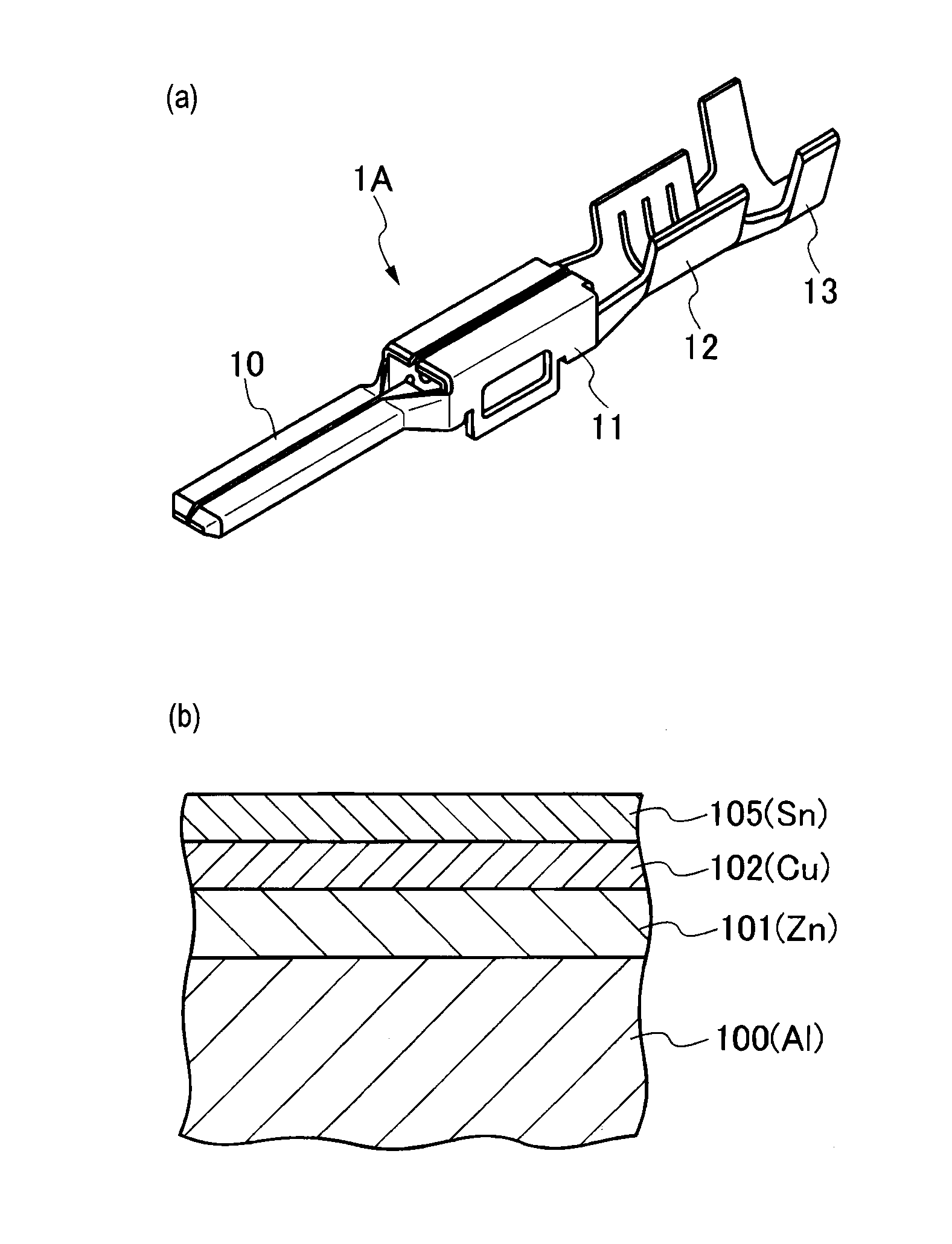

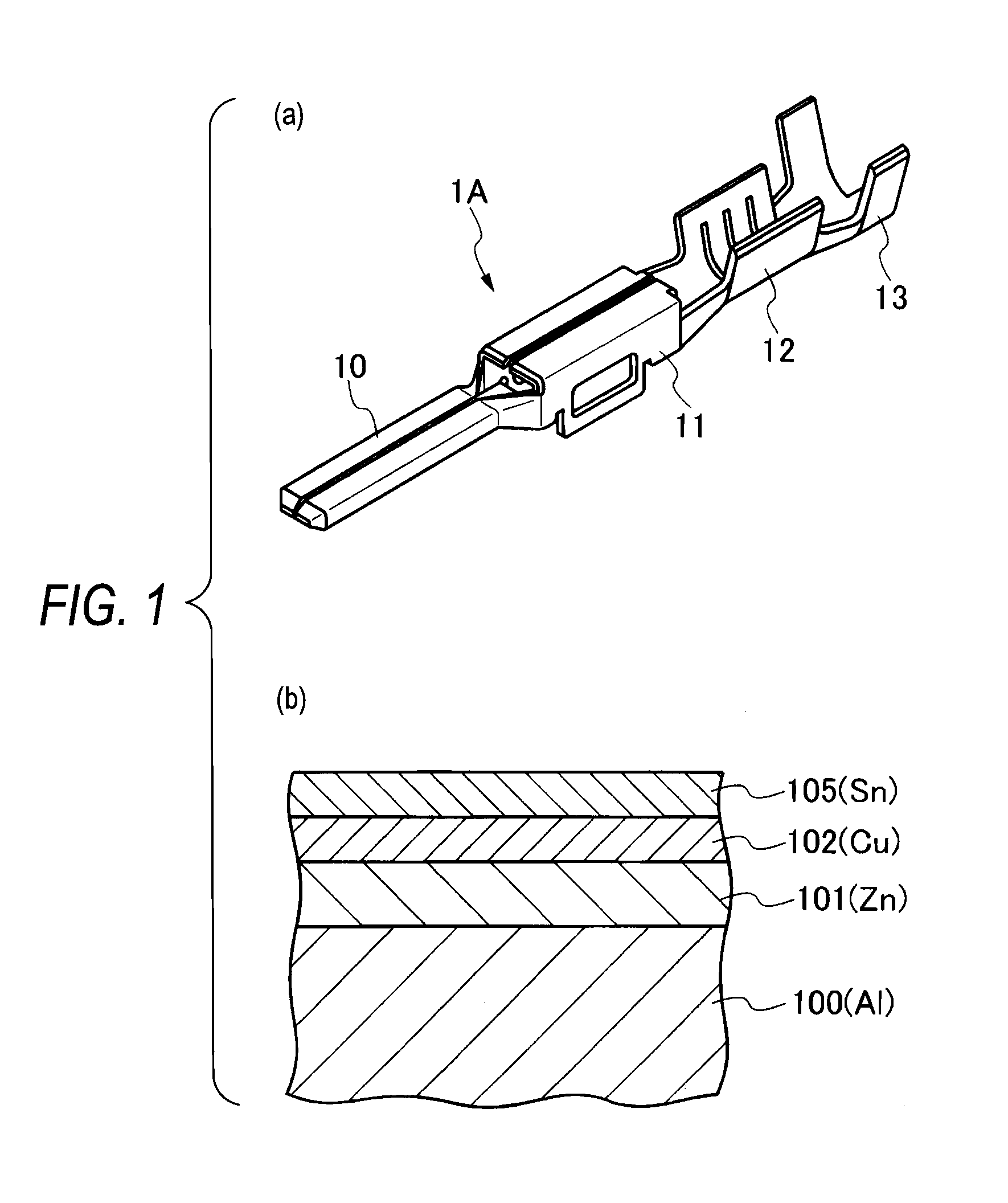

