Method for preparing anisotropy MnAlC single variant through uniaxial pressure constraint transformation

A uniaxial pressure, anisotropic technology, applied in the field of MnAlC-τ phase single variant, can solve the problem of low permanent magnet performance, achieve the effects of good permanent magnet performance, elimination of twins, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

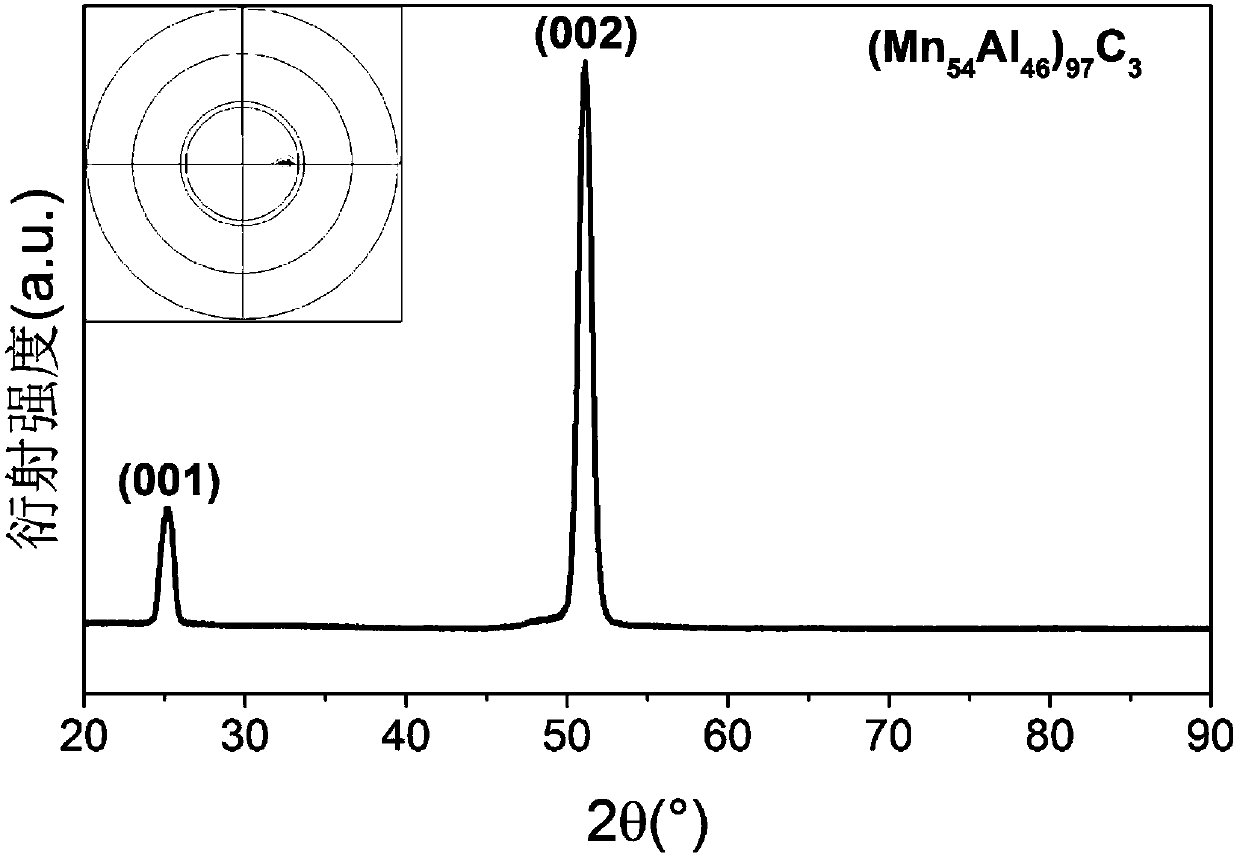

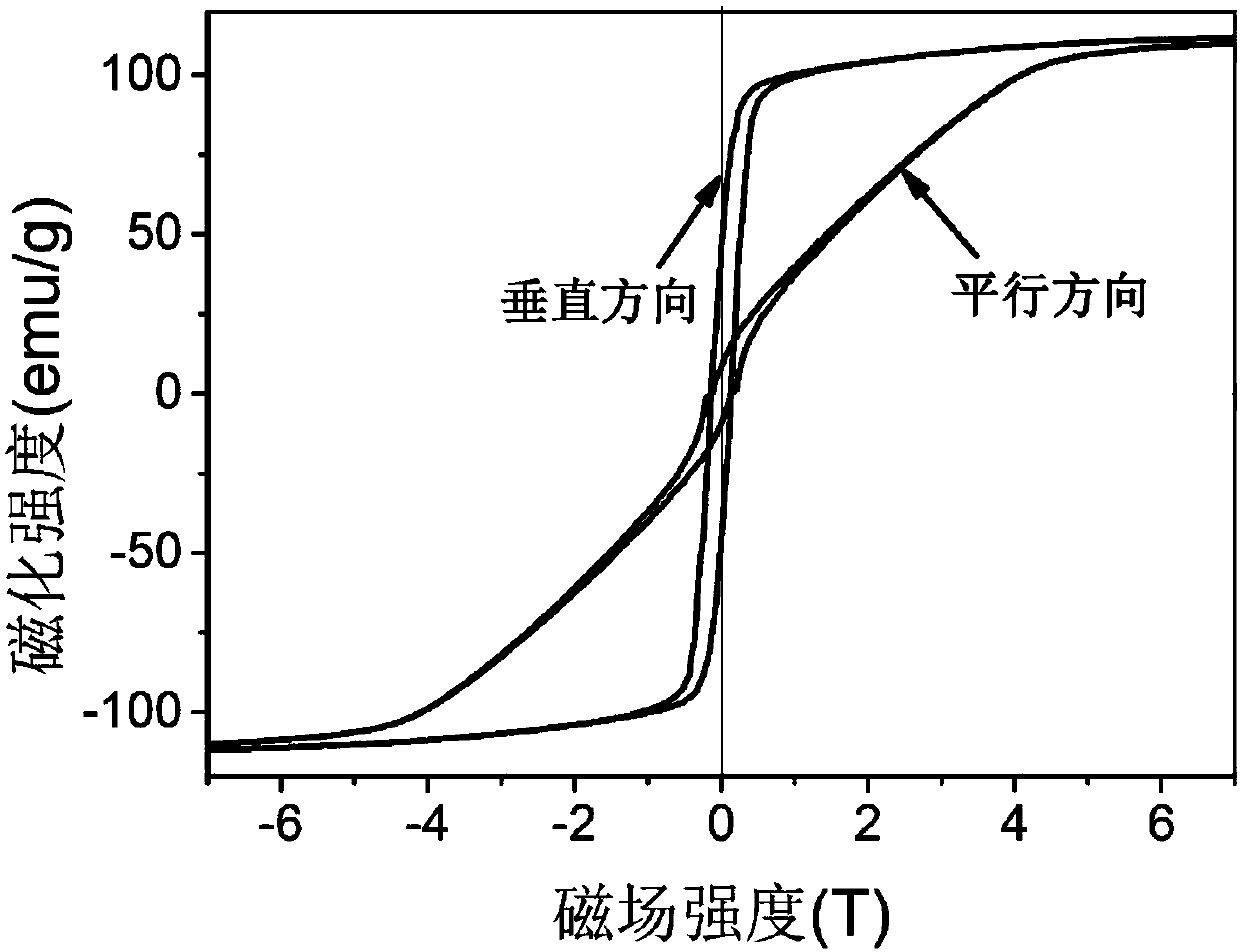

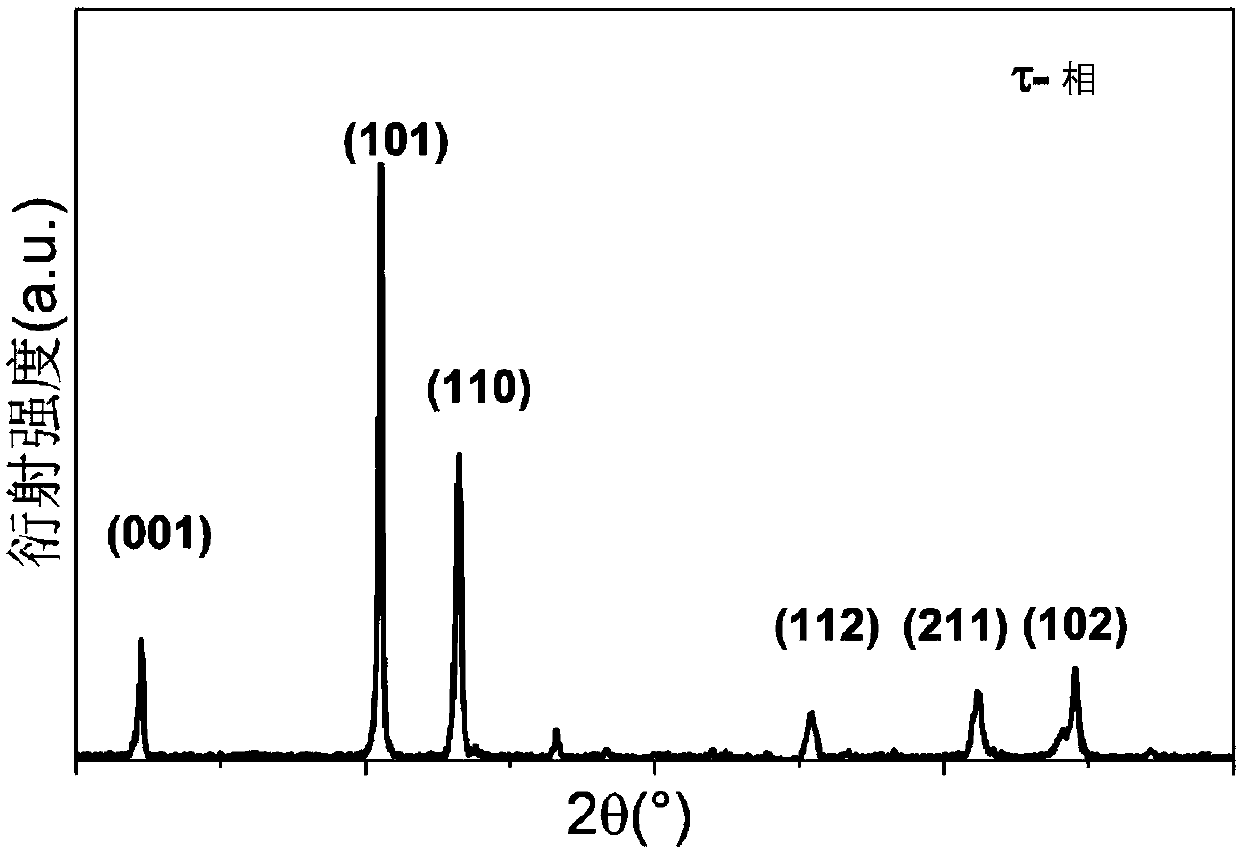

[0040] The saturation magnetization is 117emu / g (Mn 54 al 46 ) 97 C 3 single variant

[0041] The first step: making MnAlC rods

[0042] Press (Mn 54 al 46 ) 97 C 3 Prepare the master alloy with the target composition; then put the master alloy in the vacuum electric arc furnace, and adjust the vacuum degree of the vacuum chamber to 4×10 -3 Pa, filled with argon to 0.7×10 5 Pa, cast after repeated smelting for 5 times (Mn 54 al 46 ) 97 C 3 bar;

[0043] The second step: making (Mn 54 al 46 ) 97 C 3 Alloy ε phase single crystal

