Device and method for recovering ammonia during wastewater treatment

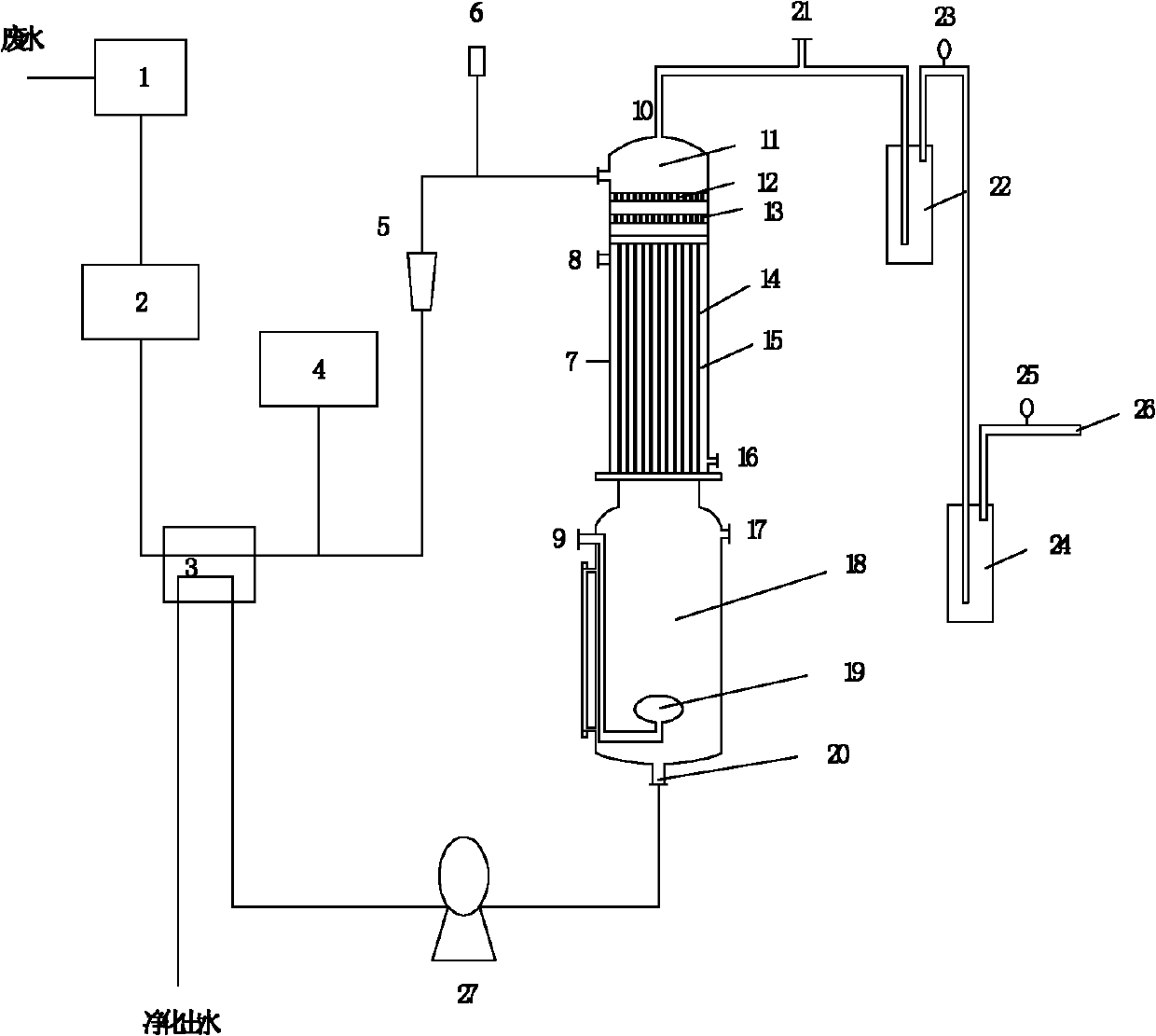

A technology for wastewater treatment and ammonia recovery, applied in water/sewage multi-stage treatment, heating water/sewage treatment, neutralized water/sewage treatment, etc., can solve the problem of inability to effectively guarantee the removal effect of ammonia nitrogen, small gas-liquid contact area, etc. Problems, to avoid air pollution, easy to operate, expand the effect of the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

