Conveying type automatic spraying machine

An automatic spraying and conveying technology, used in coatings, devices for coating liquids on surfaces, surface pretreatment, etc., can solve problems such as air pollution, easy to cause damage, affecting the spraying effect of products, etc., to reduce labor intensity, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

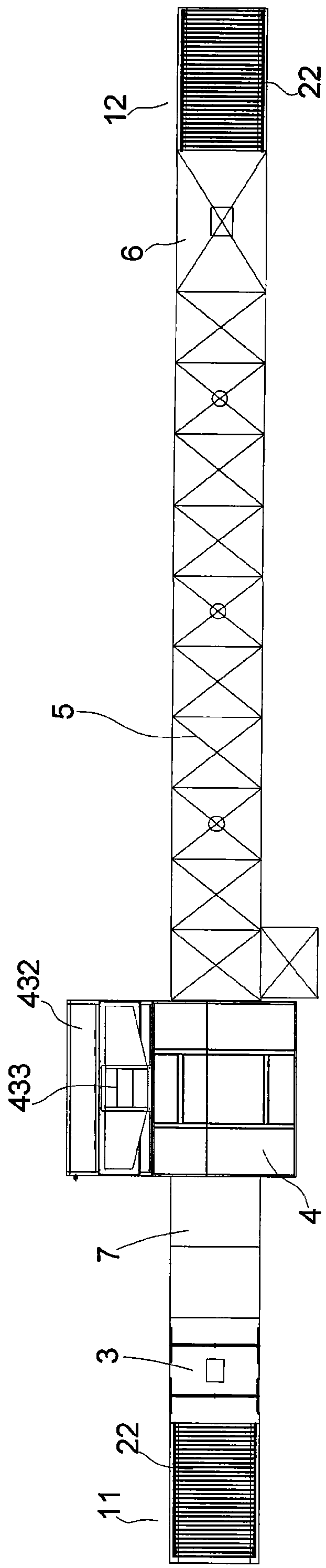

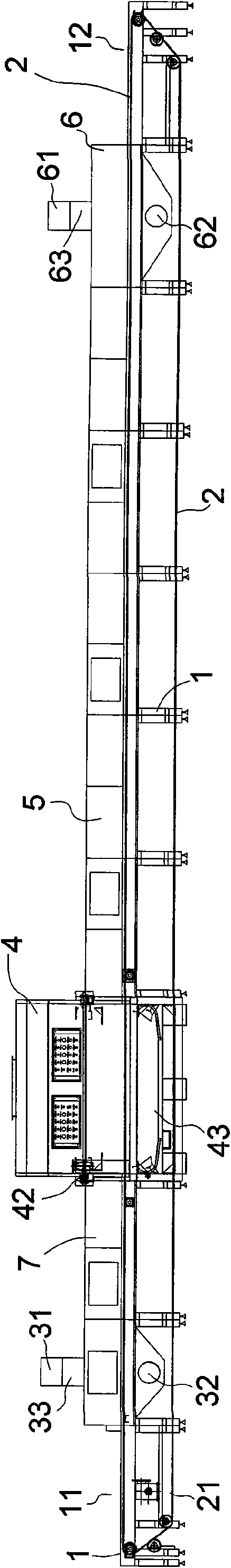

[0016] See figure 1 , 2 , the present invention comprises: have certain length strip frame 1, the conveyer belt 2 that is installed along frame 1, and the electrostatic precipitator chamber 3 that is installed on frame 1 successively, preheating chamber 7, spraying chamber 4, oven 5, Cooling chamber6.

[0017] The frame 1 is strip-shaped, and each chamber is installed along the top of the frame 1 . A feeding area 11 is vacant at the front end of the frame 1 , and a blanking area 12 is vacant at the end of the frame 2 . The user places the product to be sprayed on the conveyer belt 2 from the feeding area 11 , and takes off the sprayed product from the dropping area 12 .

