Preparation method of porous titanium and titanium alloy

A technology of porous titanium and titanium alloys, which is applied in separation methods, chemical instruments and methods, medical science, etc., and can solve the problems such as difficult design of voids in titanium alloy filter core materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The embodiment of the present invention provides a method for preparing medical porous titanium and titanium alloy, comprising the following steps:

[0022] Step 1: uniformly mixing Ti metal powder and Ni or Co metal powder, the mass percentage of Ti metal powder in the obtained mixed powder is 45% to 95%, and the mass percentage of Ni or Co metal powder is 55% to 5%;

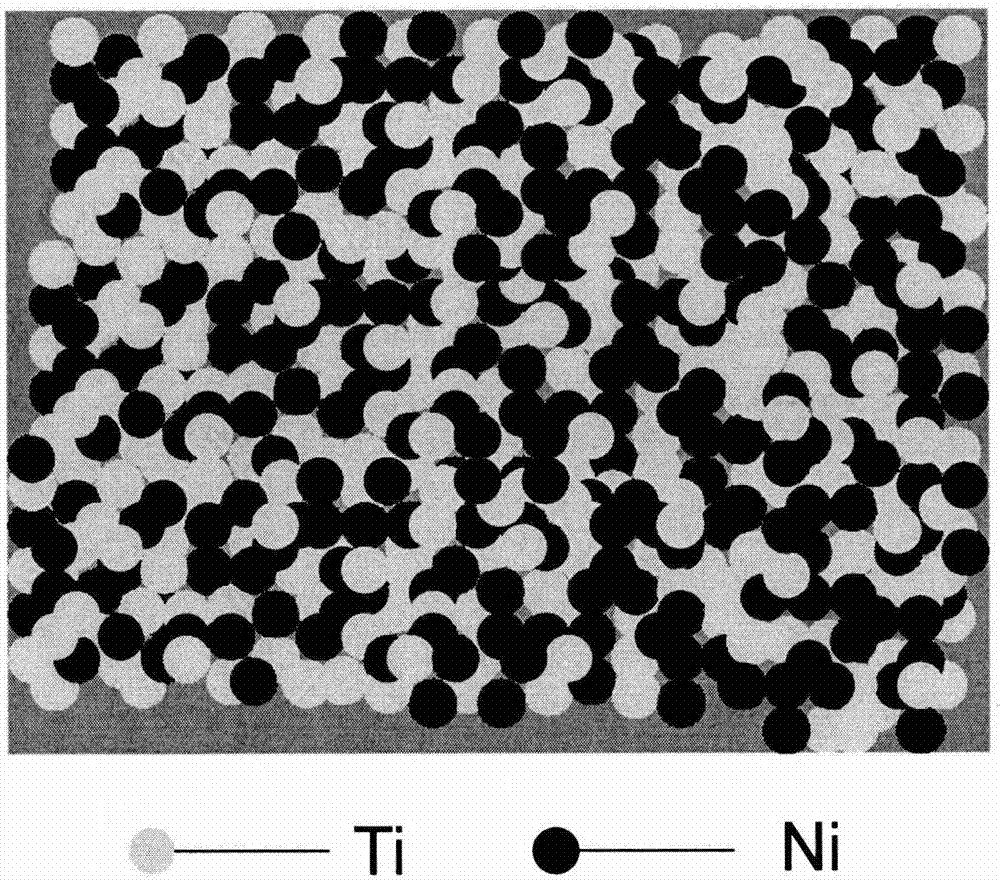

[0023] Step 2: Put the obtained mixed powder into a graphite or silicon carbide mold, place it in a vacuum sintering furnace for sintering, the vacuum degree is 0.1-10Pa, the one-way pressure is 200-1000MPa, and the heating rate is 20-100℃ / min , the sintering temperature is 800-1400°C, the sintering time is 10-60min, and then the TiNi or TiCo alloy green body is obtained after cooling with the furnace, such as figure 1 shown;

[0024] Step 3: Use the obtained TiNi or TiCo alloy blank as an anode for electrochemical dissolution to dissolve Ni or Co metal powder and dissolve the metal wire mold to obtain ...

Embodiment 1

[0026] This embodiment is a preparation method for preparing porous titanium and porous titanium alloy.

[0027] Step 1: In the mixed metal powder, the mass percentage of Ti metal powder is 50%, and the mass percentage of Ni metal powder is 50%.

[0028] Step 2: Put the mixed metal powder obtained in Step 1 into a graphite mold, place it in a vacuum sintering furnace for sintering, the vacuum degree is 5Pa, the one-way pressure is 500MPa, the heating rate is 20-100°C / min, and the sintering temperature is 1200°C, the sintering time is 40min, and then the TiNi alloy green body is obtained after cooling with the furnace.

[0029] Step 3: Then completely electrochemically dissolve the Ni metal powder in the sulfuric acid electrolyte.