[0044] The obtained (Mn 54 al 46 ) 97 C 3 The bar is cut into cylindrical material rods and seed crystal rods, and the cylindrical material rods and seed crystal rods are placed in the FZ-T-4000-H photon heating zone melting crystal growth furnace produced by Crystal Systems, and the photon heating zone melting is used prepared by method (Mn 54 al 46 ) 97 C 3 single crystal;

[0045] System (Mn 54 al 46 ) 97 C 3 Single c...

Embodiment 2

[0056] The saturation magnetization is 121emu / g (Mn 54 al 46 ) 99 C 1 Alloy tau phase single variant

[0057] The first step: making MnAlC rods

[0058] Press (Mn 54 al 46 ) 99 C 1 Prepare the master alloy with the target composition; then put the master alloy in the vacuum electric arc furnace, and adjust the vacuum degree of the vacuum chamber to 5×10 -3 Pa, filled with argon to 0.5×10 5 Pa, cast after repeated smelting for 5 times (Mn 54 al 46 ) 99 C 1 bar;

[0059] Second step: adopt the preparation method identical with embodiment 1 to make (Mn 54 al 46 ) 99 C 1 Alloy ε phase single crystal.

[0060] The third step: uniaxial pressure-confined phase transition preparation (Mn 54 al 46 ) 99 C 1 Alloy tau phase single variant

