Patents

Literature

76 results about "Uniaxial pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

(Al,Ga,In)N and ZnO direct wafer bonded structure for optoelectronic applications, and its fabrication method

InactiveUS7719020B2Reduce light absorptionLight evenlyIncadescent screens/filtersDischarge tube luminescnet screensWaferingNitrogen

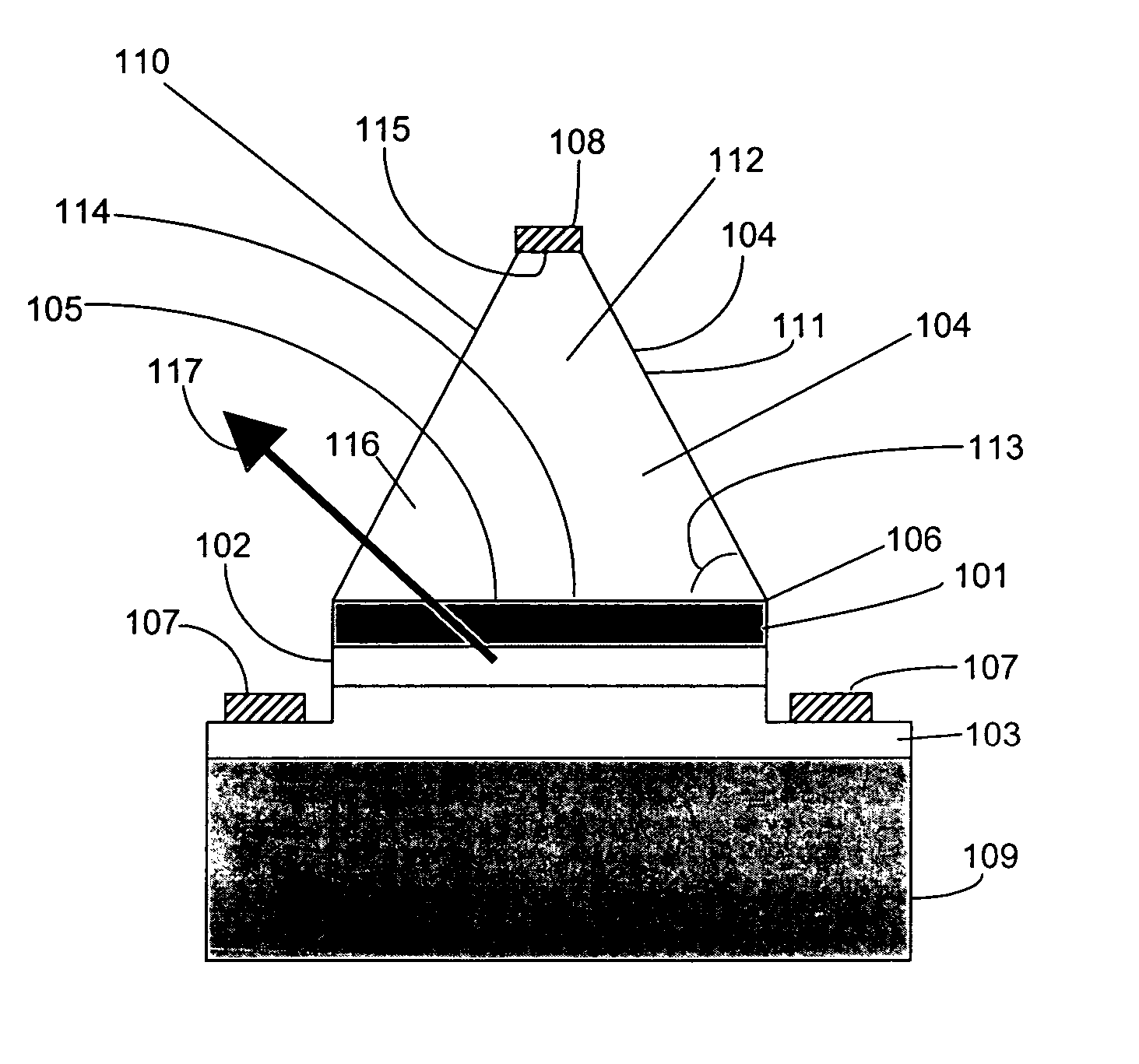

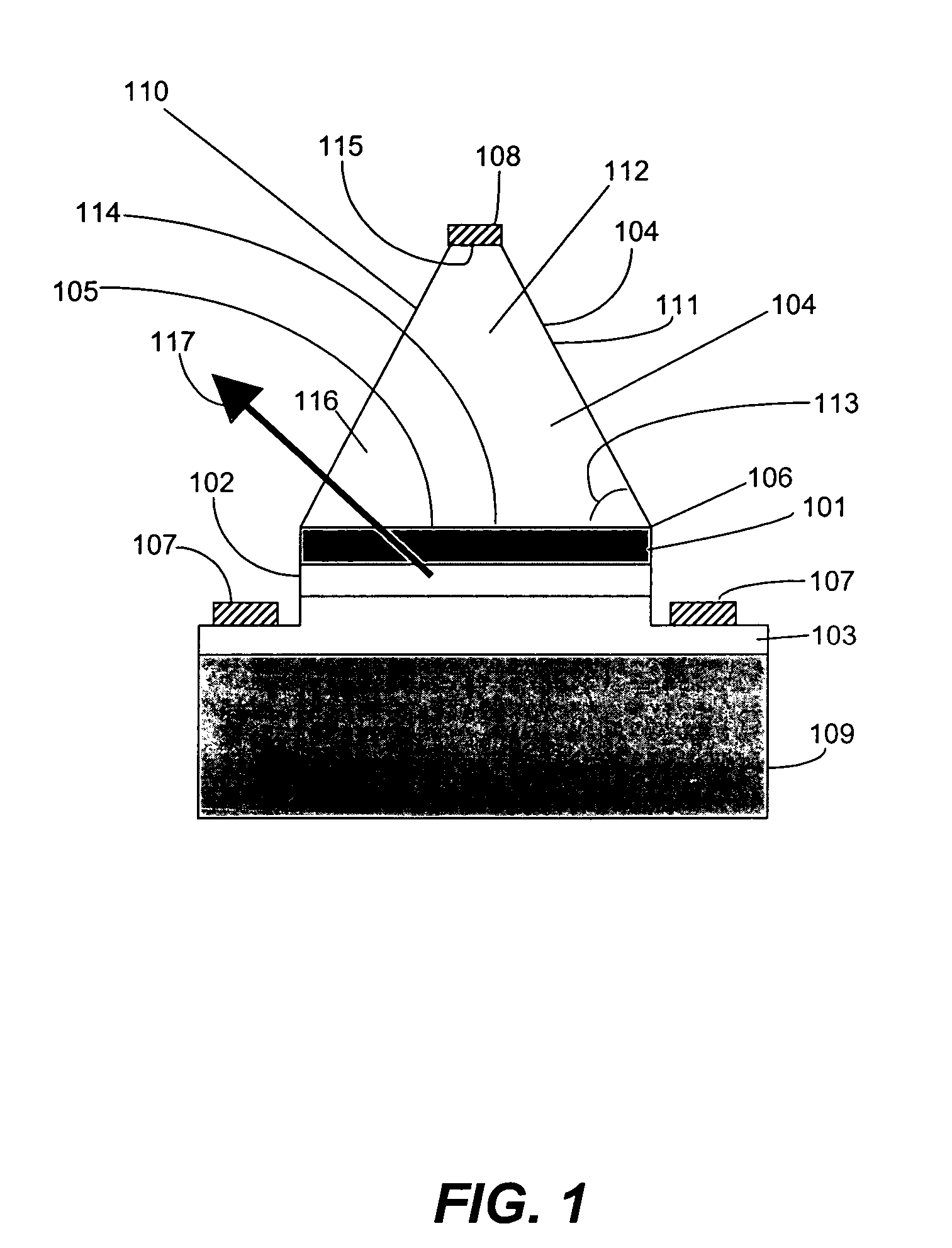

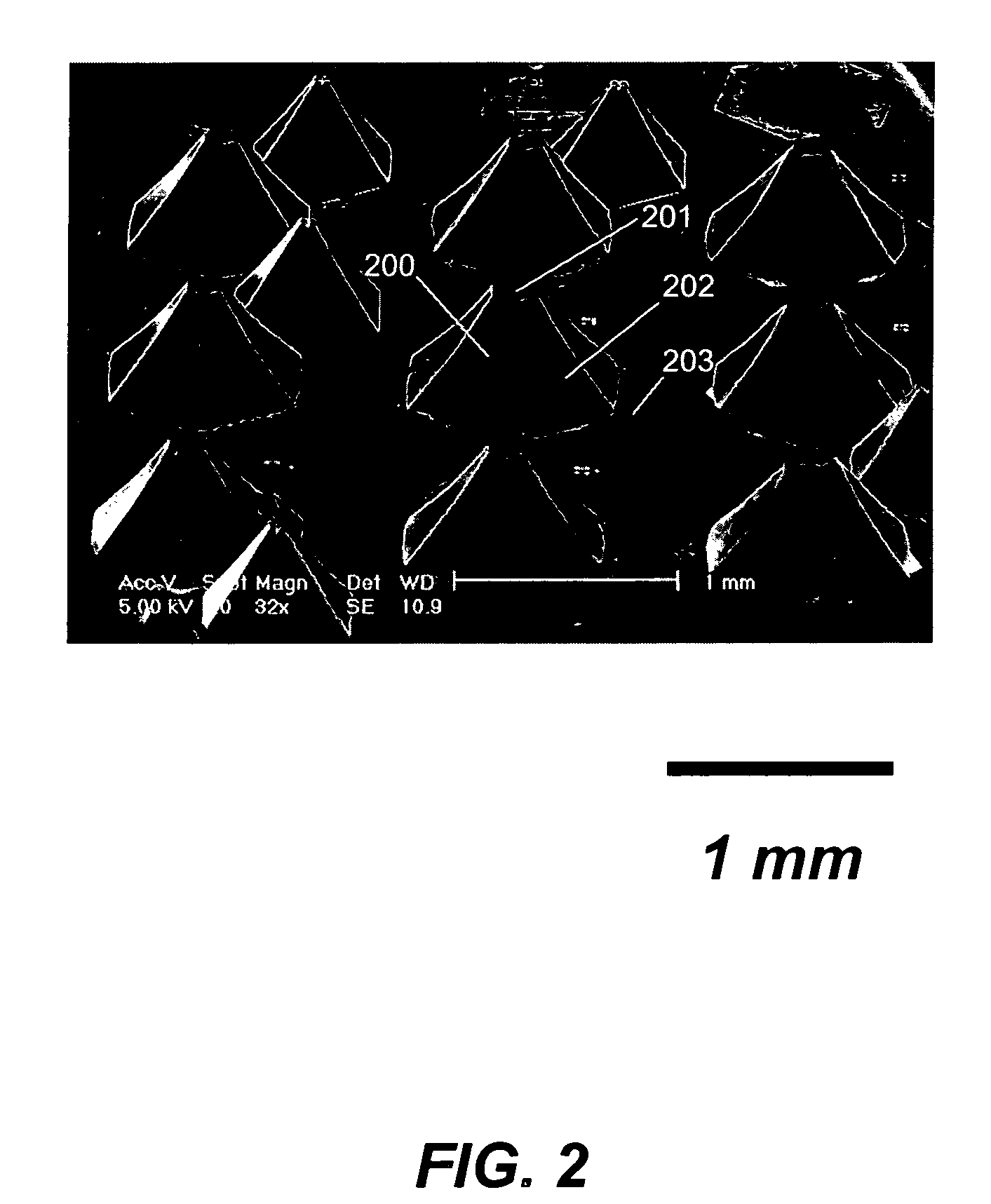

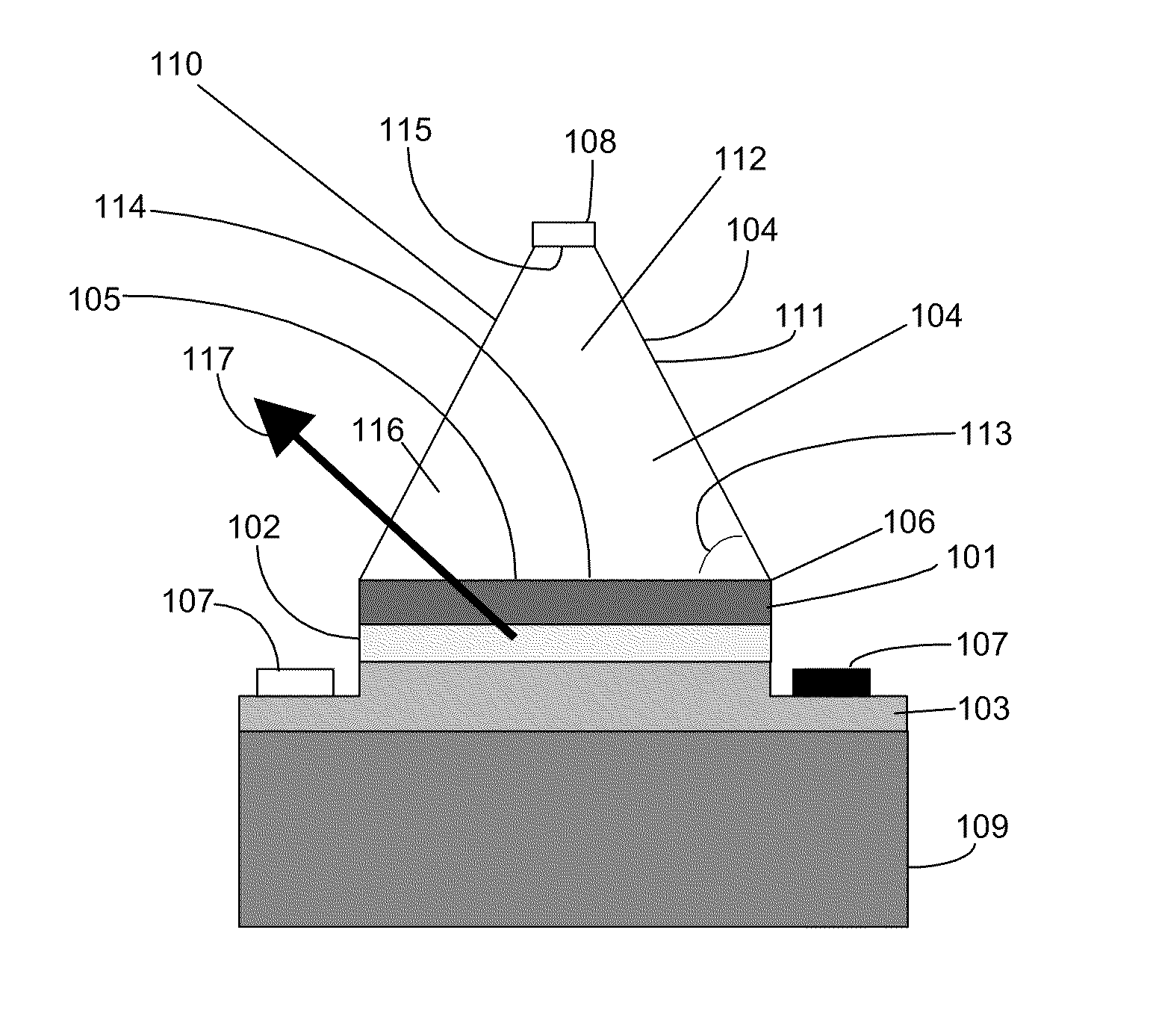

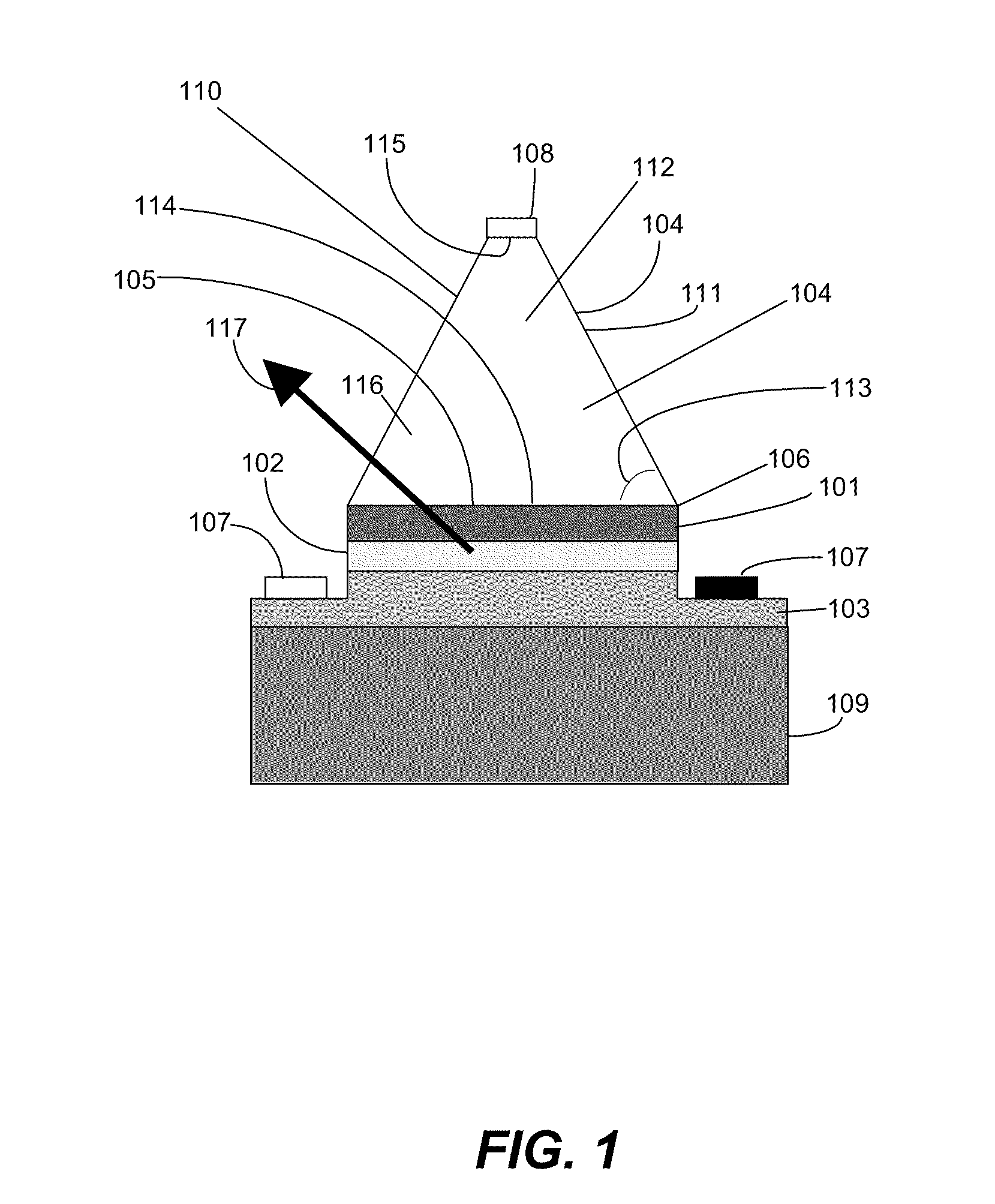

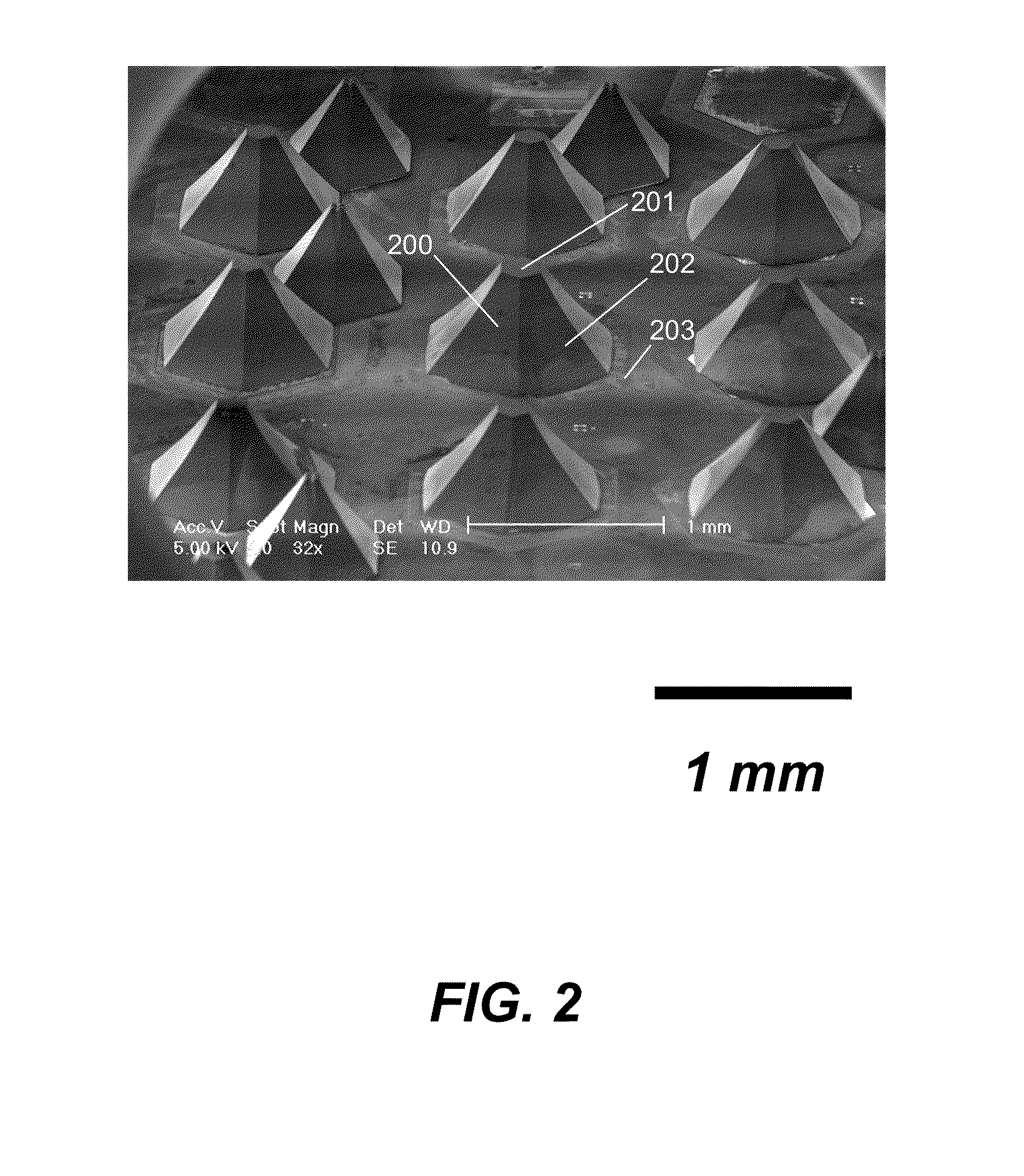

An (Al, Ga, In)N and ZnO direct wafer bonded light emitting diode (LED), wherein light passes through electrically conductive ZnO. Flat and clean surfaces are prepared for both the (Al, Ga, In)N and ZnO wafers. A wafer bonding process is then performed between the (Al, Ga, In)N and ZnO wafers, wherein the (Al, Ga, In)N and ZnO wafers are joined together and then wafer bonded in a nitrogen ambient under uniaxial pressure at a set temperature for a set duration. After the wafer bonding process, ZnO is shaped for increasing light extraction from inside of LED.

