Electric insulating epoxy resin composition, preparation method and use of composition

An epoxy resin and electrical insulation technology, applied in the field of materials, can solve the problems of improving the volume resistivity of epoxy insulating materials, affecting processability, and emphasizing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

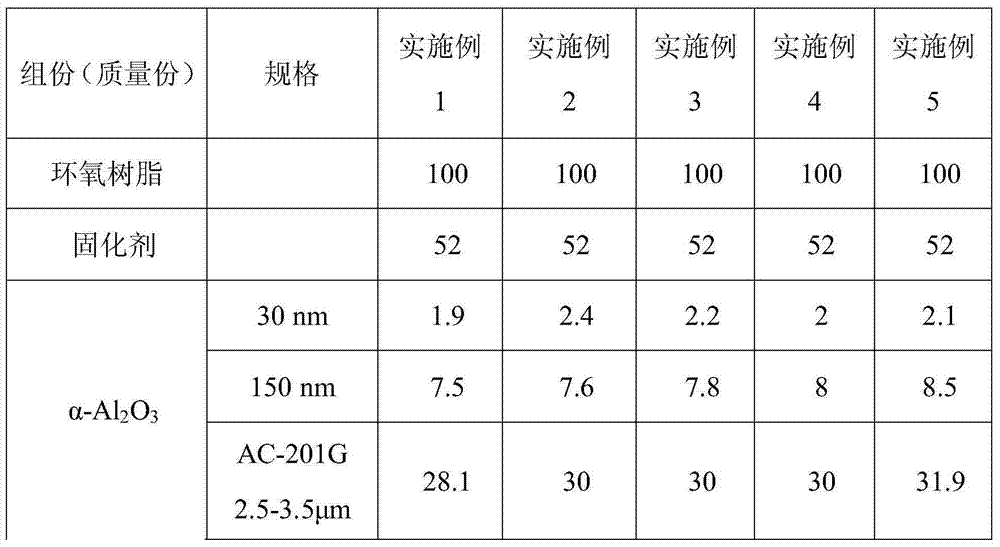

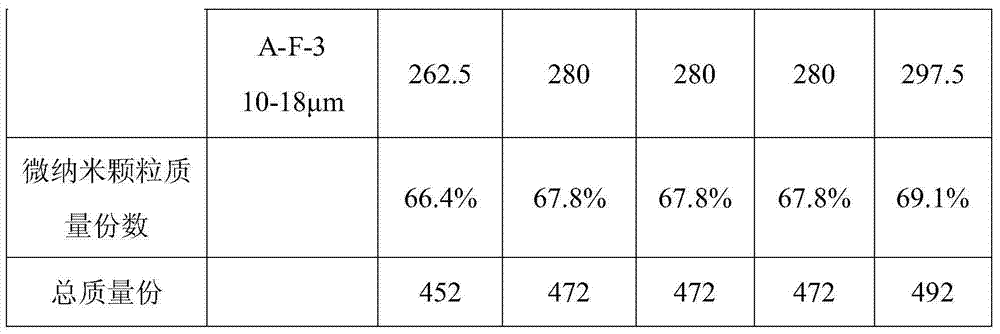

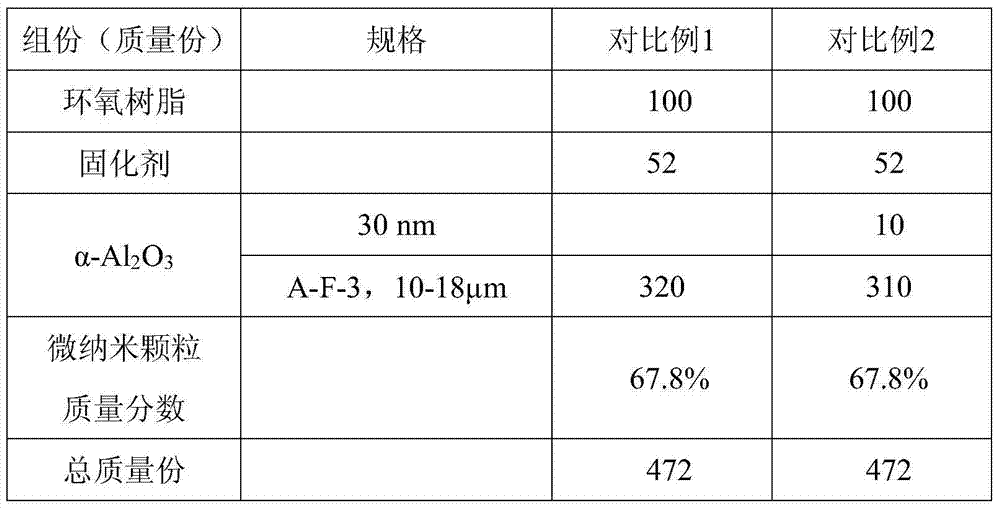

Embodiment 1-5

[0083]According to Table 1, the components of the formula amount are mixed evenly by the high-speed disperser DISPERMAT of VMA-Getzmann Company at 120-150 ° C to form an epoxy casting formula. After vacuum degassing, pour it into a preheated mold. Curing and molding at 105-150° C. to obtain Examples 1-5 of electrical insulating epoxy resin compositions.

[0084] Nanoscale and submicron α-Al adopted in the embodiment 1-5 of the present invention 2 o 3 The purity is ≥99.9%, and the sphericity is greater than or equal to 0.85.

[0085] The micronano α-Al that adopts in the embodiment 1-5 of the present invention 2 o 3 All have been surface treated, and the surface treatment agent is γ-glycidoxypropyltrimethoxysilane.

[0086] The composition and mass ratio of Component A epoxy resin of Example 1-5 of the present invention are CT200:CY179:CY5995=4:3:3

[0087] The composition and mass ratio of component B curing agent of Example 1-5 of the present invention are B-570:HY1235:P...

Embodiment 6-8

