Preparation method of neutral flotation agent for purifying quartz minerals

A flotation agent and neutral technology, which is applied in the field of preparation of neutral flotation agents, to achieve the effects of reducing treatment costs, reducing the risk of waste acid polluting the environment, and reducing investment and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0026] Example 1, take Fe 2 o 3 The vein quartz type quartz sand with a content of 130ppm and a particle size composition of 0.5mm is mixed with water to make a slurry with a mass concentration of 30%, placed in a flotation cell, stirred for 1min, and then stirred for 3min after adding an inhibitor. Take 0.2ml of neutral flotation agent, dilute it to 20ml with water, add it to the flotation tank at one time, stir for 1min, inflate for 30s, scrape to collect the foam, which is the flotation concentrate. In this scheme, the productive rate of flotation concentrate is 96%, Fe 2 o 3 The content is 85ppm.

example 2

[0027] Example two, the Fe 2 o 3 River and lake sedimentary quartz sand with a content of 0.14% and a particle size composition of 0.5mm is mixed with water to make a slurry with a mass concentration of 50%. After pretreatment by common mechanical scrubbing methods, the mud is removed to obtain scrubbing concentrate. Prepare the scrubbing fine sand and water to make a slurry with a mass concentration of 20%, put it in the flotation tank and stir for 1 minute, add the inhibitor and then stir for 3 minutes. Take 0.4ml of this neutral flotation agent, dilute it to 20ml with water, add it to the flotation tank at one time, stir for 2min, inflate for 30s, scrape to collect the foam, which is the flotation concentrate. In this scheme, the productive rate of flotation concentrate is 70%, Fe 2 The O content is 0.08%.

example 3

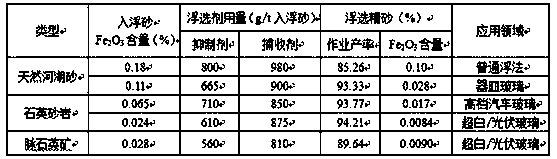

[0028] Example 3: Utilize the neutral flotation of the present invention to purify other qualified size grade quartzite and vein quartz type quartz sand. Under the same flotation conditions, the flotation agent consumption and flotation fine sand product index are shown in Table 1.

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com