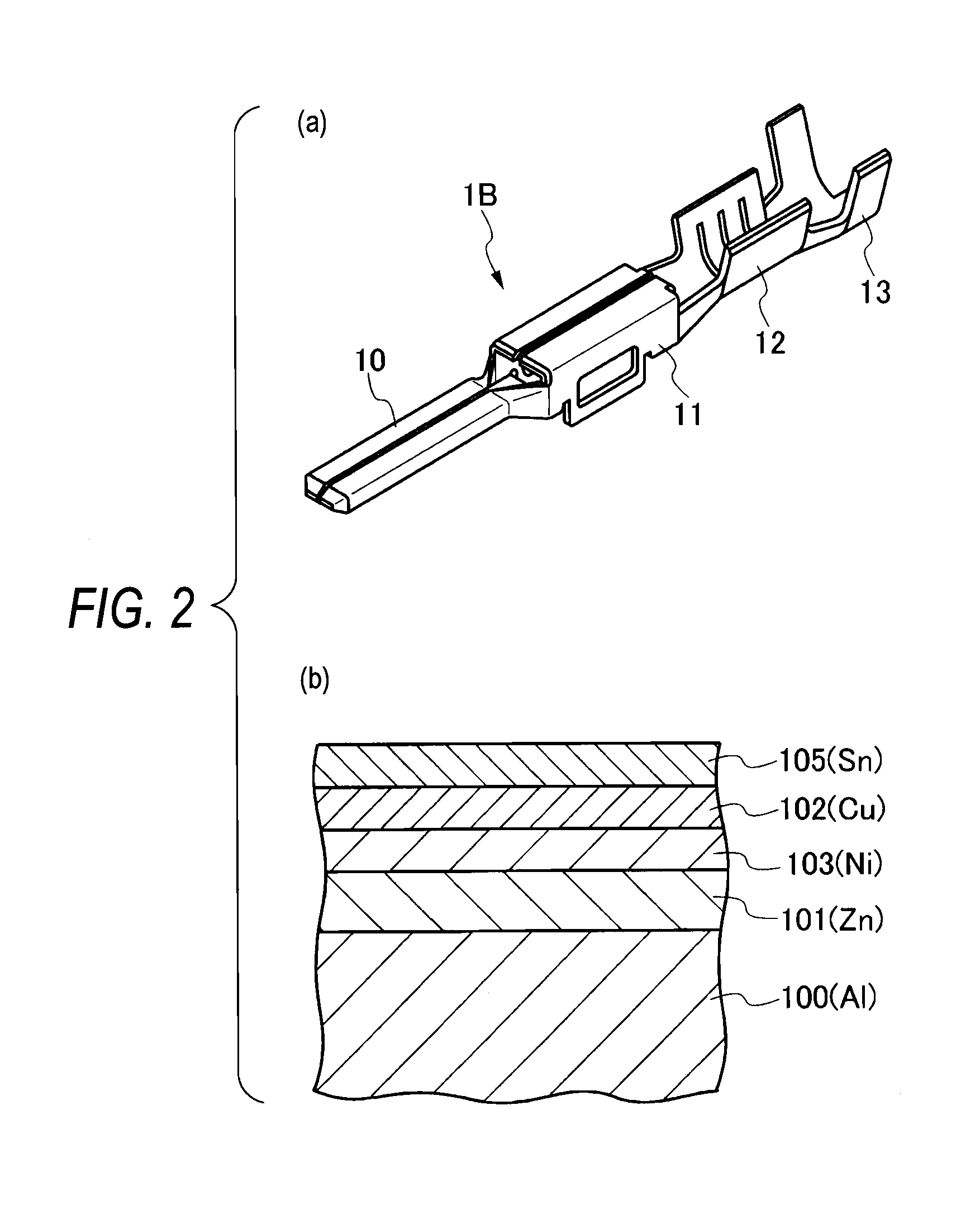

