White packaging film for double-glazed photovoltaic module and preparation method thereof

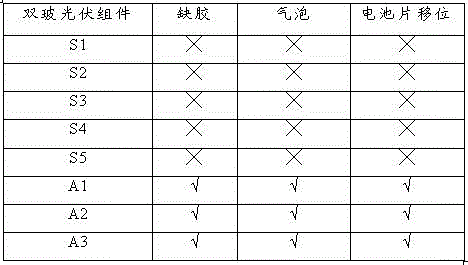

A technology for encapsulating adhesive films and double-glass photovoltaics, applied in adhesives, film/sheet adhesives, adhesive additives, etc., can solve the problems of weak elasticity and impact strength of EVA film, power reduction of double-glass photovoltaic modules, Inability to effectively reflect sunlight and other problems, to avoid displacement and lack of glue, improve photoelectric conversion efficiency, superior toughness and elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

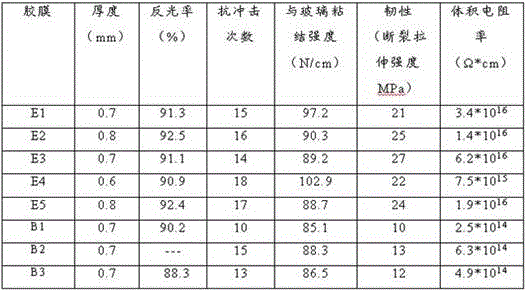

Embodiment 1

[0039] (1) Preparation of white masterbatch

[0040] In terms of parts by mass, 0.3 parts of titanium dioxide, 0.1 parts of sodium silicate and 100 parts of EVA [the mass percentage of VA content is 28%, the melt index is 25g / 10min (190°C, 2.16kg), and the DSC melting point is 70 ℃, French Arkema Company, 2825] fully mixed evenly, carried out melt extrusion, cooling, and granulation in a twin-screw extruder to obtain a white masterbatch with a mass concentration of white pigment of 0.3%;

[0041] (2) Preparation of white EVA film for double-glass photovoltaic modules

[0042] In terms of parts by mass, add 40 parts of ethylene-propylene rubber (50% ethylene content, 4520, American Dow Company) to 55 parts of EVA2825, 0.1 part of cross-linking agent dicumyl peroxide, and 0.3 parts of auxiliary cross-linking agent Triallyl isocyanate, 0.1 part of tackifier aminopropyltriethoxysilane, 0.3 part of antioxidant butylated hydroxyanisole (BHA), 5 parts of white masterbatch, 0.4 part ...

Embodiment 2

[0046] (1) Preparation of white masterbatch

[0047] In terms of parts by mass, 0.2 parts of zirconium dioxide, 0.2 parts of sodium tripolyphosphate and 100 parts of EVA [the VA weight percentage is 18%, the melting index is 2.5g / 10min (190°C, 2.16kg), and the DSC melting point is 88°C, DuPont Company of the United States, 460] fully mixed evenly, melt-extruded, cooled, and granulated in a twin-screw extruder to obtain a white masterbatch with a mass concentration of white pigment of 0.2%;

[0048] (2) Preparation of white EVA film for double-glass photovoltaic modules

[0049] In terms of parts by mass, add 36 parts of ethylene-propylene rubber (55% ethylene content, 4640 from Dow, USA) to 60 parts of EVA460, 0.2 part of cross-linking agent 1,1-di(tert-butyl peroxy) ring Hexane, 0.3 part of co-crosslinking agent triallyl cyanurate, 0.2 part of tackifier glycidylmioxypropyl trimethoxysilane, 0.3 part of antioxidant 2,6-tertiary butyl-4- Methyl phenol, 4 parts of white master...

Embodiment 3

[0053] (1) Preparation of white masterbatch

[0054] In terms of parts by mass, 0.3 parts of zinc oxide, 0.1 parts of sodium hexametaphosphate and 100 parts of EVA2825 were fully mixed and uniformly melted and extruded in a twin-screw extruder, cooled and granulated to obtain a white pigment with a mass concentration of 0.3 % of white masterbatch;

[0055] (2) Preparation of white EVA film for double-glass photovoltaic modules

[0056] In parts by mass, add 39 parts of ethylene-propylene rubber 4640 to 55 parts of EVA2825, 0.3 part of crosslinking agent 2-(2′-hydroxy-5′-methylphenyl) benzotriazole, 0.2 part of auxiliary crosslinking agent Ethylene glycol dimethacrylate, 0.1 part tackifier methacryloxypropyltrimethoxysilane, 0.3 part antioxidant bis(3,5-tertiary butyl-4-hydroxyphenyl)sulfur Ether, 6 parts of white masterbatch, 0.4 parts of anti-overflow rubber filler ultra-fine glass fiber, mix all the raw materials evenly, add them to the single-screw extruder, adjust the di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com