Owner:JAPAN SCI & TECH CORP

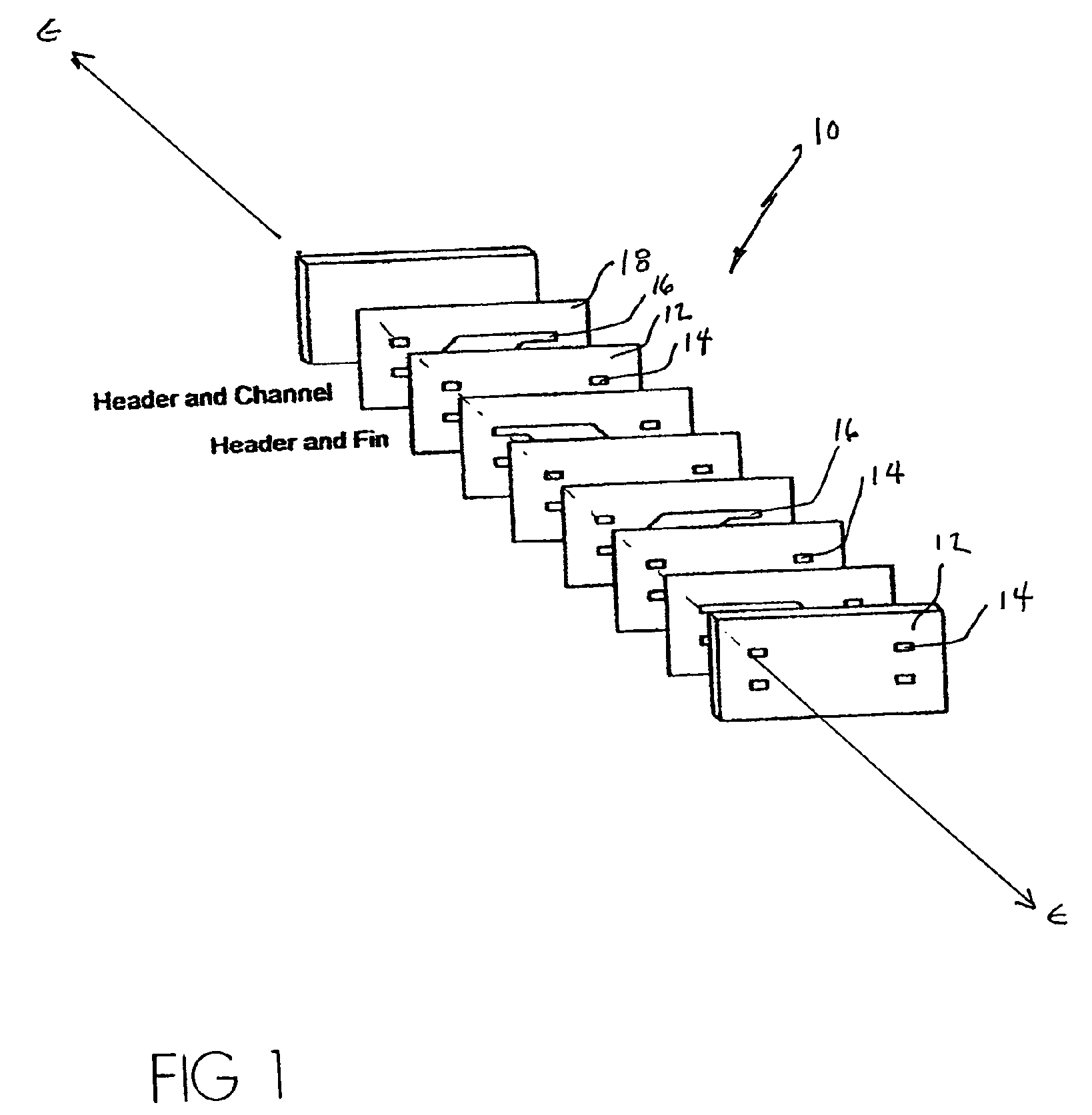

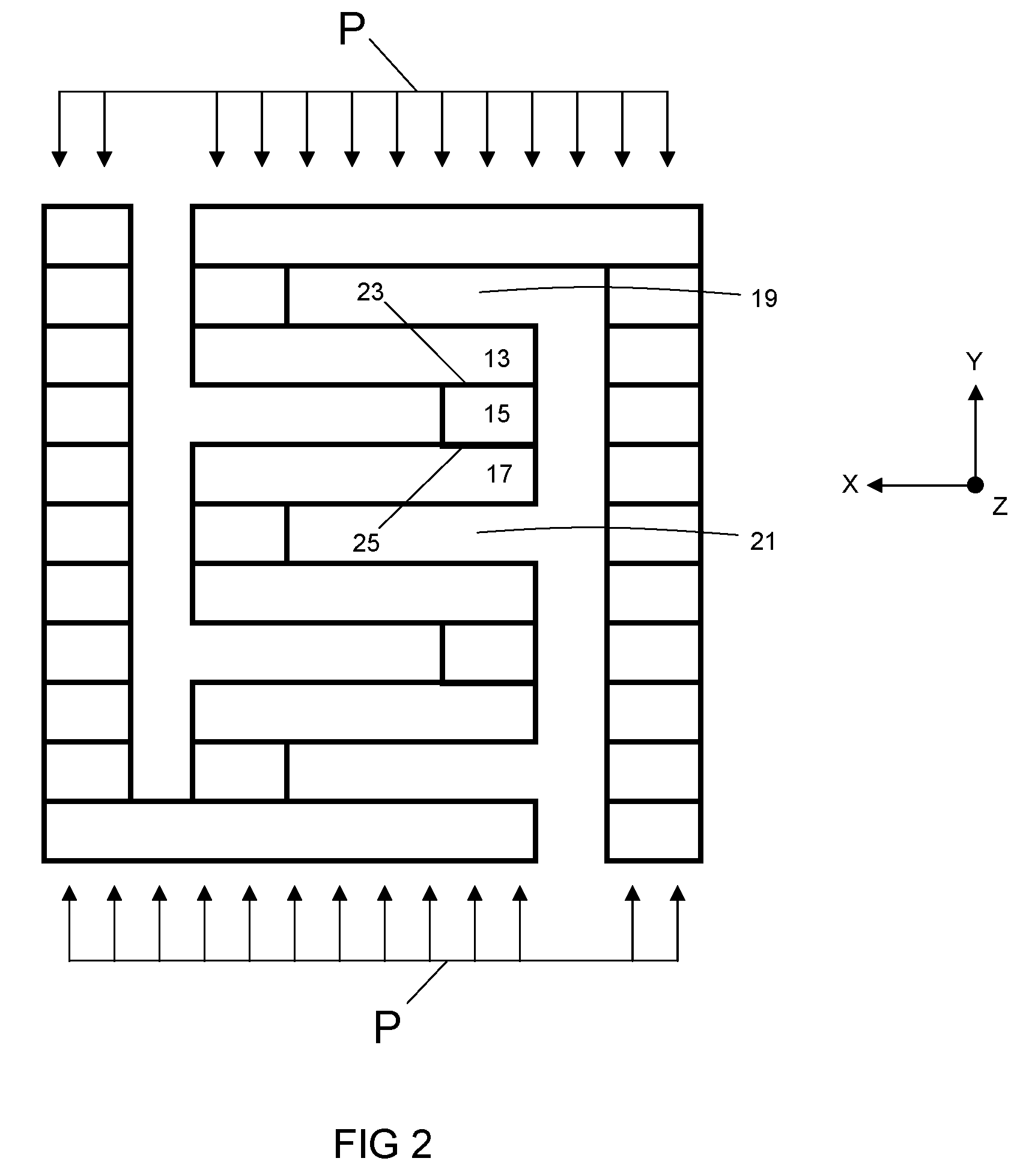

Method for producing components with internal architectures, such as micro-channel reactors, via diffusion bonding sheets

InactiveUS7900811B1Prevent collapseAvoid distortionAdhesive processesVegetable fibre separation from seedsCombustorChemical reactor

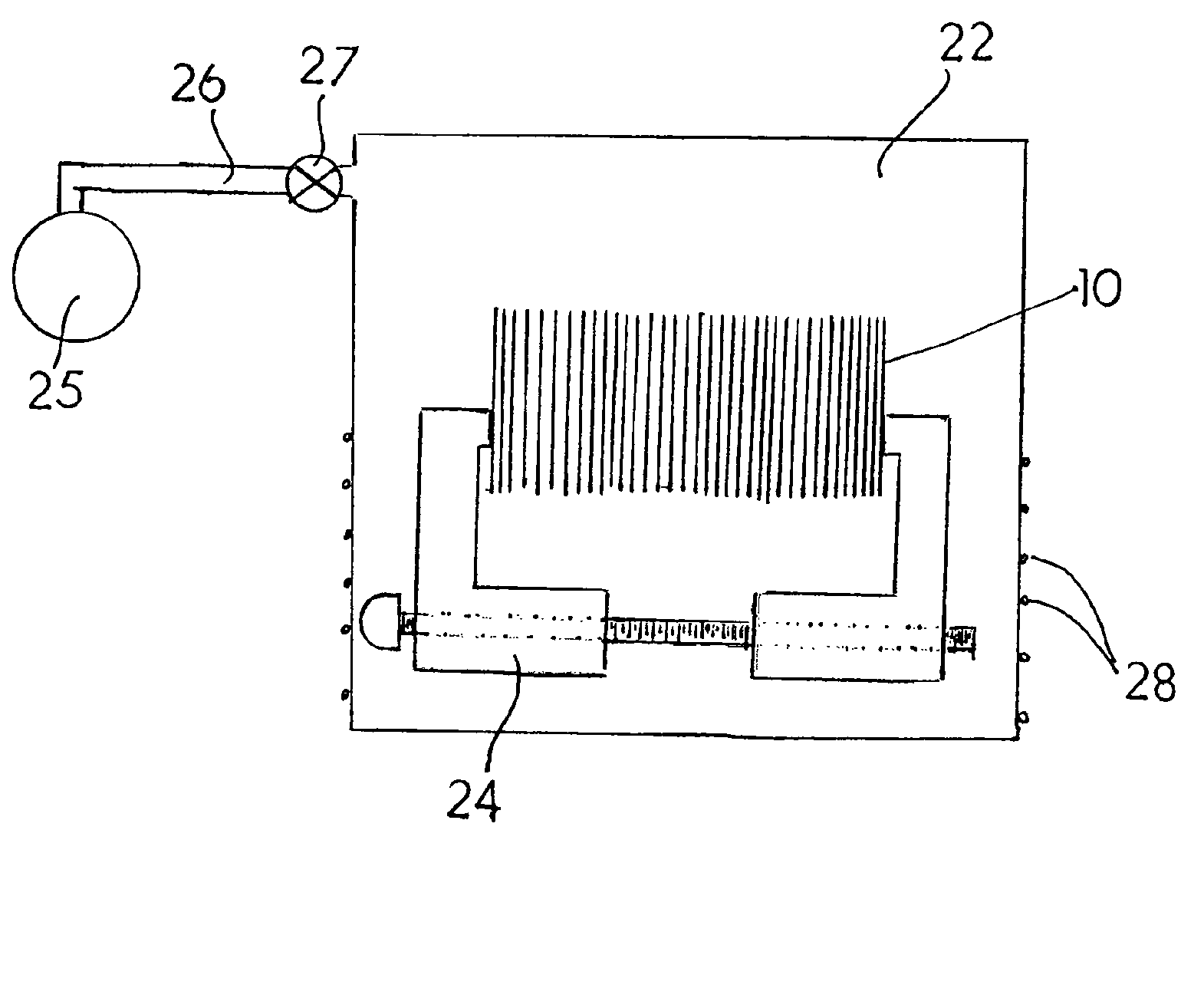

This invention relates to a method for producing components with internal architectures, and more particularly, this invention relates to a method for producing structures with microchannels via the use of diffusion bonding of stacked laminates. Specifically, the method involves weakly bonding a stack of laminates forming internal voids and channels with a first generally low uniaxial pressure and first temperature such that bonding at least between the asperites of opposing laminates occurs and pores are isolated in interfacial contact areas, followed by a second generally higher isostatic pressure and second temperature for final bonding. The method thereby allows fabrication of micro-channel devices such as heat exchangers, recuperators, heat-pumps, chemical separators, chemical reactors, fuel processing units, and combustors without limitation on the fin aspect ratio.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

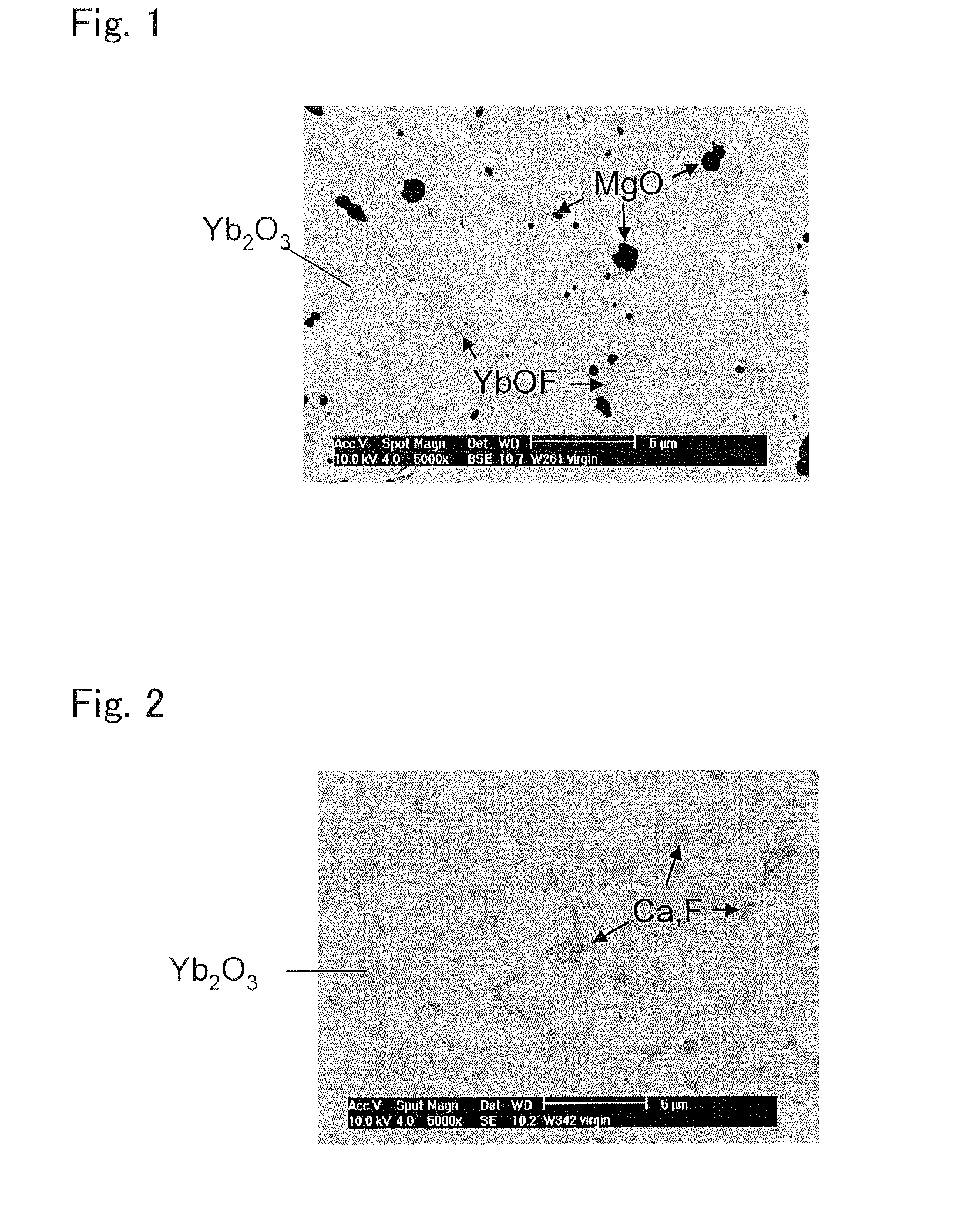

Corrosion-resistant member for semiconductor manufacturing apparatus and method for manufacturing the same

ActiveUS20130023401A1Reduce etch rateReduce the amount requiredSemiconductor/solid-state device manufacturingCeramic shaping apparatusManufactured apparatusManufactured material

Initially, an Yb2O3 raw material was subjected to uniaxial pressure forming at a pressure of 200 kgf / cm2, so that a disc-shaped compact having a diameter of about 35 mm and a thickness of about 10 mm was produced, and was stored into a graphite mold for firing. Subsequently, firing was performed by using a hot-press method at a predetermined firing temperature (1,500° C.), so as to obtain a corrosion-resistant member for semiconductor manufacturing apparatus. The press pressure during firing was specified to be 200 kgf / cm2 and an Ar atmosphere was kept until the firing was finished. The retention time at the firing temperature (maximum temperature) was specified to be 4 hours. In this manner, the corrosion-resistant member for semiconductor manufacturing apparatus made from an Yb2O3 sintered body having an open porosity of 0.2% was obtained.

Owner:NGK INSULATORS LTD

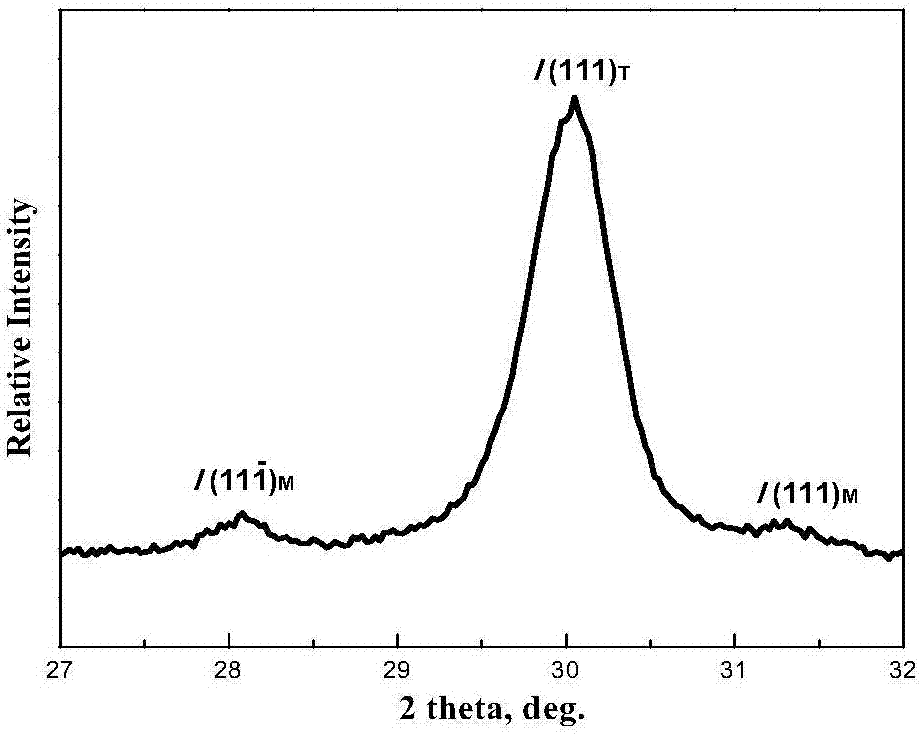

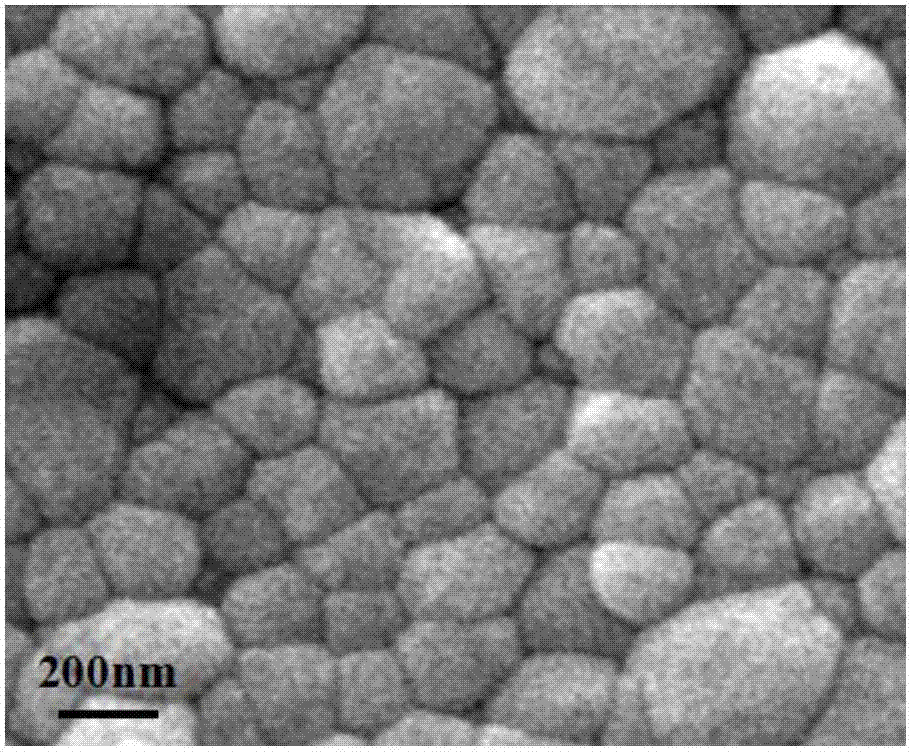

POLYCRYSTALLINE MgO SINTERED BODY, PRODUCTION METHOD THEREFOR, AND MgO SPUTTERING TARGET

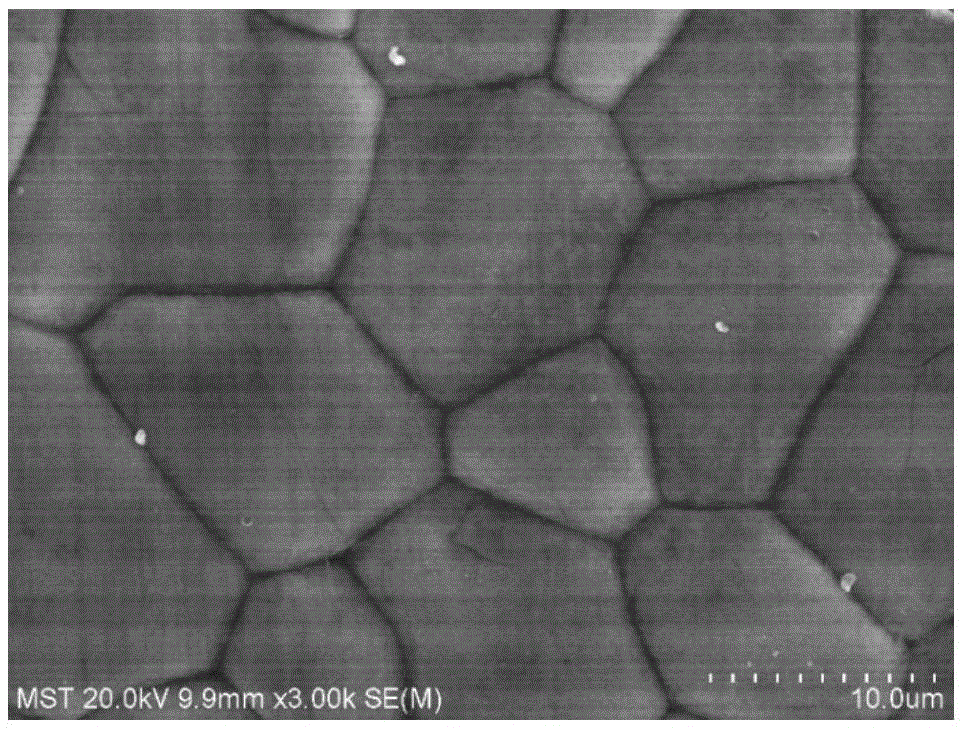

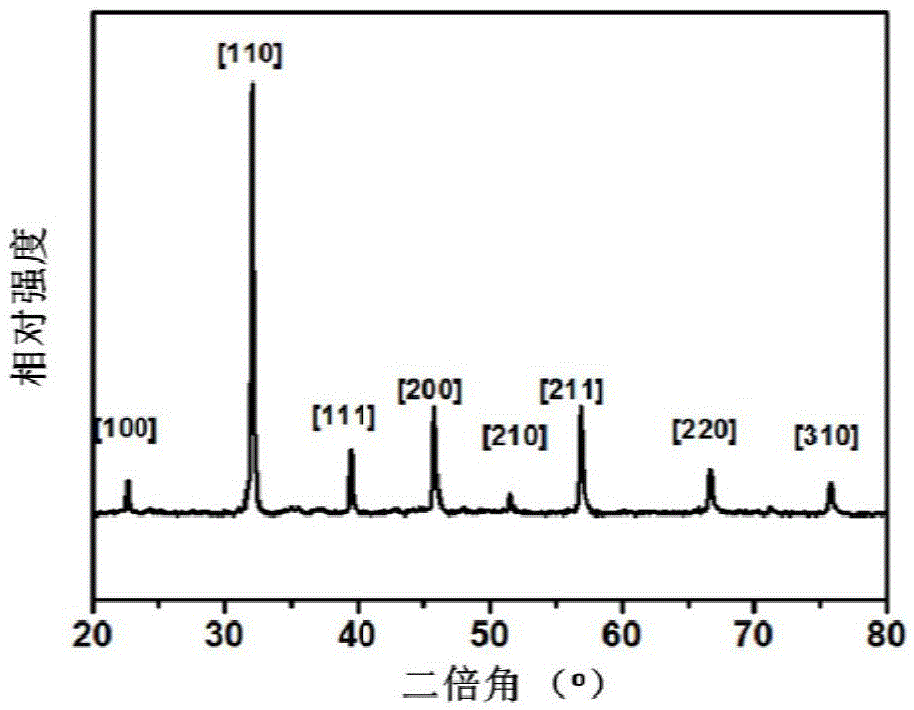

ActiveUS20100294657A1Increase chanceShrink poresLayered productsVacuum evaporation coatingSputteringHigh rate

Provided is a polycrystal MgO sintered body which is capable of having a sintered density close to a theoretical density thereof, and exhibiting excellent mechanical properties and heat conductivity, while reducing contamination of an atmosphere due to gas generation, and a production method for the sintered body. The polycrystal MgO sintered body has a unique crystalline anisotropy in which (111) faces are oriented along a surface applied with a uniaxial pressure at a high rate. The polycrystalline MgO sintered body is obtained by a method which comprises the steps of: sintering an MgO raw material powder having a particle size of 1 μm or less, under a uniaxial pressure; and then subjecting the sintered powder to a heat treatment under an atmosphere containing 0.05 volume % or more of oxygen, at a temperature of 1273 K or more for 1 minute or more.

