Glass formula for producing direct current glass insulator

A glass insulator and glass technology, which is applied in the field of glass formulations for producing DC glass insulators, can solve the problems of aggravating sodium ion migration, accelerating glass aging, etc., and achieves the effect of significant suppression effect, preventing or slowing migration, and improving volume resistivity.

Active Publication Date: 2009-07-08

南京电气绝缘子有限公司

View PDF0 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, under the condition of DC transmission, the sodium ions in the soda-lime glass migrate in one direction and gather locally under the long-term action of the DC electric field, causing irreversible "aging" of the glass, especially due to the effect of the leakage conduction current, the heating of the insulator aggravates the migration of sodium ions , accelerates the aging of glass

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0012] The glass formula for producing DC glass insulators of the present invention may contain the following components: SiO 2 65%~72%;Al 2 o 3 1.5%~3.5%; Fe 2 o 3 0.05%~0.4%; CaO 5%~8%; MgO 2%~4%; K 2 O 5%~9%; BaO 0.1%~3%; Na 2 O 6%~9%; Li 2 O 0.1%~1%; SrO 0.1%~2%; B 2 o 3 0.1% to 1%.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

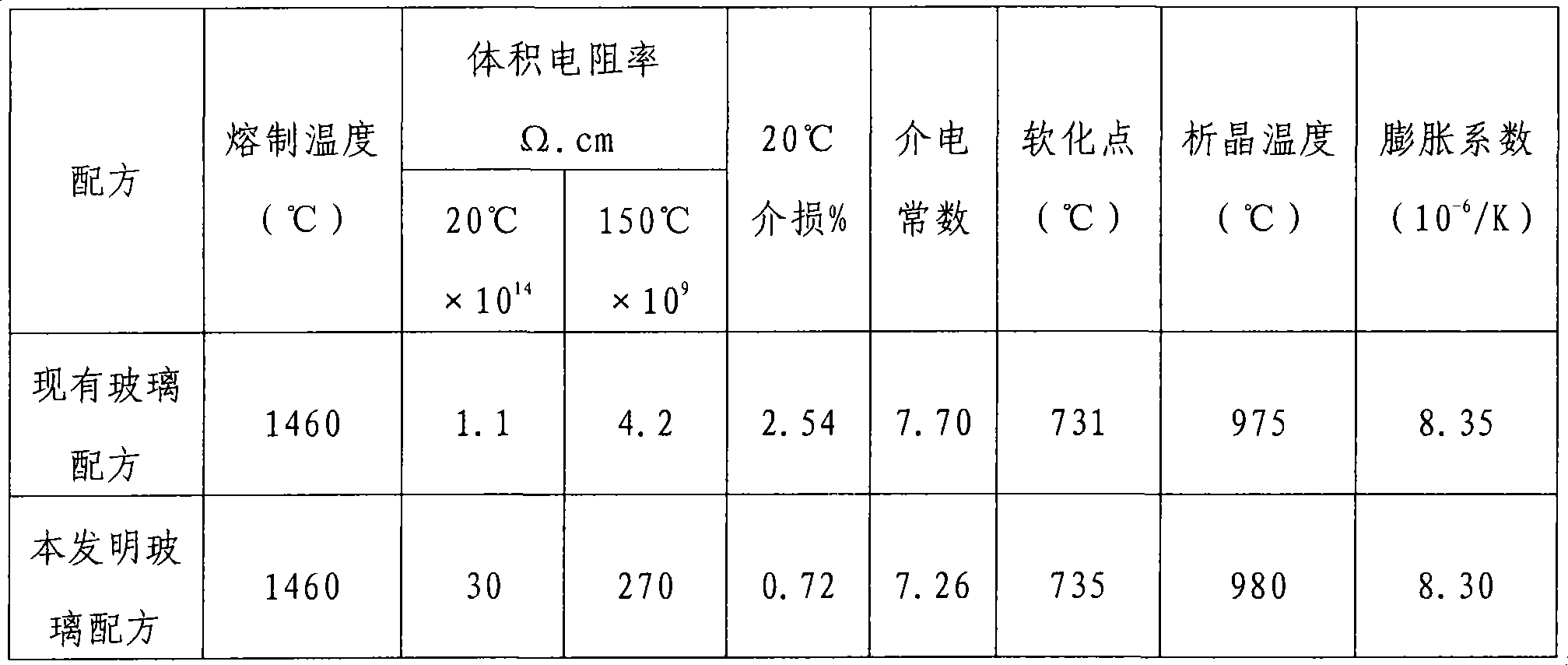

The invention discloses a formulation of glass for producing a direct current glass insulator. The formulation is characterized in that the glass comprises the following compositions in percentage by weight: 65 to 72 percent of SiO2, 1.5 to 3.5 percent of Al2O3, 0.05 to 0.4 percent of Fe2O3, 5 to 8 percent of CaO, 2 to 4 percent of MgO, 5 to 9 percent of K2O, 0.1 to 3 percent of BaO and 6 to 9 percent of Na2O; and simultaneously, the glass also comprises 0.1 to 1 percent of Li2O and 0.1 to 2 percent of SrO. The formulation can effectively reduce the transfer of sodions, improve volume resistivity of the glass, reduce dielectric loss and improve electrical performance of the glass insulator.

Description

technical field [0001] The invention relates to a glass formulation, in particular to a glass formulation for producing DC glass insulators. Background technique [0002] Soda-lime glass currently on the market has a mass percentage of: SiO 2 65%~72%;Al 2 o 3 1.5%~3.5%; Fe 2 o 3 0.05%~0.4%; CaO 5%~8%; MgO 2%~4%; K 2 O 1%~3%; Na 2 O 10% ~ 15%; BaO 0% ~ 3%, with low melting temperature and high thermal expansion coefficient, excellent melting process performance and toughening performance, and can be used in the manufacture of AC glass suspension insulators. However, under the condition of DC transmission, the sodium ions in the soda-lime glass migrate in one direction and gather locally under the long-term action of the DC electric field, causing irreversible "aging" of the glass, especially due to the effect of the leakage current, the heating of the insulator aggravates the migration of sodium ions , accelerated the aging of glass. Therefore, DC glass insulators ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C03C3/087

Inventor 蔡海龙孔祥云石玉秉

Owner 南京电气绝缘子有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com