Production processes of packaging adhesive film with ultra-low ionic mobility and photovoltaic component

A technology of ion mobility and encapsulation film, which is applied in the field of photovoltaic power generation accessories to achieve the effects of improving blending compatibility, improving poor mechanical properties and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

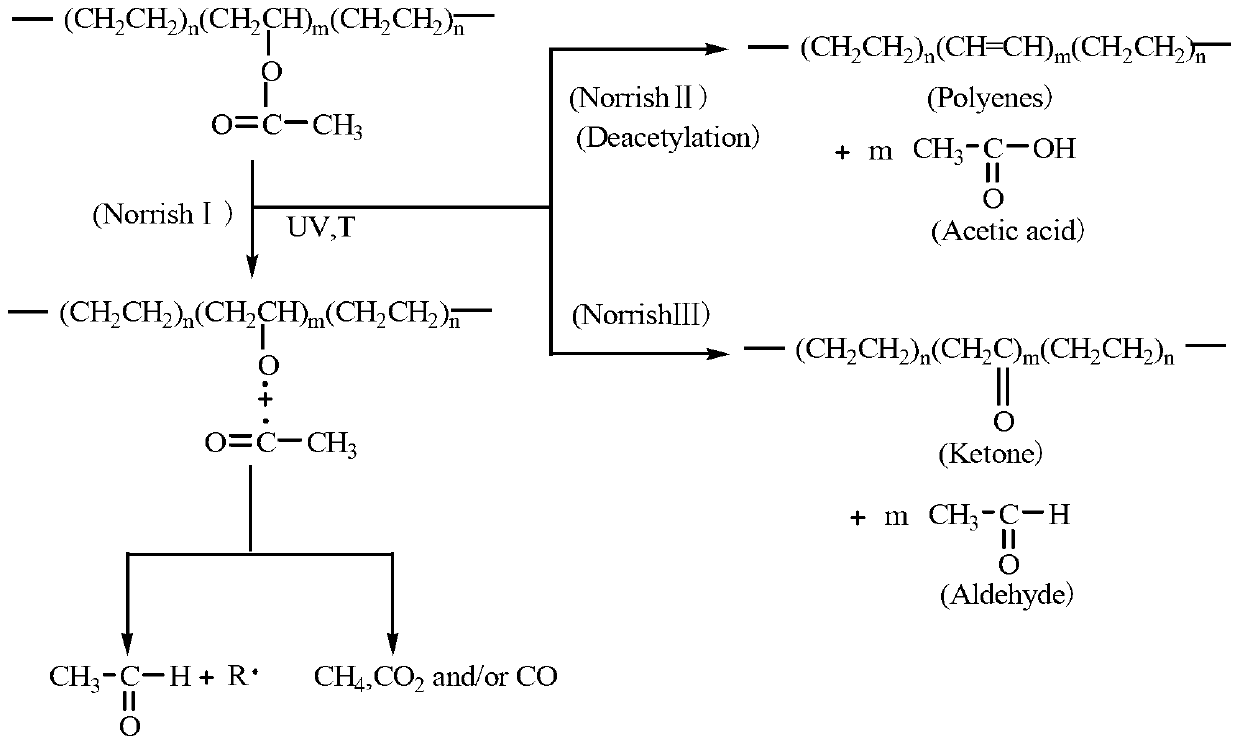

Problems solved by technology

Method used

Image

Examples

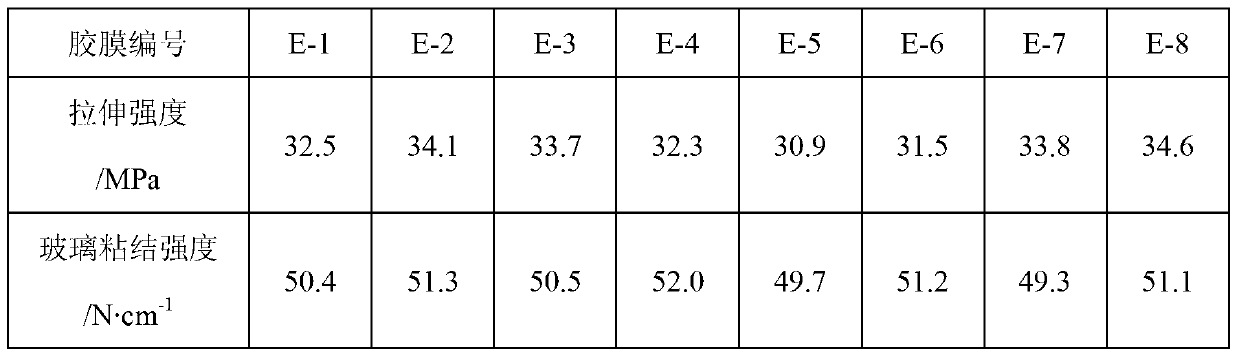

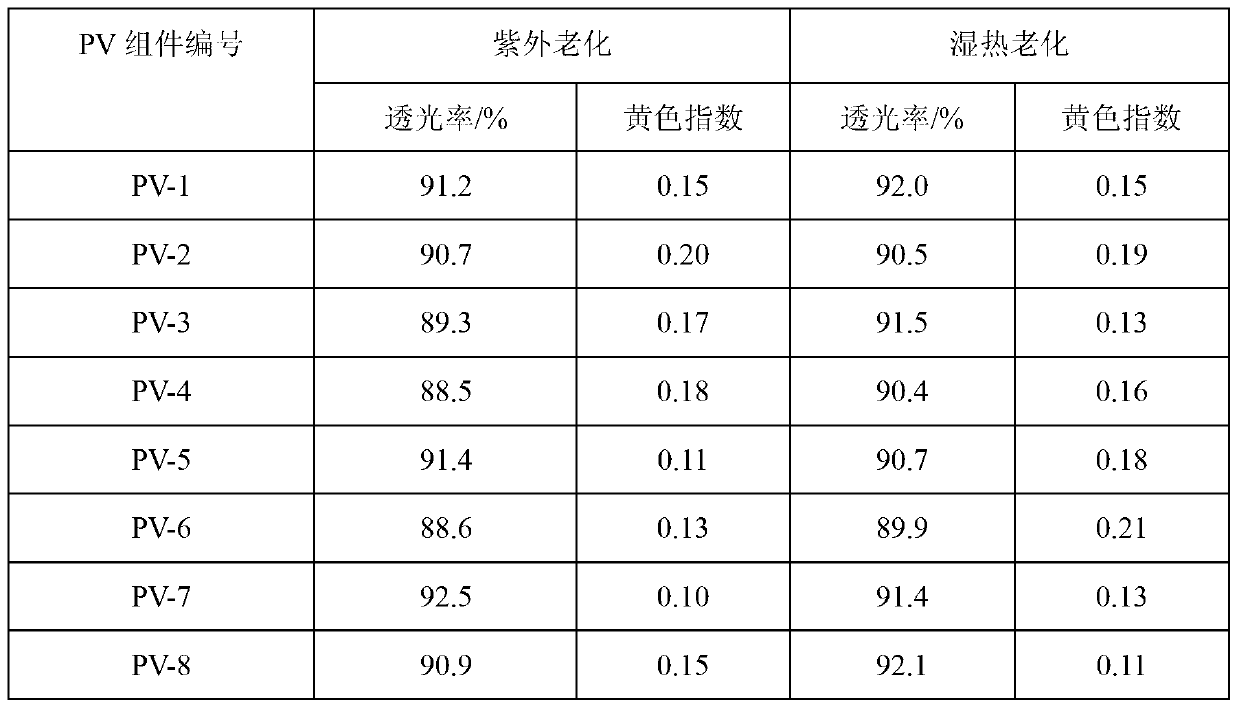

Embodiment 1

[0044] Adhesive layer: in terms of mass fraction, in 90 parts of ethylene-vinyl acetate copolymer, 5 parts of polyvinyl butyral mixed resin, add 5 parts of polypropylene glycol diglycidyl ether, 0.05 parts of 2-hydroxy-4-n- Octyloxybenzophenone, 0.05 part bis-2,2,6,6-tetramethylpiperidinol sebacate, 0.03 part β-(3,5-di-tert-butyl-4-hydroxyphenyl ) n-octadecyl propionate, 0.03 part of pentaerythritol distearyl diphosphite, 0.4 part of vinylethoxysilane, 0.4 part of tert-butyl peroxide 3,5,5-trimethylhexanoate.