Owner:NIPPON TUNGSTEN CORP +1

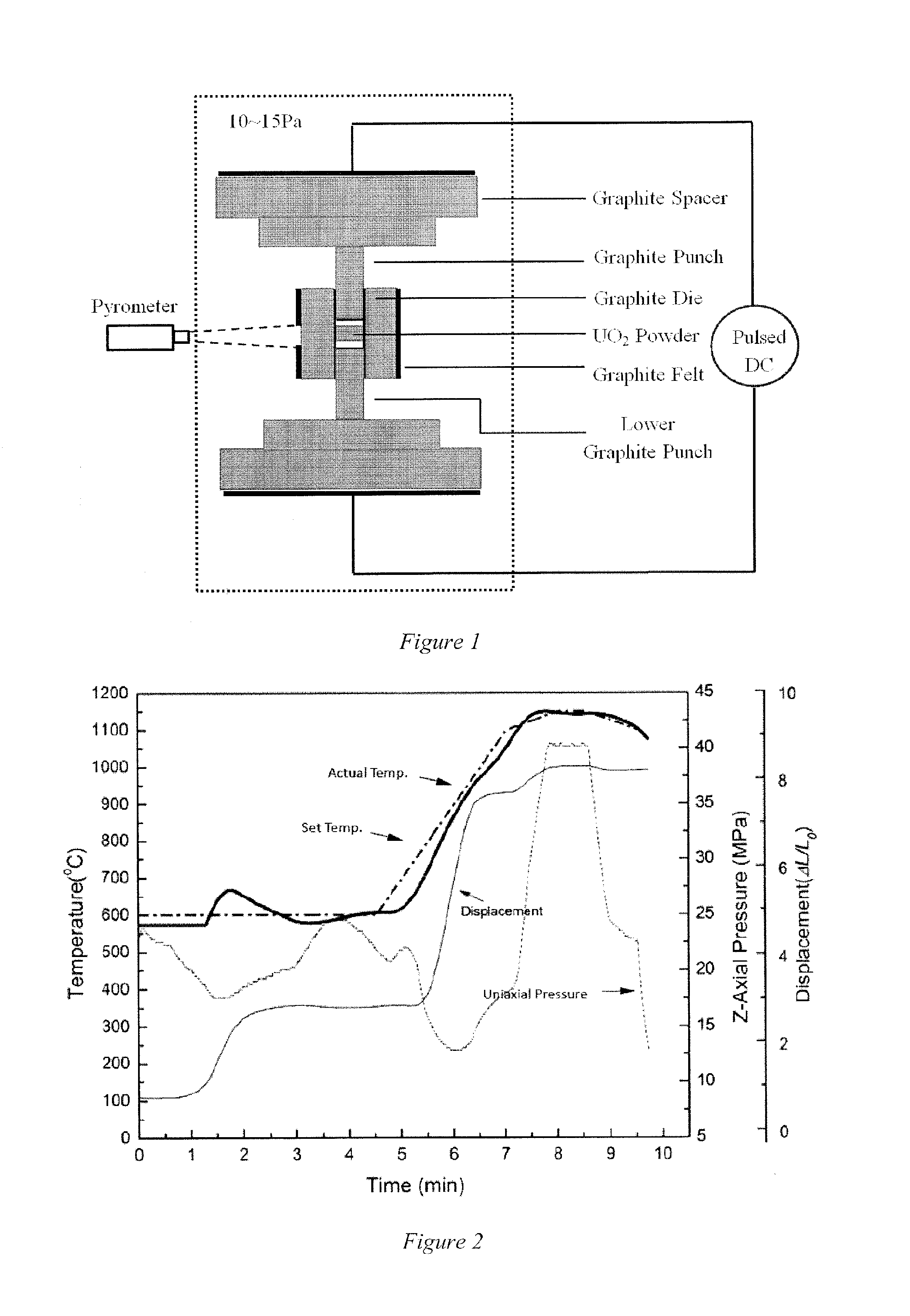

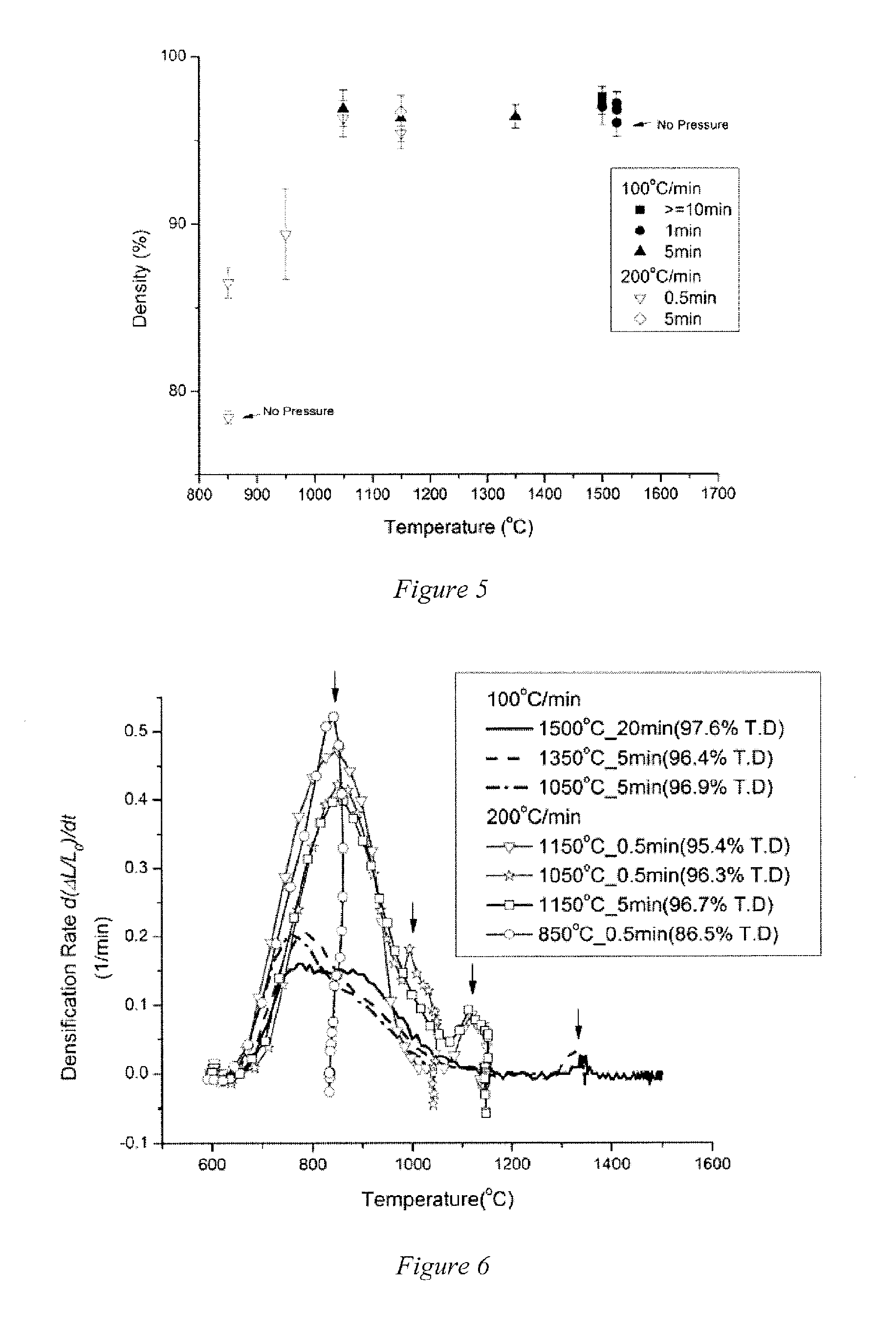

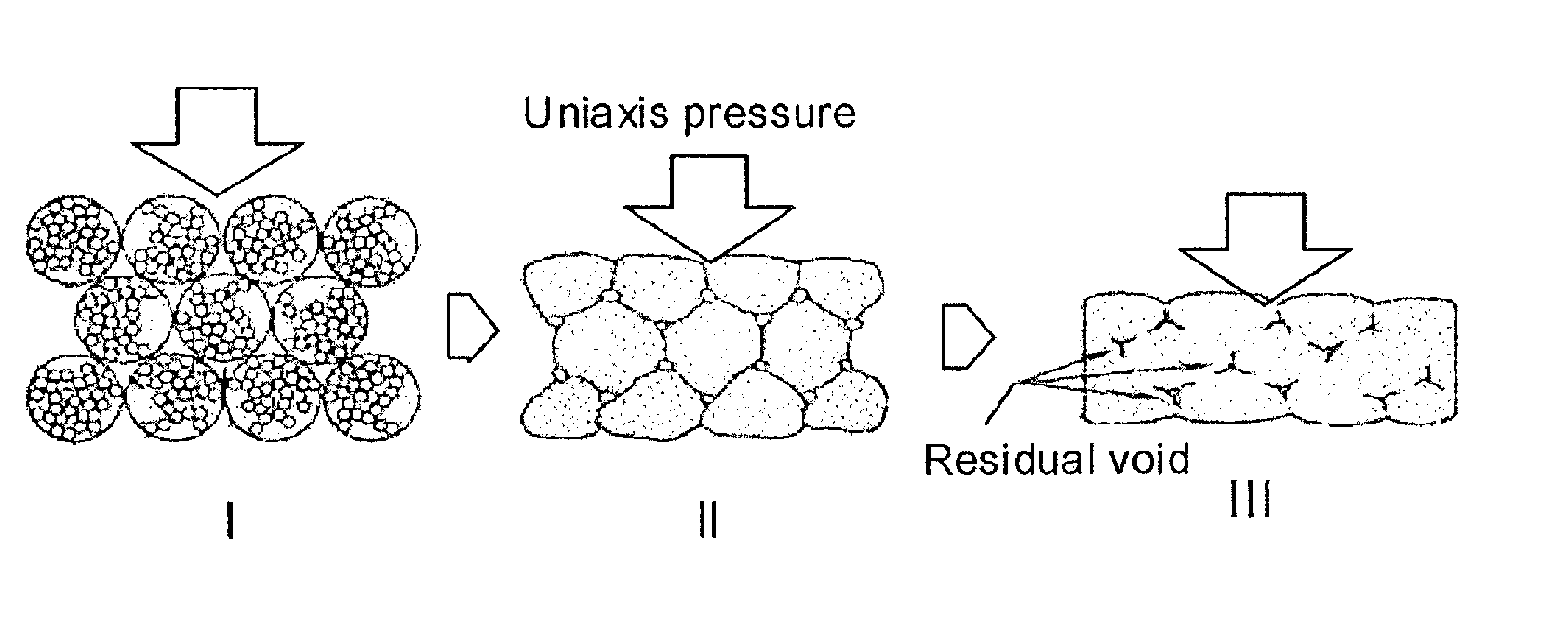

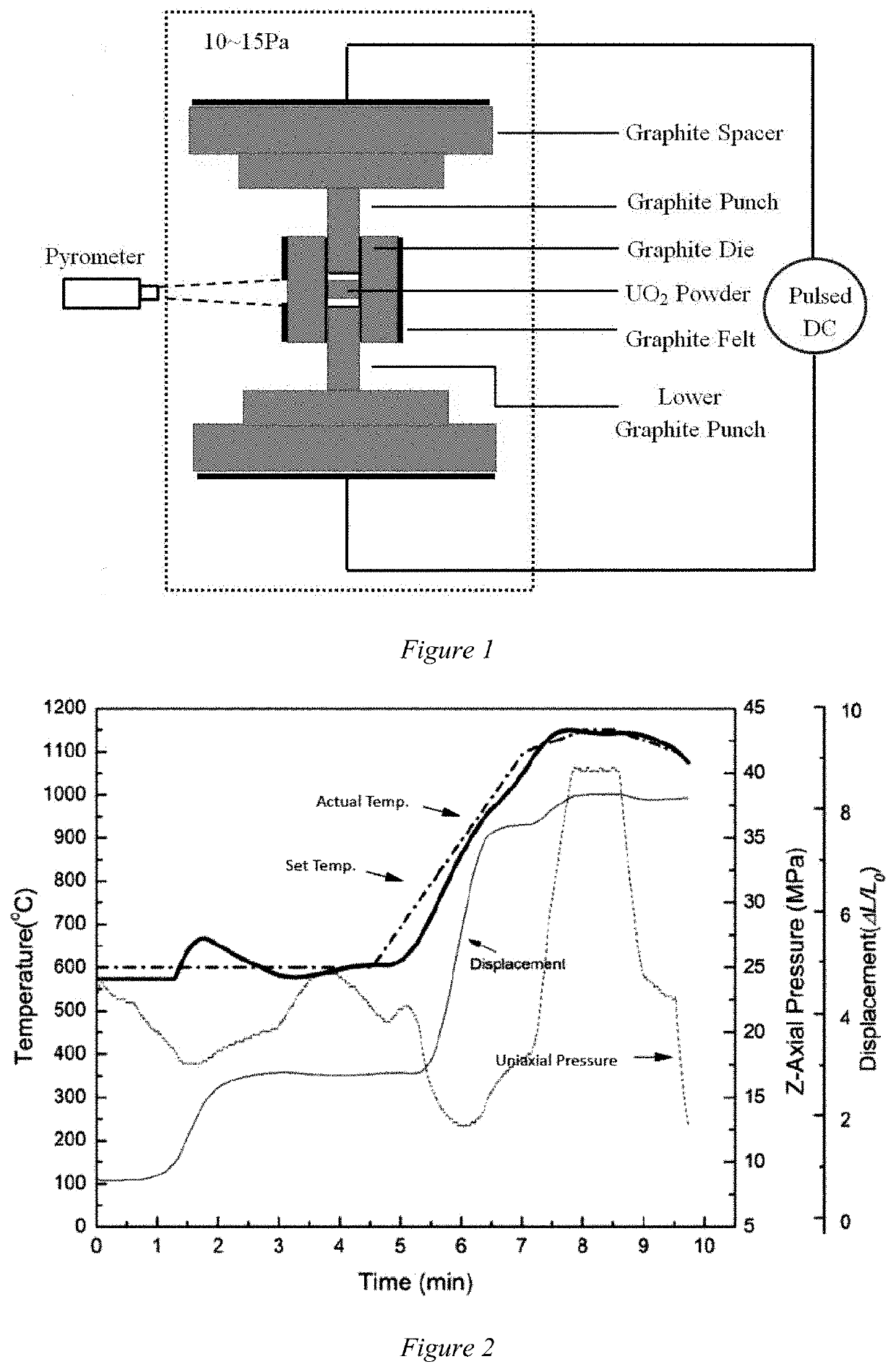

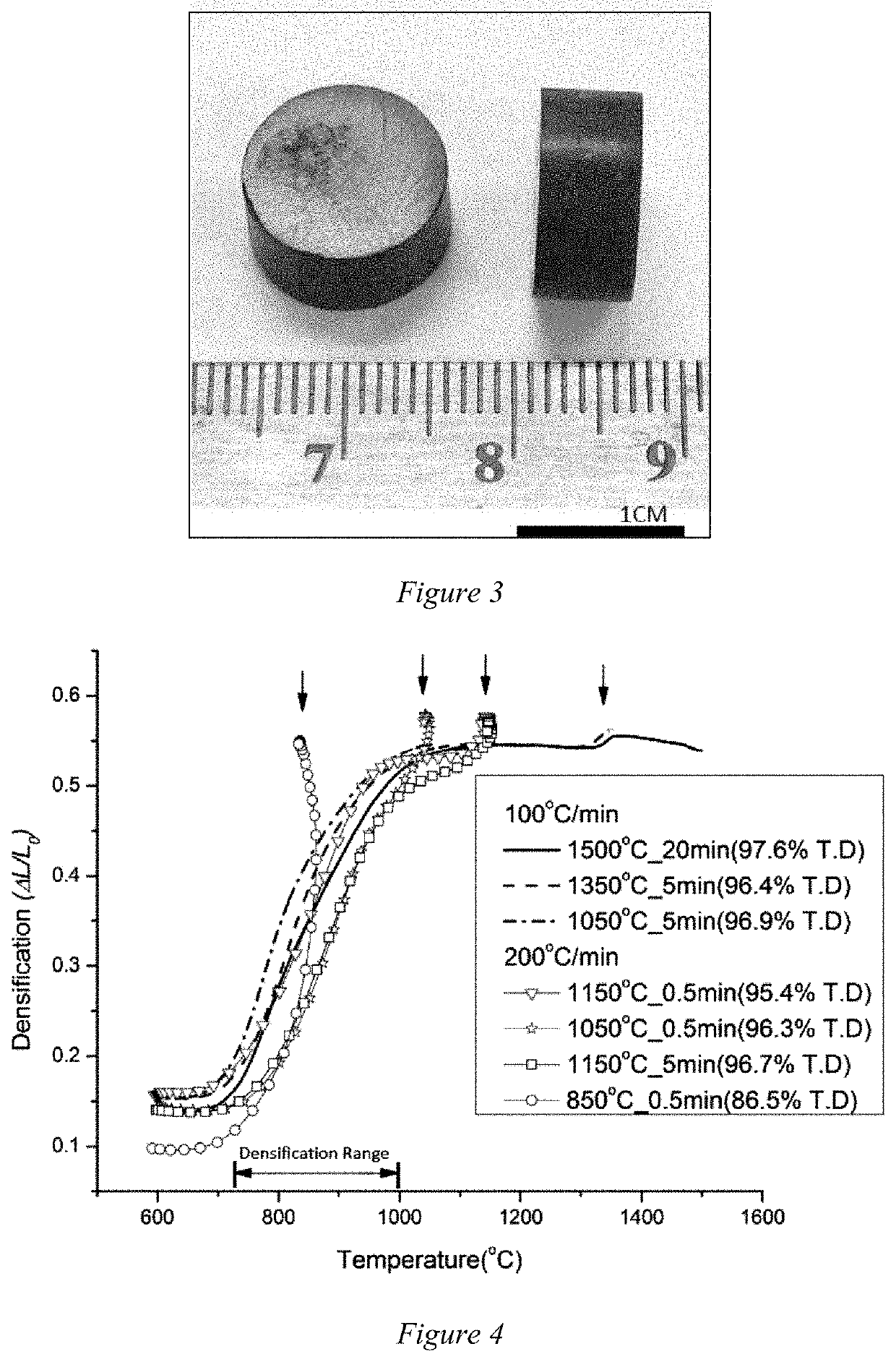

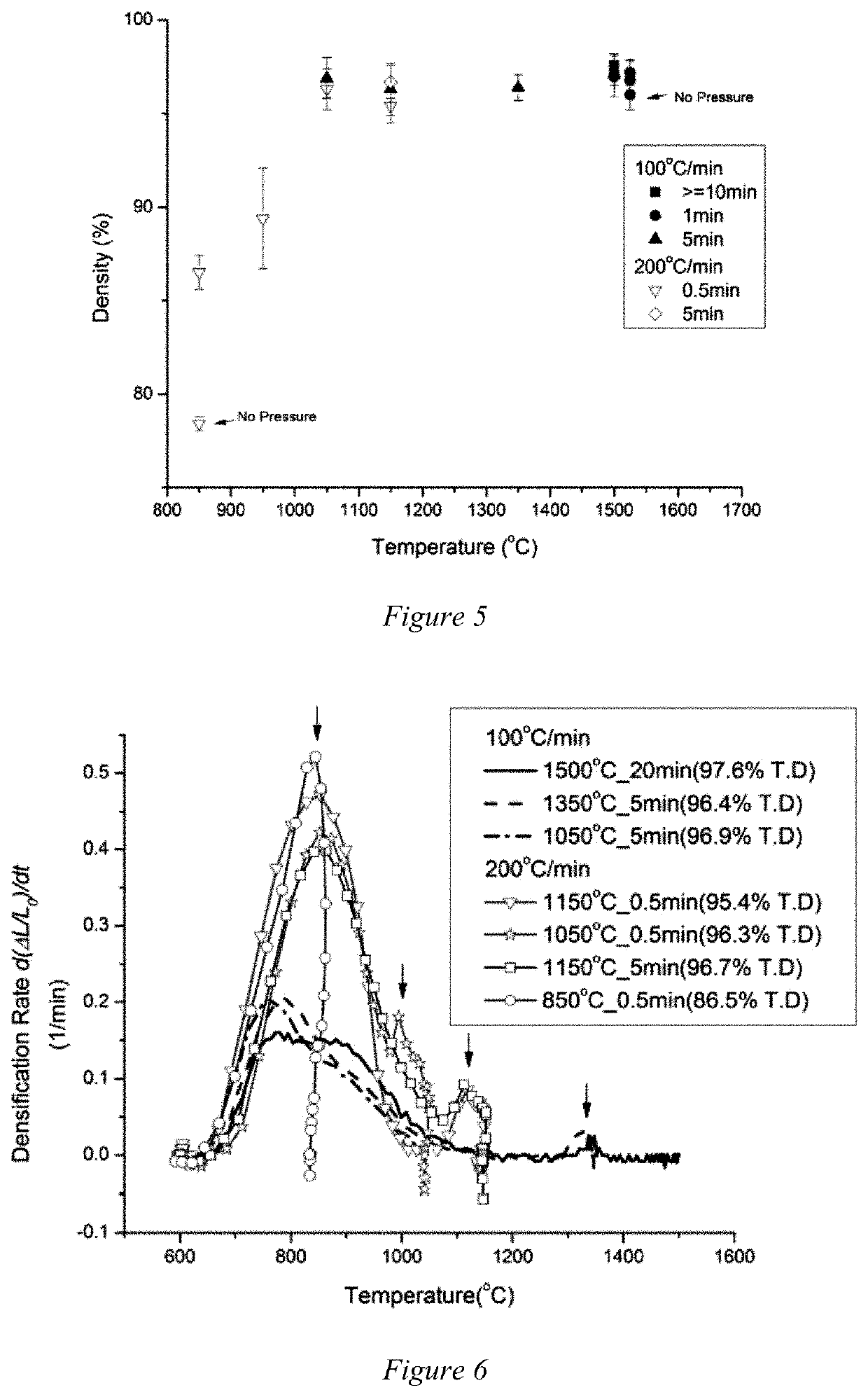

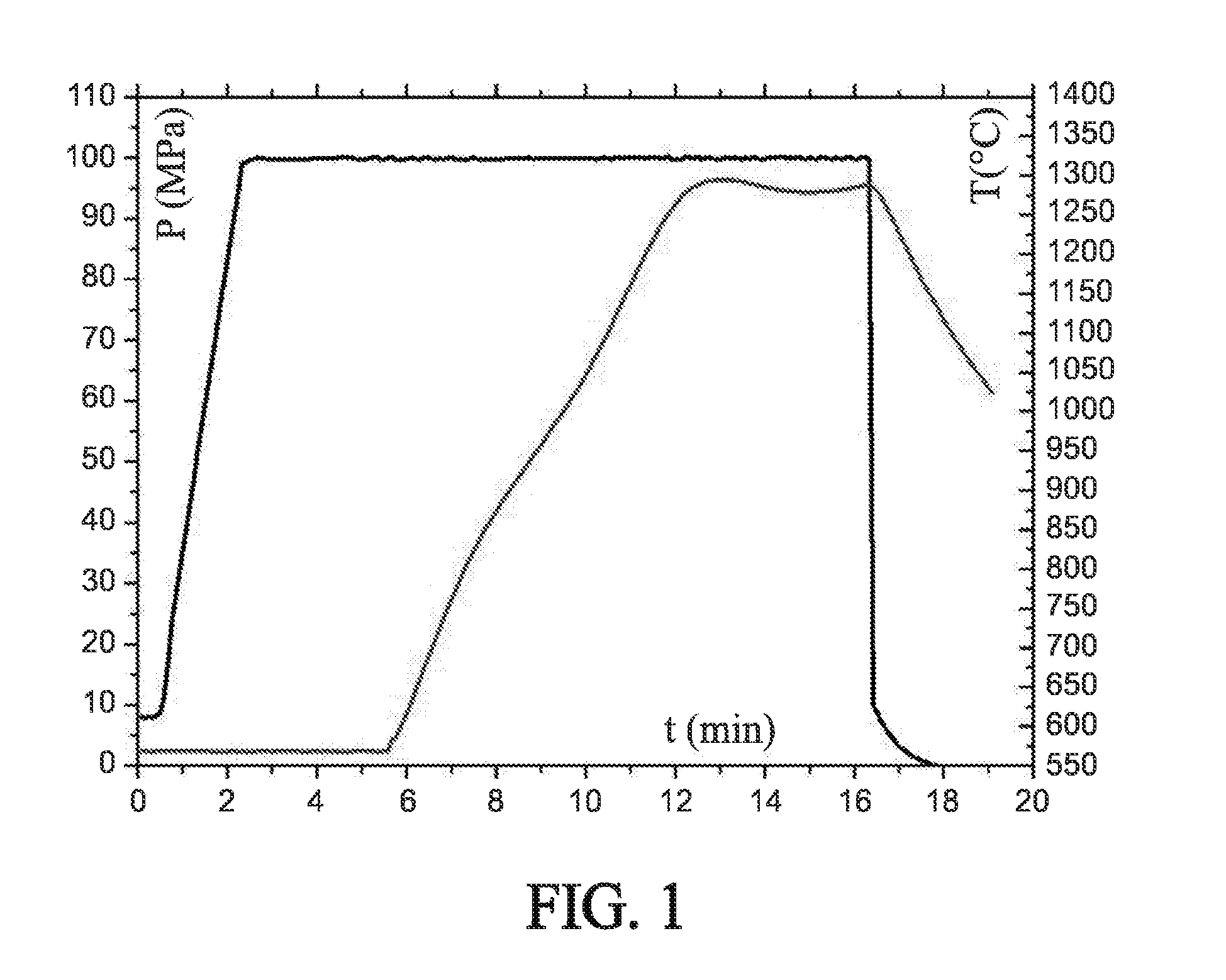

High density u02 and high thermal conductivity uo2 composites by spark plasma sintering (SPS)

Embodiments of the invention are directed to a method for production of a nuclear fuel pellet by spark plasma sintering (SPS), wherein a fuel pellet with more than 80% TD or more than 90% TD is formed. The SPS can be performed with the imposition of a controlled uniaxial pressure applied at the maximum temperature of the processing to achieve a very high density, in excess of 95% TD, at temperatures of 850 to 1600° C. The formation of a fuel pellet can be carried out in one hour or less. In an embodiment of the invention, a nuclear fuel pellet comprises UO2 and a highly thermally conductive material, such as SiC or diamond.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

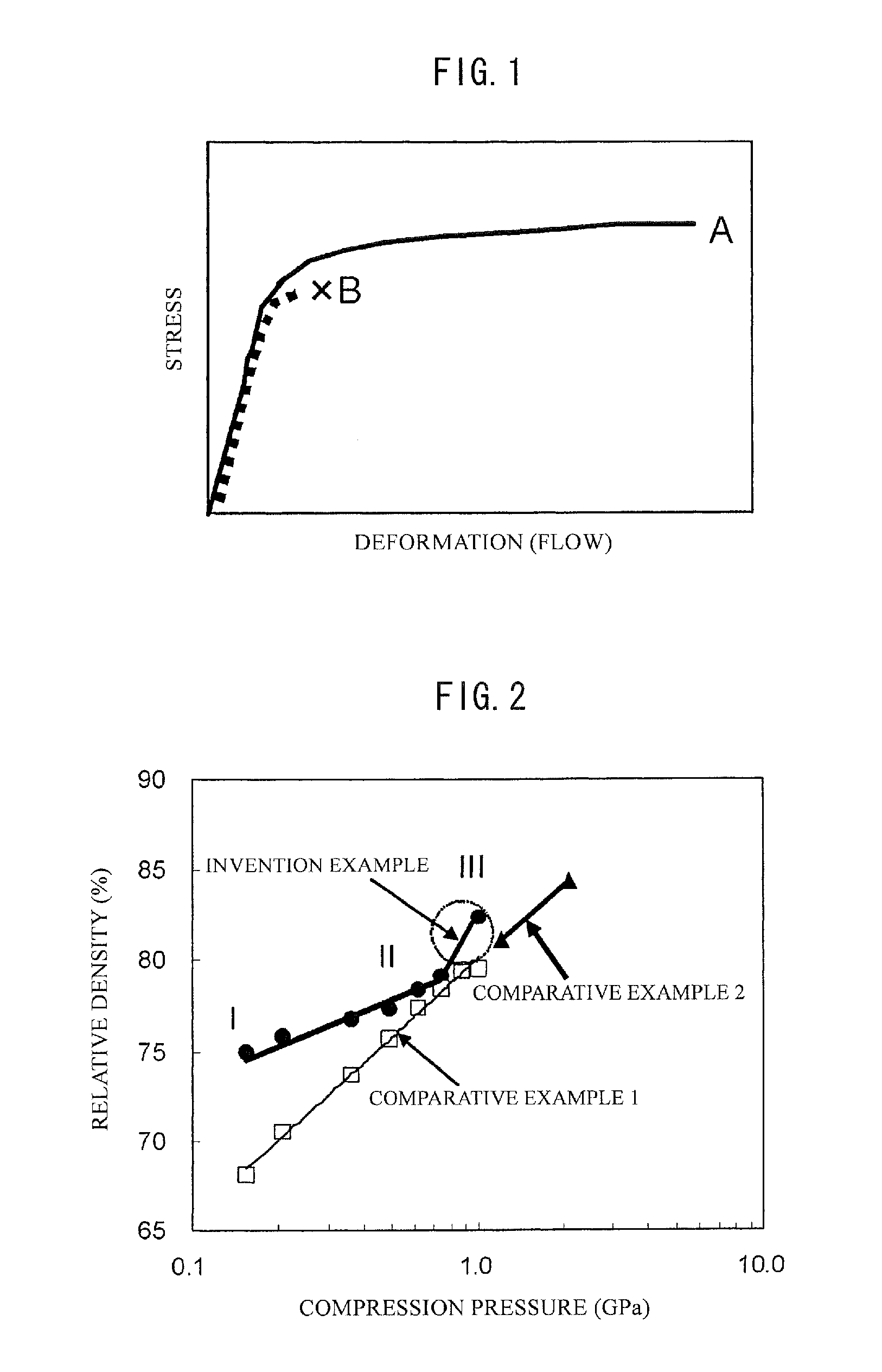

Method for producing fully dense rare earth-iron-based bonded magnet

InactiveUS20140043125A1Improve radial compressive strengthHigh dimensional accuracyPermanent magnetsInductances/transformers/magnets manufactureRare earthUniaxial pressure

