A low-temperature cold-sintering preparation method of a zirconia ceramic setter plate used for MnZn ferrite sintering

A technology of zirconia ceramics and setter plates, applied in lighting and heating equipment, furnace components, furnaces, etc., can solve the problems of high sintering temperature and difficulty in densification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

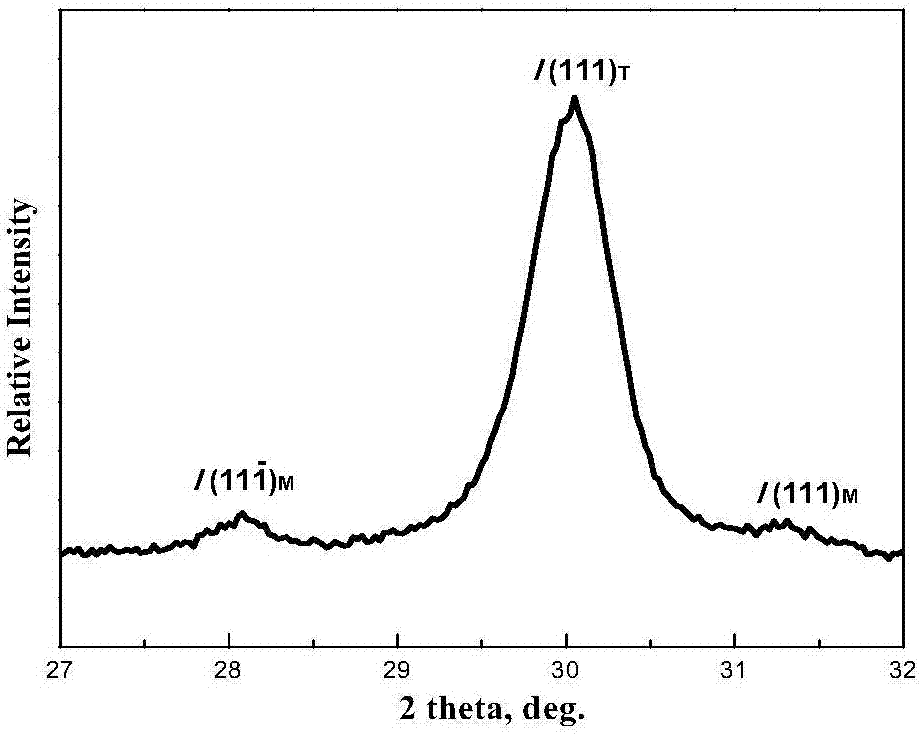

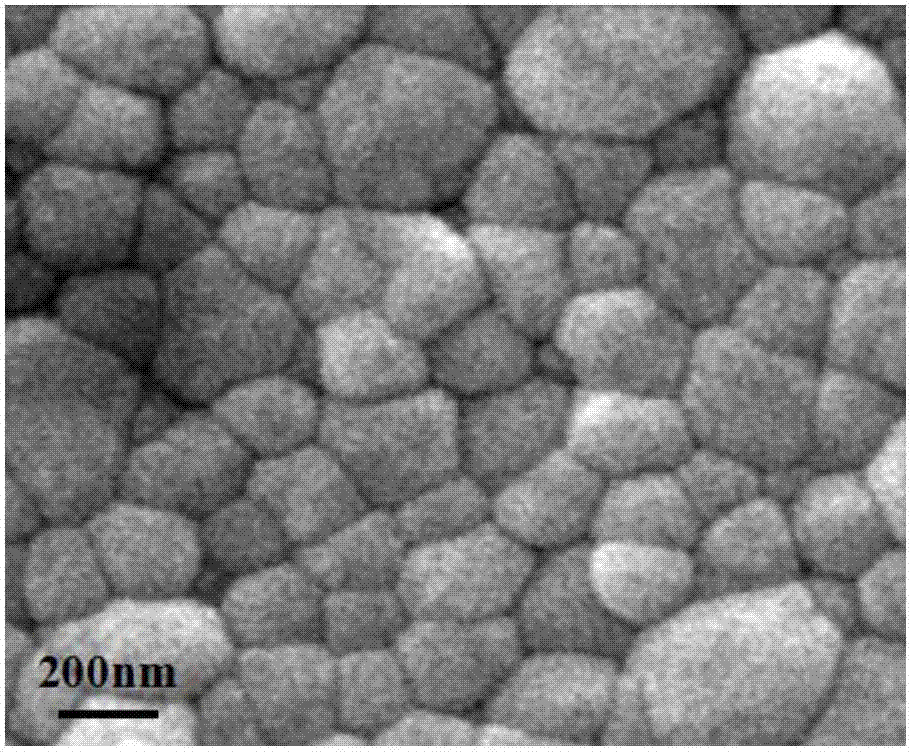

[0015] Select 3Y-PSZ powder with a purity of 99.5% and an average particle diameter of 40nm, put it into 30wt.% deionized water solvent according to the mass calculated in claim 1, ultrasonically disperse and stir for 20min, and obtain 3Y-PSZ The suspension was ground in a mortar for 10 min. According to the steps in claim 2, pour the prepared suspension into the mold, press cold at room temperature for 10 minutes, keep the temperature at 180° C. and hold the pressure for 3 hours, and the pressure is 400 MPa. Dry the 3Y-PSZ ceramic pre-sintered blank at 180°C for 12h. Adopt the process in claim 4 to carry out vacuum pressureless sintering, the process parameters are: sintering temperature 1000°C, holding time 4h, vacuum degree 1.3×10 -2 Pa.

[0016] Prepared ZrO 2 The density of ceramics can reach 94.5%, the bending strength of the material at room temperature is 573.5MPa, and its fracture toughness is 5.30MPa m 1 / 2 ; In the atmosphere furnace with inert gas, after 1100 ° ...

Embodiment 2

[0018] Select 3Y-PSZ powder with a purity of 99.5% and an average particle size of 30nm, put it into 30wt.