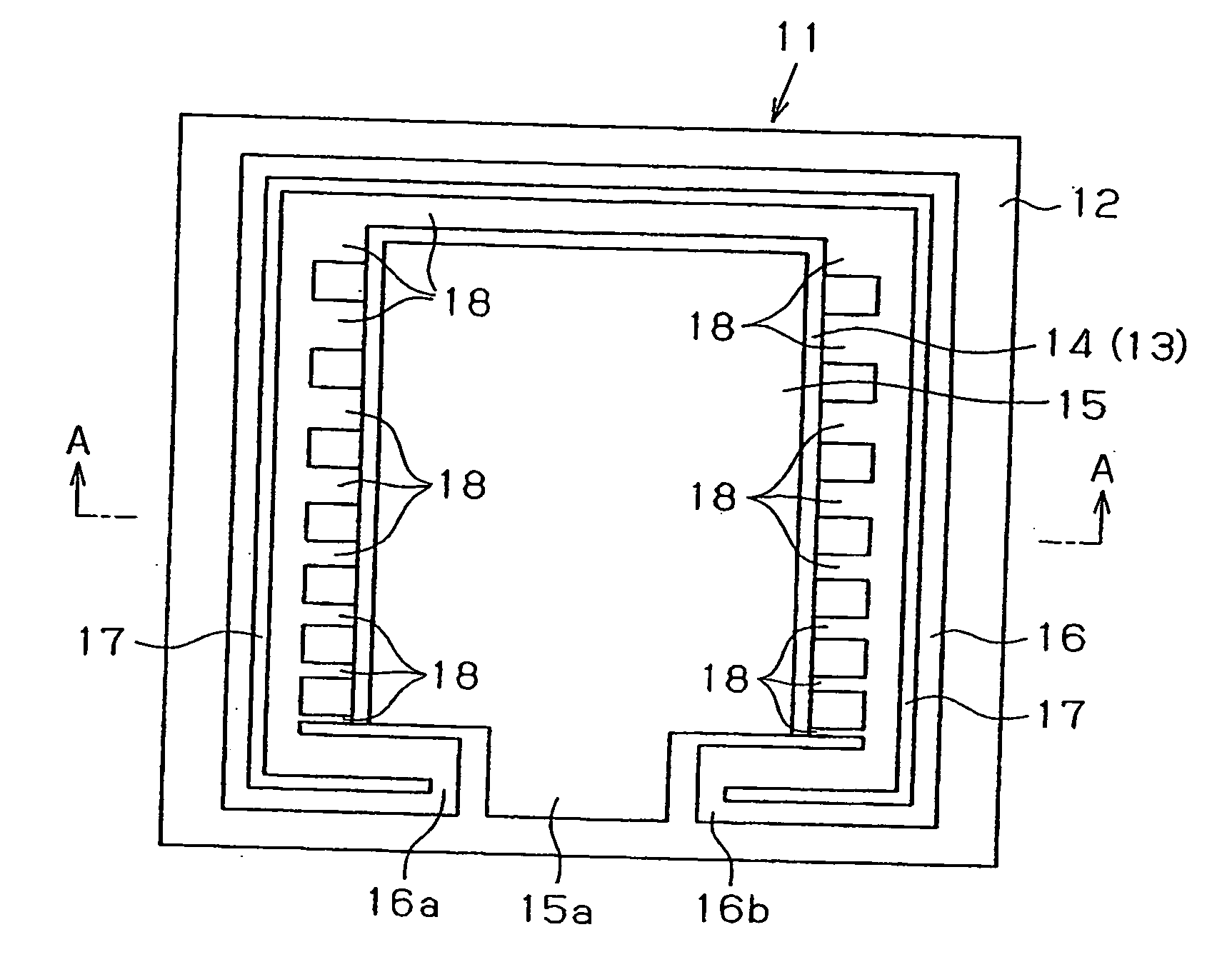

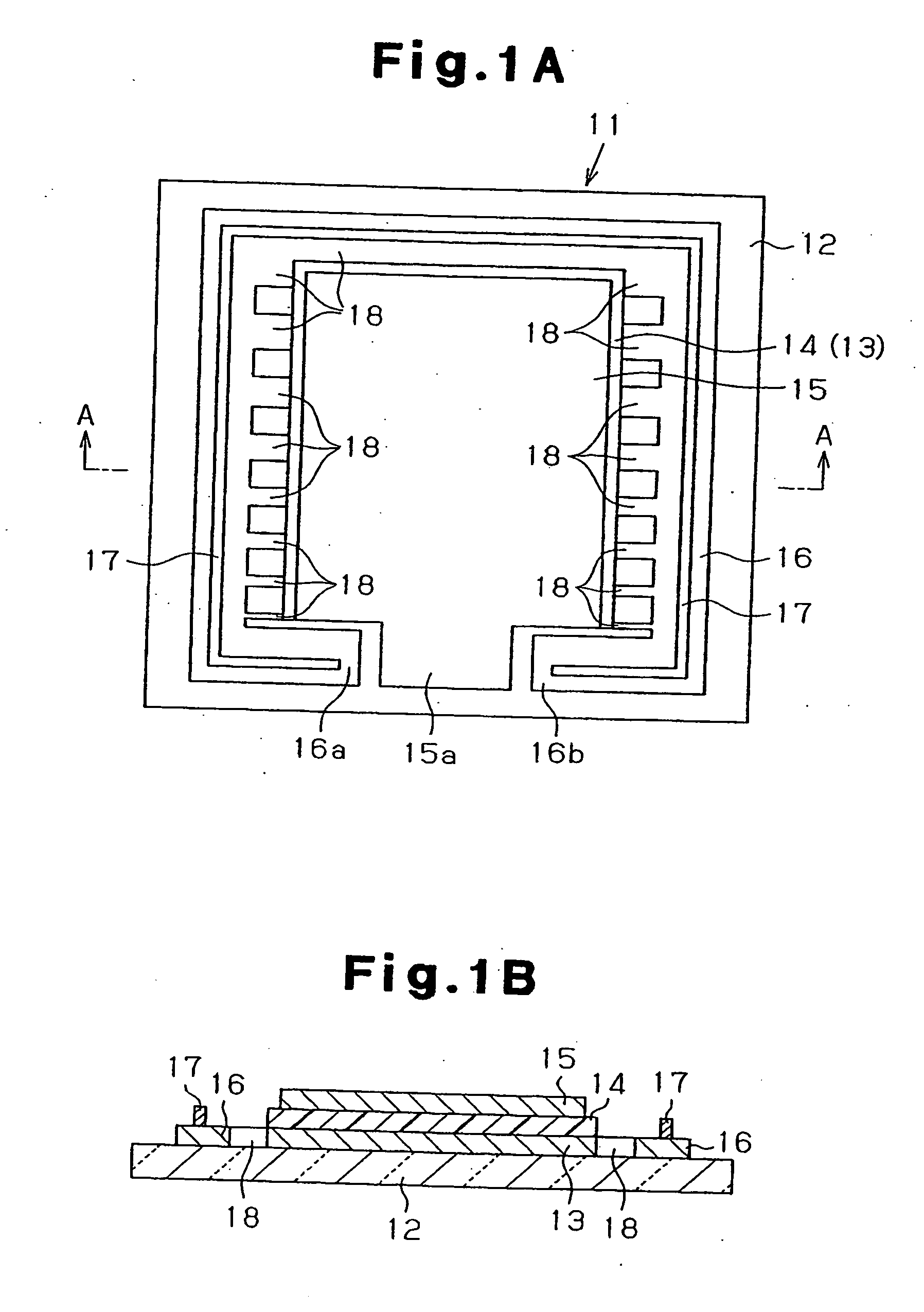