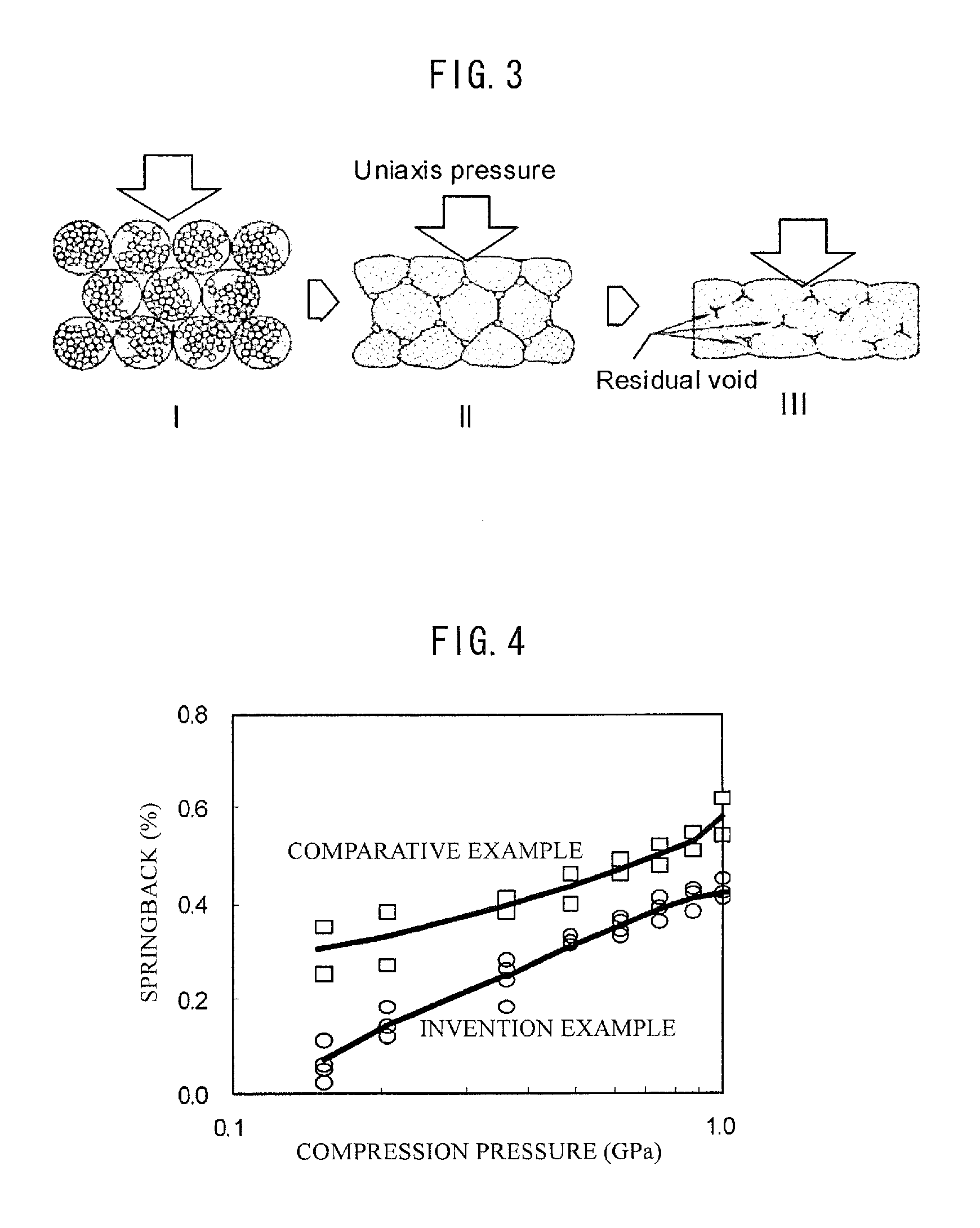

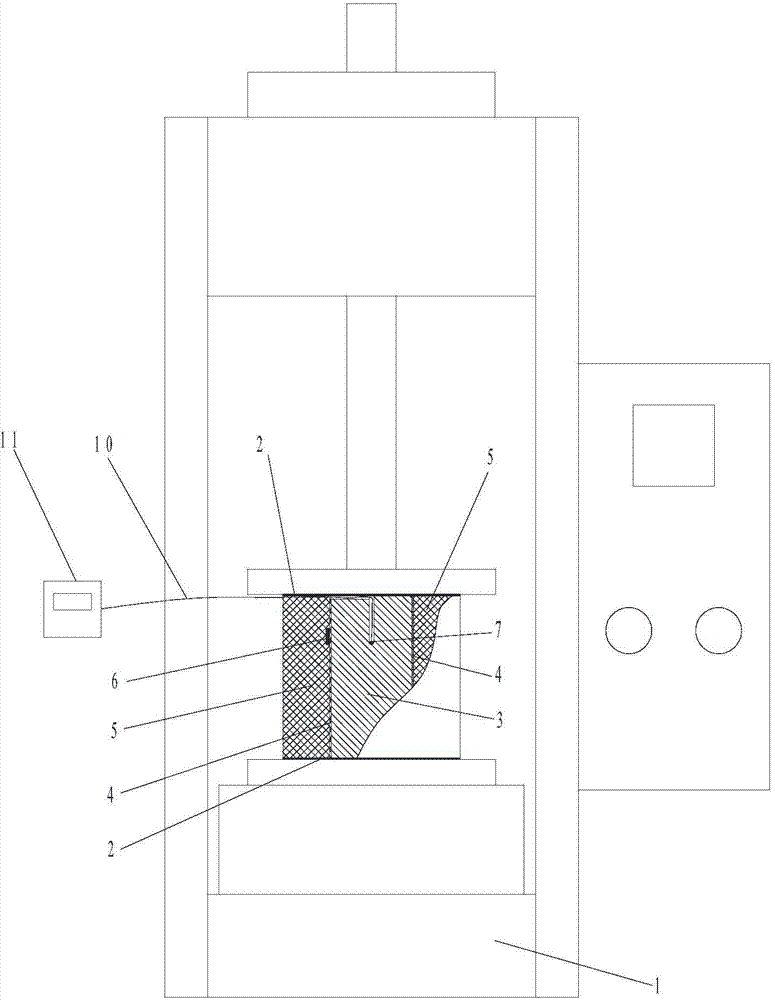

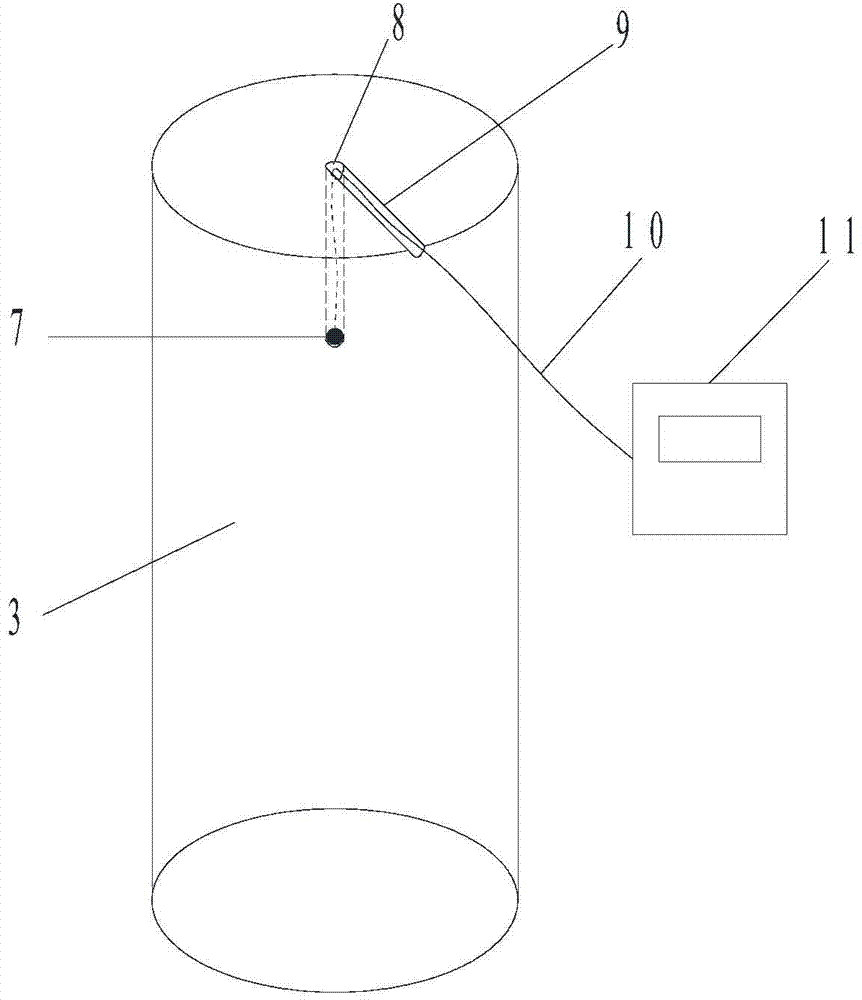

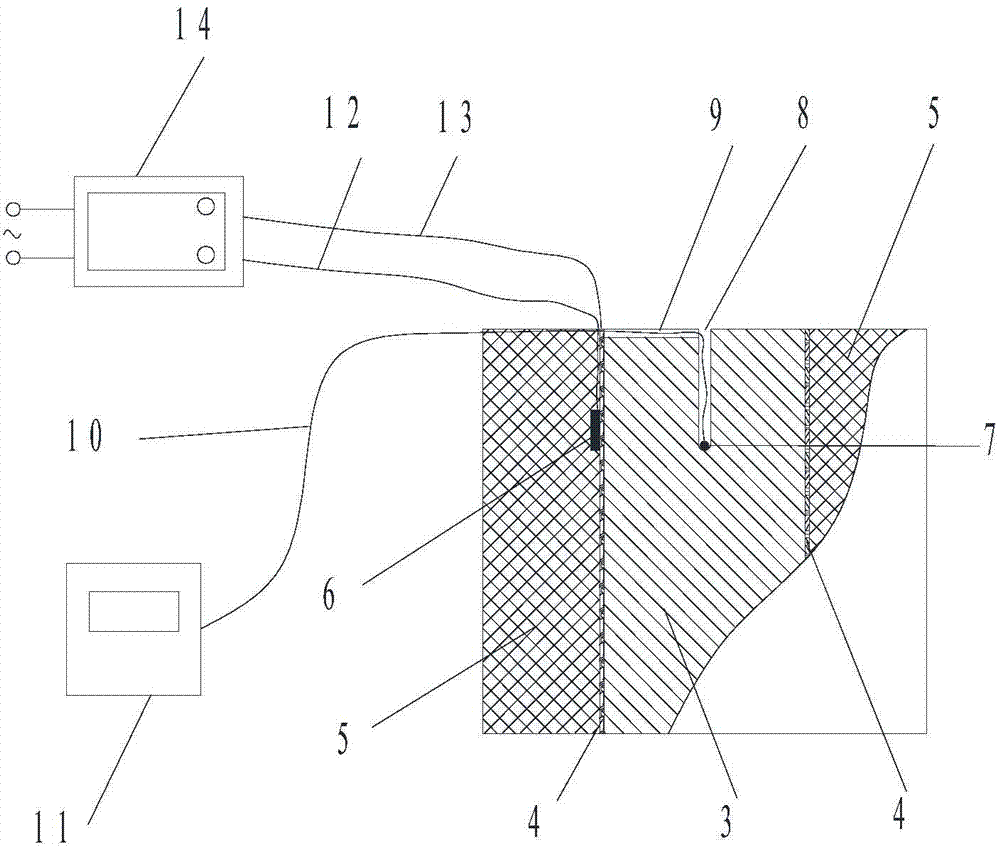

Provided is a method for producing a fully dense rare earth-iron-based bonded magnet, the method comprising: kneading a non-tacky thermosetting resin composition with rare earth-iron-based magnet flakes to produce a solid granular composite magnetic material; filling the granular composite magnetic material into a cavity, applying a uniaxial pressure higher than or equal to the yield stress of the thermosetting resin composition to the granular composite magnetic material so as to produce a green compact in which voids are reduced as a result of an interaction between brittle fracture of the magnet flakes and plastic deformation of the thermosetting resin composition, the rare earth-iron-based magnet flakes are piled on top of one another highly compact in the direction of the pressure axis, and the mutual positional relations of the magnet flakes are set almost regularly; and heating the green compact to cure the thermosetting resin composition constituting the green compact.

Owner:MINEBEA CO LTD

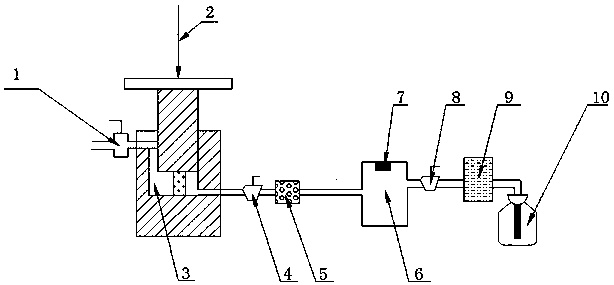

Method for measuring rock thermal coefficient of linear expansion by utilizing pressure tester

ActiveCN104749210AGuaranteed accuracyThe principle is simpleMaterial thermal coefficient of expansionInsulation layerThermal coefficient

The invention relates to a method for measuring rock thermal coefficient of linear expansion by utilizing a pressure tester. The method comprises the following steps of selecting a rock sample, drilling a circular hole and engraving a wire leading groove; installing a silica gel heating element heating device; wrapping a heat preservation and insulation layer; installing an electric couple; placing the assembled rock sample onto a uniaxial pressure tester, putting heat preservation and insulation mats on the top surface and the bottom surface of the rock sample; starting the uniaxial pressure tester to apply an initial load on the rock sample; setting finishing temperature required to be applied, recording a finishing load value and axis finishing temperature after a system is stabilized; finally, calculating the thermal coefficient of linear expansion. The invention utilizes the common pressure tester to measure the rock thermal coefficient of linear expansion, so that compared with other existing methods, the time required for single measuring can be well shortened, the problem of cooling of heating equipment does not need to be considered, the measurement of the next sample can be carried out directly, and high-efficient measurement of the rock thermal coefficient of linear expansion in engineering design is realized.

Owner:GUANGXI UNIV

Preparation method of porous titanium and titanium alloy

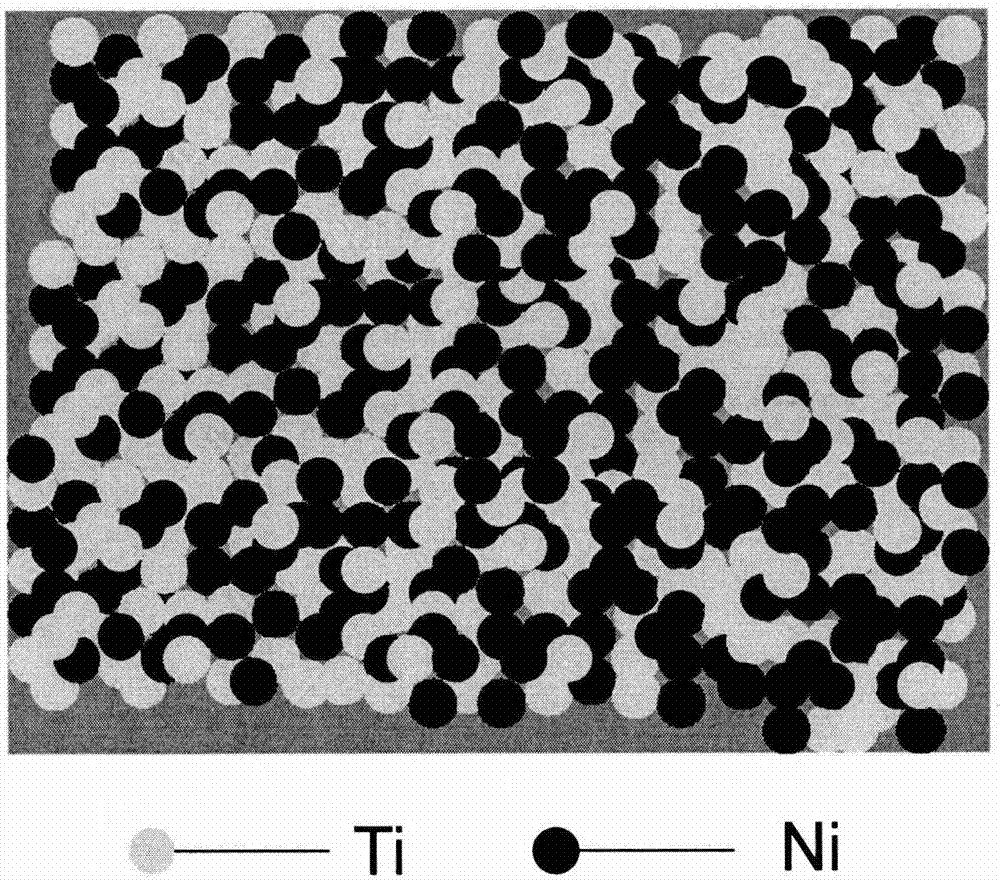

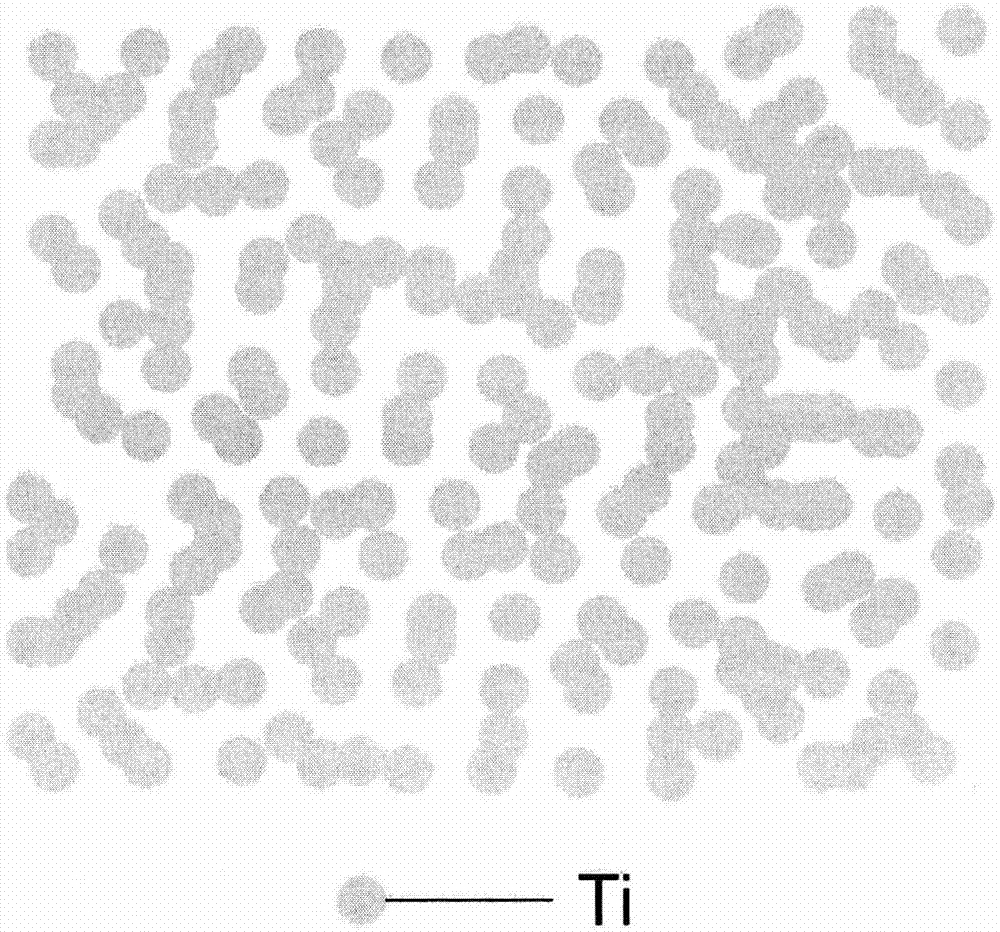

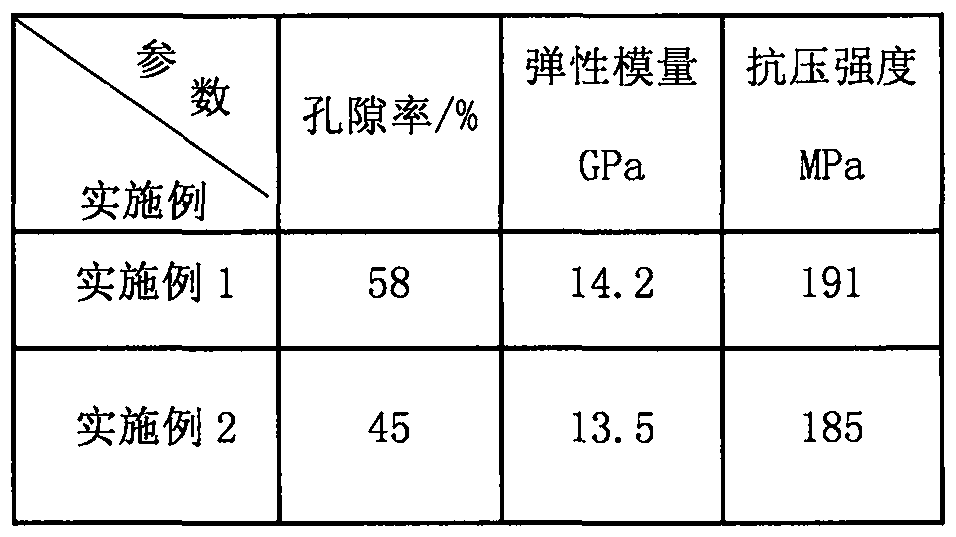

InactiveCN107012352AUniform distribution of poresControllable size arrangementFiltration separationProsthesisRoom temperatureGraphite

The invention discloses a preparation method of porous titanium and titanium alloy, comprising the following steps: uniformly mixing Ti metal powder and alloy powder, the mass percentage of Ti metal powder in the obtained mixed powder is 45%-95%, and the mass percentage of alloy powder The percentage is 55%~5%; put the obtained mixed powder into a graphite or silicon carbide mold, place it in a vacuum sintering furnace for sintering, the vacuum degree is 0.1~10Pa, the one-way pressure is 200~1000MPa, and the heating rate is 20~100℃ / min, sintering temperature 800-1400°C, sintering 10-60min, then cooling to room temperature with the furnace and taking it out to obtain the alloy green body; use the obtained alloy green body as an anode to electrochemically dissolve the alloy metal powder, dissolve the metal wire mold, and be porous titanium. The pores of the porous titanium obtained in the invention have uniform distribution of pores and controllable size arrangement, and can be applied to medical porous titanium and titanium alloy materials and titanium and titanium alloy filter core materials.

Owner:BAOJI UNIV OF ARTS & SCI

(Al,Ga,In)N AND ZnO DIRECT WAFER BONDED STRUCTURE FOR OPTOELECTRONIC APPLICATIONS, AND ITS FABRICATION METHOD

InactiveUS20100187555A1Reduce light absorptionLight evenlySemiconductor/solid-state device manufacturingSemiconductor lasersWaferingNitrogen

An (Al, Ga, In)N and ZnO direct wafer bonded light emitting diode (LED), wherein light passes through electrically conductive ZnO. Flat and clean surfaces are prepared for both the (Al, Ga, In)N and ZnO wafers. A wafer bonding process is then performed between the (Al, Ga, In)N and ZnO wafers, wherein the (Al, Ga, In)N and ZnO wafers are joined together and then wafer bonded in a nitrogen ambient under uniaxial pressure at a set temperature for a set duration. After the wafer bonding process, ZnO is shaped for increasing light extraction from inside of LED.

Owner:RGT UNIV OF CALIFORNIA

Corrosion-resistant member for semiconductor manufacturing apparatus and method for manufacturing the same

ActiveUS8685313B2Reduce etch rateReduce the amount requiredElectric discharge tubesSemiconductor/solid-state device manufacturingAir atmosphereSlurry

A mixed powder was prepared by weighing Yb2O3 and SrCO3 in such a way that the molar ratio became 1:1. The resulting mixed powder was subjected to uniaxial pressure forming, so as to produce a disc-shaped compact. The compact was heat-treated in an air atmosphere, so that a complex oxide was synthesized. The resulting complex oxide was pulverized. After the pulverization, a slurry was taken out and was dried in a nitrogen gas stream, so as to produce a synthesized powder material. The resulting synthesized powder material was subjected to uniaxial pressure forming, so as to produce a disc-shaped compact. The resulting compact was fired by a hot-press method, so as to obtain a corrosion-resistant member for semiconductor manufacturing apparatus. The resulting corrosion-resistant member was made from a SrYb2O4.

Owner:NGK INSULATORS LTD

Application of fluorine-doped perovskite-type membrane in oxygen separation

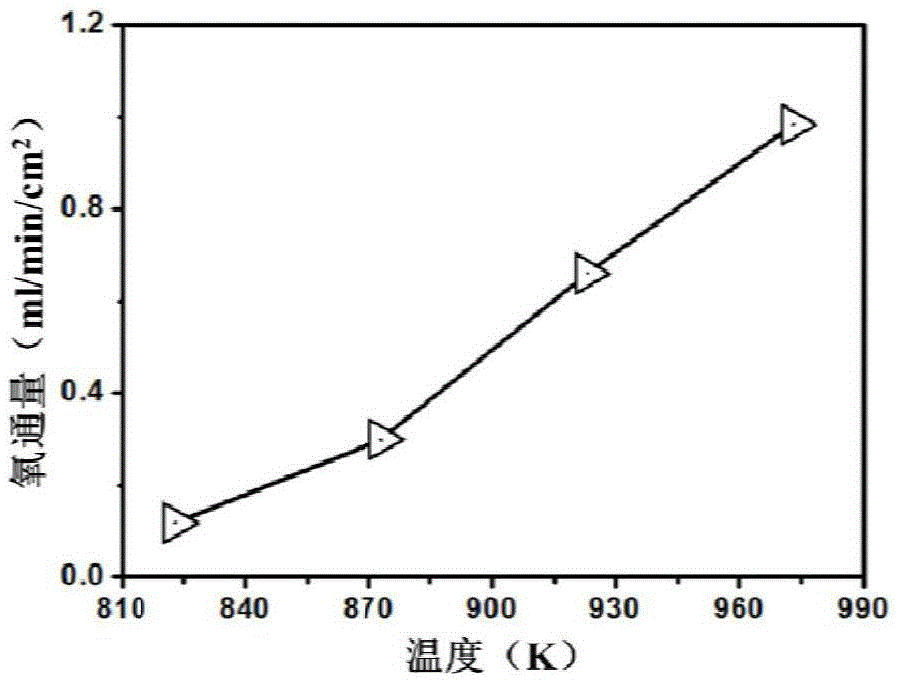

ActiveCN105536447AImprove throughputImprove stabilitySemi-permeable membranesMembranesLattice defectsSolid state reaction method

The invention relates to application of a fluorine-doped perovskite-type membrane in oxygen separation. A membrane material is perovskite crystal form of oxyfluoride shown by a general formula AxA'1-xByB'1-yO3-gamma F delta, wherein the gamma represents the number of oxygen lattice defects, the A and the A' are any one of the elements Ce, Pr, Nd, Ca, Sr, Ba and La, the B and the B' are any one of the elements Co, Fe, Nb, Ta, Mo, W, Sc, Ti, Zr, Sn and Sb, 0 <= x <= 1, 0 <= y <= 1, and 0 <= gamma <= 1. The material is prepared by adopting a solid-phase reaction method, a uniaxial pressure method, a plastic extrusion method or a phase transformation method is adopted in the membrane forming process, the oxygen permeation capacity of the oxygen permeation membrane material can be remarkably improved by doping nonmetal fluorine, the high stability of the material at oxygen partial pressure is kept, and the fluorine-doped perovskite-type membrane further has excellent medium and low temperature performances, is suitable for long-term operation of low-temperature oxygen separation and meets the demand of industrial application.

