Patents

Literature

38results about How to "Improved hydrodynamic properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

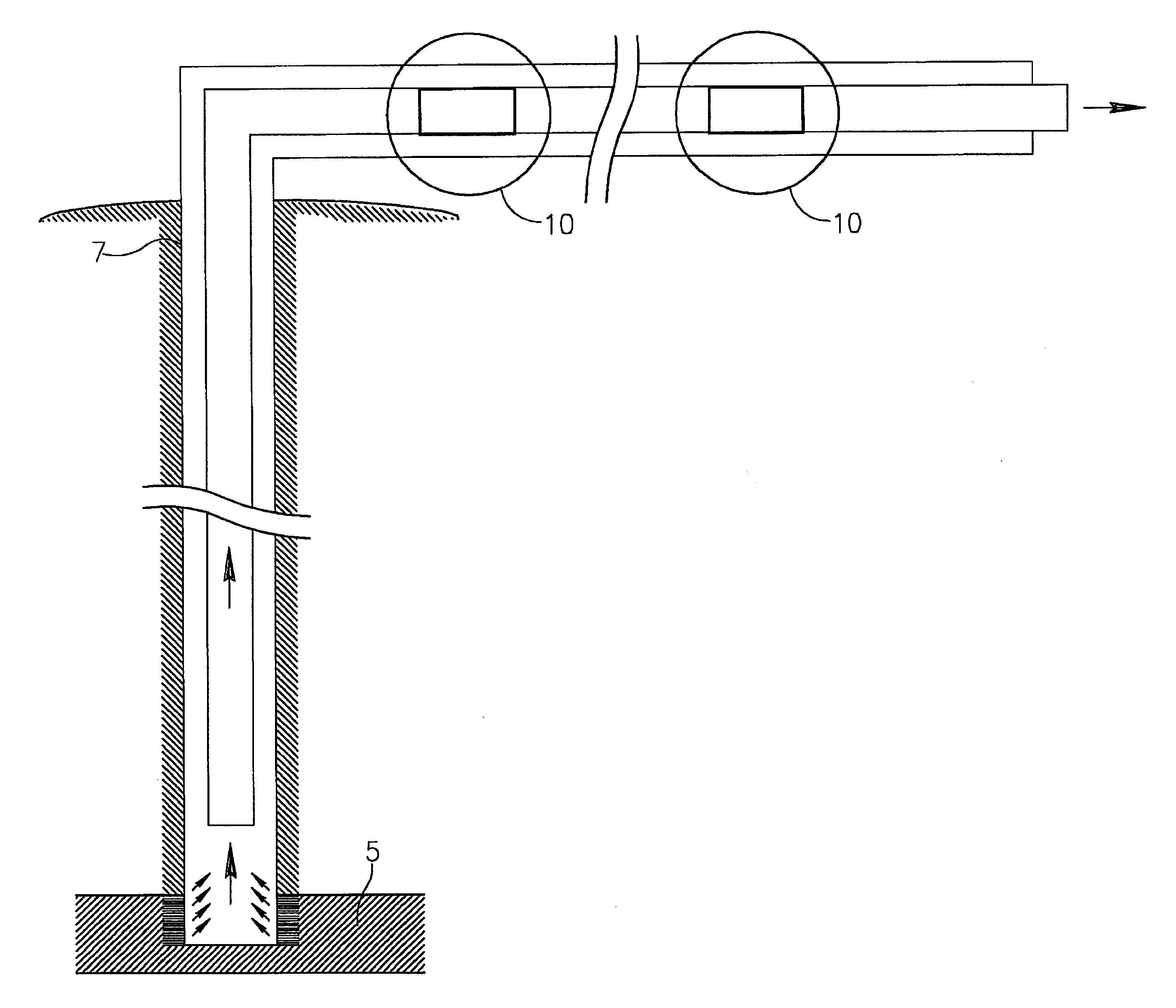

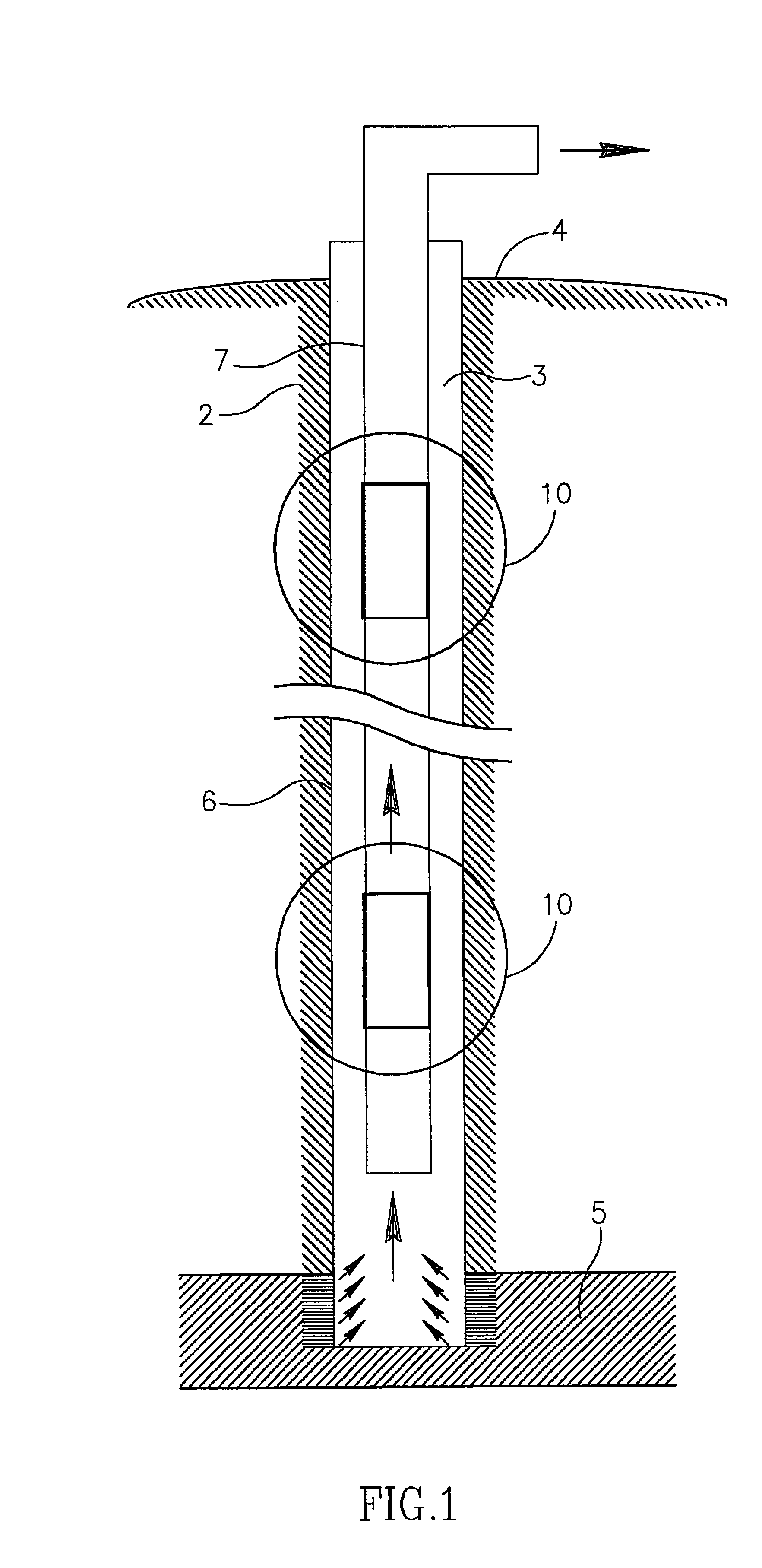

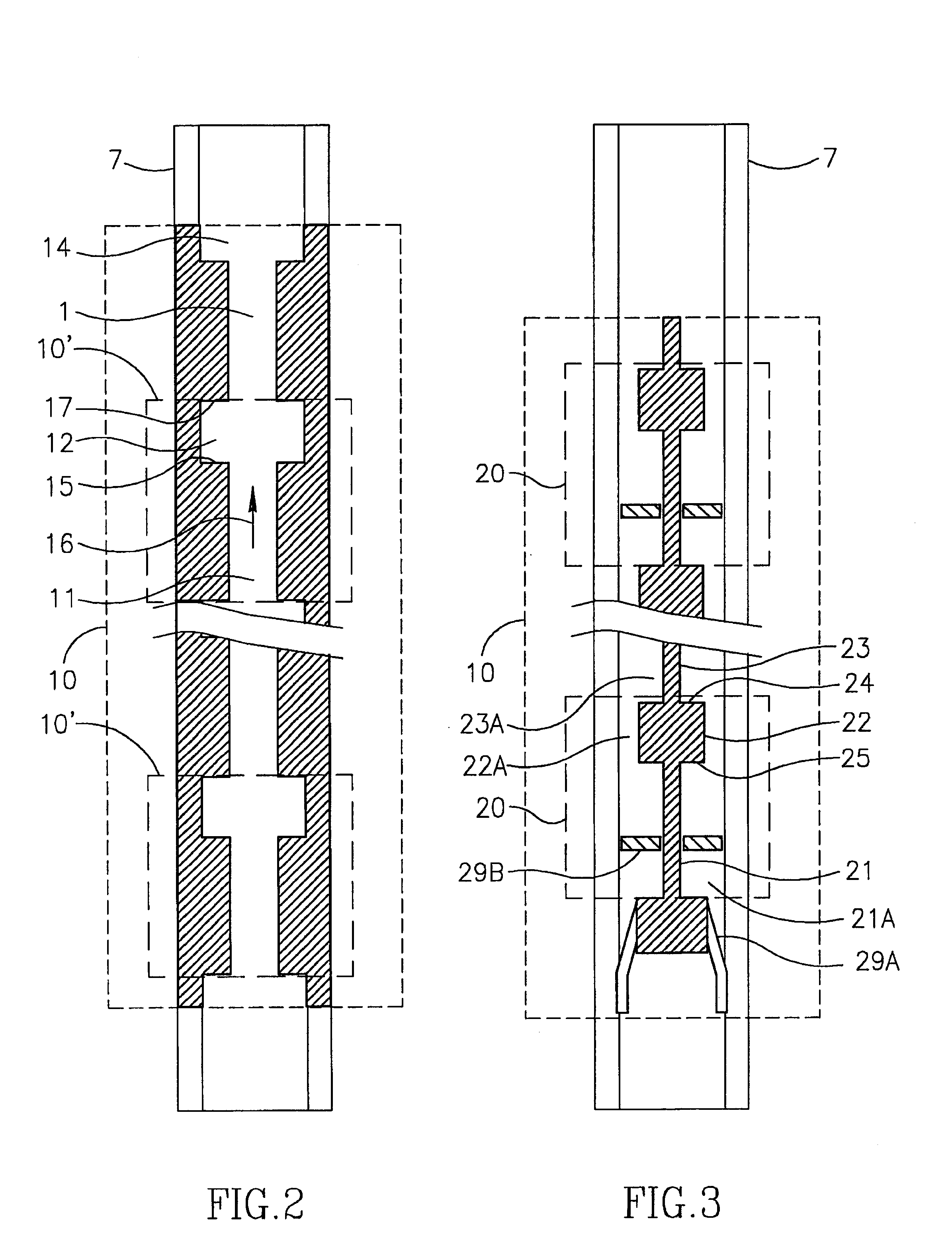

Method and apparatus for conveying fluids, particularly useful with respect to oil wells

InactiveUS6568477B1Reduce deliveryIncrease productionDrilling rodsFluid removalViscous liquidLow speed

A method and apparatus for conveying a fluid flowing through a flow passageway (16) in a tubing (7), by; introducing into the flow passageway (16) flow zones of small cross-sectional area (11) alternating with flow zones of large cross-sectional area (12) to produce high-velocity, low-pressure zones alternating with low-velocity, high-pressure zones; and providing abrupt transitions from the small cross-sectional area zones (11) to the large cross-sectional area zones (12) to produce a turbulent flow generating swirls and eddies (19) at such transitions. The method and apparatus are particulary useful in oil well applications where the fluid is an oil-gas mixture, but could be used in other applications where the fluid is a liquid-sand mixture, a gas-liquid mist, or a viscous liquid.