[0061] The obtained (Mn 54 al 46 ) 99 C 1 Single crystal cutting, to obtain a cuboid single crystal sample, so that the longer direction is direction; then the cuboid single crystal sample was placed in the environmental c...

Embodiment 3

[0065] The saturation magnetization is 104emu / g (Mn 54 al 46 ) 97 C 3 single variant

[0066] The first step: adopt the preparation method identical with embodiment 1 to make (Mn 54 al 46 ) 97 C 3 bar.

[0067] The second step: making (Mn 54 al 46 ) 97 C 3 single crystal;

[0068] The obtained (Mn 54 al 46 ) 99 C 1 The bar is cut into cylindrical material rods and seed crystal rods, and the cylindrical material rods and seed crystal rods are placed in the FZ-T-4000-H photon heating zone melting crystal growth furnace produced by Crystal Systems, and the photon heating zone melting is used prepared by method (Mn 54 al 46 ) 97 C 3 single crystal;

[0069] System (Mn 54 al 46 ) 97 C 3 Single crystal process parameters:

[0070] Adjust the vacuum degree of the vacuum chamber in the growth furnace to 2×10 -3 Pa;

[0071] Filled with high-purity argon to 1.2×10 5 Pa, the flow rate of argon gas is 2.0L / min, and high-purity argon is used as the flowing gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com