Heating constant-temperature device and method for high-temperature rock uniaxial compression test

A technology of uniaxial compression test and constant temperature device, applied in the direction of measuring device, using stable tension/pressure test material strength, instruments, etc., can solve the problem of affecting test accuracy and test safety, reducing the accuracy of test results, and the influence of heating area Large range and other problems, to avoid uneven heating, easy to control temperature, and strong test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

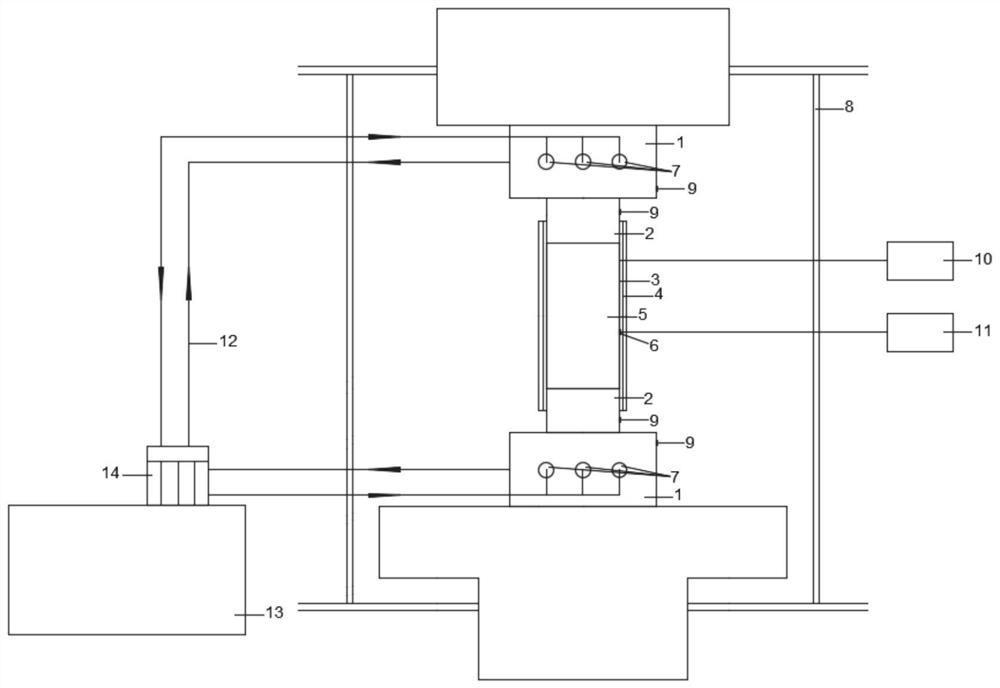

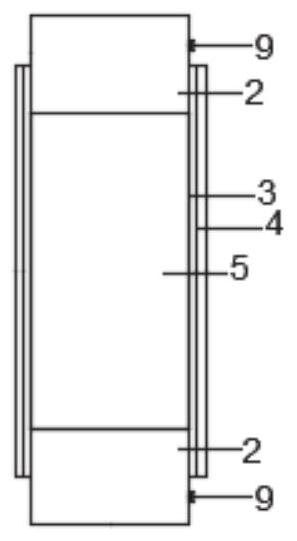

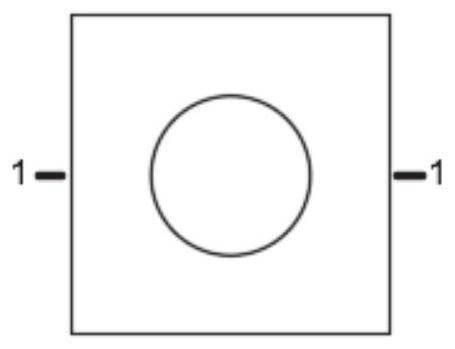

[0043]The invention discloses a heating and constant temperature device for high-temperature rock uniaxial compression test, which comprises a heating and constant temperature unit, a force transmission unit, a protection unit and a monitoring unit. The protection unit is equipped with a heating constant temperature unit, a force transmission unit and a monitoring unit. The monitoring unit can be in contact with the standard cylindrical rock test piece 5, the heating constant temperature unit, and the force transmission unit. The heating constant temperature unit can cover the standard cylindrical rock test piece 5 On the side, the force transmission unit is connected to the press to apply pressure to the standard cylindrical rock specimen 5, and the force transmission unit is also connected to the protection unit for cooling.

[0044] The heating constant temperature unit includes a heating belt 3 , thermal insulation cotton 4 and a temperature control box 10 . Cover the side...

Embodiment 2

[0051] This embodiment discloses a method for uniaxial compression test of high temperature rock, using the heating constant temperature device for uniaxial compression test of high temperature rock as described in Example 1, comprising the following steps:

[0052] Step 1, using the signal transmission line to connect the heating belt 3, the temperature control box 10 and the power supply to form a heating constant temperature unit.

[0053] Step 2, in the loading system on the uniaxial press, the pads and the standard cylindrical rock specimen 5 are placed to form a force transmission unit.

[0054] Step 3, connect the temperature sensor 11 to the standard cylindrical rock specimen 5 and the heating belt 3, and connect the displacement sensor 9 to the side of the high-strength heat-resistant pad.

[0055] Step 4, binding the heating belt 3 and the thermal insulation cotton 4 to make it cover the side of the standard cylindrical rock specimen 5 .

[0056] Step 5, turn on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com