[0045] Isolation layer: In terms of mass fraction, in 90 parts of dimethyl polysiloxane and 10 parts of ethylene-methyl acrylate copolymer mixed resin, add 0.5 parts of pentaerythritol distearyl diphosphite, 0.4 parts of peroxide 3 , tert-butyl 5,5-trimethylhexanoate.

[0046] The adhesive layer composition and the ion isolation layer composition are respectively mixed, melt-extruded, and cast into a film, and then the two films are stacked according to a thickness rat...

Embodiment 2

[0048] Adhesive layer: In terms of mass fraction, add 15 parts of phenyl glycidyl ether, 0.05 parts of 2-(2'-hydroxy- 3'-tert-butyl-5'-methylphenyl)-5-chlorobenzotriazole, 0.05 part of 2,4-dihydroxybenzophenone, 0.05 part of poly[1-(2'-hydroxyethyl base)-2,2,6,6-tetramethyl-4-hydroxypiperidine succinate], 0.05 part poly{[6-[(1,1,3,3-tetramethylbutyl)amino ]]-1,3,5-triazine-2,4-[(2,2,6,6,-tetramethyl-piperidinyl)imino]-1,6-hexylenediene[(2, 2,6,6-Tetramethyl-4-piperidinyl)imino]}, 0.05 part of triphenyl phosphite, 0.05 part of tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl ) propionate] pentaerythritol ester, 5 parts of γ-methacryloxypropyltrimethoxysilane, 10 parts of 1,1-(t-butyldiperoxy)-3,3,5-trimethylcyclohexyl alkyl.

