Extra-high-voltage heat-resistant insulating material and preparation method thereof

A heat-resistant insulation, ultra-high voltage technology, applied in the direction of organic insulators, plastic/resin/wax insulators, etc., can solve the problem of unfavorable large-scale production, can not improve the heat resistance and anti-aging properties of materials, and the preparation process is complicated, etc. problem, to achieve the effect of suppressing the accumulation of space charges, avoiding flashover along the surface, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

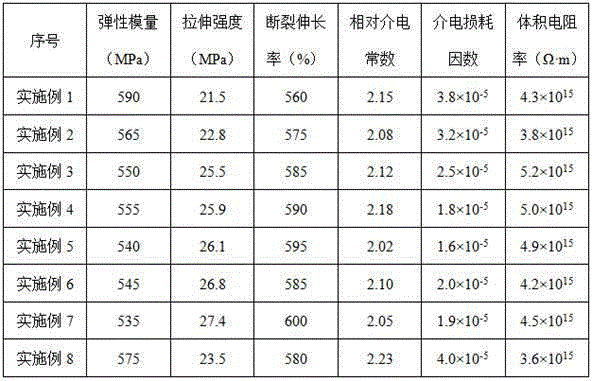

Examples

preparation example Construction

[0036] The present invention also provides a preparation method for the above-mentioned UHV heat-resistant insulating material, comprising the following steps:

[0037]1) Add 0.1~1 parts by weight of butyl titanate to 10~50 parts by weight of distilled water, place in a magnetic stirrer, stir for 20~40min at 20~40°C, and then add 2~6 parts by weight of nano-dioxide silicon, ultrasonically treated, filtered, and then dried at 50-60°C to obtain surface-modified nano-silica;

[0038] 2) Add the surface-modified nano-silica obtained in step 1) and 80-100 parts by weight of epoxy resin to the torque rheometer in sequence, and mix at 140-180°C for 20-40 minutes to obtain nano-silica Silicon modified epoxy resin;

[0039] 3) The nano-silica modified epoxy resin obtained in step 2), 15-30 parts by weight of polytetrafluoroethylene, 2-10 parts by weight of nano-silicon carbide, nano-boron nitride and nano-titanium dioxide mixture, 2-5 parts by weight 1 part compatibilizer is put into...

Embodiment 1

[0048] A method for preparing a UHV heat-resistant insulating material, comprising the following steps:

[0049] 1) Add 0.1 parts by weight of butyl titanate to 10 parts by weight of distilled water, place it in a magnetic stirrer, stir at 20°C for 20 minutes, then add 2 parts by weight of nano-silica, ultrasonic treatment, ultrasonic frequency 15kHz, power 300W, time 20min, repeat 3 times, each interval is 5min, filter, and then dry at 50°C to obtain surface-modified nano-silica;

[0050] 2) Add the surface-modified nano-silica and 80 parts by weight of epoxy resin obtained in step 1) to the torque rheometer in sequence, and mix at 140°C for 20 minutes to obtain nano-silica-modified epoxy resin ;

[0051] 3) The nano-silica modified epoxy resin obtained in step 2), 15 parts by weight of polytetrafluoroethylene with a particle size of 0.5-5 μm, 2 parts by weight of nano-silicon carbide and nano-nitrided particles with a particle size of 30-60 nm A mixture of boron and nano-t...

Embodiment 2

[0055] A method for preparing a UHV heat-resistant insulating material, comprising the following steps:

[0056] 1) Add 0.3 parts by weight of butyl titanate to 15 parts by weight of distilled water, place it in a magnetic stirrer, stir at 23°C for 25 minutes, then add 3 parts by weight of nano-silica, ultrasonic treatment, ultrasonic frequency 18kHz, power 350W, time 25min, repeat 3 times, each interval 8min, filter, and then dry at 55°C to obtain surface-modified nano-silica;

[0057] 2) Add the surface-modified nano-silica and 85 parts by weight of epoxy resin obtained in step 1) to the torque rheometer in sequence, and mix at 150°C for 25 minutes to obtain nano-silica-modified epoxy resin ;

[0058] 3) The nano-silica modified epoxy resin obtained in step 2), 20 parts by weight of polytetrafluoroethylene with a particle size of 0.5-5 μm, and 5 parts by weight of nano-silicon carbide and nano-nitrided particles with a particle size of 30-60 nm A mixture of boron and nano-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com