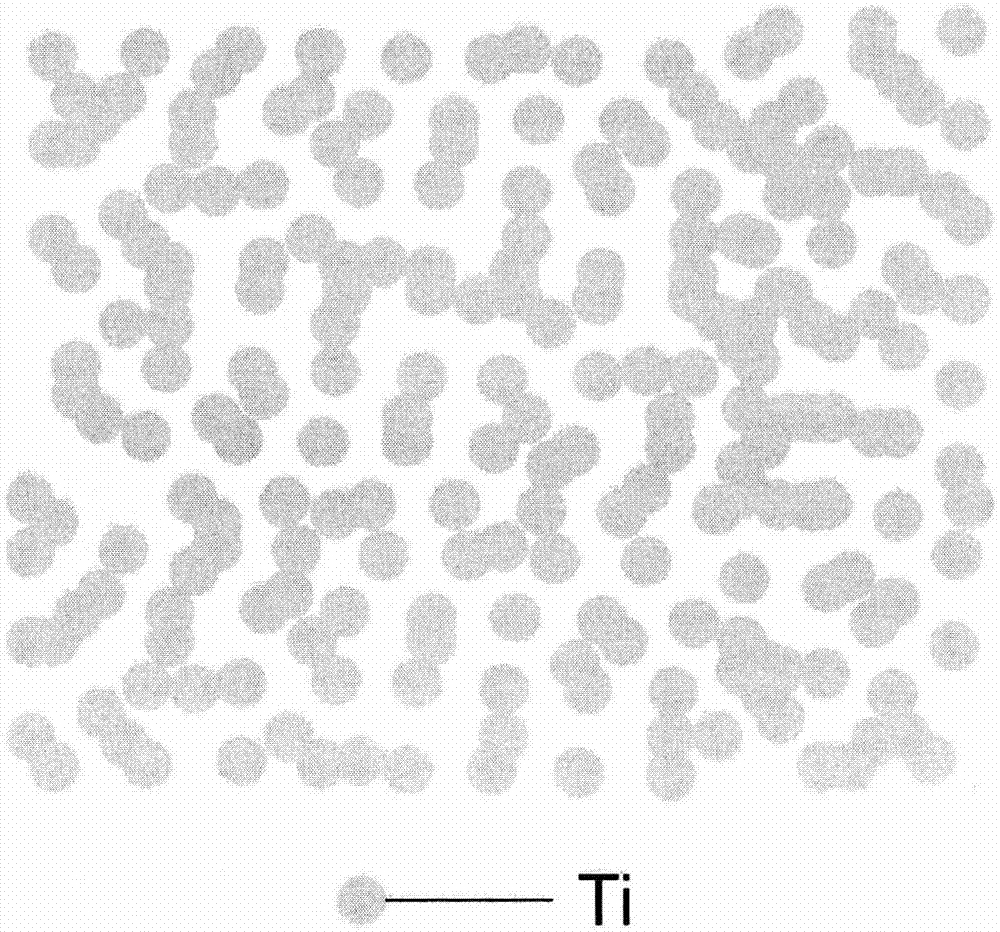

[0030] Step 4: Cleaning the porous titanium and titanium alloy after complete electrolysis of Ni to obtain porous titanium and titanium alloy with similar distribution characteristics of pores and nickel powder.

Embodiment 2

[0032] This embodiment is a preparation method for preparing porous titanium and porous titanium alloy.

[0033] Step 1: In the mixed metal powder, the mass percentage of Ti metal powder is 60%, and the mass percentage of Ni metal powder is 40%.

[0034] Step 2: Put the mixed metal powder obtained in Step 1 into a graphite mold, place it in a vacuum sintering furnace for sintering, the vacuum degree is 5Pa, the one-way pressure is 500MPa, the heating rate is 20-100°C / min, and the sintering temperature is 1200°C, the sintering time is 40min, and then the TiNi alloy green body is obtained after cooling with the furnace.

[0035] Step 3: Then completely electrochemically dissolve the Ni metal powder in the sulfuric acid electrolyte.

[0036] Step 4: Cleaning the porous titanium and titanium alloy after complete electrolysis of Ni to obtain porous titanium and titanium alloy with similar distribution characteristics of pores and nickel powder.

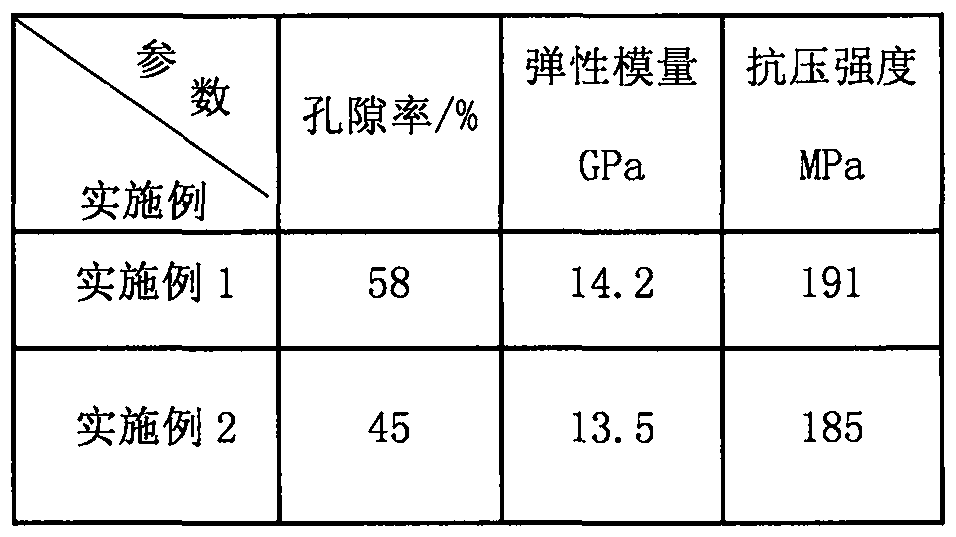

[0037] Table 1 shows the paramete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com