Preparation method of ammonium polyphosphate wrapped with fluorine-containing silicone oil on surface

A technology of ammonium polyphosphate and fluorine-containing silicone oil, which is applied in the treatment of dyed organosilicon compounds, fibrous fillers, etc., can solve the problems of reduced flame retardant performance, easy precipitation of flame retardants, etc., and achieves improved hydrophobicity, excellent hydrophobicity, The effect of low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

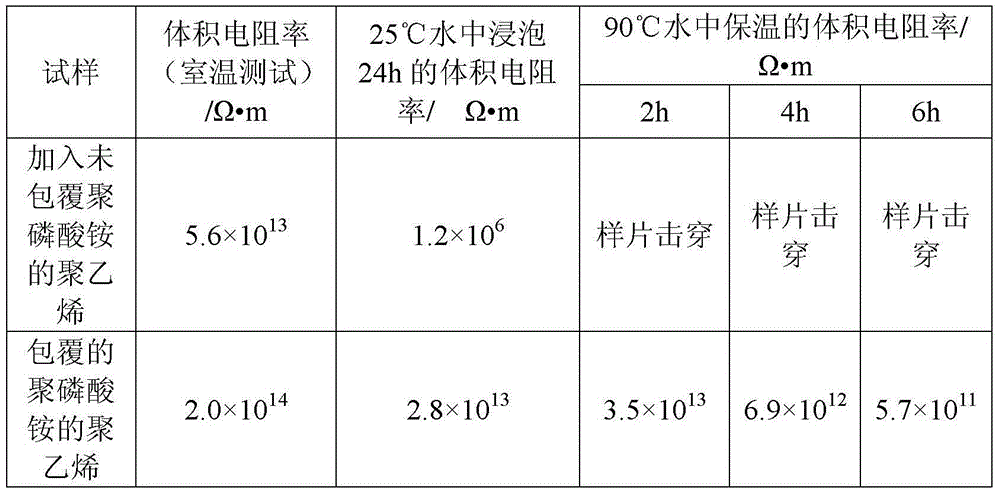

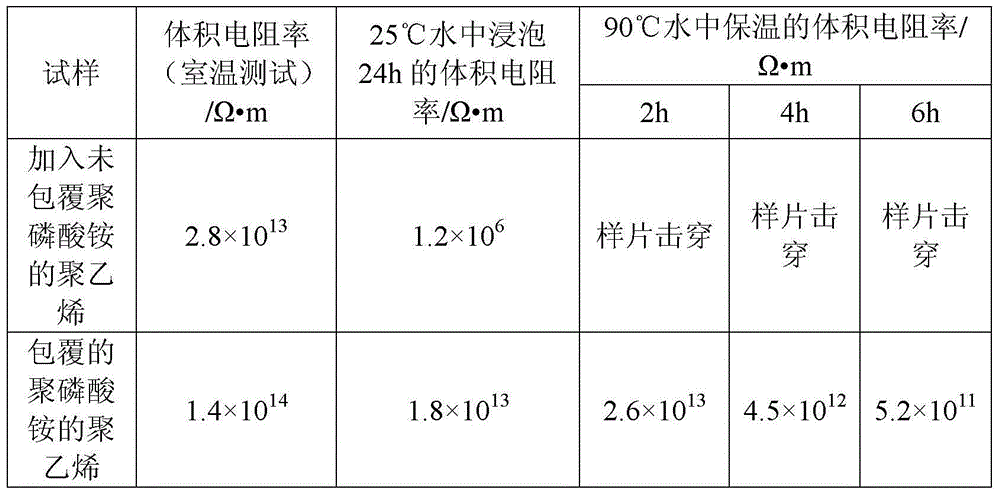

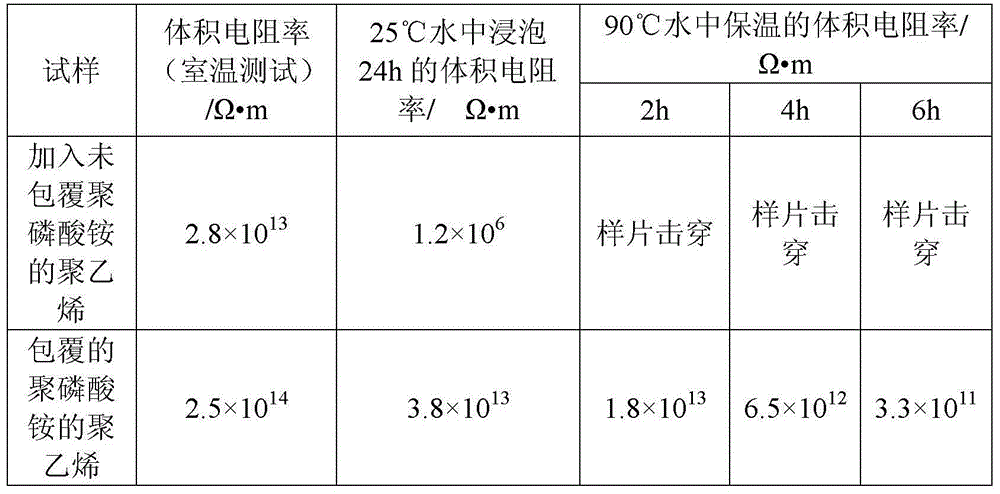

Examples

specific Embodiment approach 1

[0018] Embodiment 1: This embodiment is a method for preparing ammonium polyphosphate coated with fluorine-containing silicone oil on the surface, specifically according to the following steps:

[0019] 1. Heating ammonium polyphosphate at a temperature of 70°C to 100°C for 3min to 10min to obtain heated ammonium polyphosphate;

[0020] 2. Mix the modifier and the dispersant uniformly at a temperature of 70°C to 100°C to obtain a mixed liquid, add the heated ammonium polyphosphate obtained in step 1 to the mixed liquid, and rotate at a speed of 1000r / min~ Stir at 2000r / min and temperature of 70°C to 100°C for 10min to 20min, then pulverize and sieve to obtain ammonium polyphosphate coated with fluorosilicone oil on the surface; the heated ammonium polyphosphate obtained in step 1 described in step 2 The mass ratio of ammonium polyphosphate and modifying agent is 100:(0.1~5); The mass ratio of modifying agent described in step 2 and dispersant is 1:(10~40); The modification des...

specific Embodiment approach 2

[0026] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the fluorine-containing silicone oil described in step 2 is heptadecafluorodecyltriethoxysilane, trifluoropropylmethyl polysiloxane, three Fluoromethyltrimethylsilane or trifluoropropylhydroxysiloxane. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0027] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the dispersant described in step two is acetone, absolute ethanol, absolute methanol, dichloromethane, chloroform, sherwood oil, diethyl ether or benzene. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com