Owner:PARADIGM GEOPHYSICAL LTD +4

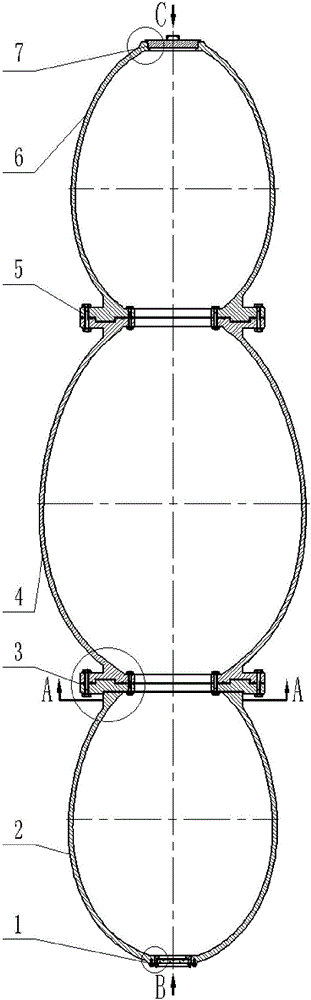

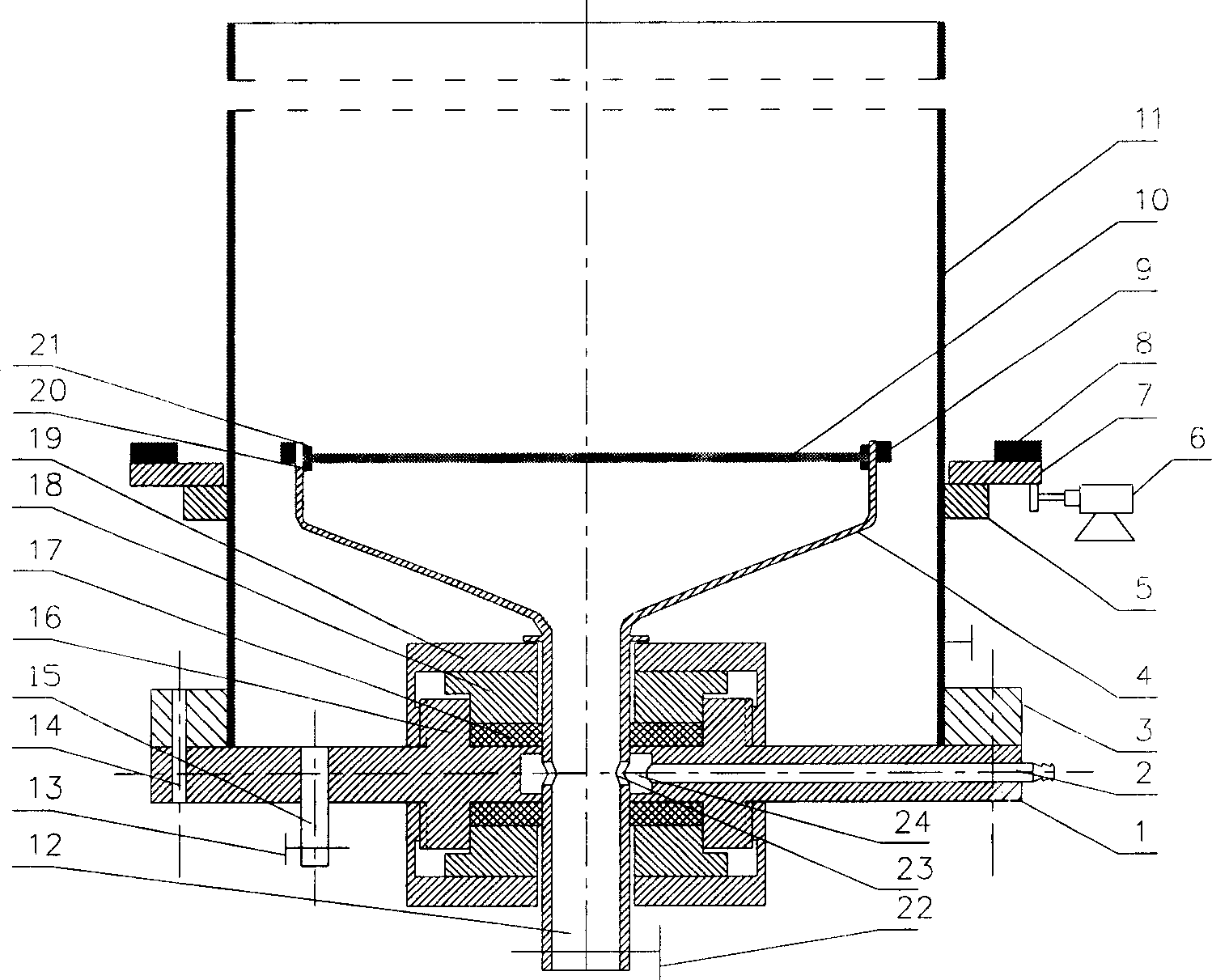

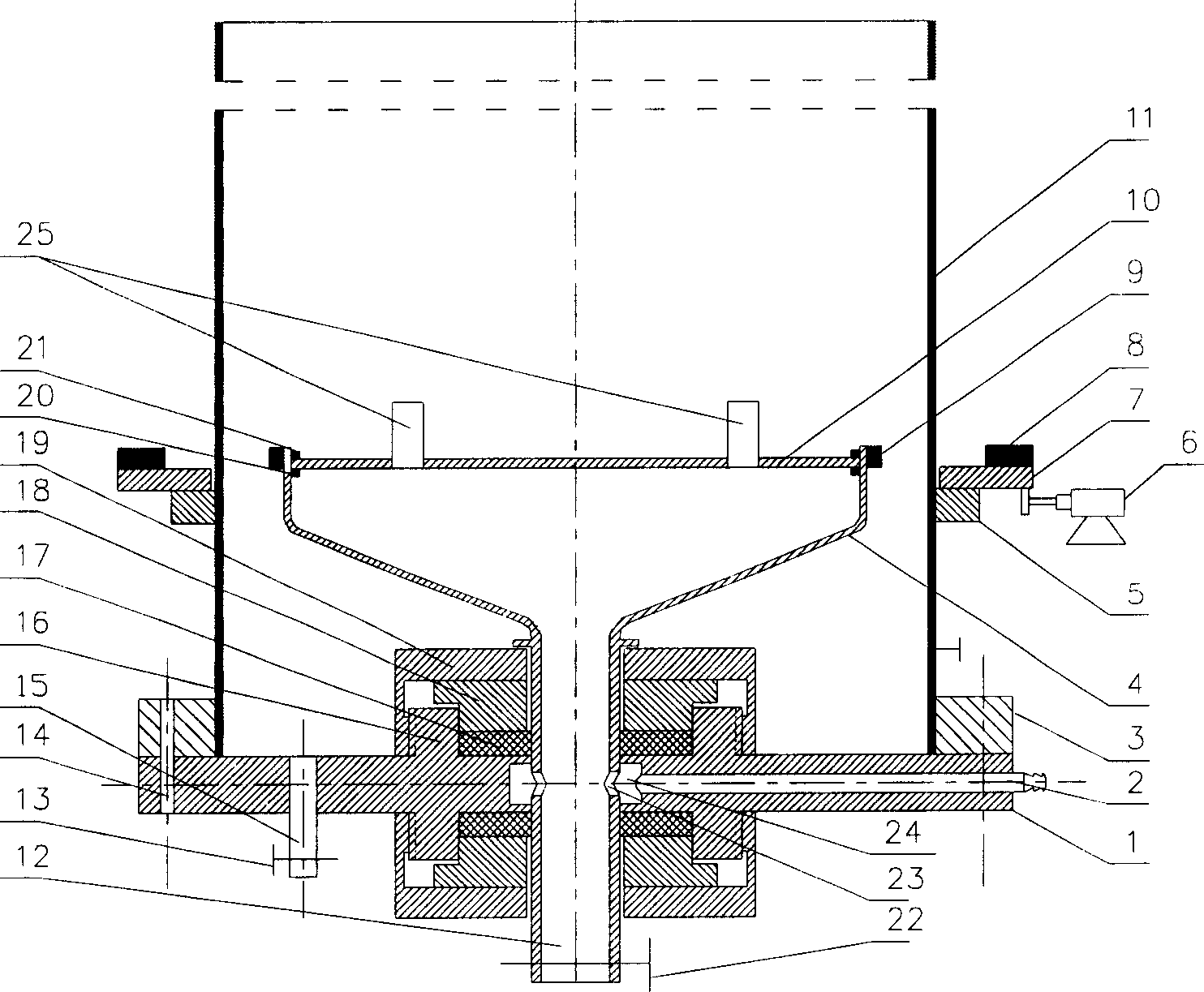

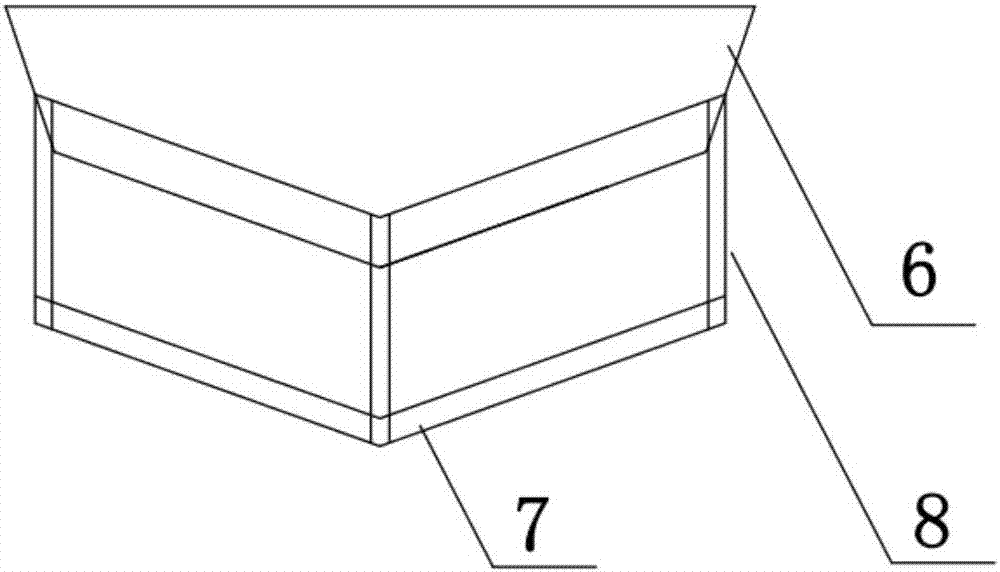

Bionic pressure-resisting device

ActiveCN104986312AReduce resistanceImproved hydrodynamic propertiesUnderwater vesselsUnderwater equipmentMan machineEngineering

The invention discloses a bionic pressure-resisting device. The bionic pressure-resisting device comprises a plurality of egg-shaped bionic pressure-resisting shells, and the two ends of each egg-shaped bionic pressure-resisting shell are a blunt end and a sharp end; the blunt ends and the sharp ends of the adjacent egg-shaped bionic pressure-resisting shells are sequentially connected through a shell connecting device, and an observation window device is arranged on the bow of the bionic pressure-resisting device; and a cabin door device is arranged on the tail of the bionic pressure-resisting device. According to the bionic pressure-resisting device, through the scheme that the egg-shaped bionic pressure-resisting shells are connected, the space of a cabin is increased, the man-machine loop characteristics are improved, and meanwhile segmented manufacturing is facilitated; and the scheme that the egg-shaped shells in different sizes are connected is adopted, assembly line light shells are conveniently arranged, fluid resistance of a submersible is reduced, and the fluid dynamic characteristic of the submersible is improved.