Owner:NANJING TECH UNIV

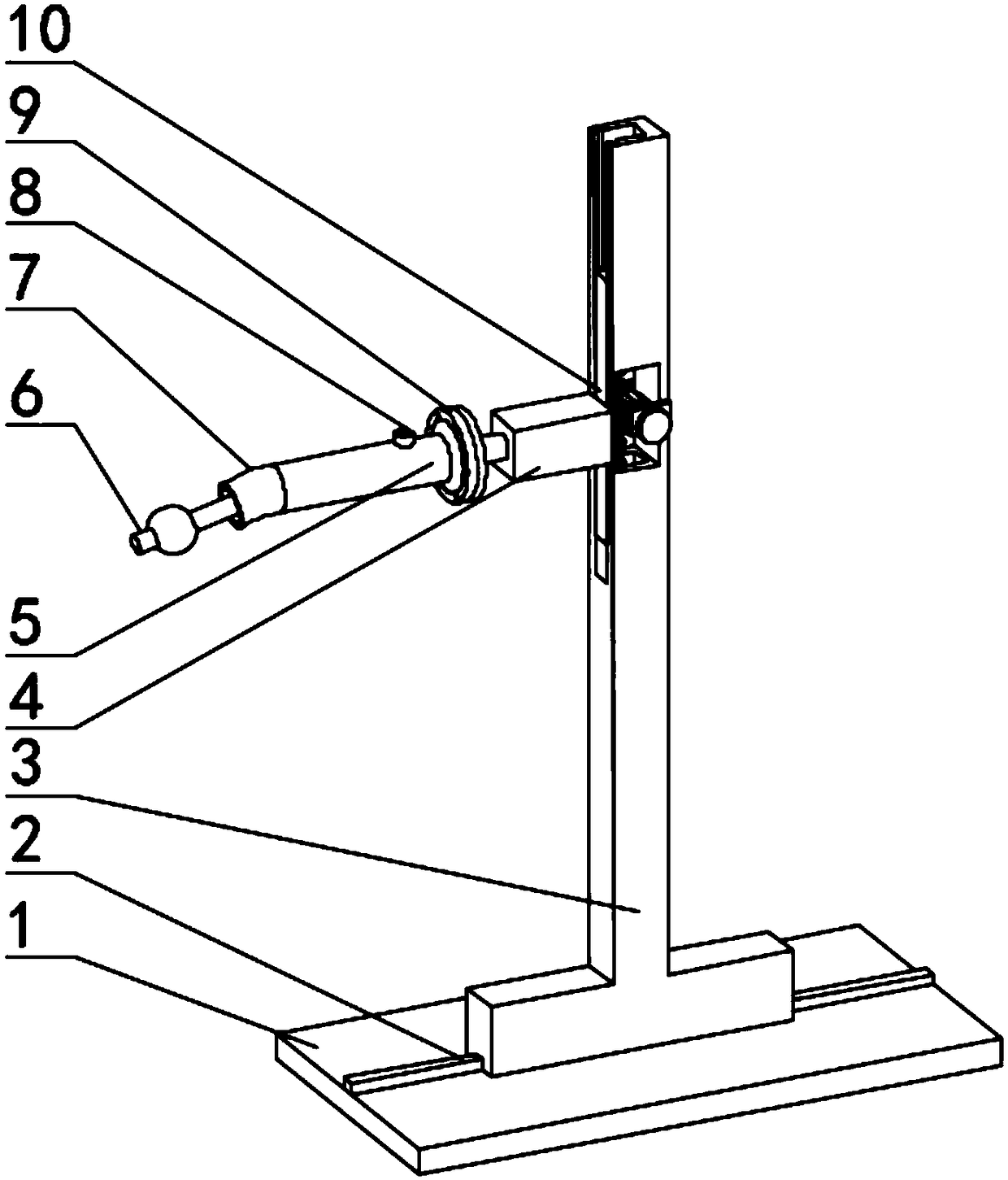

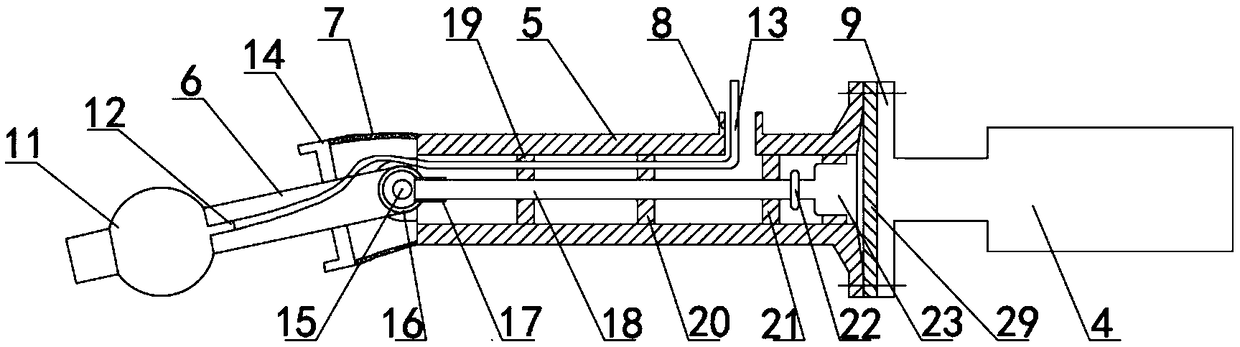

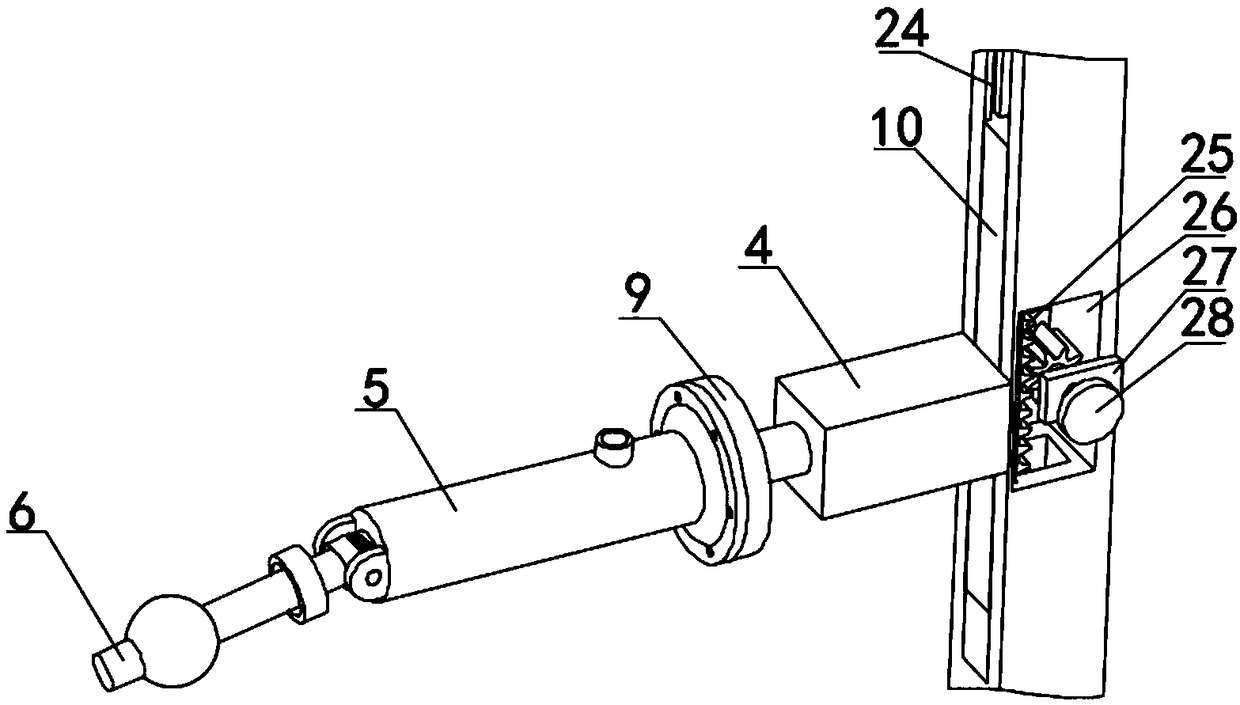

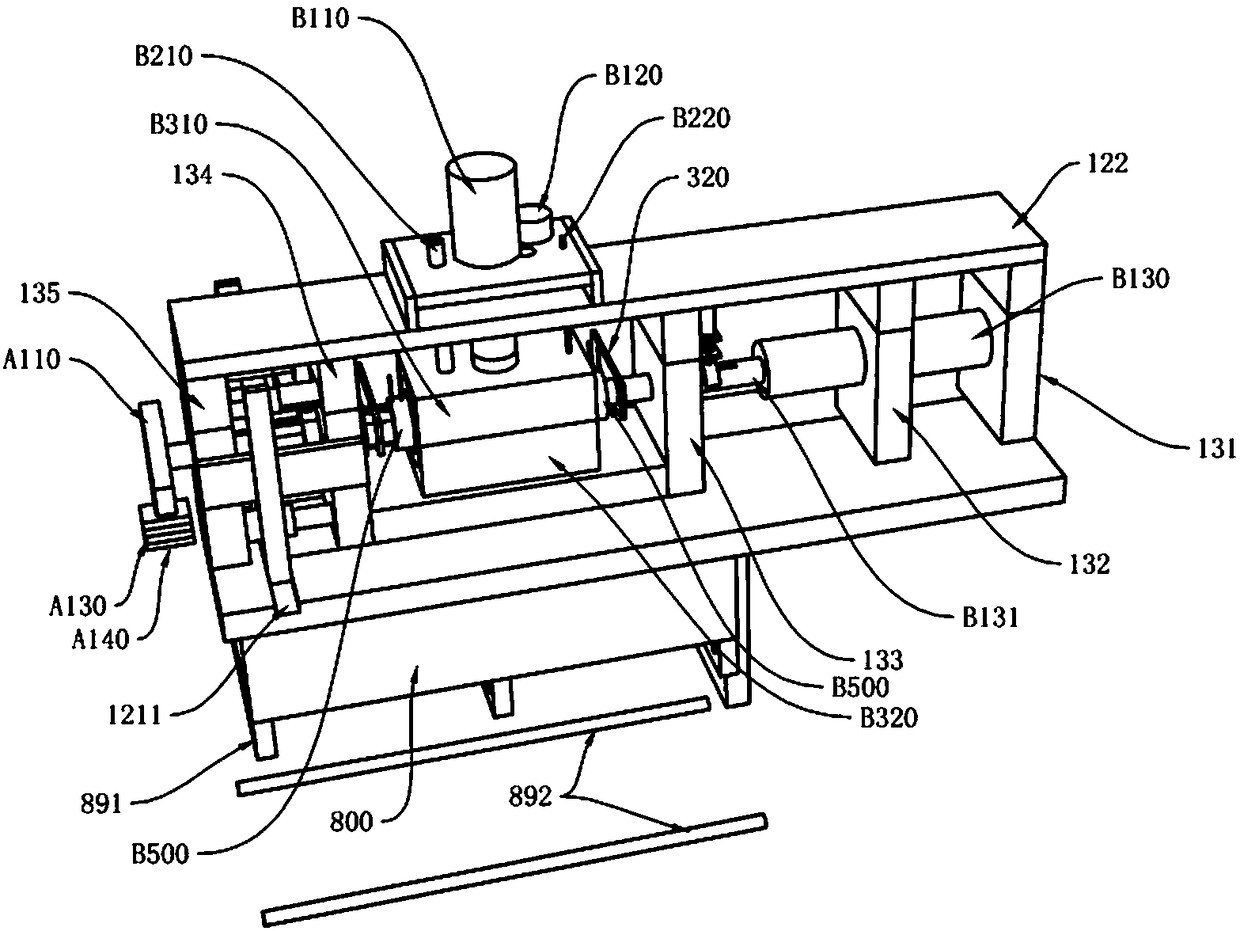

Automatic rotary uterine lifting device and method thereof

PendingCN109124745ARealize manual controlTake up a lot of spaceDiagnosticsObstetrical instrumentsUniaxial pressureMechanical engineering

The invention discloses an automatic rotary uterine lifting device and a method thereof, comprising a swinging structure, a rotating structure, an airbag assembly, a height adjusting structure and a support structure. The swing structure comprises a swing uterus rod, a crown wheel, a swing uterus rod shaft, a spur gear, a spur gear shaft, a second coupling and a second motor, wherein the head of the swing uterus rod is connected with a lifting cup and an air bag assembly. The rotating structure includes a rotating rod, a uniaxial pressure sensor, a first electric machine and a first coupling.The height adjusting structure comprises a sliding table, a sliding rail, a rack, a handle fixture and a handle, wherein a first motor of the rotating structure is connected with the sliding table ofthe height adjusting structure. The feeding system comprises a support seat, a rail and a support frame. The execution structure of uterine lifter can swing properly, rotate 360 degrees and feed forward and backward, which can solve the problem of low efficiency of manual adjustment of uterine lever, waste of human resources and simplify the operation process.

Owner:SHANDONG UNIV QILU HOSPITAL

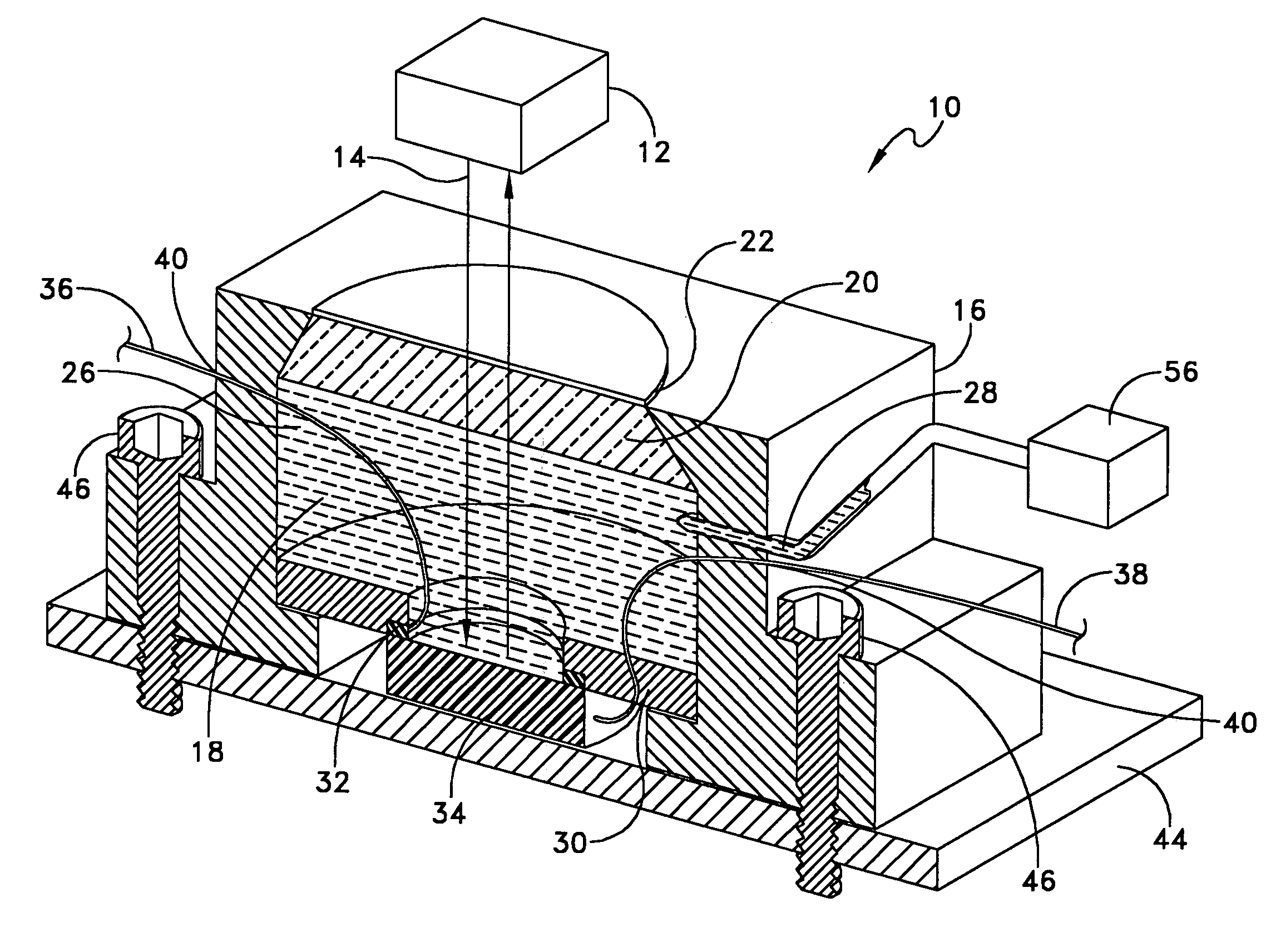

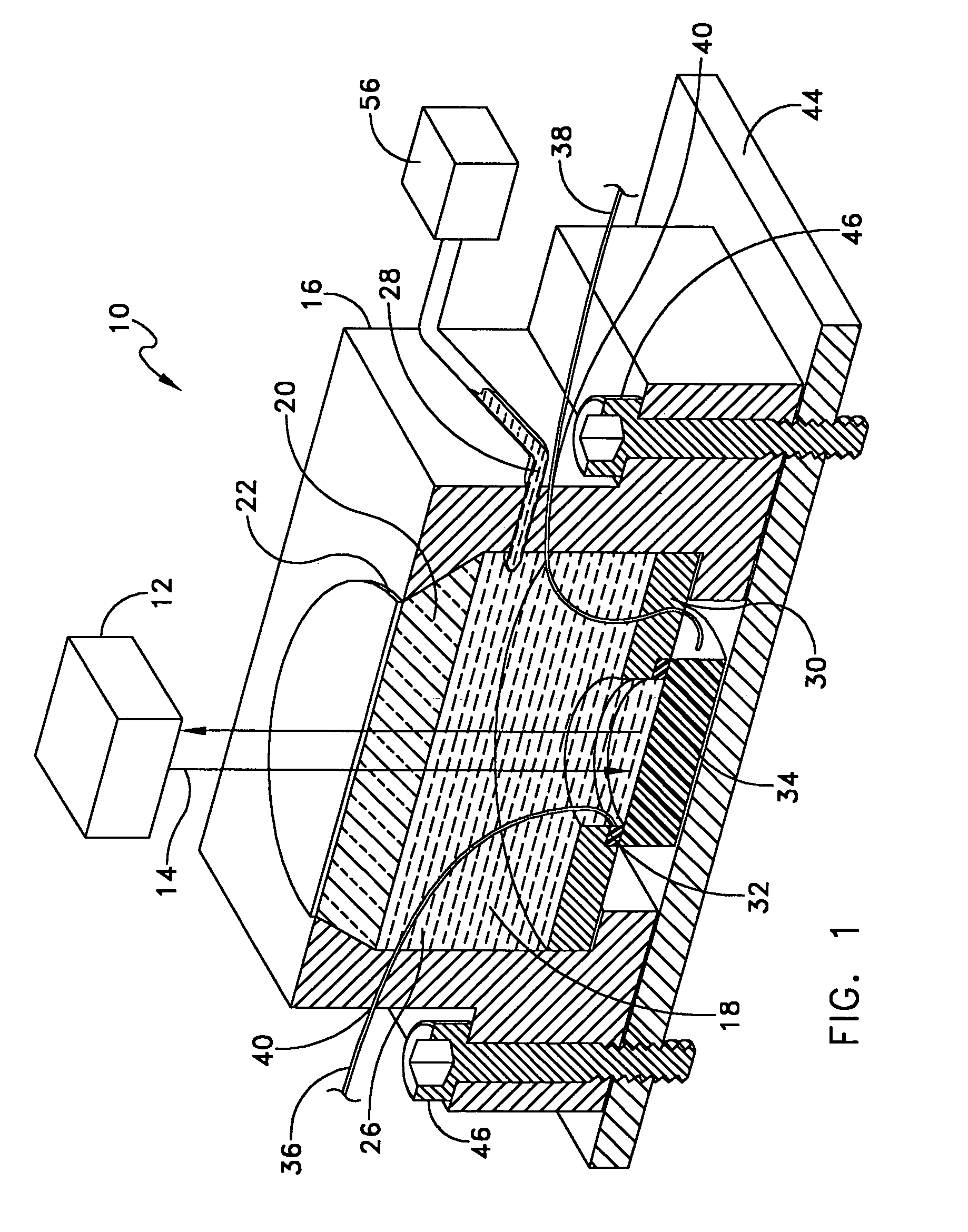

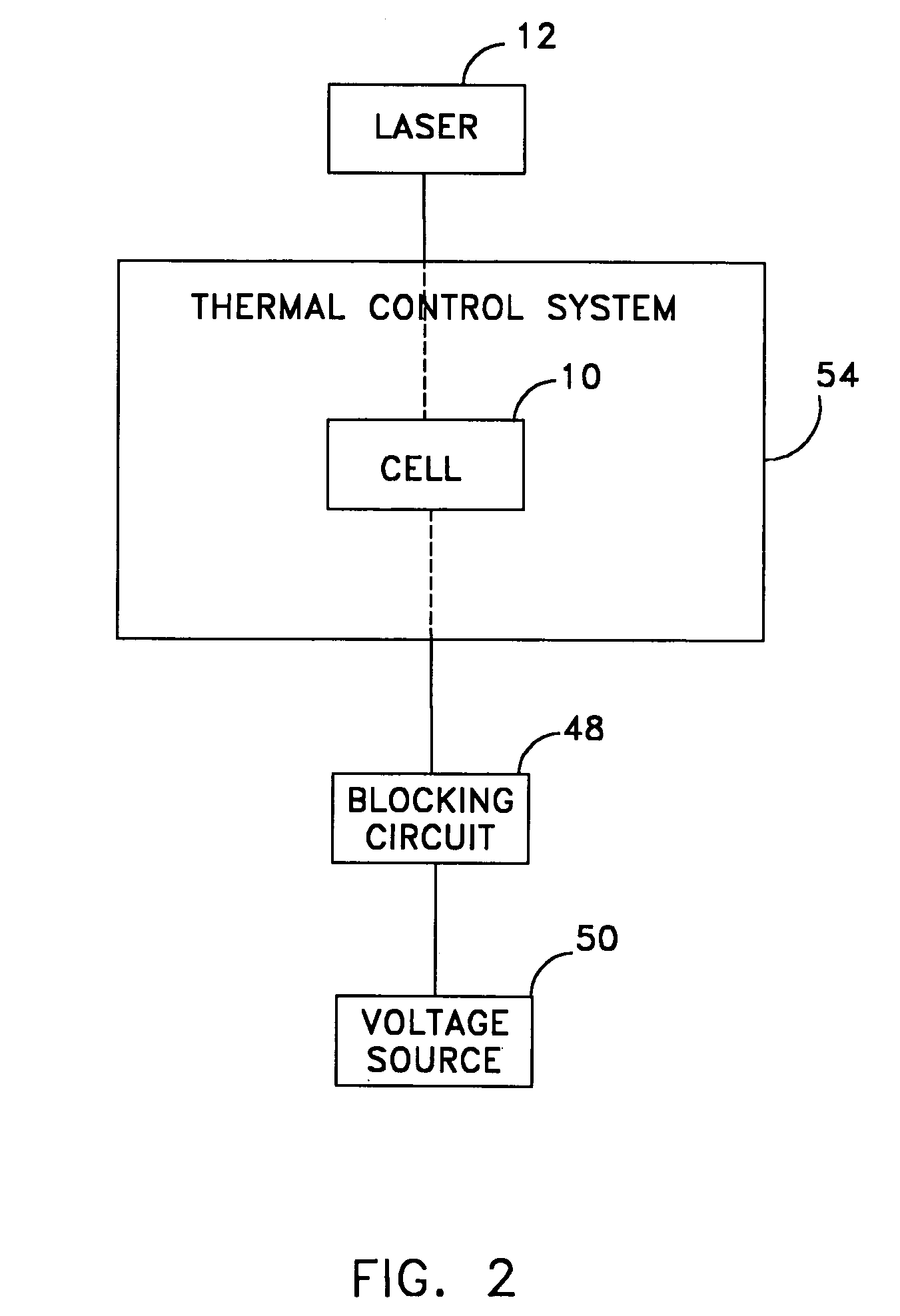

System and apparatus for measuring displacements in electro-active materials

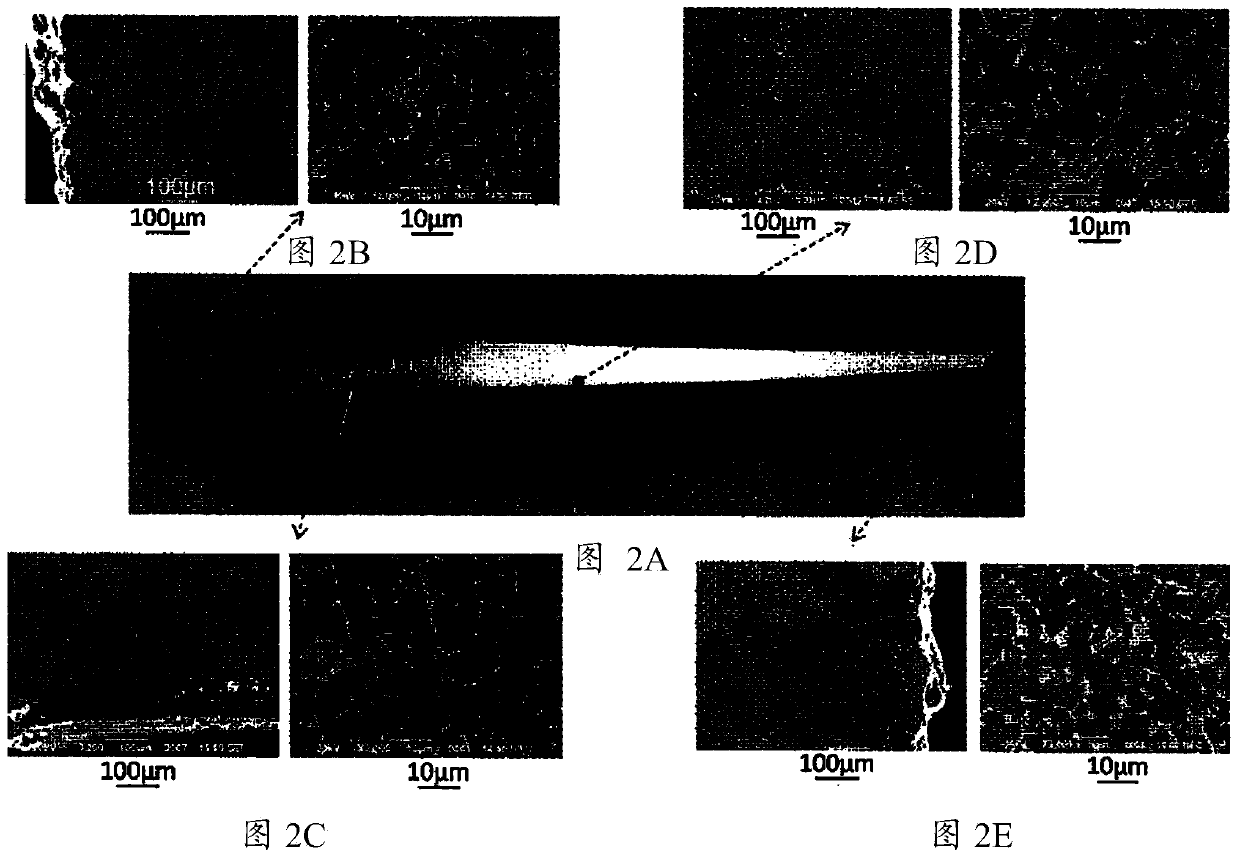

InactiveUS7236252B1Ensure reproducibilityTesting/calibration apparatusForce measurementThermal control systemUniaxial pressure

A device designed to apply uniaxial pressure to the surface of an electro-active material while simultaneously applying a current to the material under controlled temperature conditions and then measuring the displacement of the material by means of a laser interferometer. The device involves a housing with a chamber in which a sample of material is secured. The chamber has an aperture with a quartz window that allows the laser beam from the interferometer to pass. The sample is connected to electrodes and the chamber is filled with dielectric oil that applies the uniaxial pressure to one side of the sample. The device is placed onto a thermal control system. When the appropriate thermal and pressure conditions are established, current is applied to the sample and the interferometer measures the displacement.