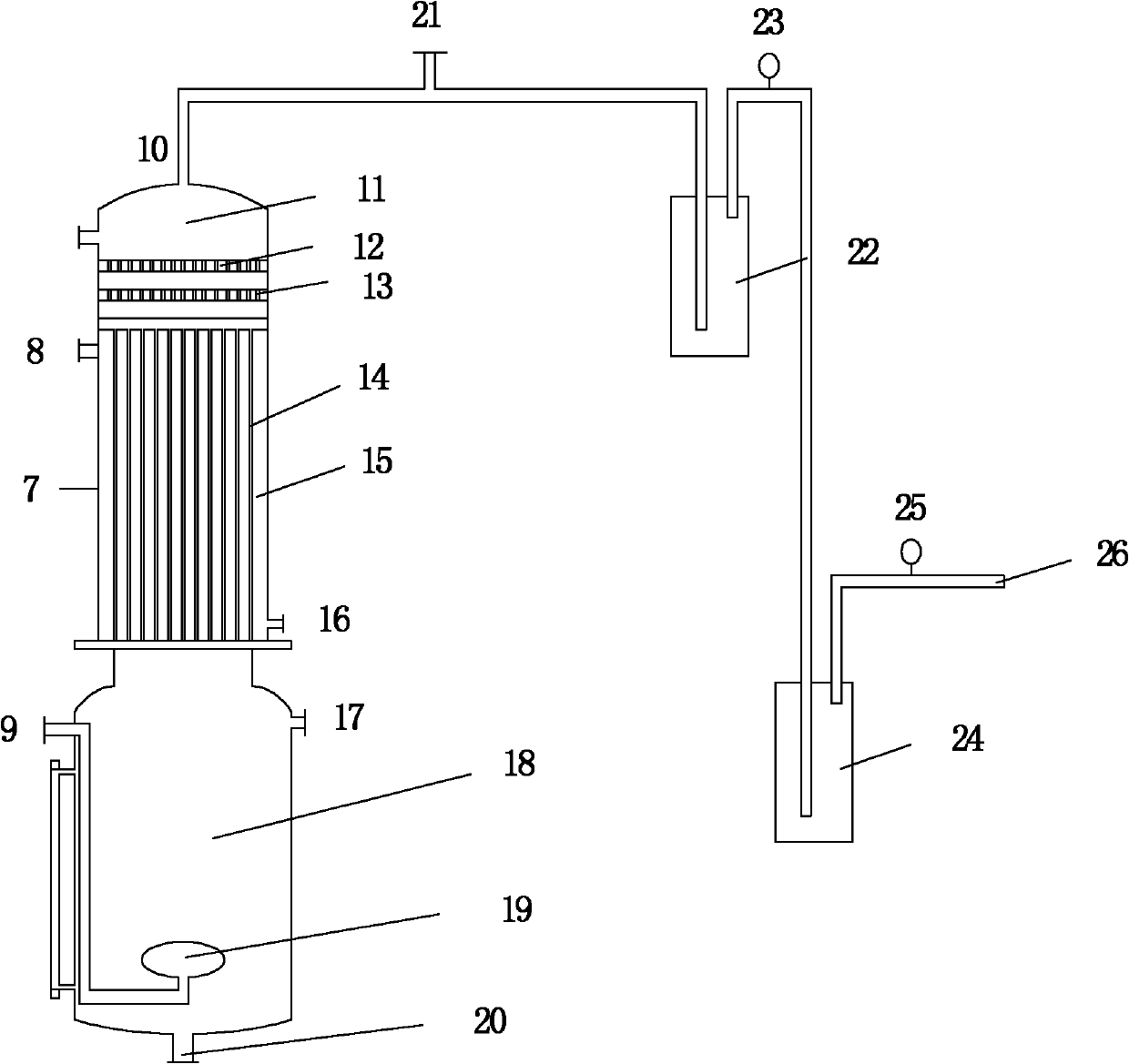

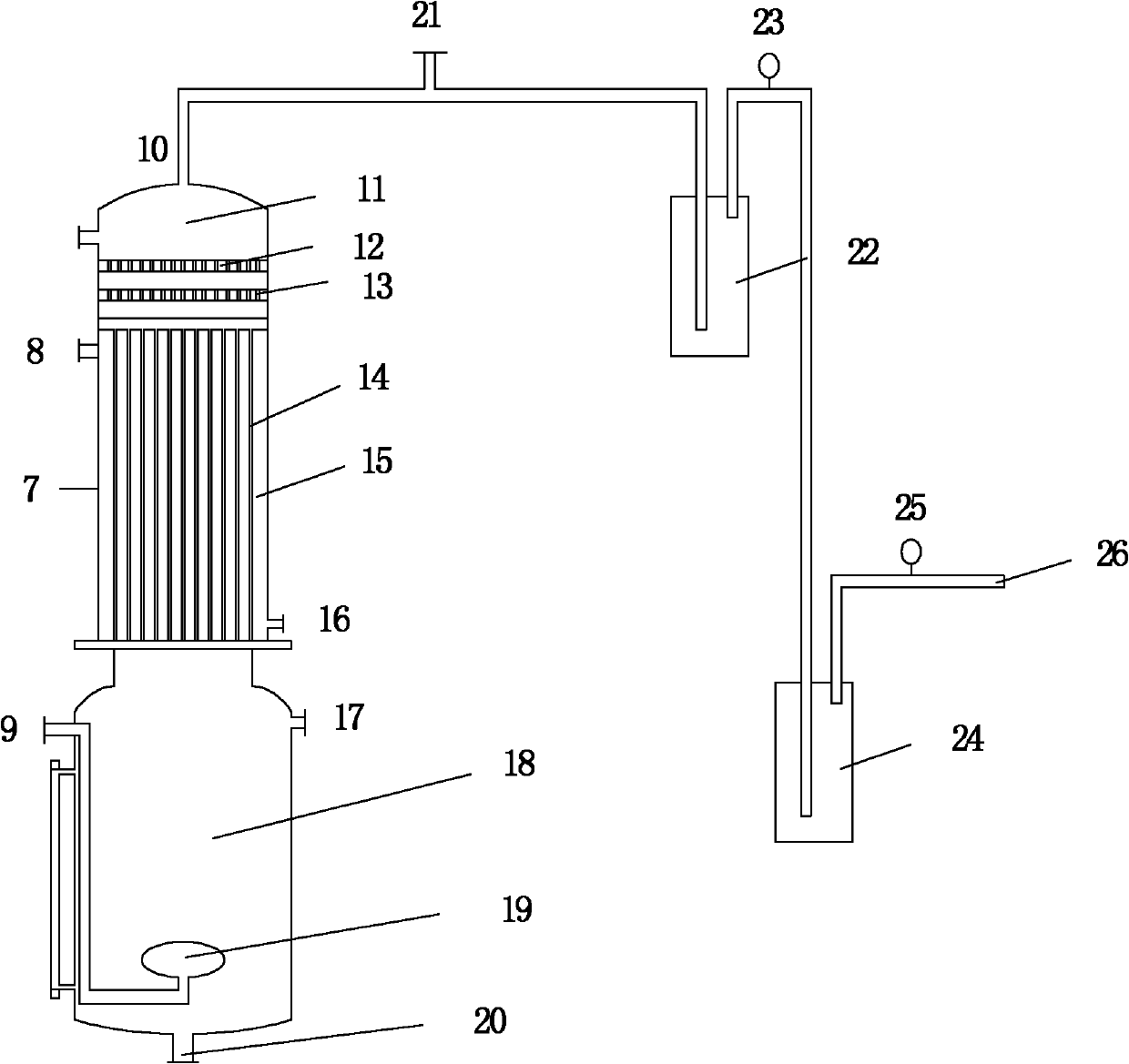

Method used

Image

Examples

Embodiment 1

[0021] The wastewater with an ammonia nitrogen content of 1194 mg / L ammonium chloride is treated and ammonia is recovered. The experimental vacuum is controlled at 0.04-0.06MPa, and the heater temperature is controlled at 40-50°C. The removal rate of ammonia nitrogen reaches over 99% within three hours.

[0022] time (h)

Embodiment 2

[0024] The phenol-containing wastewater with an ammonia nitrogen content of 3000mg / L is treated and ammonia is recovered. In the experiment, the vacuum degree was controlled at 0.04-0.06MPa, and the heater temperature was controlled at 40-50°C. The removal rate of ammonia nitrogen reaches over 99% within three hours, and the recovery rate of ammonia reaches over 99%.

[0025] time (h)

Embodiment 3

[0026] Example 3: Treat oily wastewater with an ammonia nitrogen content of 1322 mg / L and recover ammonia. The experimental vacuum is controlled at 0.04-0.06MPa, and the heater temperature is controlled at 40-50°C. The removal rate of ammonia nitrogen reached over 99% within three hours, and the presence of oil did not have much influence on the removal of ammonia nitrogen.

[0027] time (h)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com