Owner:JIANGSU UNIV OF SCI & TECH

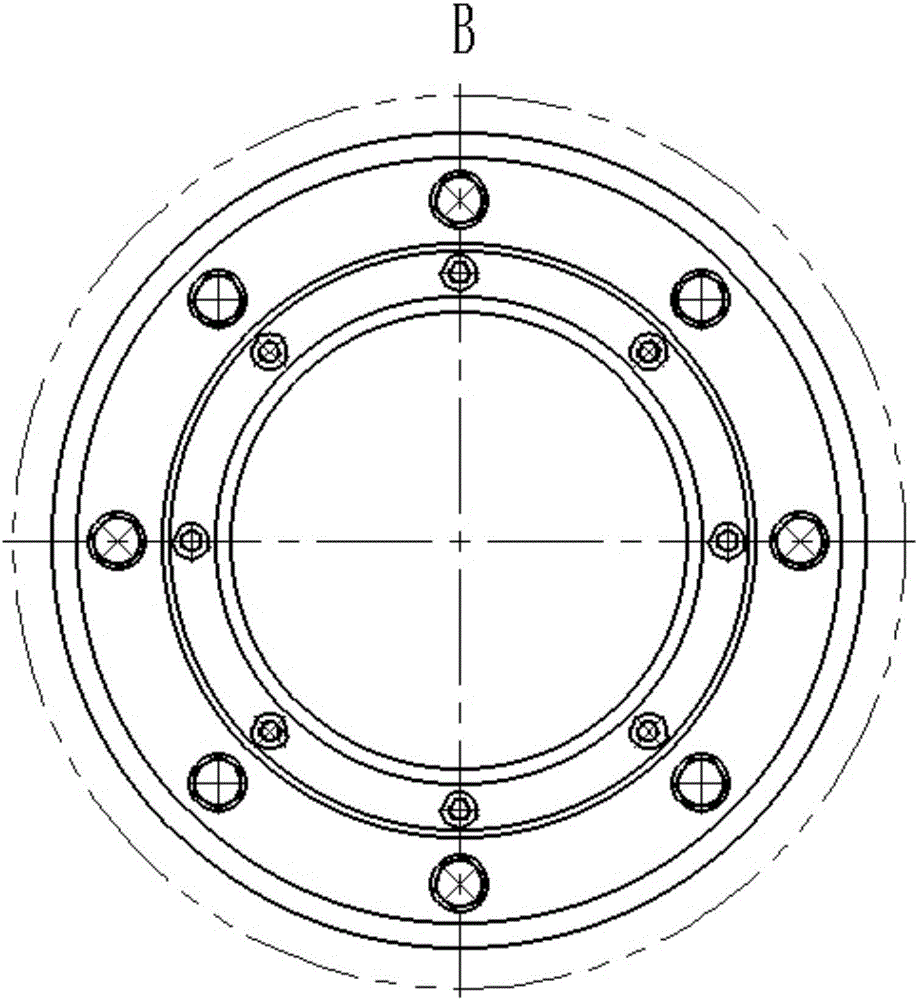

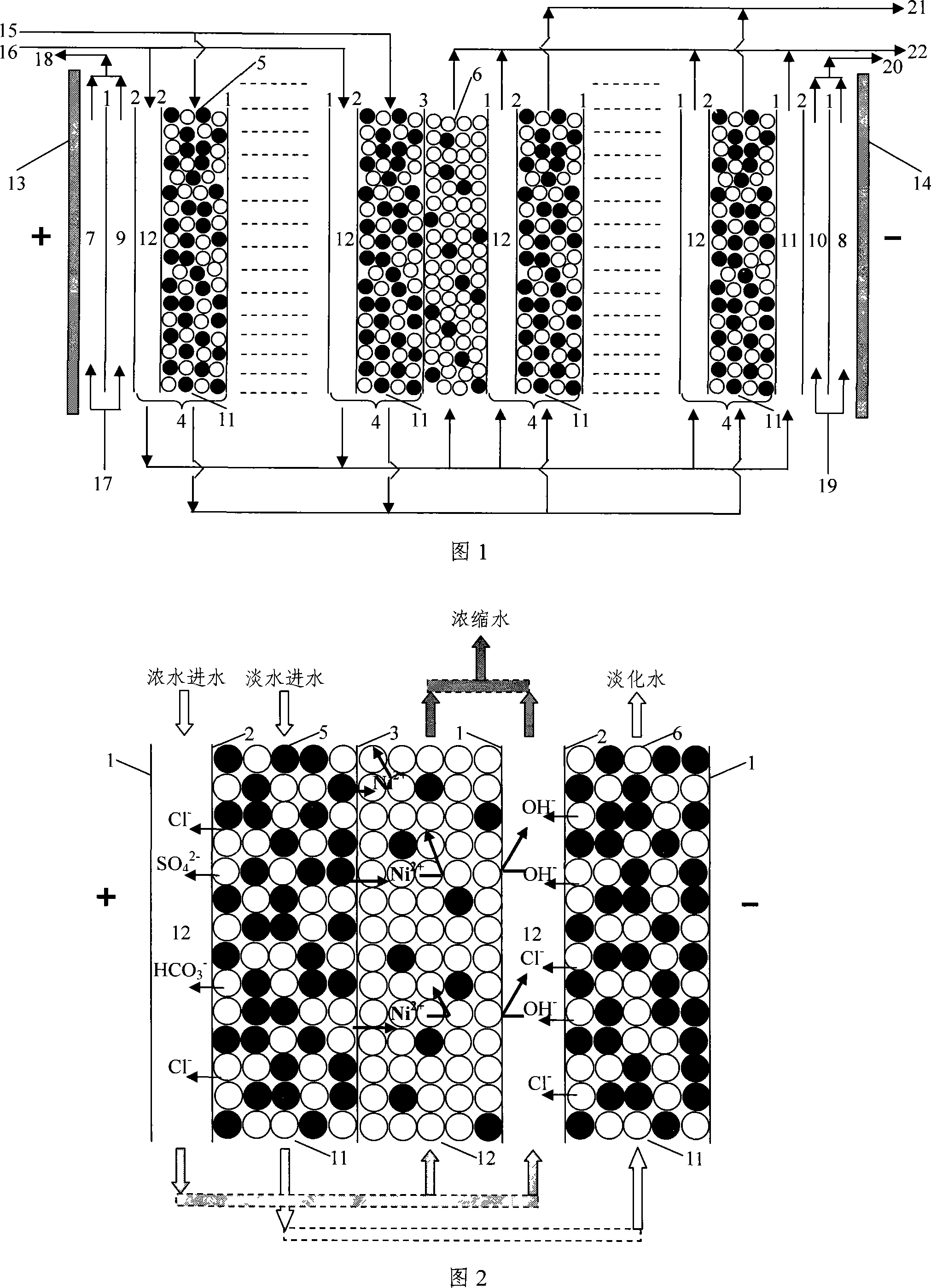

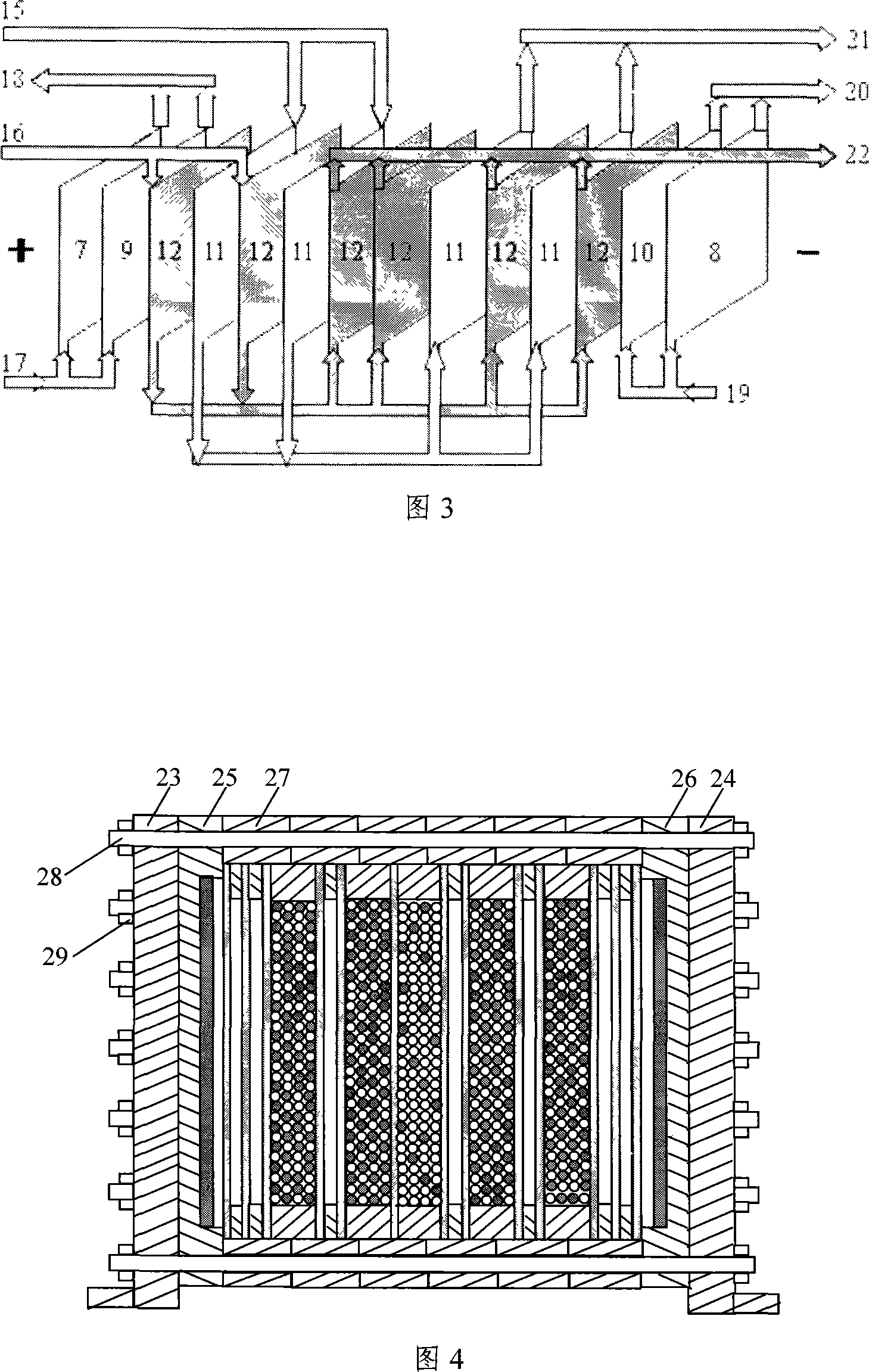

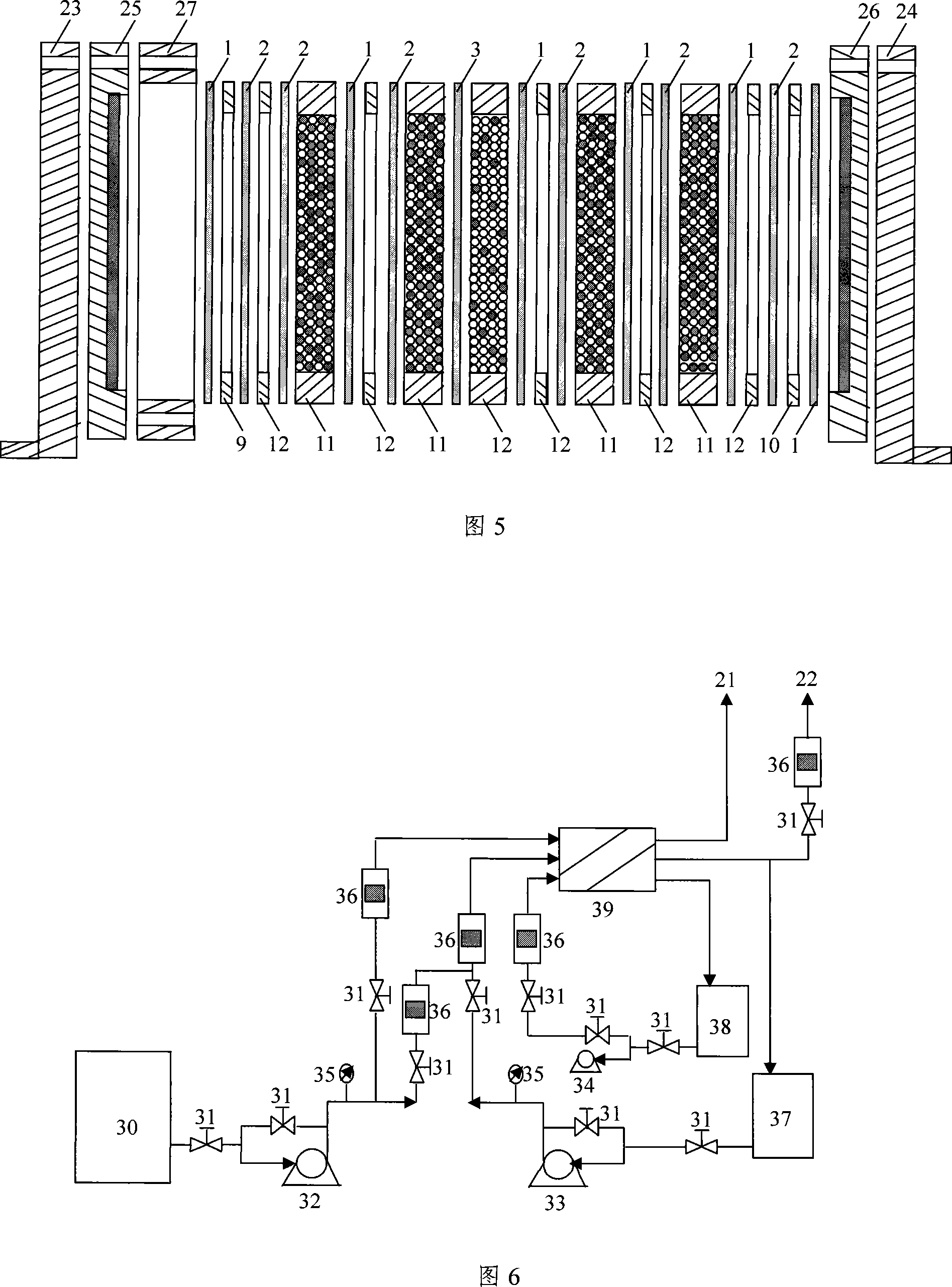

Electro-deionization method and device for synchronously concentrating and purifying heavy metal wastewater

InactiveCN101200325ALow flow resistanceImproved hydrodynamic propertiesDispersed particle separationWater/sewage treatment by ion-exchangeStrong acidsPollution

The invention relates to an electro-deionization method and device for concentrating and purifying heavy metal wastewater synchronously, belonging to a wastewater treatment technique, which adopts first-stage two-section or first-stage multi-section electro-deionization device, wherein the inner sides of the positive and negative poles are arranged with corresponding pole protection chambers, the desalting chamber is filled with large-hole strong-acid strong-base mixed bed resin with narrow particles distributed; cation exchange film is adopted as the direction-turning film, after direction-turning, two adjacent concentration chambers are arranged continuously, both are separated by cation exchange film, simultaneously after direction-turning, the first concentration chamber is filled with large-hole mixed bed resin with the volume of cathode resin more than 50 percent, the heavy metal wastewater to be treated enters the desalting chamber and the concentration chamber in two paths, the heavy metal ion and cathode in the desalted water flow are transferred into the concentration chamber so as to obtain the desalted water, the concentrated water flow is partially circulated or closely circulated so as to obtain the concentrated liquid of metal wastewater, thereby recycling valence metals and pure water resources synchronously and realizing zero emission and resource treatment of wastewater. Compared with the prior art, the wastewater treatment process has higher separation efficiency, more reliable operation, more convenient operation, continuous process operation and no secondary pollution.