[0106] According to Table 5, the components of the formula amount are mixed evenly by the high-speed disperser DISPERMAT of VMA-Getzmann Company at 120-150 °C to form an epoxy casting formula. After vacuum degassing, pour it into a preheated mold. Curing and molding at 105-150° C. to obtain Examples 6-8 of electrical insulating epoxy resin compositions.

[0107] Nanoscale and submicron-scale α-Al adopted in the embodiment 6-8 of the present invention 2 o 3 The purity is ≥99.9%, and the sphericity is greater than or equal to 0.85.

[0108] The micro-nano particles used in Examples 6-8 of the present invention are all surface-treated, and the surface treatment agent is γ-glycidoxypropyltrimethoxysilane

[0109] The composition and mass ratio of the component A epoxy resin in Examples 6-8 of the present invention are CT200:CT5532:CY5995=2:1:1.

[0110] The composition and mass ratio of component B curing agent of Example 6-8 of the present invention are B-570:HY5996:PAPA=9:2:1...

Embodiment 9~12

[0118] According to Table 7, the components of the formula amount are mixed evenly by the high-speed disperser DISPERMAT of VMA-Getzmann Company at 120-150 ° C to form an epoxy casting formula. After vacuum degassing, pour it into a preheated mold. Curing and molding at 105-150°C to obtain an electrical insulating epoxy resin composition.

[0119] The composition and mass ratio of the component A epoxy resin in Examples 9-12 of the present invention are CT200:CY179:CY5995=3:1:1.

[0120] The composition and mass ratio of the component B curing agent of Examples 9-12 of the present invention are B-570:HY5996:PAPA=8:2:1.

[0121] The micronano α-Al that adopts in the embodiment 9-12 of the present invention 2 o 3 The purity is ≥99.9%, and the sphericity is greater than or equal to 0.85.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com