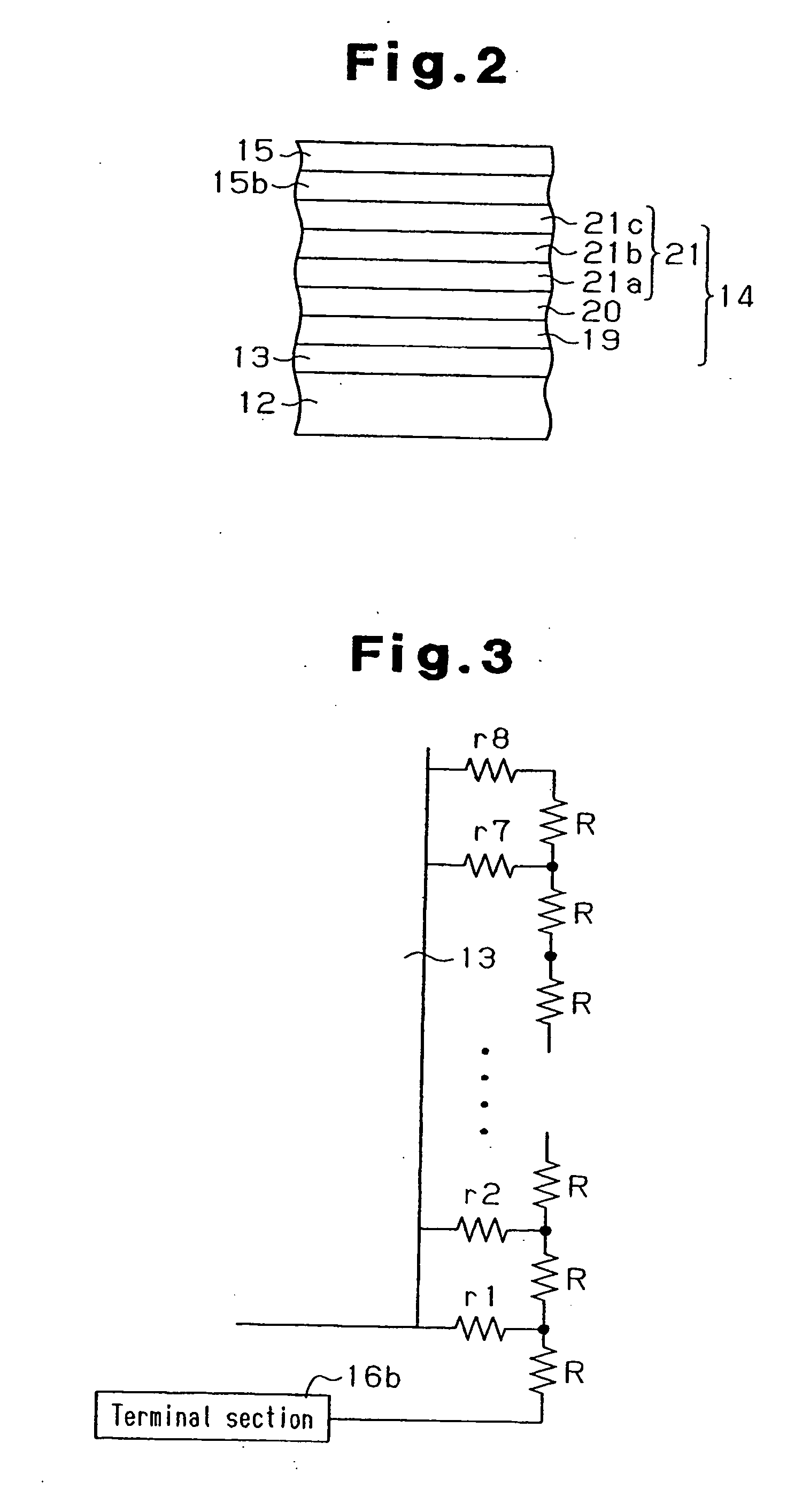

Connector terminal

ActiveUS20120115375A1Reduce weightDecreased crimping forceCoupling contact membersLiquid/solution decomposition chemical coatingMating connectionElectrical conductor

