Electro-deionization method and device for synchronously concentrating and purifying heavy metal wastewater

An electrodeionization and heavy metal technology, applied in the field of wastewater treatment and heavy metal wastewater treatment, can solve the problems of contact between metal bolts and ion exchange membrane, short circuit, leakage, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

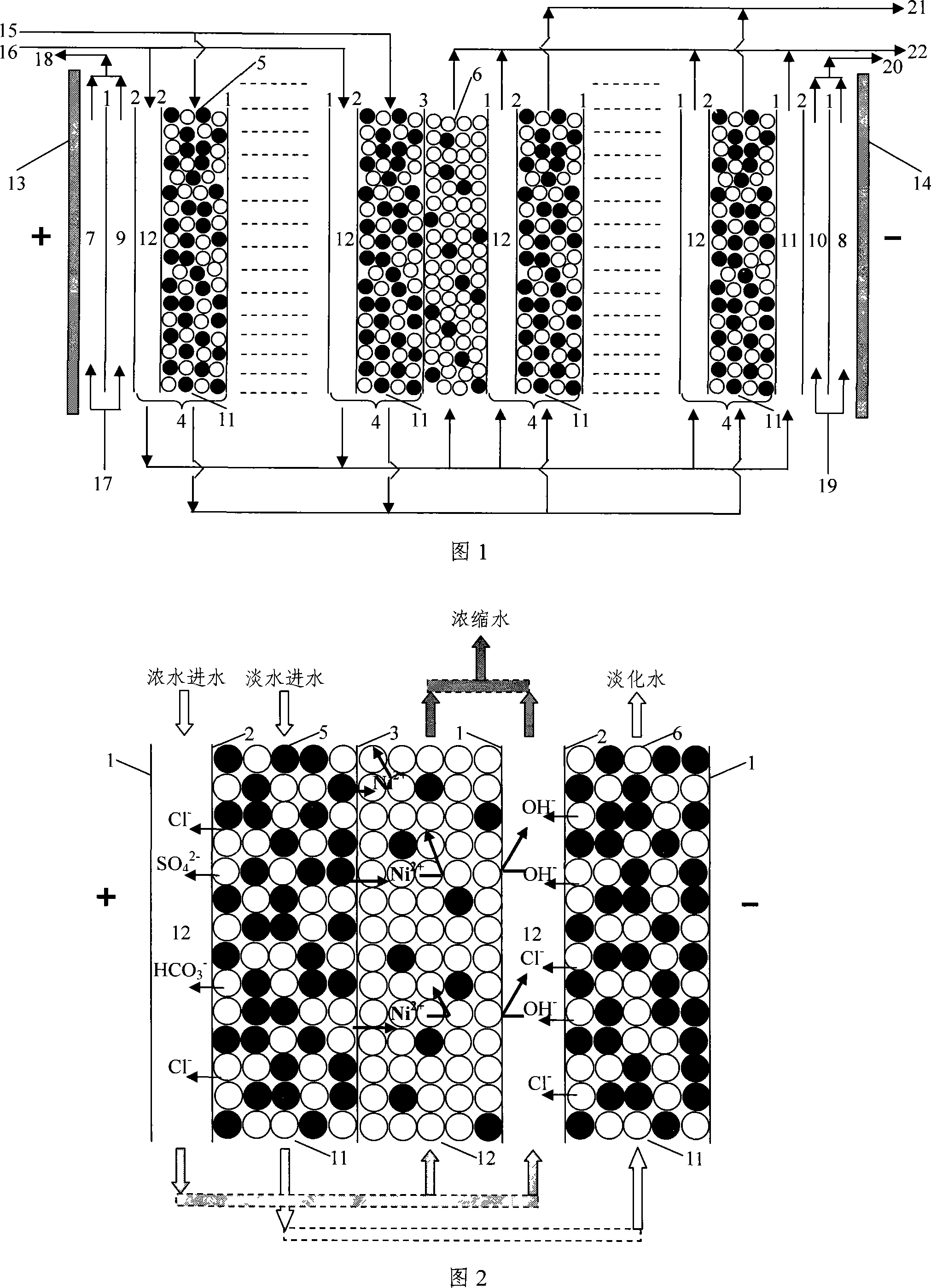

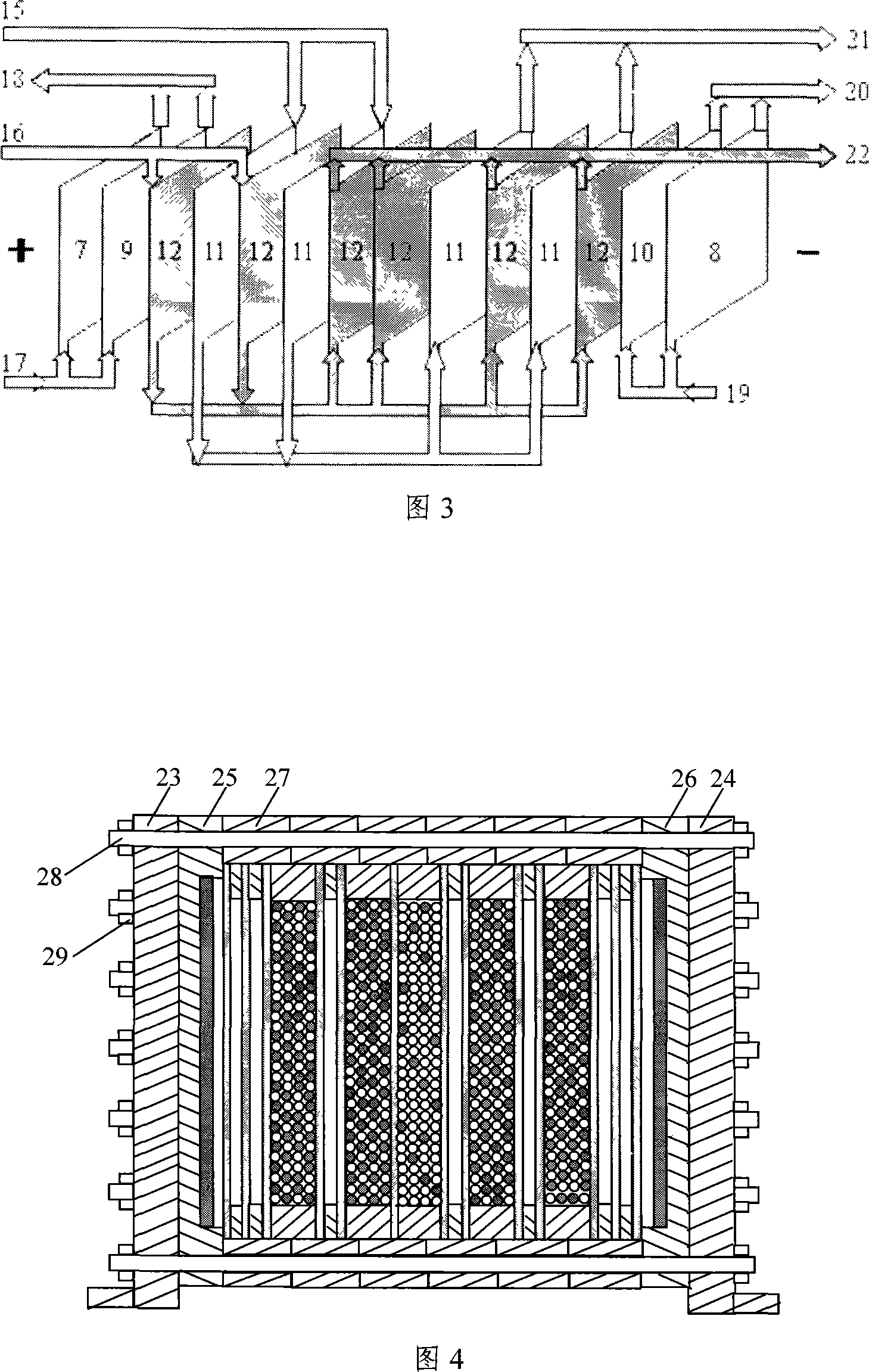

Embodiment 1

[0049] In this embodiment, the electrodeionization device is a one-stage two-stage structure, and each stage contains two desalination chambers, and its cross-section is shown in Figures 4 and 5 . The separator of the desalination chamber is 100*300*3mm, the separator of the concentration chamber is 100*300*0.9mm, the specification of the separator of the first concentration chamber filled with resin after reversing is also 100*300*3mm, and the effective membrane area 160cm 2 . The ion-exchange membrane used is a special-purpose ion-exchange membrane for heterogeneous low-permeability electrodeionization, produced by Zhejiang Qianqiu Environmental Protection Water Treatment Co., Ltd.; the ion-exchange resins are D072 and D296 macroporous strong acid and strong basic resins, and the volume of the anion and yang resins in the desalination chamber The ratio is 1:1, and the volume ratio of the anion and yang resins filled in the first concentrating chamber after the water flow is...

Embodiment 2

[0052] In this example, the structure of the electrodeionization device, the specifications of the partitions of the concentration chamber and the desalination chamber, the internal water flow, and the ion exchange membrane are all the same as those in Example 1, and the ion exchange resins used are also D72 and D296 macroporous strong acid, strong Basic resin, but the resin particle size range is the standard particle size, that is, 0.3-1.25mm.