% deionized water solvent according to the mass calculated in claim 1, ultrasonically disperse and stir for 30min, and obtain 3Y-PSZ The suspension was ground in a mortar for 15 min. According to the steps in claim 2, pour the obtained suspension into a mold, press coldly at room temperature for 15 minutes, keep the temperature at 190° C. and hold the pressure for 3 hours, and the pressure is 450 MPa. Dry the 3Y-PSZ ceramic pre-sintered blank at 190°C for 12h. Vacuum pressureless sintering is carried out using the process in claim 4, and the process parameters are: sintering temperature 1050°C, holding time 4h, vacuum degree 1.3×10 -2 Pa.

[0019] Prepared ZrO 2 The density of ceramics can reach 94.9%, the bending strength of the material at room temperature is 580.3MPa, and its fracture toughness is 5.42MPa m 1 / 2 ; In an atmosphere furnace fed with inert gas, after 11...

Embodiment 3

[0021] Select 3Y-PSZ powder with a purity of 99.9% and an average particle size of 20nm, put it into 30wt.% deionized water solvent according to the mass calculated in claim 1, ultrasonically disperse and stir for 40min, and obtain 3Y-PSZ The suspension was ground in a mortar for 20 min. According to the steps in claim 2, pour the prepared suspension into the mold, press cold at room temperature for 20 minutes, keep the temperature at 200° C. and hold the pressure for 3 hours, and the pressure is 450 MPa. The 3Y-PSZ ceramic pre-sintered compact was dried at 200°C for 18 hours. Vacuum pressureless sintering is carried out by adopting the process in claim 4, and the process parameters are: sintering temperature 1100°C, holding time 4h, argon protection.

[0022] Prepared ZrO 2 The density of ceramics can reach 95.5%, the bending strength of the material at room temperature is 615MPa, and its fracture toughness is 5.78MPa m 1 / 2 ; In an atmosphere furnace with inert gas, after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com