Anisotropic nano/amorphous composite phase bulk permanent magnet material and preparation method thereof

A permanent magnet material, anisotropic technology, applied in the field of high-performance bulk permanent magnet materials, can solve the problems of grain growth, performance deterioration, unavoidable and other problems, achieve less consumption of rare earth elements, easy control of the process, and reduce The effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

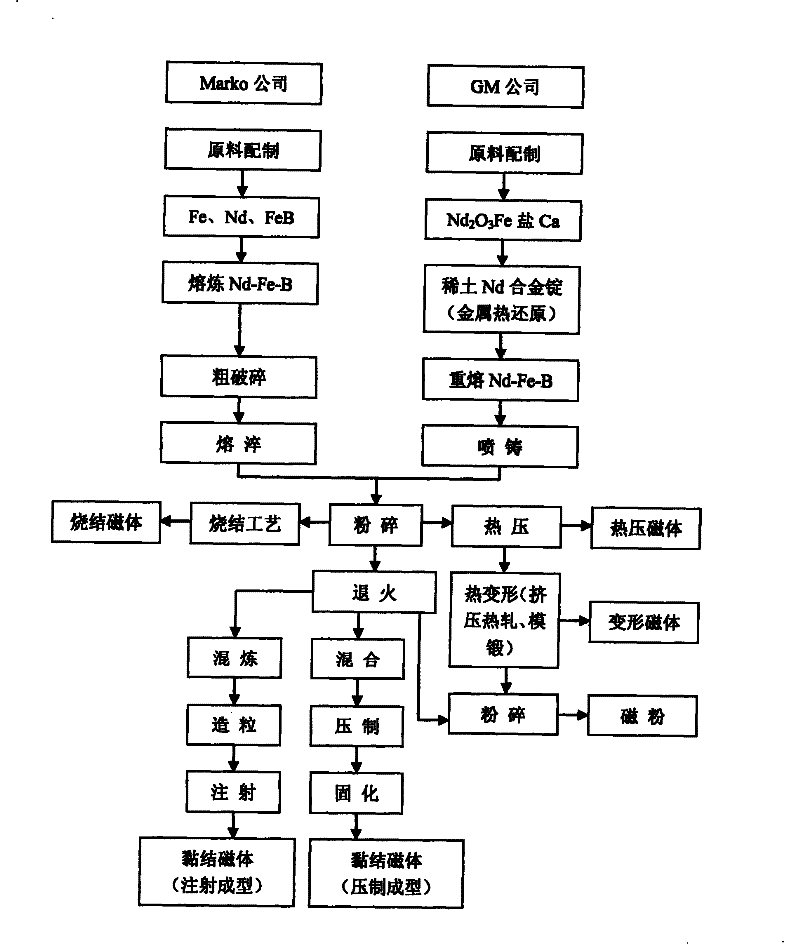

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: the nominal composition that the embodiment of the invention adopts is (Fe 71 B 21 Nd 8 ) 96 Nb 4 (atomic percent). The nominal purity of the raw materials used in the embodiment is Fe99.99%, B99.99%, Nd99.99%, Nb99.8%.

[0030] Fe-BMG preparation: at higher than 10 -3 Under the vacuum of Pa, the Nd is first melted by arc melting, the melting current is 550A, and the stirring voltage is 0.8V. Take it out after cooling, re-polish the surface and put Nb, Fe, B and purified Nd together into the crucible according to the nominal composition ratio, and evacuate to 10 -3 Pa, rush into high-purity Ar gas, degas with Zr and use arc melting together. The evenly smelted master alloy ingot is placed in a vacuum-sealed perforated quartz glass tube (hole diameter 1.0mm) and re-melted evenly by induction heating. The melt tension prevents the alloy melt from flowing down by itself. The induction melting temperature is 1240°C. Using high-purity Ar gas at a press...

Embodiment 2

[0032] Embodiment 2: the nominal composition that the embodiment of the invention adopts is (Fe 71 B 21 Nd 8 ) 96 Nb 4 (atomic percent). The nominal purity of the raw materials used in the embodiment is Fe99.99%, B99.99%, Nd99.99%, Nb99.8%.

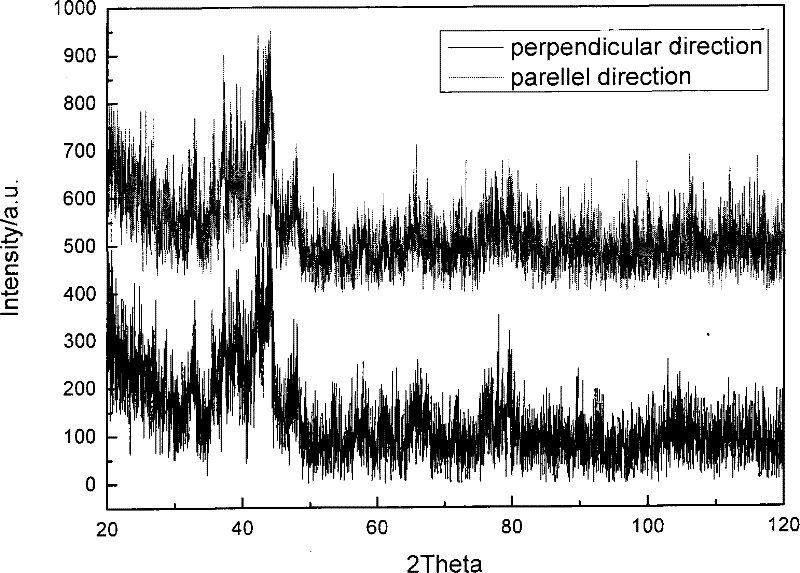

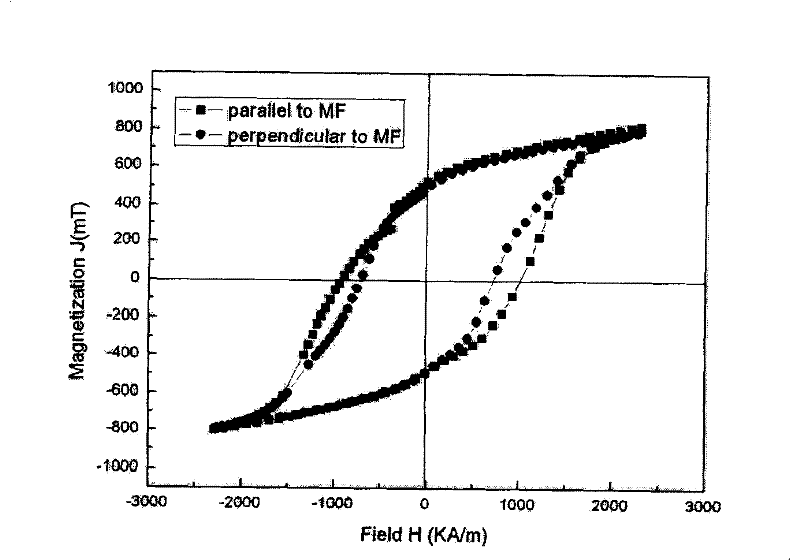

[0033] The preparation of Fe-BMG is the same as in Example 1. Place the Fe-BMG obtained above under a strong magnetic field of 12-19T, and rapidly raise the temperature to 720°C. After the temperature is stabilized (within about half a minute), keep the temperature constant for 10 minutes, then slowly cool to 290°C for 10 minutes under a magnetic field, and then take the sample out for air cooling. Table 1 shows the magnetic comparison, and it can be seen that it has obvious anisotropy.

[0034] Table 1 Performance comparison of anisotropic permanent magnet materials.

[0035]

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com