Owner:NANKAI UNIV

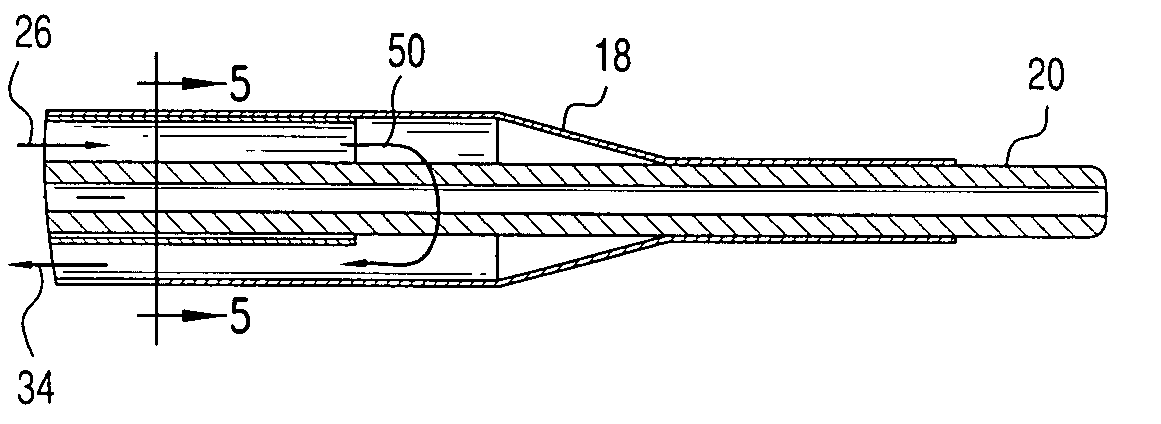

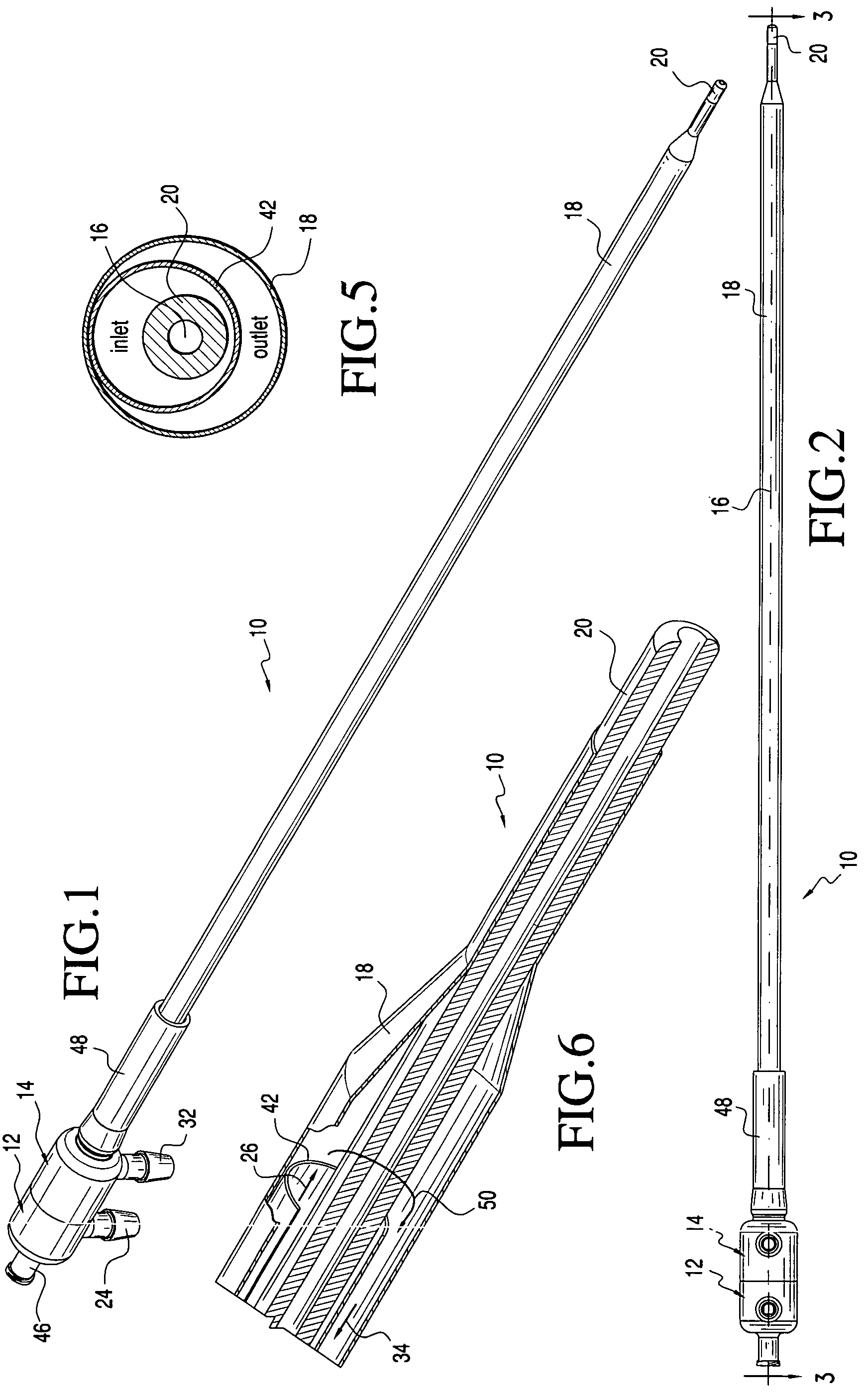

Heat exchange catheter and method of use

ActiveUS7621889B2Prevent urethral sloughingImproved hydrodynamic propertiesMedical devicesDilatorsEngineeringInlet flow

An inlet flow of heat exchange fluid flows from an inflow housing inlet section, and through an inflow housing main section. It then flows through an inlet fluid passageway formed between an inner balloon and a discharge tube. The flow continues around a distal end of the inner balloon, thus becoming an outlet flow of the heat exchange fluid which is directed through an outlet fluid passageway formed between the inner balloon and an outer balloon, then through an outflow housing main section and finally discharged through an outflow housing outlet section. The inner balloon is in a position offset from the central axis of the catheter. The offset relationship enhances the fluid dynamic properties of the catheter. It provides an increased turbulence, which, in turn, maximizes the heat exchange efficiency.