A connector terminal which can achieve high mechanical connection strength and stabilized low electrical connection resistance when it is crimped to an aluminum electric wire, and in addition, can suppress electrical contact resistance low when it is fitted to a mating connector terminal is provided. In a connector terminal (1A) having an electrical contact section (10) which is brought into contact and conducted with a mating connector terminal by fitting to the mating connector terminal, and a conductor crimping section (12) which is crimped to the conductor of an electric wire, a metal material which constitutes the terminal uses aluminum or an aluminum alloy as a base material (100), a Zn layer (101) having a thickness in the range from 0.1 μm to 2.0 μm by electroless plating and a Cu layer (102) having a thickness in the range from 0.5 μm to 1.0 μm by electrolytic plating are formed in sequence on the surface of the base material (100), and an Sn layer (105) having a thickness in the range from 0.7 μm to 1.7 μm by electrolytic plating is formed on the outermost surface.

Owner:YAZAKI CORP

Insulation adhesive material for compound photovoltaic backsheet and application

ActiveCN107353859AImprove insulation performanceImprove cohesive energyPolyureas/polyurethane adhesivesEpoxy resin adhesivesHeat resistanceAcid value

The invention discloses an insulation adhesive material for a compound photovoltaic backsheet and application. The insulation adhesive material is composed of a component A and a component B. The component A contains matrix resin, assistant resin and an assistant, wherein the matrix resin is hydroxyl polyester resin, which has a hydroxyl value of 5-30mgKOH / g, an acid value of 0.2-5mgKOH / g, a number-average molecular weight of 5000-50000, a glass transition temperature ranging from -40DEG C to 30DEG C, and is prepared by esterification polycondensation reaction of small molecular polyprotic acid and polyol under inert gas protection. The component B is a crosslinked component. During use, the component A and the component B are mixed in different proportions according to requirements. The insulation adhesive material provided by the invention not only has long-term and stable bonding performance, but also has excellent performance in heat resistance, insulation and weatherability, and can be used for preparation of high weather resistant compound photovoltaic backsheets. Also, the raw materials are easily available, the process is controllable, and the operation is simple.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

Connector terminal

ActiveUS8915761B2Reduce weightImprove electrical contact reliabilityCoupling contact membersLiquid/solution decomposition chemical coatingElectrical conductorMetallic materials

A connector terminal which can achieve high mechanical connection strength and stabilized low electrical connection resistance when it is crimped to an aluminum electric wire, and in addition, can suppress electrical contact resistance low when it is fitted to a mating connector terminal is provided. In a connector terminal (1A) having an electrical contact section (10) which is brought into contact and conducted with a mating connector terminal by fitting to the mating connector terminal, and a conductor crimping section (12) which is crimped to the conductor of an electric wire, a metal material which constitutes the terminal uses aluminum or an aluminum alloy as a base material (100), a Zn layer (101) having a thickness in the range from 0.1 μm to 2.0 μm by electroless plating and a Cu layer (102) having a thickness in the range from 0.5 μm to 1.0 μm by electrolytic plating are formed in sequence on the surface of the base material (100), and an Sn layer (105) having a thickness in the range from 0.7 μm to 1.7 μm by electrolytic plating is formed on the outermost surface.

Owner:YAZAKI CORP

Electroluminescence element

InactiveUS20060214157A1High volume resistivityLower volume resistivityElectroluminescent light sourcesSolid-state devicesEngineeringLight emission

An electroluminescence element includes a first electrode, a second electrode, and a light emission layer arranged between the first electrode and the second electrode. The first electrode is formed of a material having a higher volume resistivity than that of the material of the second electrode. A connector portion electrically connects a feeder portion to the first electrode. The resistance value of the connector portion differs in correspondence with a position at which the connector portion connects the feeder portion to the first electrode. The brightness distribution of the electroluminescence element is thus adjusted to a desired state.

Owner:TOYOTA IND CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com