[0049] Isolation layer: In terms of mass fraction, add 0.1 part of tetrakis[β-(3,5-di-tert-butyl- 4-Hydroxyphenyl)propionate]pentaerythritol ester, 5 parts of 1,1-(t-butyldiperoxy)-3,3,5-trimethylcyclohexane. Perform the same operation as in Example 1 t...

Embodiment 3

[0051] Adhesive layer: In terms of mass fraction, in 70 parts of ethylene-vinyl acetate copolymer and 5 parts of polyvinyl butyral mixed resin, add 10 parts of allyl glycidyl ether, 0.1 part of 2-(2'-hydroxy -3',5'-dipentylphenyl)benzotriazole, 0.1 parts of 2-hydroxy-4-n-octyloxybenzophenone, 5 parts of bis(2,2,6,6-tetramethyl -4-piperidinyl) sebacate, 0.05 parts n-octadecyl β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate, 5 parts pentaerythritol distearyl diphosphite Alcohol esters, 0.2 parts γ-aminopropyltriethoxysilane, 0.1 parts vinylethoxysilane, 5 parts tert-butyl peroxy-2-ethylhexyl carbonate .

[0052] Isolation layer: In terms of mass fraction, add 5 parts of tetrakis[β-(3,5-di-tert-butyl 4-hydroxyphenyl) propionate] pentaerythritol ester, 5 parts Peroxidation -2-Ethylhexyl tert-butyl carbonate . Perform the same operation as in Example 1 to obtain a 0.6 mm thick encapsulation film E-3 (the thickness ratio of the adhesive layer to the isolation layer is 1:3) a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com