Owner:THE US SEC OFTHE NAVY

Method for manufacturing a part having a complex shape by flash sintering, and device for implementing such a method

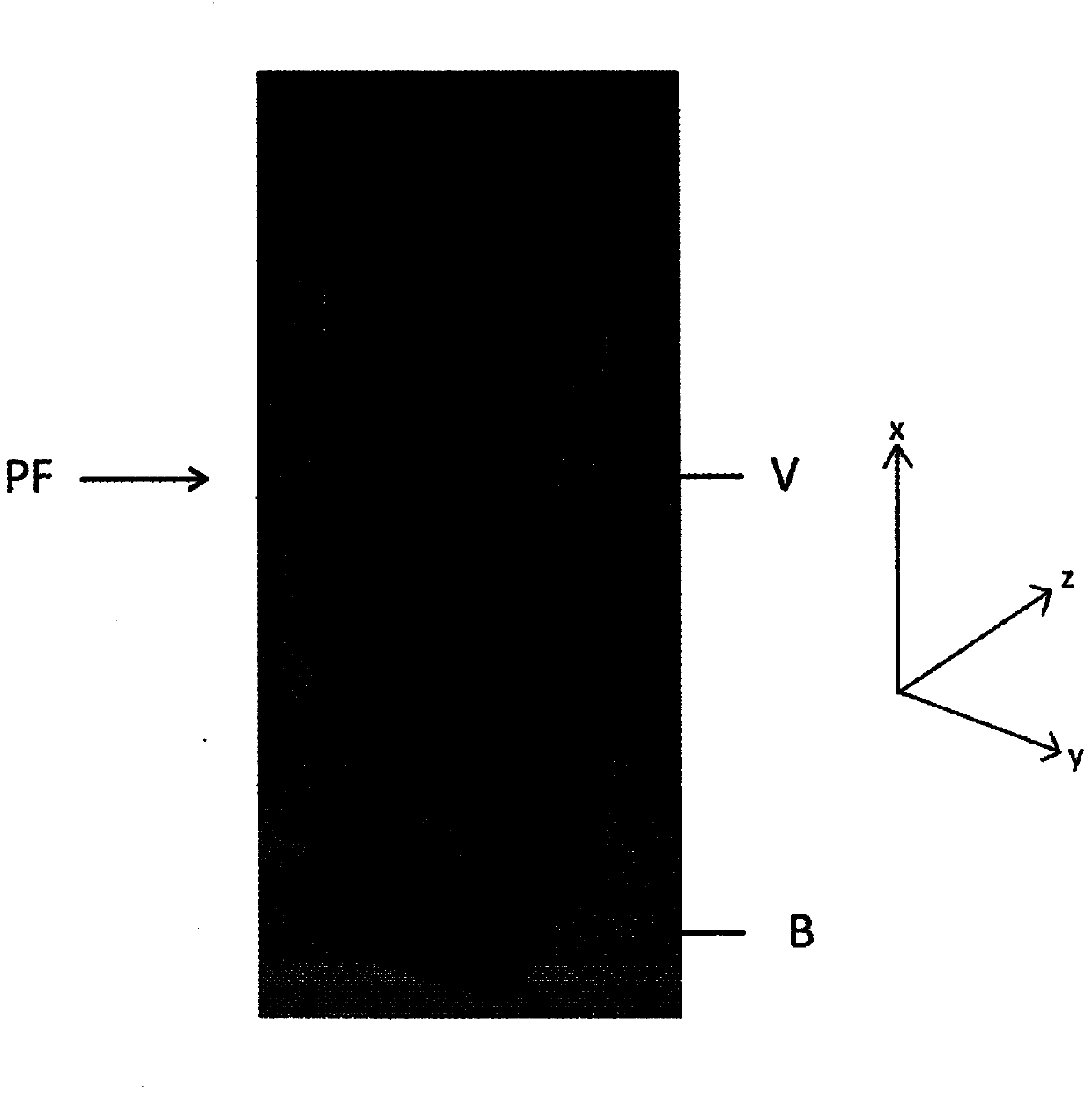

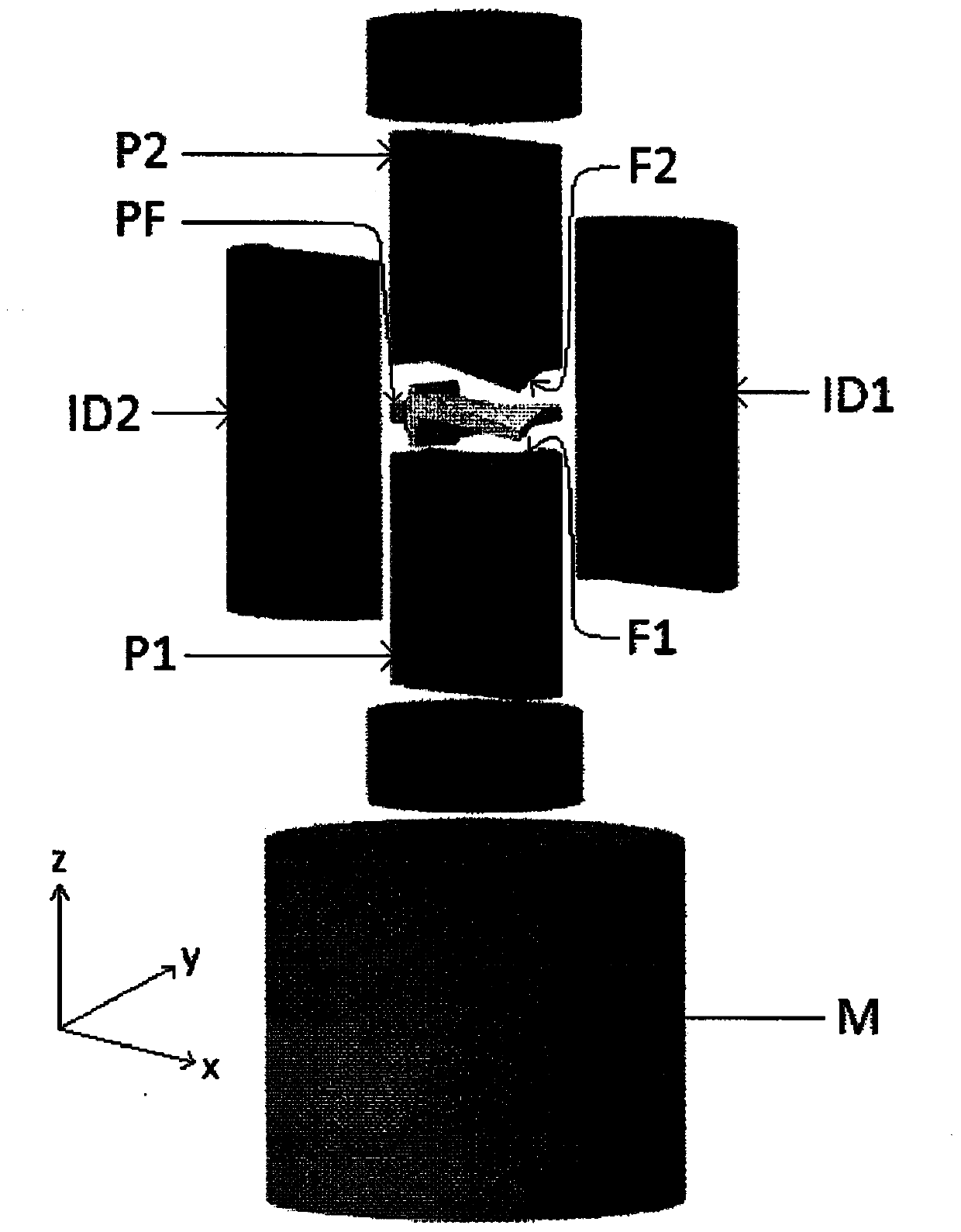

The invention relates to a method for manufacturing a metal, ceramic, or composite part (PF) by flash sintering, which comprises simultaneously applying, inside a die (M), a uniaxial pressure and an electric current to a device containing a powder constituent material, said uniaxial pressure being applied by means of at least two pistons (P1, P2) which slide toward one another inside said die and each of which has a bearing surface (F1, F2) contacting said material, said bearing surfaces engaging so as to define the shape of the part to be manufactured, characterised in that: said part has a complex shape, including at least one first slender portion (V), such as a rod, plate, bevel, or shell, and a second portion (B), such as a base, plinth, or solid part, which is not slender in the slender direction of said first portion, and in that said uniaxial pressure is applied in a direction (z) substantially parallel to the smallest dimension of said first portion of the part, or to one of the two smallest dimensions thereof if said part is a rod. The invention also relates to a device for implementing such a method, and to a turbine blade made of a TiAl intermetallic alloy or a metal / silicide composite sintered by flash sintering.

Owner:CENT NAT DE LA RECHERCHE SCI

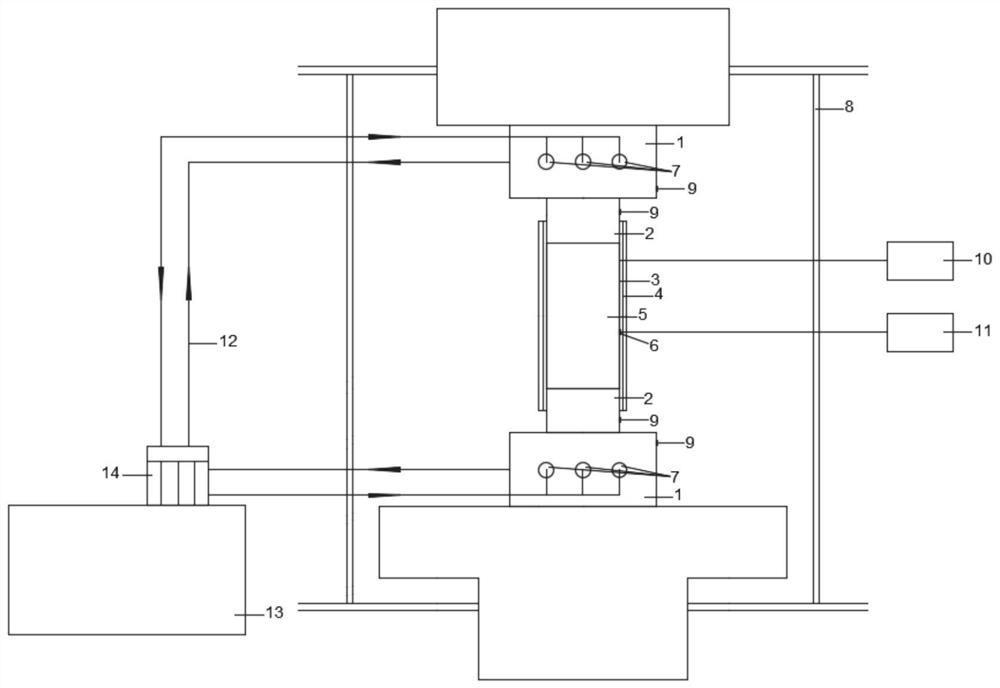

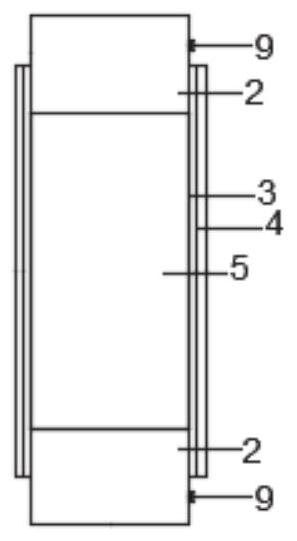

Heating constant-temperature device and method for high-temperature rock uniaxial compression test

PendingCN111721641AEvenly heatedEasy temperature controlMaterial strength using tensile/compressive forcesUniaxial compressionThermodynamics

The invention discloses a heating constant-temperature device for a high-temperature rock uniaxial compression test. The heating constant-temperature device comprises a heating constant-temperature unit, a force transmission unit, a protection unit and a monitoring unit. The heating constant-temperature unit, the force transmission unit and the monitoring unit are arranged in the protection unit;the monitoring unit can be in contact with a standard cylindrical rock test piece, the heating constant-temperature unit and the force transmission unit, the force transmission unit is connected witha press machine to apply pressure to the standard cylindrical rock test piece, the heating constant-temperature unit can wrap the standard cylindrical rock test piece, and the force transmission unitis further communicated with the protection unit to conduct cooling. The device can be used in cooperation with a uniaxial press to simulate the influence of different temperature environments on themechanical property of a rock test piece, and has the remarkable advantages of being easy to operate, easy to control and high in test efficiency, can effectively avoid test errors caused by hydraulicoil invasion and test element temperature rise, and can conveniently and accurately obtain basic mechanical parameters of high-temperature rock.

Owner:SHANDONG UNIV

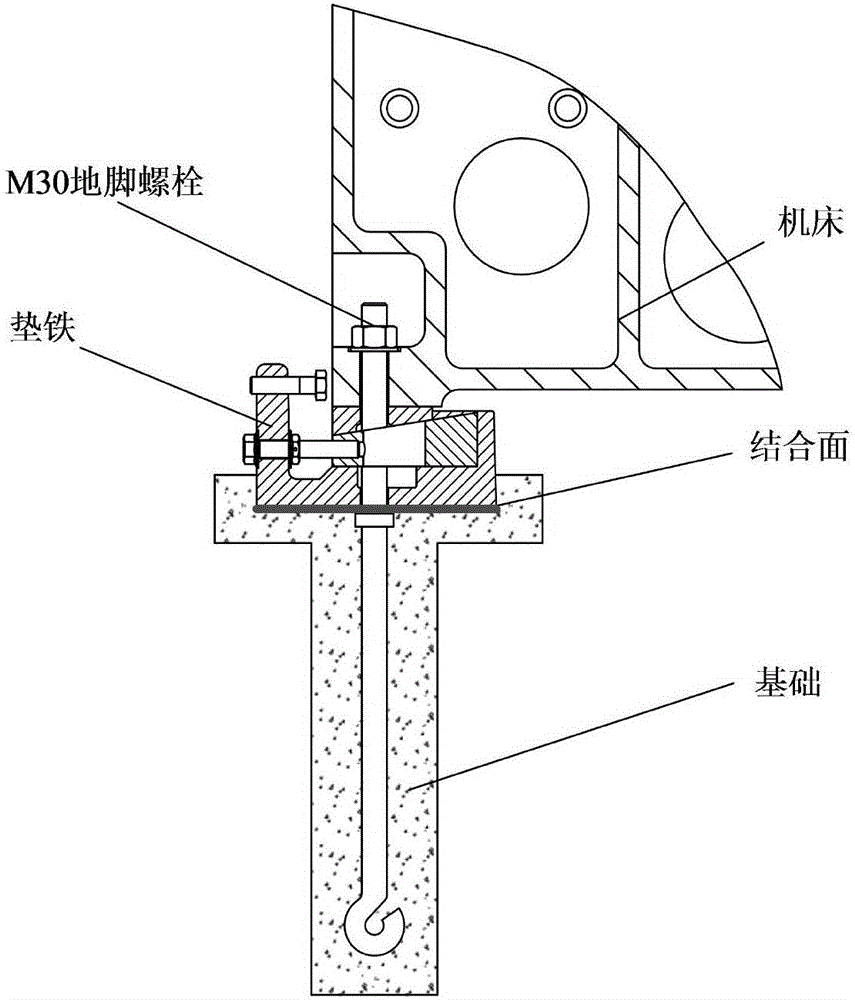

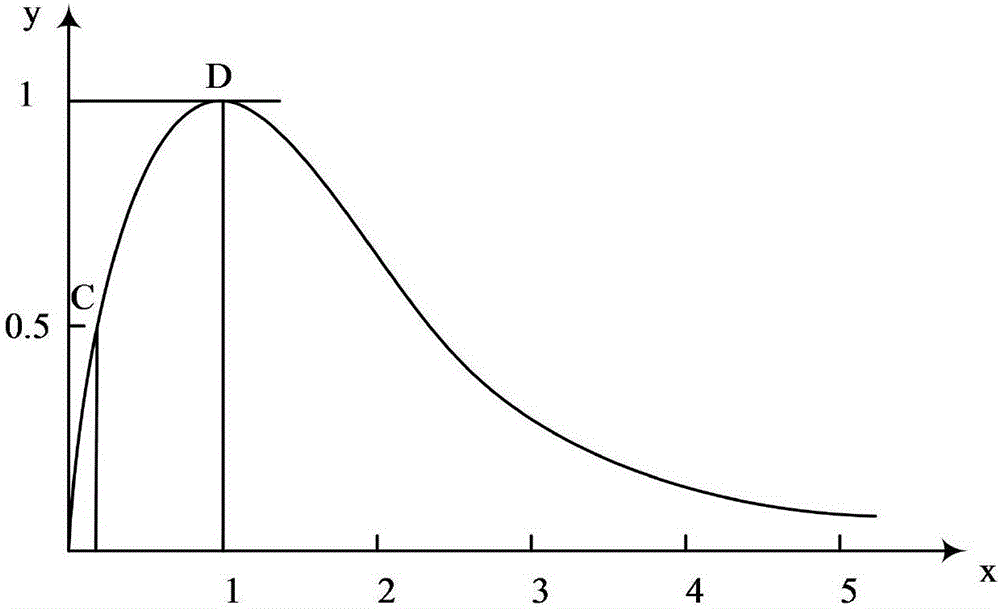

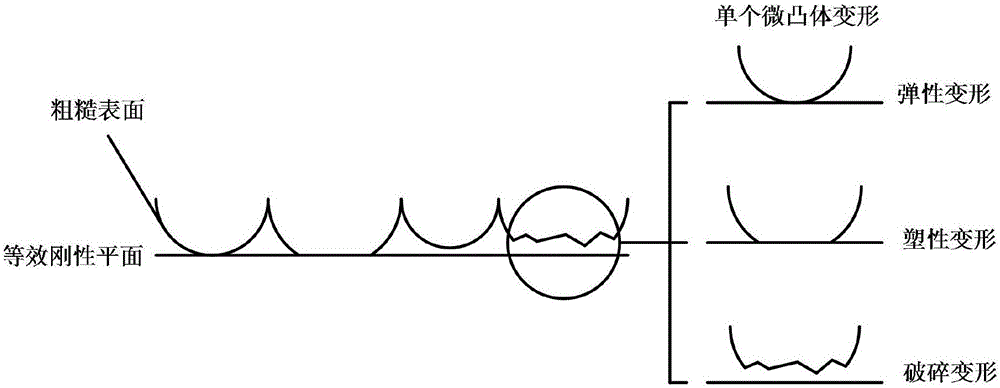

Machine tool-base joint surface contact stiffness calculation method in consideration of concrete asperity fracture

ActiveCN106768741AThe contact stiffness is obtainedImprove working precisionElasticity measurementContact pressureTheory model

The invention discloses a machine tool-base joint surface contact stiffness calculation method in consideration of concrete asperity fracture. According to the method, a fracture phenomenon is thought to be generated when the asperity on the surface of the concrete suffers from large load, the originally-fractured asperity load is shouldered by other un-fractured asperities, fracture of an asperity continues to happen, and so on and so forth, a balance state is achieved. Firstly, according to a uniaxial pressure stress-strain curve of a corresponding concrete mark, the relationship between the concrete critical fracture stress and a critical fracture area of a single asperity is built, a critical deformation area value of the single asperity is acquired, and based on a fractal theory, the bearing forces of the concrete asperity in elasticity, plasticity and fracture deformation stages are solved respectively. A finite element method is adopted to extract the contact pressure of a sample joint surface under different pretightening forces, the concrete-steel joint surface contact stiffness is acquired and calculated on the basis, simulation analysis is carried out by using ANSYS, and an experiment is designed to verify a theoretical model.

Owner:BEIJING UNIV OF TECH

Method for preparing microcrystal materials from waste residues

The invention provides a method for preparing microcrystal materials from waste residues. The method includes steps of 1), mixing the quartz sand waste residues, the metallurgical ore residues, the tailing residues and the sludge incineration ash residues with one another according to a mass ratio of 1:1:1:1 to obtain mixtures; 2), heating the mixtures in a high-temperature smelting furnace, smelting the mixtures at the temperature of 1400-1600 DEG C for 3-4 h to obtain molten glass and then carrying out water quenching treatment on the molten glass to obtain base glass; 3), grinding the base glass until the size of the base glass is smaller than 80 meshes, pressing the base glass in uniform directions by the aid of a ceramic press machine under the uniaxial pressures of 100 MPa to obtain rectangular samples, carrying out heat treatment on the samples in a heat treatment furnace and polishing and cutting the samples to obtain microcrystal glass. The method for preparing the microcrystal materials from the waste residues has the advantages that the method is high in waste residue utilization rate, and the waste residue utilization rate can reach 60-70%.

Owner:NANTONG MING YU NEW MATERIAL TECH CO LTD

High density stainless steel product and method for the preparation thereof

InactiveUS20030033903A1Easy to optimizeImprove sintered densityTransportation and packagingMetal-working apparatusHigh densityVolumetric Mass Density

The invention concerns a method of preparing compacts having a sintered density of above 7.3 g / cm3. This method comprises the steps of subjecting an annealed, water-atomised, essentially carbon free stainless steel powder, which in addition to iron, comprises at least 10% by weight of chromium, not more than 0.4%, preferably not more than 0.3% by weight of oxygen, not more than 0.05%, preferably not more than 0.02% and most preferably not more than 0.015% of carbon, not more than 0.5% by weight of Si and not more than 0.5% of impurities, to HVC compaction with an uniaxial pressure movement with a ram speed of at least 2 m / s, and sintering the green body.

Owner:HOGANAS AB

Polycrystalline magnesium oxide (MgO) sintered body and MgO sputtering target

ActiveUS8454933B2Increase chanceShrink poresLayered productsVacuum evaporation coatingSputteringHigh rate

The invention provides a polycrystal magnesium oxide (MgO) sintered body which is capable of having a sintered density close to a theoretical density thereof. The MgO sintered body exhibits excellent mechanical properties and heat conductivity, while reducing contamination of an atmosphere due to gas generation. The invention also provides a production method for the sintered body. The polycrystal MgO sintered body has a unique crystalline anisotropy in which (111) faces are oriented along a surface applied with a uniaxial pressure at a high rate. The polycrystalline MgO sintered body is obtained by a method which includes the steps of: sintering an MgO raw material powder, having a particle size of 1 μm or less, under a uniaxial pressure and then subjecting the sintered powder to a heat treatment under an atmosphere containing 0.05 volume % or more of oxygen, at a temperature of 1273 K or more for 1 minute or more.

Owner:NIPPON TUNGSTEN CORP +1

A low-temperature cold-sintering preparation method of a zirconia ceramic setter plate used for MnZn ferrite sintering

InactiveCN107473736AImprove mechanical propertiesImprove thermal shock resistanceCharge supportsSolventAqueous solution

Aiming at problems that zirconia ceramic sintering temperatures are high and densification is difficult to achieve, the invention provides a low-temperature cold-sintering preparation method of a zirconia ceramic setter plate. Nanometer partially stabled zirconia powder (3Y-PSZ) is adopted as raw material powder, water or an aqueous solution is adopted as a solvent, a 3Y-PSZ ceramic presintered compact is prepared at a presintering temperature lower than 200 DEG C under a high uniaxial pressure, and then dense zirconia ceramic (the efficiency of space filling of which is greater than 94.0%) is prepared at an extremely low sintering temperature (not more than 1100 DEG C) by adopting pressureless sintering, hot press sintering and hot isostatic pressing sintering processes respectively. The prepared zirconia ceramic has excellent mechanical properties and thermal shock resistance. The method is simple in process, environmentally friendly and extremely low in energy consumption, can be an ideal preparation method for the zirconia ceramic setter plate used for MnZn ferrite sintering, and has a wide industrial application prospect.

