Antistatic high-rigidity rotational-moulded polyethylene composition and preparation method thereof

A high-rigidity, polyethylene technology, applied in the field of rotomoulding polyethylene composition and its preparation, can solve the antistatic performance of nano-carbon fiber synergistically modified polyethylene, which affects the performance of CNF composite materials, aspect ratio and specific surface area Large and other problems, to achieve the effect of highlighting antistatic performance, good resistance to environmental stress cracking, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

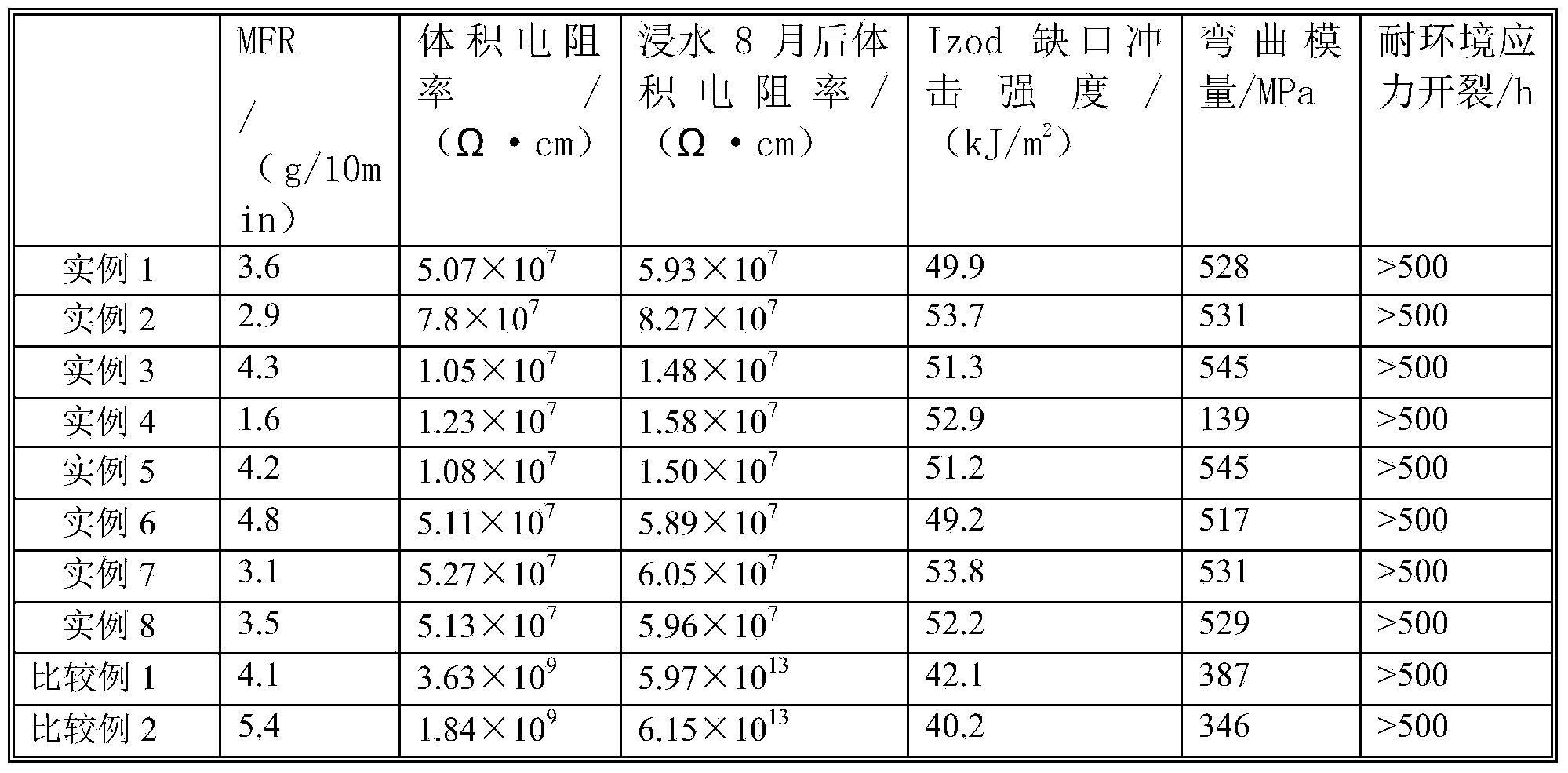

Embodiment 1

[0027] Add carbon nanofibers (CNF) and diluted aminopropyltriethoxysilane coupling agent KH550 to the high-speed mixer successively, and mix at 80°C for 8 minutes to modify the surface of CNF. The amount of surface modifier 0.5% of the weight of CNF. 100 parts of LLDPE with a melt flow rate of about 5g / 10min, 0.4 parts of octadecyl dimethyl hydroxyethyl quaternary ammonium nitrate, 0.6 parts of polyorganoboron, 0.1 part of CNF after surface modification, four [β -(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol 0.05 part, tris(2,4-di-tert-butylphenyl) phosphite 0.1 part, ethylenediamine distearyl Add 0.08 parts of amide into a high-speed mixer, mix for 5 minutes, and then extrude and granulate through a twin-screw extruder at a normal processing temperature of 180-240°C to obtain a polyethylene composition for rotomolding. The mechanical properties are shown in Table 1.

Embodiment 2

[0029]Add CNF and diluted bis(dioctyloxypyrophosphate)ethylene titanate coupling agent NDZ-311 successively to the high-speed mixer, and mix at 80°C for 9 minutes to modify the surface of CNF, wherein The surface modifier was used in an amount of 1% by weight of CNF. 100 parts of LLDPE with a melt flow rate of about 5g / 10min, 0.1 part of polyoxyethylene stearate, 1 part of surface-modified CNF, tetrakis[β-(3,5-di-tert-butyl-4-hydroxybenzene Base) propionic acid] pentaerythritol ester 0.05 parts, 1,3,5, tris (3,5-di-tert-butyl, 4-hydroxybenzyl)-s-triazine-2,4,6-(1H,3H,5H) Add 0.1 part of triketone, 0.2 part of bis(2,4-di-tert-butylphenyl) pentaerythritol diphosphite, and 0.05 part of acyl stearic acid into the high-speed mixer, mix for 5 minutes, and then add the Under the condition of 240°C, the polyethylene composition for rotomolding was obtained by extruding and granulating with a twin-screw extruder, and its mechanical properties are shown in Table 1.

Embodiment 3

[0031] Add CNF and diluted distearoyloxyisopropoxyaluminate coupling agent SG-Al821 to the high-speed mixer successively, and mix at 80°C for 10 minutes to modify the surface of CNF, wherein the surface modifier The dosage is 3% of CNF weight. 100 parts of LLDPE with a melt flow rate of about 5g / 10min, 0.5 parts of octylphenol polyoxyethylene ether, 0.8 parts of surface-modified CNF, 1,3,5-tris(4-tert-butyl-3- Add 0.7 part of hydroxy-2,6-dimethylbenzyl)1,3,5-triazine-2,4,6-(1H,3H,5H)-trione and 0.1 part of erucamide into the high-speed mixer , mixed for 5 minutes, and then extruded and granulated by a twin-screw extruder at a conventional processing temperature of 180-240° C. to obtain a polyethylene composition for rotomolding. The mechanical properties are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com