Special insulating material for electrical equipment and preparation method for special insulating material

A technology for insulating materials and power equipment, applied in the direction of organic insulators, plastic/resin/wax insulators, etc., can solve the problem of not improving the corrosion resistance and aging resistance of materials, unfavorable large-scale production, charge surface flashover, etc. to avoid surface flashover, optimize electric field distribution, and reduce stress cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

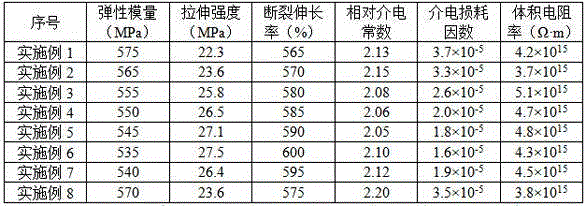

Examples

preparation example Construction

[0036] The present invention also provides a preparation method of the above-mentioned special insulating material for electric equipment, comprising the following steps:

[0037] 1) Add 0.2~1 parts by weight of butyl titanate to 20~40 parts by weight of distilled water, place in a magnetic stirrer, stir for 30~45 minutes at 25~35°C, and then add 15~20 parts by weight of nano inorganic powder , ultrasonic treatment, ultrasonic frequency 25~30kHz, power 300~500W, ultrasonic time 35~40min, filter, and then dry at 70~75°C to obtain surface-modified nano-inorganic powder;

[0038] 2) Add the surface-modified nano-inorganic powder obtained in step 1) and 90-100 parts by weight of epoxy resin to the torque rheometer in sequence, and mix at 150-175°C for 15-30 minutes to obtain modified epoxy resin resin;

[0039] 3) The modified epoxy resin obtained in step 2), 15-25 parts by weight of methyl vinyl silicone rubber, 20-25 parts by weight of fluorosilicone resin, 15-20 parts by weigh...

Embodiment 1

[0046] A special insulating material for electric power equipment, which contains components and their contents: 90 parts by weight of epoxy resin, 15 parts by weight of methyl vinyl silicone rubber, 20 parts by weight of fluorosilicone resin, and polystyrene with a particle size of 0.8 to 3.5 μm. 15 parts by weight of tetrafluoroethylene, 10 parts by weight of glass fibers with a length of 2 to 3 mm, 15 parts by weight of nano inorganic powder, 0.2 parts by weight of butyl titanate, 20 parts by weight of distilled water, maleic anhydride grafted polyethylene and maleic anhydride Grafted polypropylene is 1 weight part of compatibilizer mixed according to the ratio of 7:3 by weight, 1 weight part of aluminum hydroxide, 0.3 weight part of antioxidant 300, 1 weight part of dibenzoyl peroxide;

[0047] Among them, the nano-inorganic powder is Al with a particle size of 15-30nm 2 o 3 , nano-SiO 2 , Nano B 4 C. Nano-Si 3 N 4 and nano TiO 2 mixture of nano-Al 2 o 3 , nano-SiO...

Embodiment 2

[0055] A special insulating material for power equipment, which contains components and their contents: 91 parts by weight of epoxy resin, 16 parts by weight of methyl vinyl silicone rubber, 21 parts by weight of fluorosilicone resin, and polystyrene with a particle size of 0.8 to 3.5 μm. 16 parts by weight of tetrafluoroethylene, 11 parts by weight of glass fibers with a length of 2 to 3 mm, 16 parts by weight of nano-inorganic powder, 0.3 parts by weight of butyl titanate, 22 parts by weight of distilled water, maleic anhydride grafted polyethylene and maleic anhydride Grafted polypropylene is 2 parts by weight of compatibilizer mixed in a ratio of 7:3 by weight, 1.5 parts by weight of aluminum hydroxide, 0.4 parts by weight of antioxidant 1076, and 2 parts by weight of dicumyl peroxide;

[0056] Among them, the nano-inorganic powder is Al with a particle size of 15-30nm 2 o 3 , nano-SiO 2 , Nano B 4 C. Nano-Si 3 N 4 and nano TiO 2 mixture of nano-Al 2 o 3 , nano-SiO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com