Owner:王诗阳

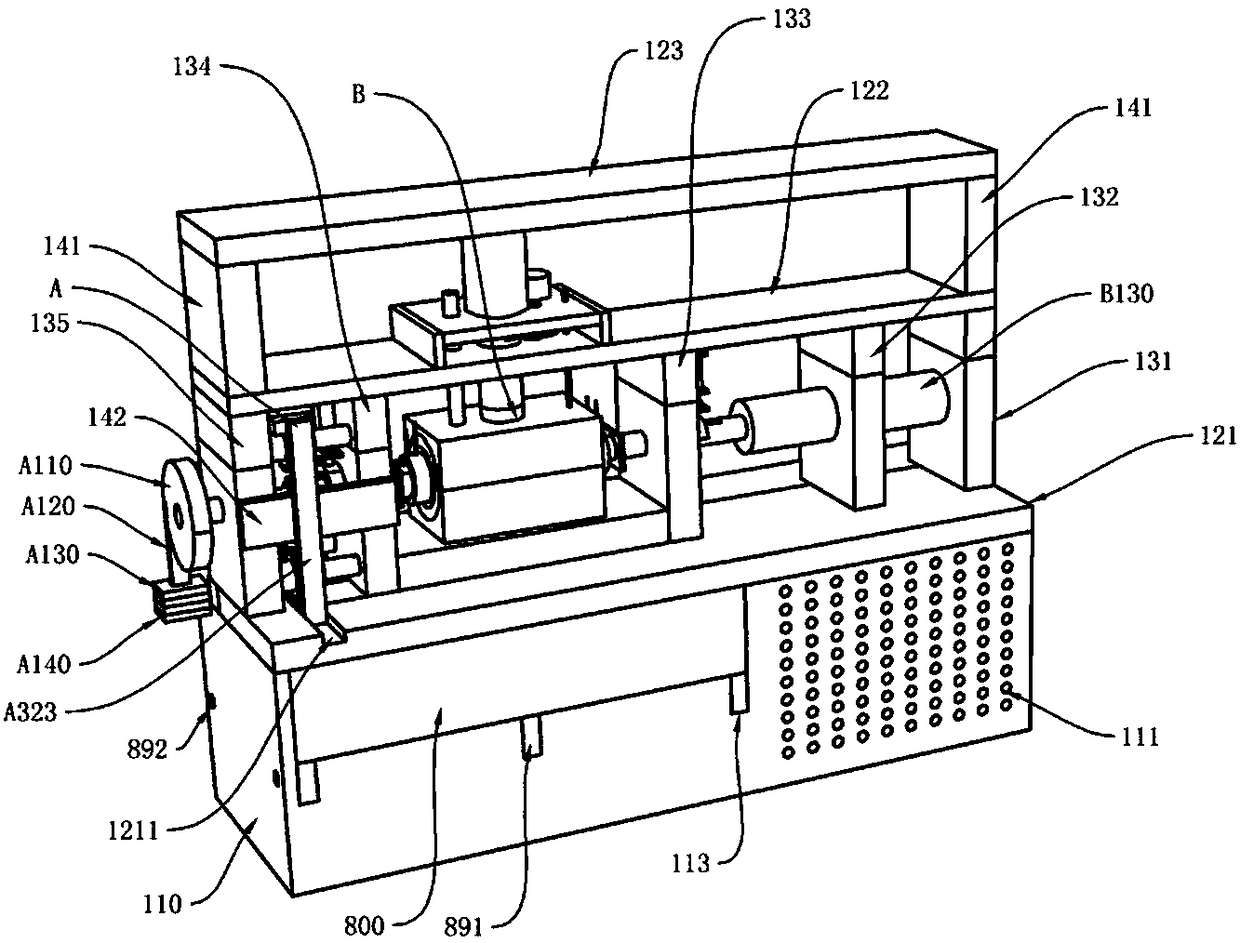

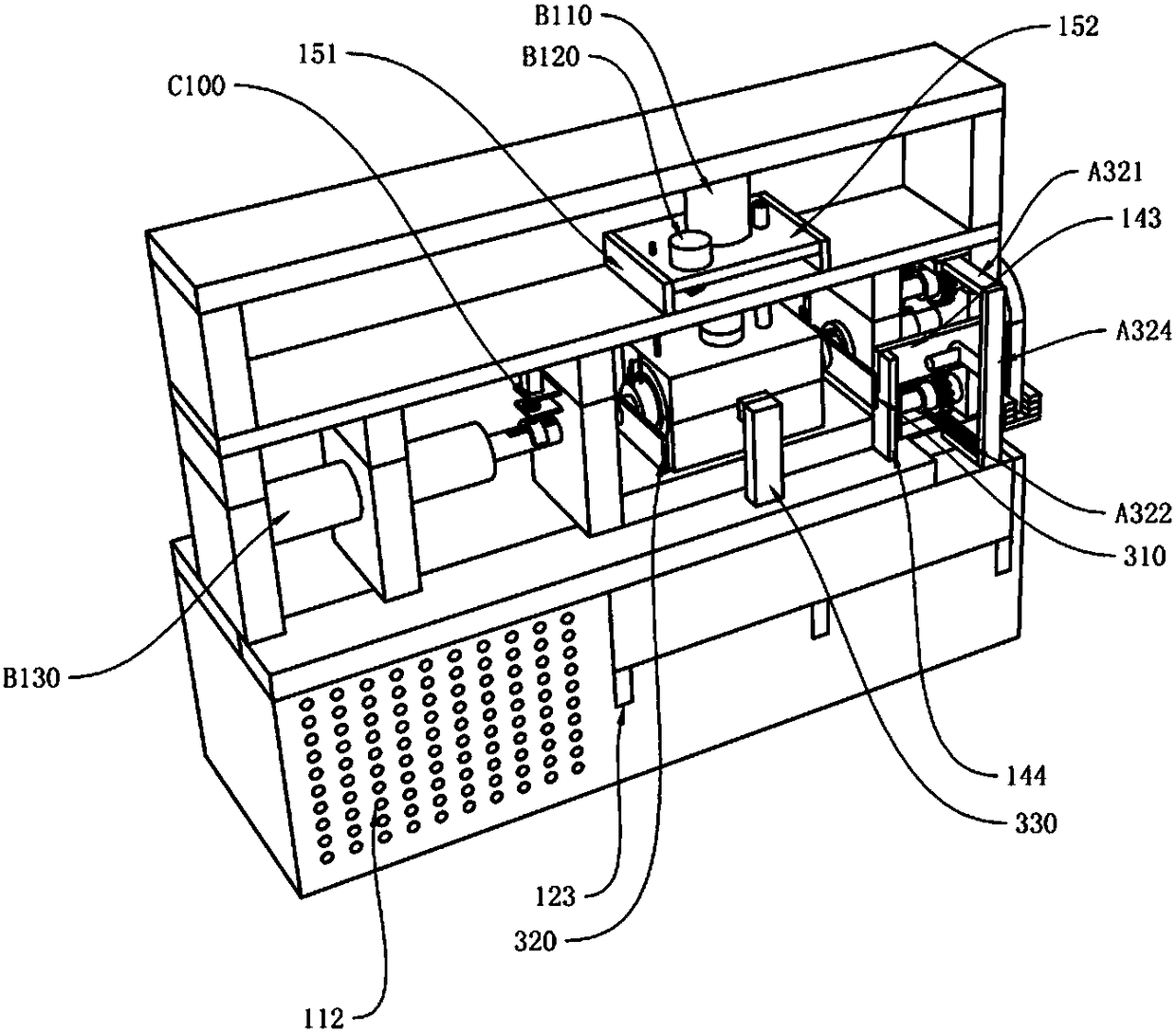

Experimental device for testing rock disturbance-delayed elasticity

ActiveCN108444831AImprove sealingEasy to take outMaterial strength using tensile/compressive forcesEngineeringUniaxial pressure

The invention discloses an experimental device for testing rock disturbance-delayed elasticity; the experimental device comprises a base assembly, a first partition plate is fixed on the top of the base assembly, the first partition plate is fixedly provided with a first vertical plate, a second vertical plate, a third vertical plate, a fourth vertical plate and a fifth vertical plate, and the tops of the first vertical plate, the second vertical plate, the third vertical plate, the fourth vertical plate and the fifth vertical plate are fixedly assembled with a second partition plate; two sixth vertical plates are fixed on the second partition plate, and a third partition plate is fixed on the top of the sixth vertical plate; the first vertical plate is fixedly assembled with the end of apressurized oil cylinder, the pressurized oil cylinder passes through the second vertical plate and is fixedly assembled with the second vertical plate; a pressurized telescopic shaft of the pressurized oil cylinder passes through the third vertical plate, and is fixedly assembled with pressure applying components, the pressure applying components are disposed on a loading component; the number ofthe pressure components is two, the pressure applying components are respectively distributed on both sides of the loading component, and one pressure applying component is fixedly assembled with oneend of the disturbance shaft of a disturbance component. The experimental device can detect a sample in the aspects of disturbance, relaxation, uniaxial pressure applying and delayed elasticity.

Owner:ANHUI UNIV OF SCI & TECH

High density stainless steel products and method for the preparation thereof

InactiveUS20040062674A1Less energySimple geometryTransportation and packagingMetal-working apparatusHigh densityMetallurgy

The invention concerns a method of preparing products having a sintered density of above 7.3 g / cm<3>. This method comprises the steps of subjecting a water-atomised, stainless steel powder to HVC compaction with an uniaxial pressure movement with a ram speed of at least 2 m / s, and sintering the green body.

Owner:HOGANAS AB

High density u02 and high thermal conductivity uo2 composites by spark plasma sintering (SPS)

Owner:UNIV OF FLORIDA RES FOUNDATION INC

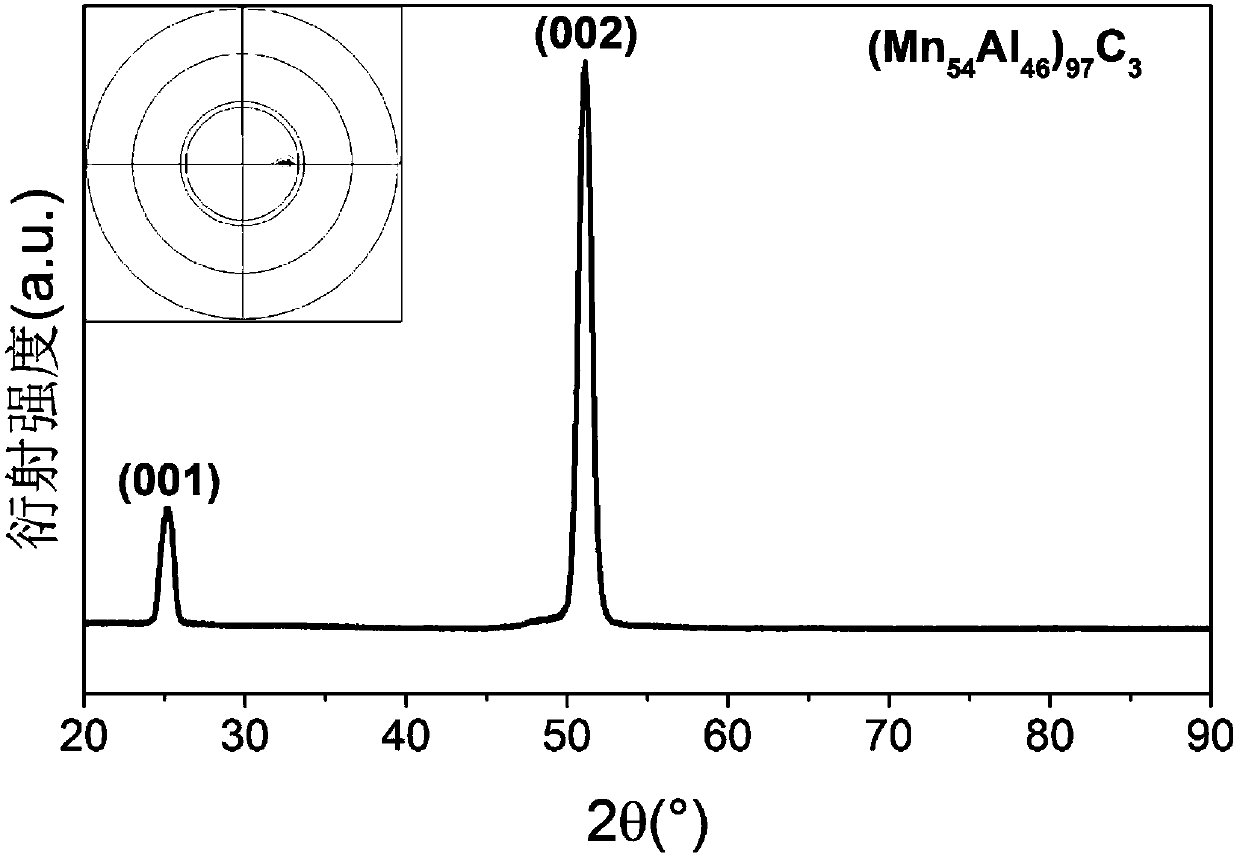

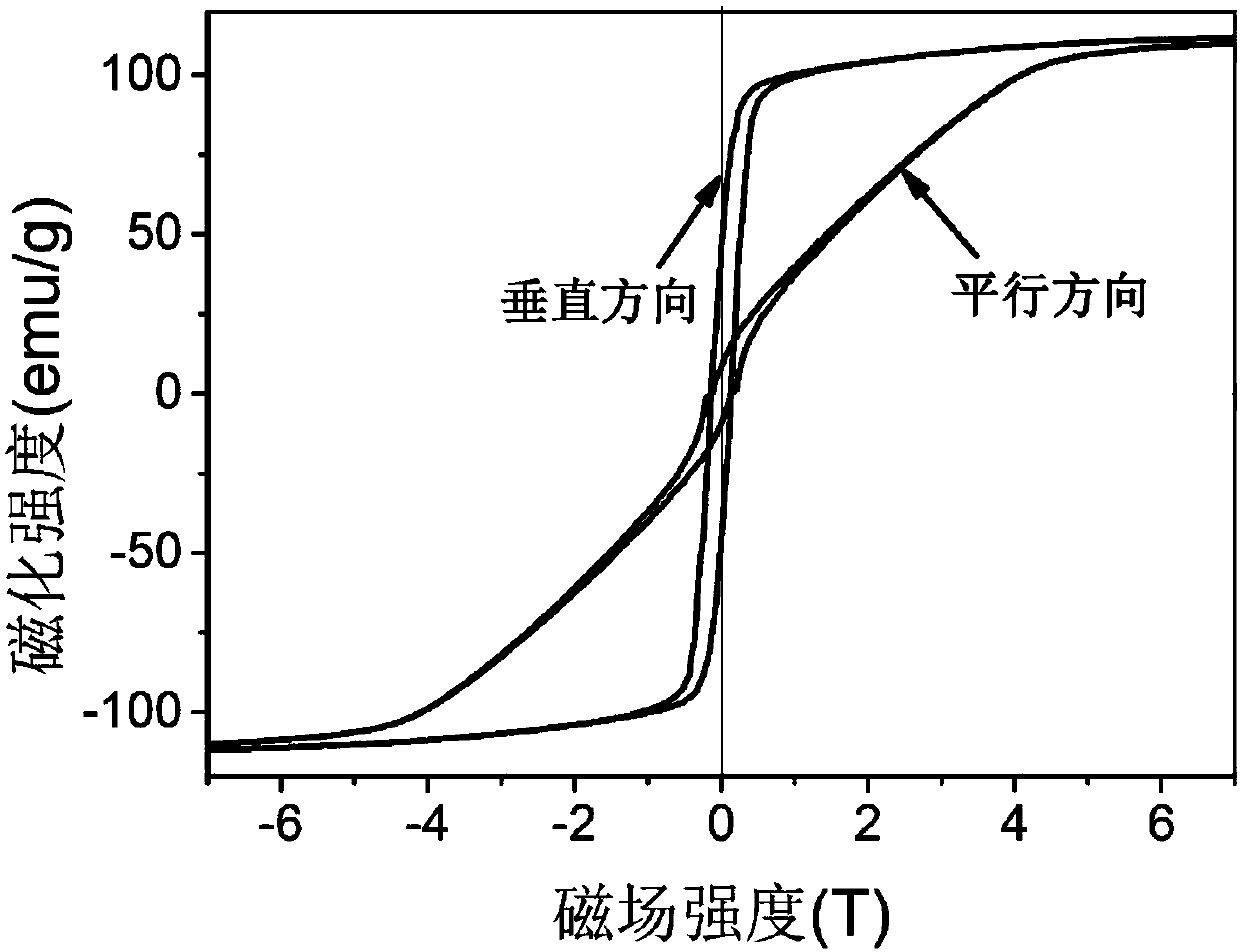

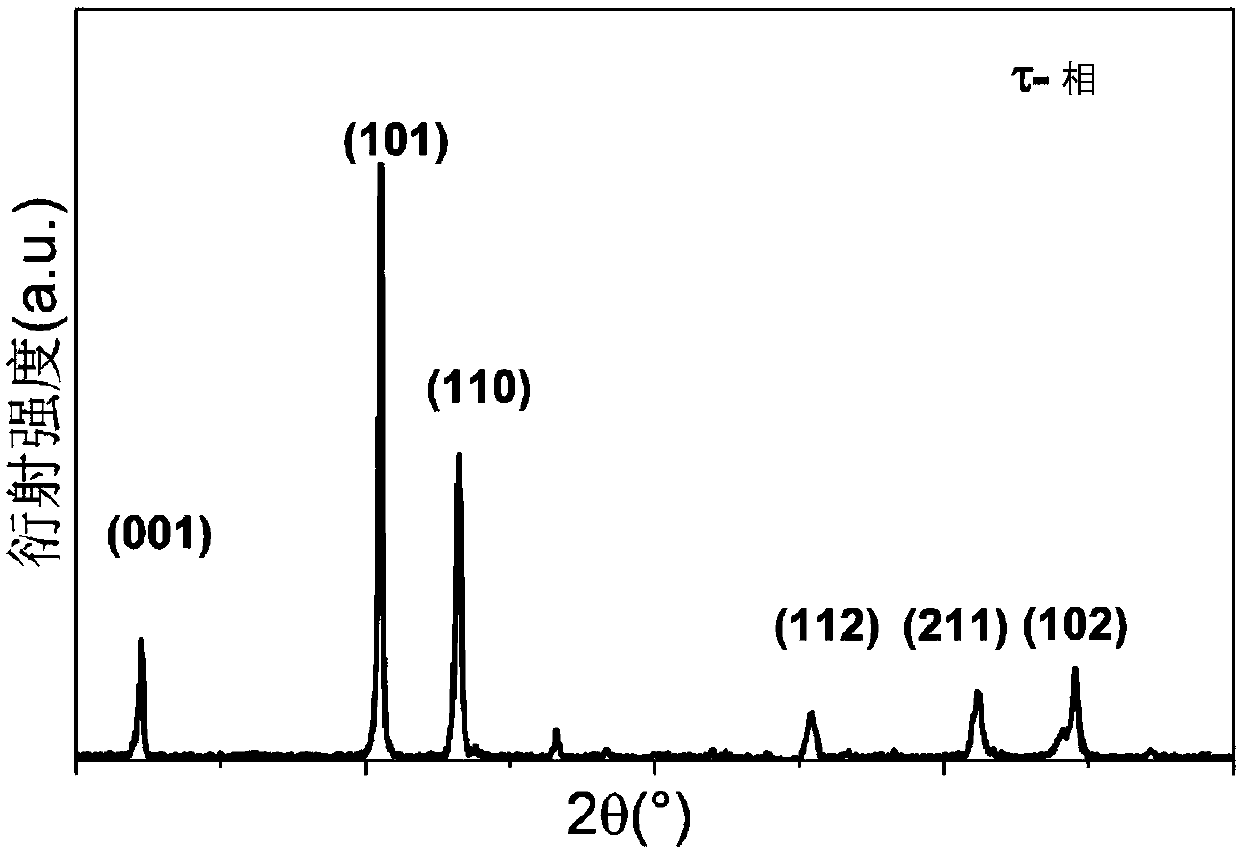

Method for preparing anisotropy MnAlC single variant through uniaxial pressure constraint transformation

InactiveCN108281247AElimination of twinningAnisotropy hasInductances/transformers/magnets manufactureMagnetic materialsConstraint transformationMagnetization

The invention provides a method for preparing an anisotropy MnAlC magnetic single variant through uniaxial pressure constraint transformation and the MnAlC single variant prepared by the method. The method comprises the steps of carrying out smelting, rod casting and single crystal growth on MnAlC raw materials to form a MnAlC-epsilon phase single crystal; and annealing the MnAlC-epsilon phase single crystal for 3-10 min under uniaxial pressure of 250-350MPa and temperature of 580-680 degrees centigrade, thereby preparing a MnAlC-tau phase single variant. The MnAlC-tau phase single variant prepared by the method has saturation magnetization intensity exceeding 100emu / g and complete anisotropy, and an equivalent magnetocrystalline anisotropy field is greater than 4T. The method and the MnAlC single variant have the advantages that (1), bicrystals in alloy can be effectively eliminated, the single variant organization is realized, the material has anisotropy, and the relatively good permanent magnet performance is obtained; (2), the technology is simple, and bad influences of produced microdefects and precipitated equilibrium phases on the magnetic performance can be completely avoided.

