Insulation adhesive material for compound photovoltaic backsheet and application

A photovoltaic backplane, composite technology, used in adhesives, photovoltaic power generation, adhesive types, etc., can solve the problems of less adhesive reliability research and few adhesive materials, etc., to achieve long-term reliability guarantee, cohesion The effect of high energy and not easy internal fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

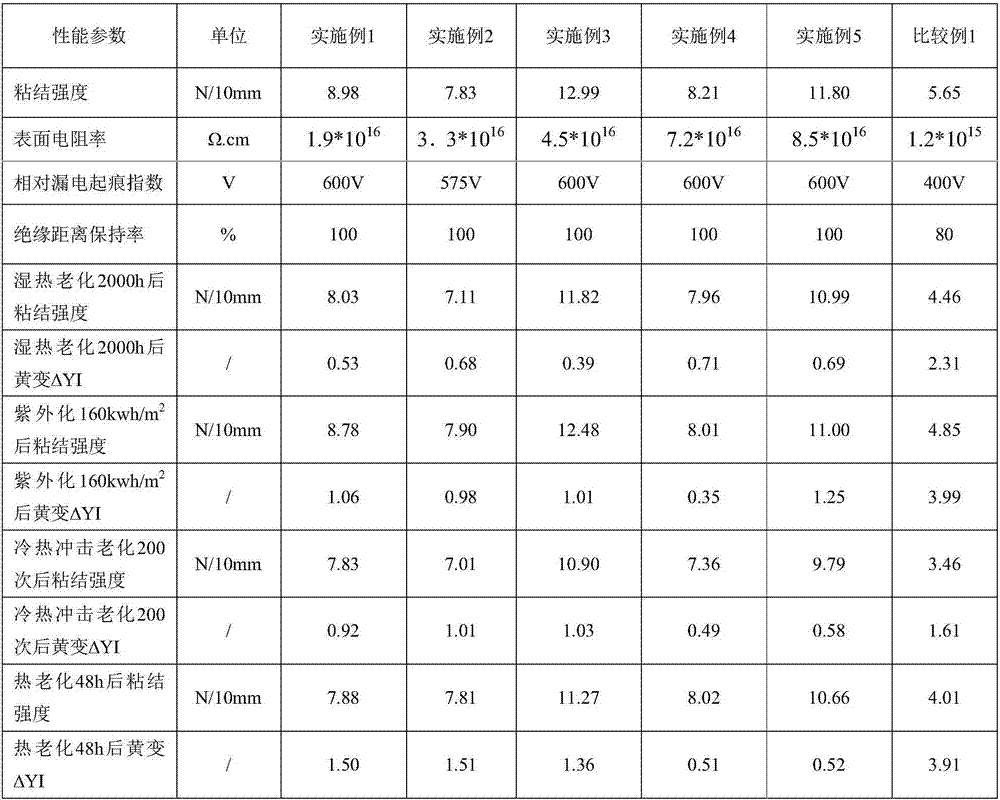

Examples

Embodiment 1

[0059] (1) Preparation of insulating adhesive:

[0060]In an inert gas atmosphere reactor, slowly add weighed polyols while stirring at 150°C, including 520.75g of neopentyl glycol (Jinggang Chemical Co., Ltd.), 104.15g of 1,5-pentanediol ( Jinggang Chemical Co., Ltd.), 73.12g of 1,8-octanediol (Lisheng Chemical Co., Ltd.). 332.26g of phthalic acid (Baiqian Chemical Co., Ltd.), 99.03g of lauric acid (Jinyu Chemical Co., Ltd.) and 0.18g of catalyst tetra-n-butyl titanate (Hongming Chemical Reagent Co., Ltd.) are slowly added to the reactor Medium; with a heating rate of 5°C / hour, the temperature was raised to 180°C; at a heating rate of 2°C / hour, the temperature was slowly raised to 230°C, and the reaction was kept for 26 hours; 0.18g of catalyst tetra-n-butyl titanate (Hongming Chemical Reagent Co., Ltd.) into the reaction kettle, turn on the vacuum pump, keep the vacuum at -0.1MPa and evacuate for 10 hours, then stop heating and evacuate, and naturally cool to 140°C while st...

Embodiment 2

[0065] (1) Preparation of insulating adhesive:

[0066] In an inert gas atmosphere reaction kettle, slowly add weighed polyols while stirring at 100°C, including 520.75g of pentaerythyl glycol (Jinggang Chemical Co., Ltd.), 67.09g of 2-ethyl-2-hydroxy Methyl-1,3-propanediol (Mingcheng Chemical Co., Ltd.), 120.15g of 2-methyl-2-hydroxymethyl-1,3-propanediol (Mingcheng Chemical Co., Ltd.), 152.18g of 1,3- Propylene glycol (Guangfeng Chemical Co., Ltd.), after being incubated for 60 minutes, the polybasic acid comprises 664.52g of terephthalic acid (Baiqian Chemical Co., Ltd.), 155.51g of sebacic acid (Jinyu Chemical Co., Ltd.), 132.12g Methylsuccinic acid and 9.06g of catalyst monobutyltin oxide (Huansi Chemical Co., Ltd.) are slowly added to the reactor; with a heating rate of 15°C / hour, the temperature is raised to 200°C; Speed, slowly heat up to 260°C, heat preservation reaction for 20 hours; add 0.09g of catalyst monobutyltin oxide (Huansi Chemical Co., Ltd.) into the react...

Embodiment 3

[0071] (1) Preparation of insulating adhesive:

[0072] In an inert gas atmosphere reactor, slowly add weighed polyols while stirring at 140°C, including 520.75g of neopentyl glycol (Jinggang Chemical Co., Ltd.), 354.51g of 1,6-hexanediol ( Guangfeng Chemical Co., Ltd.), 40.25g of 2-ethyl-2-hydroxymethyl-1,3-propanediol (Mingcheng Chemical Co., Ltd.), after 40 minutes of heat preservation, the polybasic acid containing 664.52g of ortho-benzene Diformic acid (Baiqian Chemical Co., Ltd.), 332.26g of terephthalic acid (Baiqian Chemical Co., Ltd.), 141.58g of sebacic acid (Haili Chemical Co., Ltd.), 164.60g of glutaric acid (Haili Chemical Co., Ltd. Co., Ltd.) and 6.09g of catalyst antimony trioxide (Shanghai Xindian Chemical Materials Co., Ltd.) were slowly added to the reactor; at a heating rate of 10 °C / hour, the temperature was raised to 170 °C; Heating rate: slowly raise the temperature to 240°C, and keep the temperature for 23 hours; weigh 5.89g of catalyst antimony trioxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com