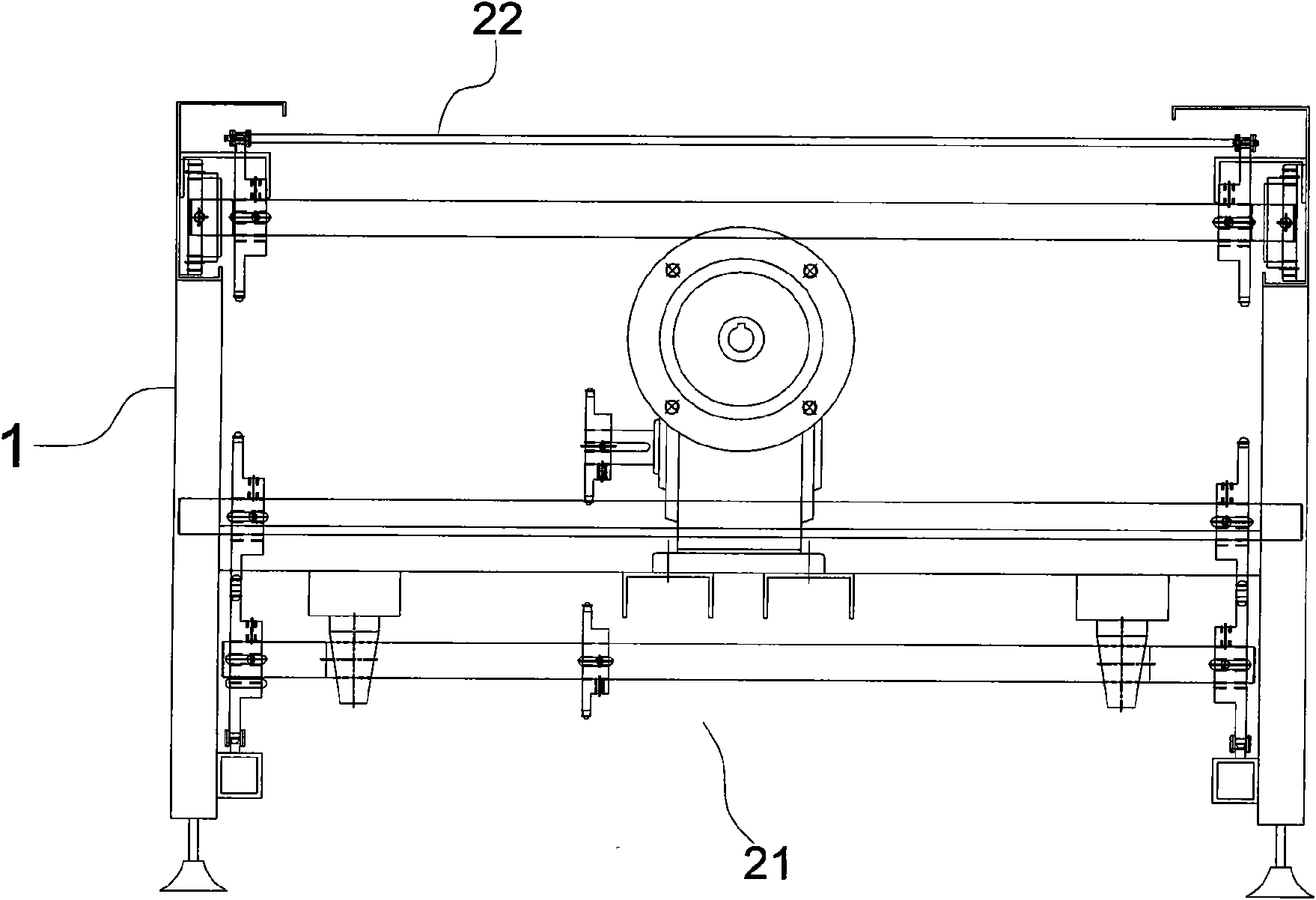

[0018] see image 3 , the conveyor belt 2 includes: a chain transmission mechanism 21 and a roller 22 laid along the frame 1 . The rollers 22 are evenly laid on the upper end of the frame 1, the chains are arranged symmetrically on both sides of the frame 1, and the two ends of the rollers 22 are connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com