Owner:BEIHANG UNIV

Method for manufacturing a titanium-aluminum alloy part

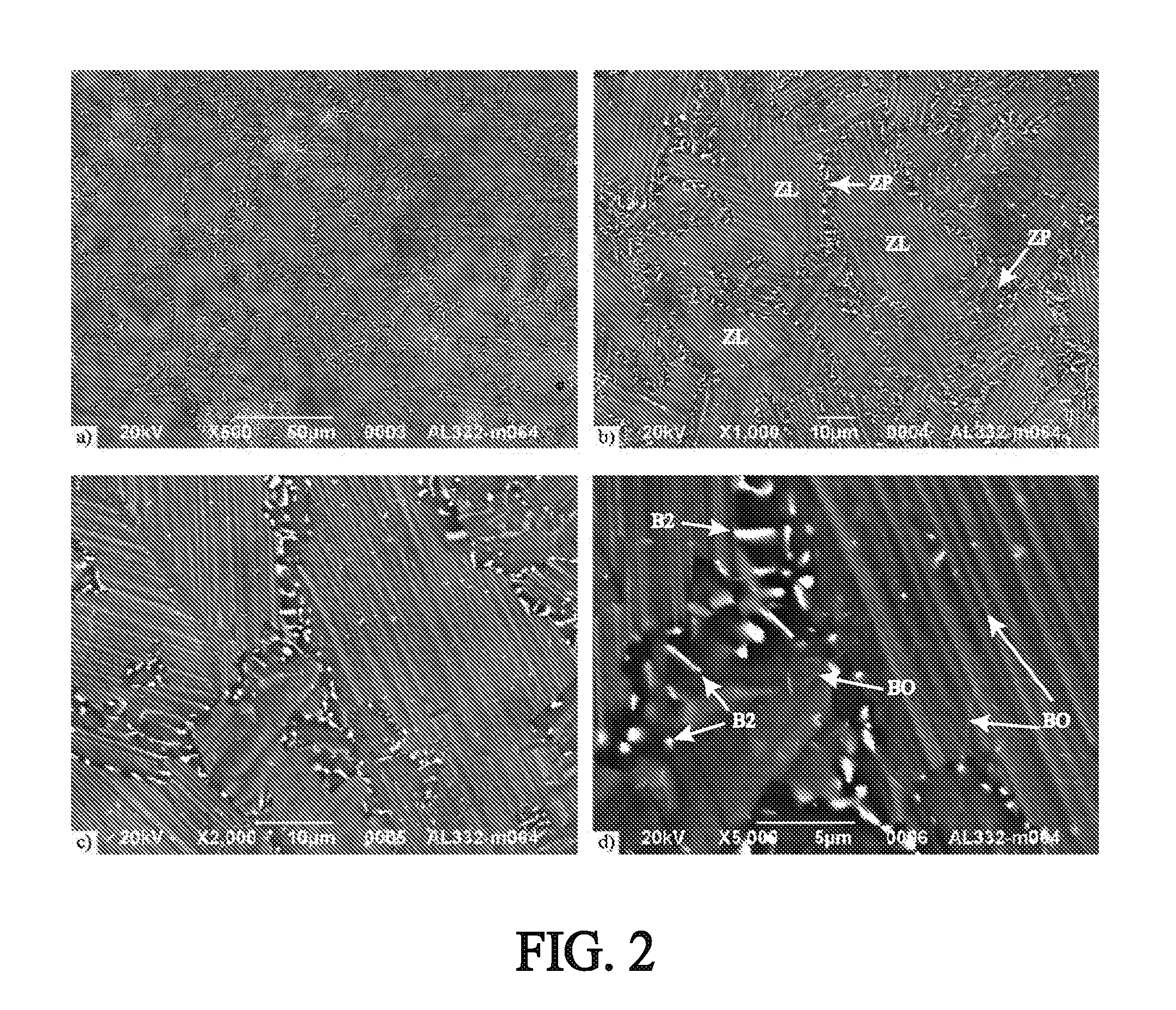

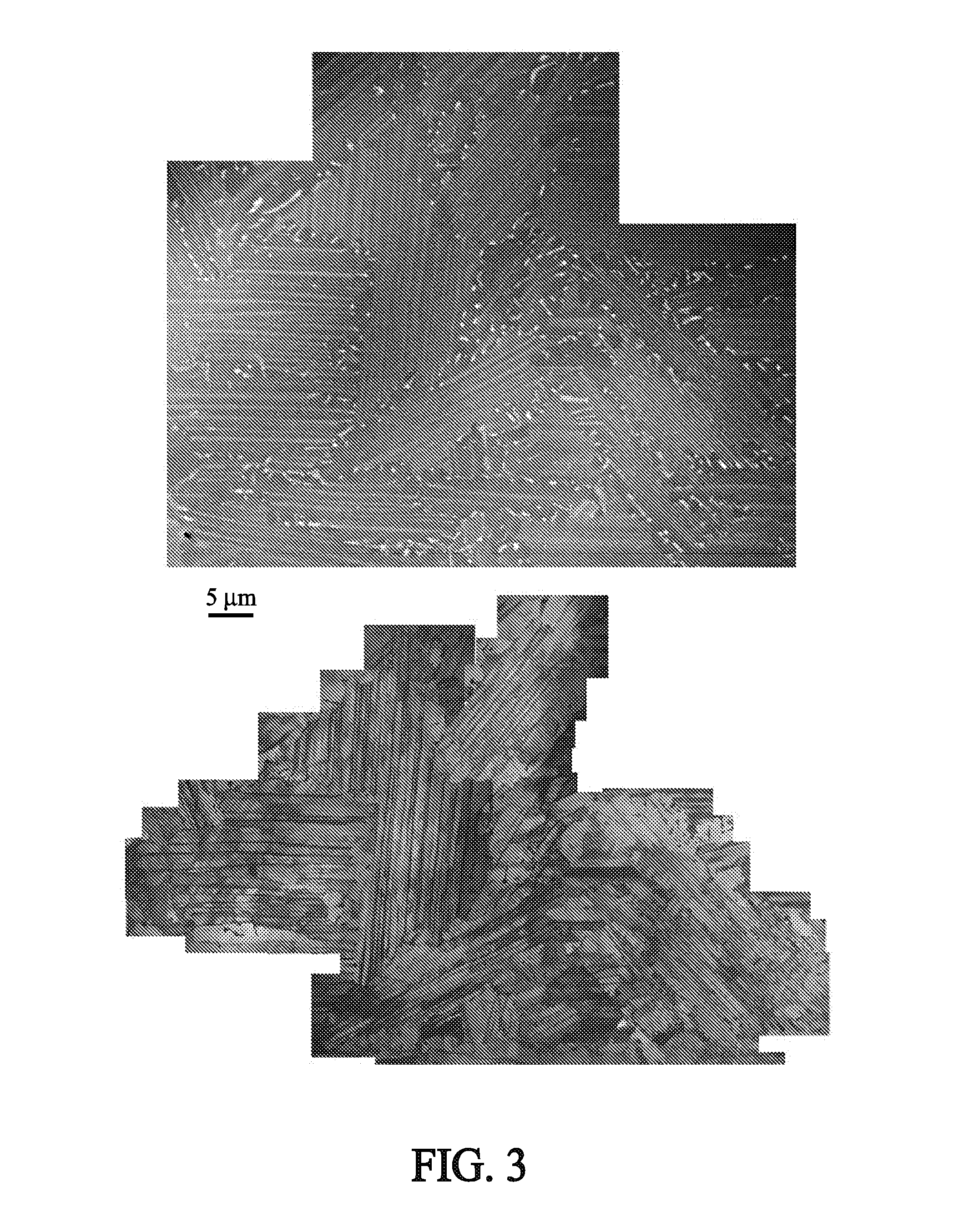

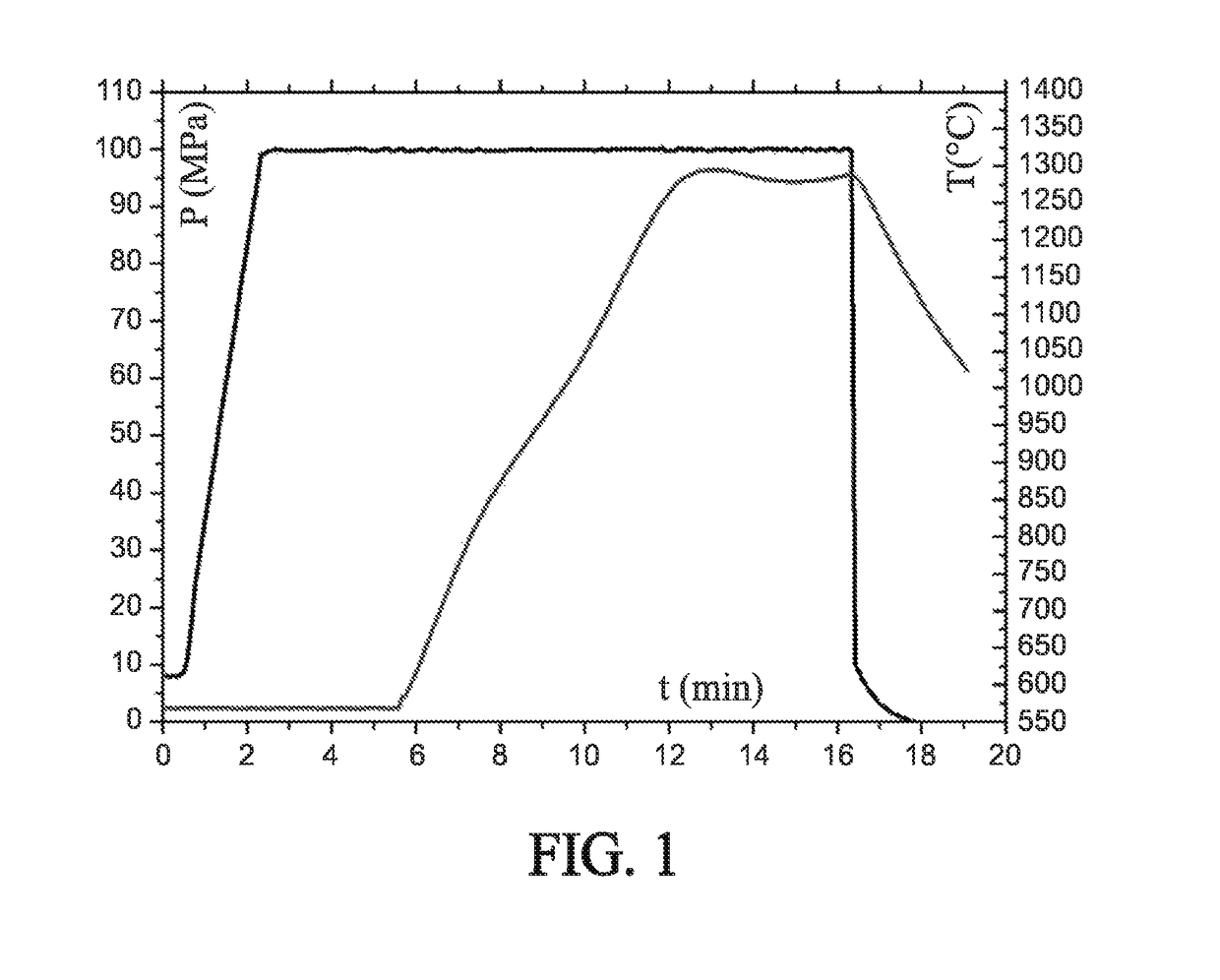

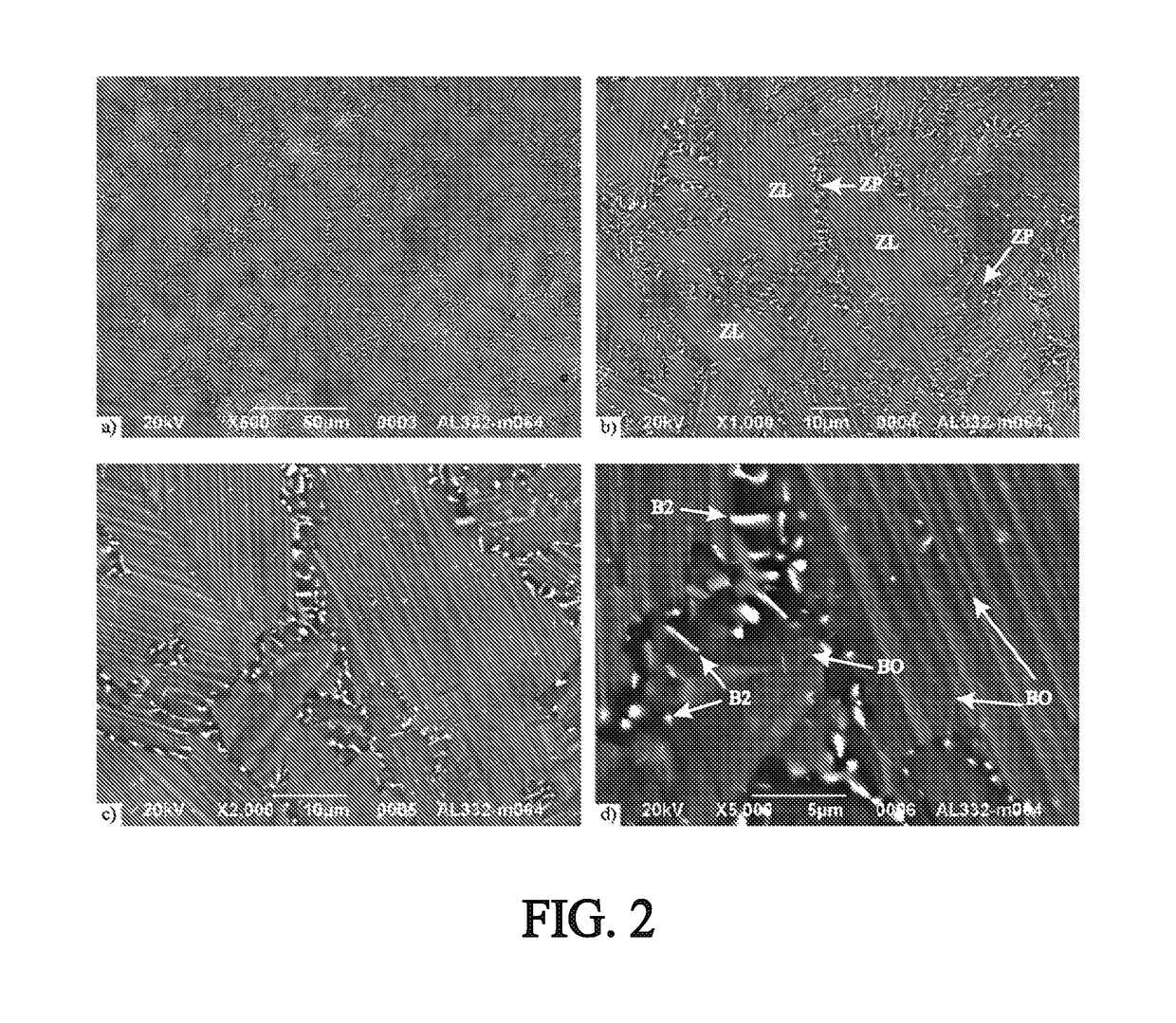

ActiveUS20160121400A1Reduce disadvantagesMaintain good propertiesTurbinesBlade accessoriesRheniumNiobium

A method manufactures a metal alloy part by spark plasma sintering. The method includes the simultaneous application, inside a die, of a uniaxial pressure and of an electric current to a powder component material that has the following composition: 42 to 49% aluminum, 0.05 to 1.5% boron, at least 0.2% of at least one element selected from tungsten, rhenium and zirconium, optionally 0 to 5% of one or more elements selected from chromium, niobium, molybdenum, silicon and carbon, the balance being titanium and the total of the elements without aluminum and titanium being between 0.25 and 12%.

Owner:CENT NAT DE LA RECHERCHE SCI +1

Method for manufacturing a titanium-aluminum alloy part

ActiveUS10183331B2Easy to solidifyImprove mechanical propertiesTurbinesBlade accessoriesRheniumNiobium

A method manufactures a metal alloy part by spark plasma sintering. The method includes the simultaneous application, inside a die, of a uniaxial pressure and of an electric current to a powder component material that has the following composition: 42 to 49% aluminum, 0.05 to 1.5% boron, at least 0.2% of at least one element selected from tungsten, rhenium and zirconium, optionally 0 to 5% of one or more elements selected from chromium, niobium, molybdenum, silicon and carbon, the balance being titanium and the total of the elements without aluminum and titanium being between 0.25 and 12%.

Owner:CENT NAT DE LA RECHERCHE SCI +1

Corrosion-resistant member for semiconductor manufacturing apparatus and method for manufacturing the same

ActiveUS20130022526A1Reduce etch rateReduce the amount requiredElectric discharge tubesSemiconductor/solid-state device manufacturingAir atmosphereSlurry

A mixed powder was prepared by weighing Yb2O3 and SrCO3 in such a way that the molar ratio became 1:1. The resulting mixed powder was subjected to uniaxial pressure forming, so as to produce a disc-shaped compact. The compact was heat-treated in an air atmosphere, so that a complex oxide was synthesized. The resulting complex oxide was pulverized. After the pulverization, a slurry was taken out and was dried in a nitrogen gas stream, so as to produce a synthesized powder material. The resulting synthesized powder material was subjected to uniaxial pressure forming, so as to produce a disc-shaped compact. The resulting compact was fired by a hot-press method, so as to obtain a corrosion-resistant member for semiconductor manufacturing apparatus. The resulting corrosion-resistant member was made from a SrYb2O4.

Owner:NGK INSULATORS LTD

Super-wear-resistant tungsten carbide hard alloy discharge plasma sintering method

InactiveCN108276001AOvercome the disadvantage of gradual decrease in hardnessGuaranteed toughnessWear resistantAlloy

The invention discloses a super-wear-resistant tungsten carbide hard alloy discharge plasma sintering method. The method comprises the following steps: adding Co powder with the purity of 99.9 percentand the granularity of 20 to 30 nm and CaC2 powder with the purity of 99.9 pecent and the granularity of 40 to 50 nm into binding phase-free nano WC powder which is protected by vacuum or inert gas and is used as a raw material; putting the mixture into a high-intensity graphite mold for compaction, and placing the mixture between an upper electrode and a lower electrode of an SPS discharge plasma sintering device; vacuumizing the die till the vacuum degree is 6 Pa, increasing uniaxial pressure to 50 MPa within a tolerance range of the graphite mold, then heating the graphite mold, and preserving the heat for 5 min to obtain a phase-free nano tungsten carbide hard alloy. According to the preparation method disclosed by the invention, a tungsten carbide material is sintered by adopting anSPS technology; the adding amount of Co is maintained at the content close to the content of 1 percent during low-Co sintering; furthermore, CaC2 is added into a sintering aid, so that the shortcomingthat the hardness of WC is gradually reduced with the increase of the Co content; furthermore, the content of Co is more than 1 percent, so that the phase-free nano tungsten carbide hard alloy has the advantage of toughness during cobalt sintering.

Owner:CHINA NAT OFFSHORE OIL CORP +1

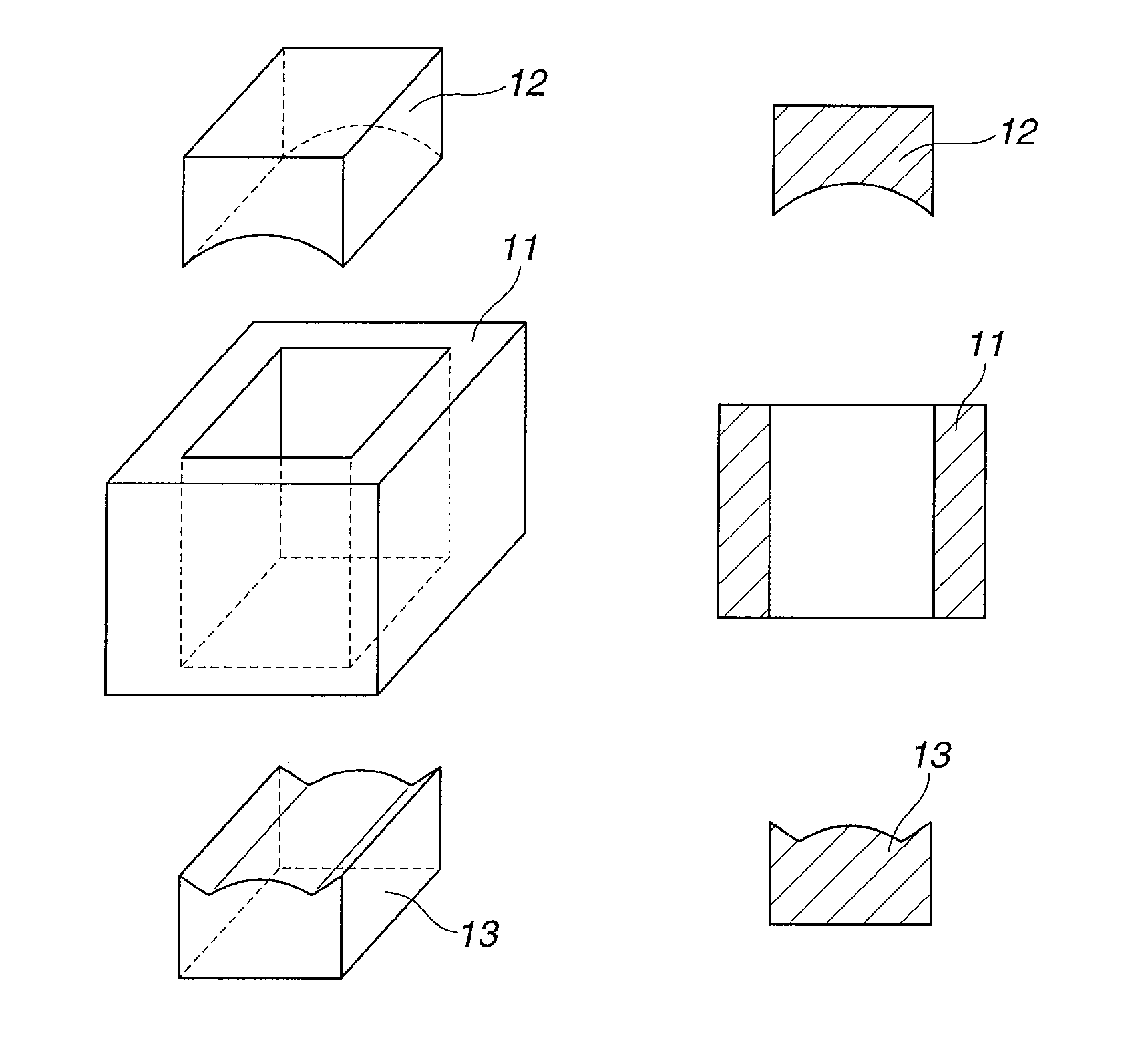

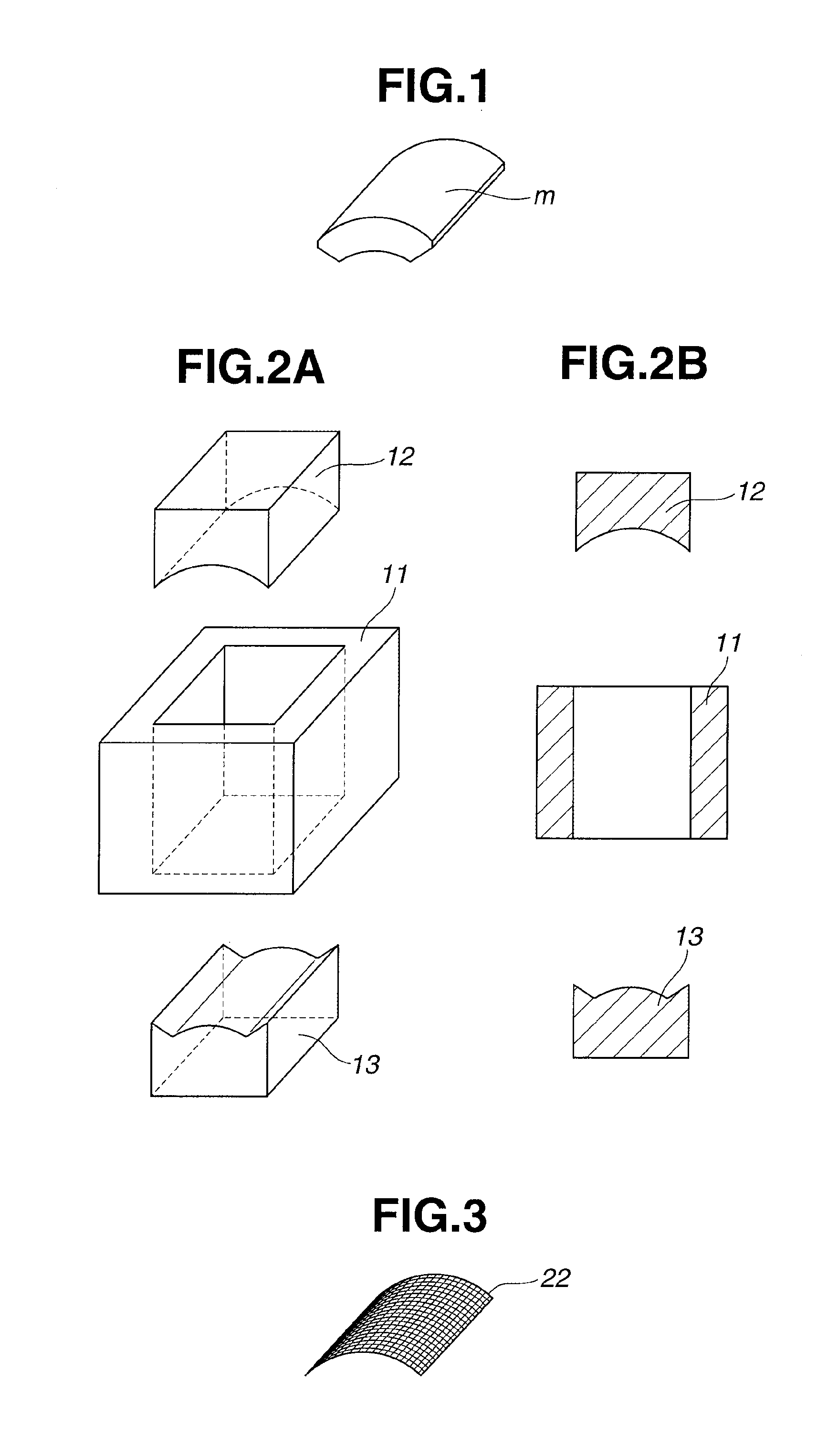

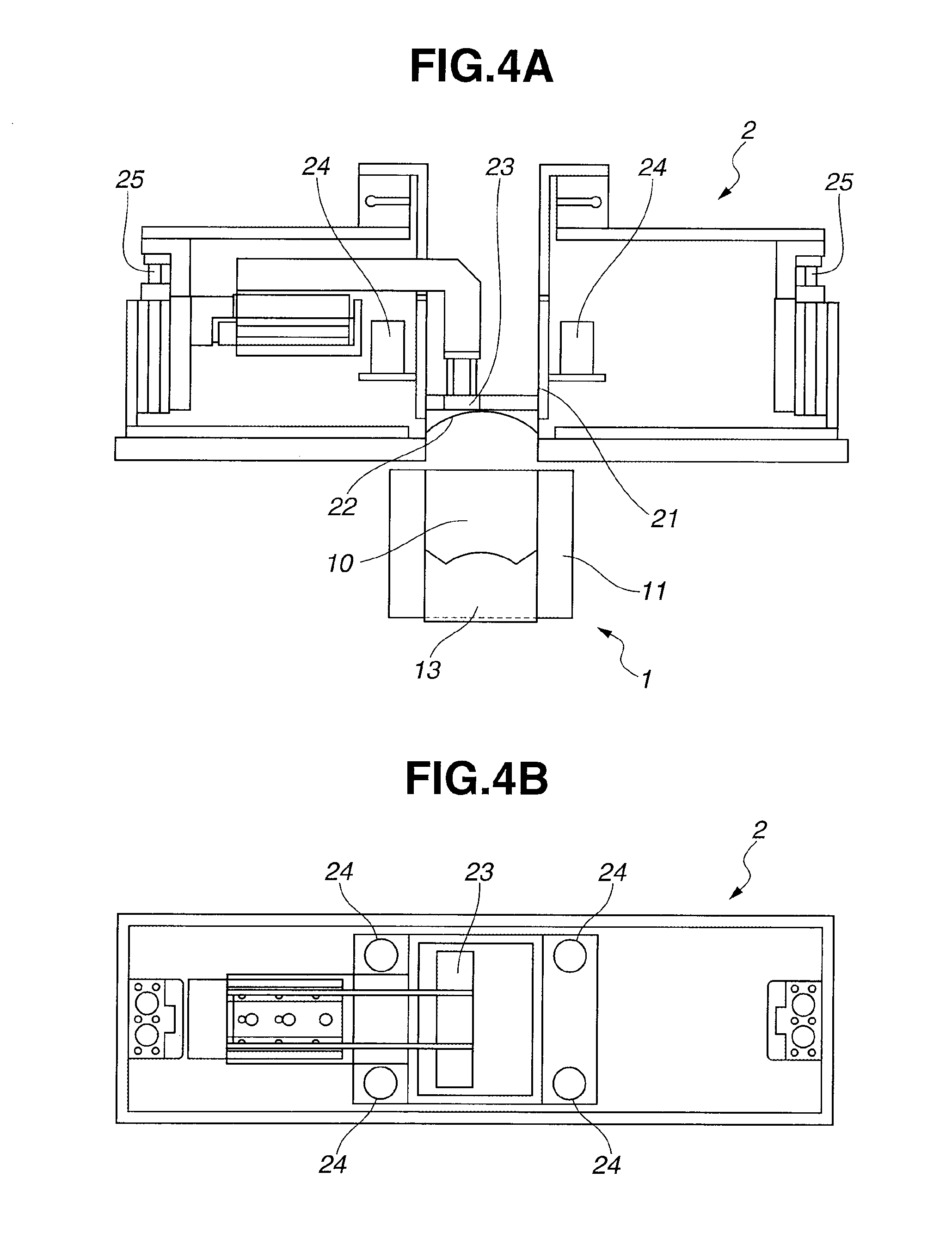

Method and apparatus for preparing rare earth sintered magnet

ActiveUS20150179336A1High yieldEfficient preparationInductances/transformers/magnets manufactureMagnetic materialsReciprocating motionRare earth

A mold comprising a die, an upper punch, and a lower punch, the pressure surface of one or both of the upper and lower punches being shaped non-planar, a cavity being defined between the die and the lower punch, is combined with a feeder including a shooter provided with a main sieve at its lower end port, the main sieve having a sifting surface of substantially the same non-planar shape as the pressure surface. A rare earth sintered magnet is prepared by feeding an alloy powder into the cavity through the shooter and sieve while applying weak vibration and vertical reciprocation to the shooter, applying a uniaxial pressure to the alloy powder fill in the cavity under a magnetic field to form a precursor, and heat treating the precursor.

Owner:SHIN ETSU CHEM IND CO LTD

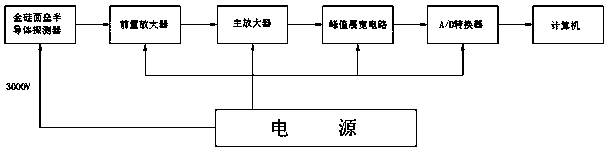

Device for measuring rock released radon under uniaxial pressure experiment

InactiveCN110082813AGood spectrometry performanceShort duration of actionX-ray spectral distribution measurementWater vaporSilica gel

The invention discloses a device for measuring rock released radon under a uniaxial pressure experiment, and belongs to the technical field of gas measurement. The rock released radon measuring devicewith small environmental pollution and high measuring precision is provided. According to the technical scheme, the device for measuring the rock released radon under the uniaxial pressure experimentcomprises a pressure machine; the pressure machine is used for compressing a rock sample in a pressure chamber through a pressure rod to release a gas sample; the pressure chamber is connected with agas inlet switch through a pipeline; the lower side of the pressure chamber is connected with a first switch through a pipeline; gas enters a radon gas chamber through the first switch and a silica gel drying tube sequentially; a gold-silicon barrier type semiconductor detector is arranged in the radon gas chamber; an outlet of the radon gas chamber is connected with a second switch; one side, far away from the radon gas chamber, of the second switch communicates with an inlet of a filter; an outlet of the filter communicates with a gas collecting bottle; the silica gel drying tube is used for filtering dust and water vapor in the gas sample; and the filter is used for removing a daughter of radon possibly existing in the gas sample.

Owner:TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com