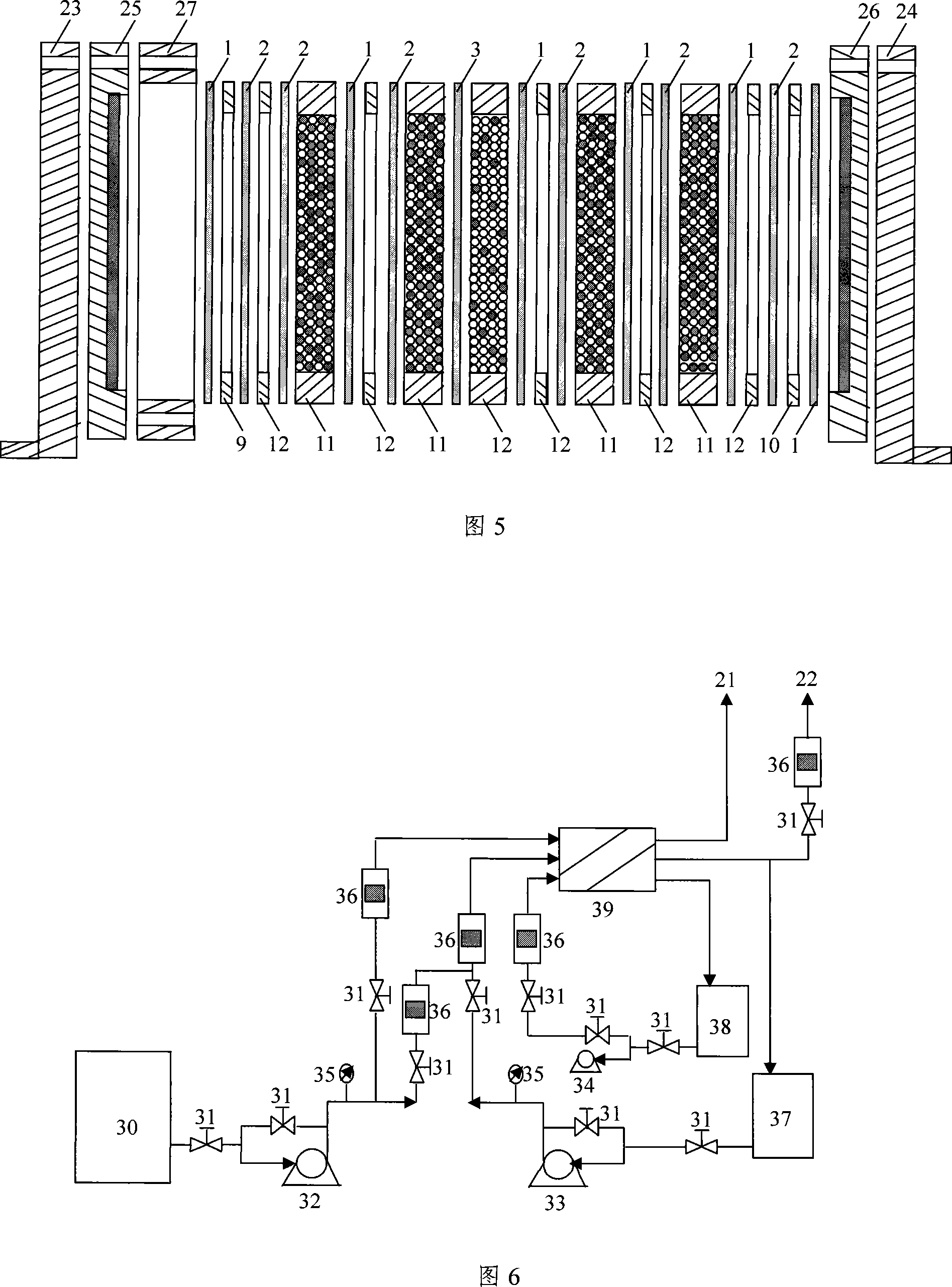

[0053] The fresh water raw water tank 30 and the concentrated water circulation tank are also pre-configured with 50 mg·L -1 nickel sulfate (NiSO 4 ) solution, and with H 2 SO 4 Adjust the pH of the raw water in the fresh water tank to 5.1, and the pH of the raw water in the concentrated water circulation tank to 3.16. The electrode water is Na with a mass concentration of 0.3%. 2 SO 4 solution. At the initial stage of operation, the concentrated water is firstly circulated in a closed circuit, and the water output from the fre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com