Owner:VARIAN MEDICAL SYSTEMS

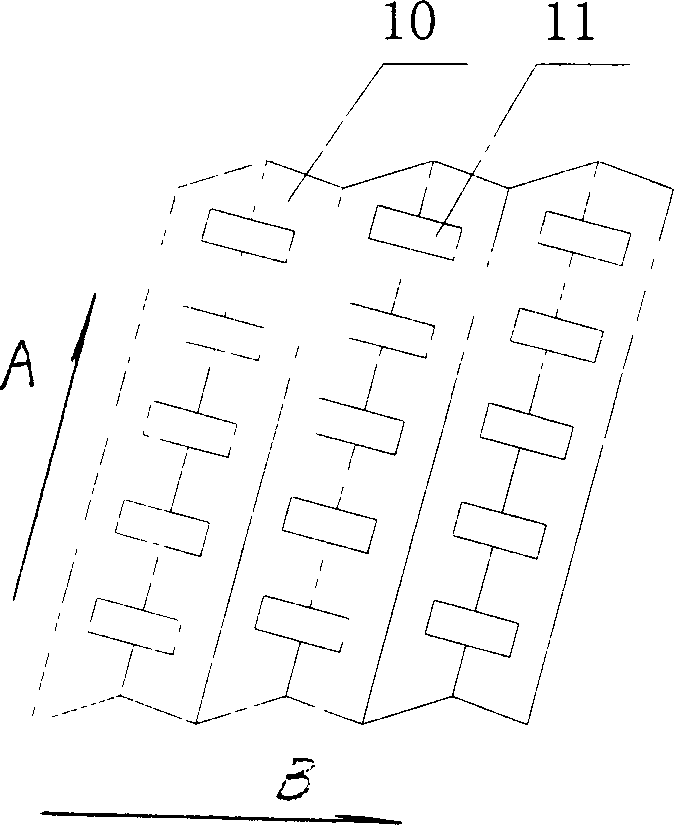

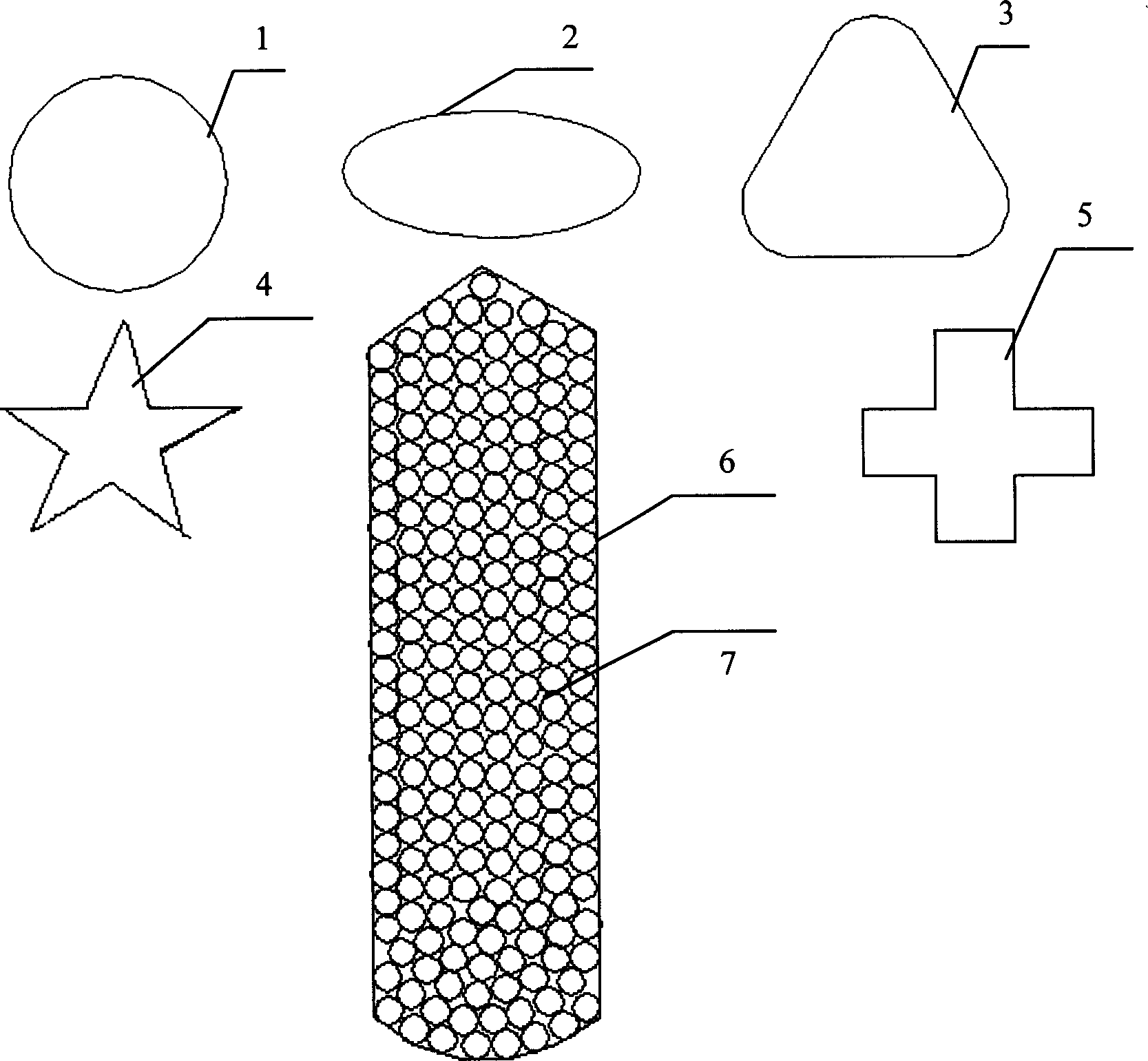

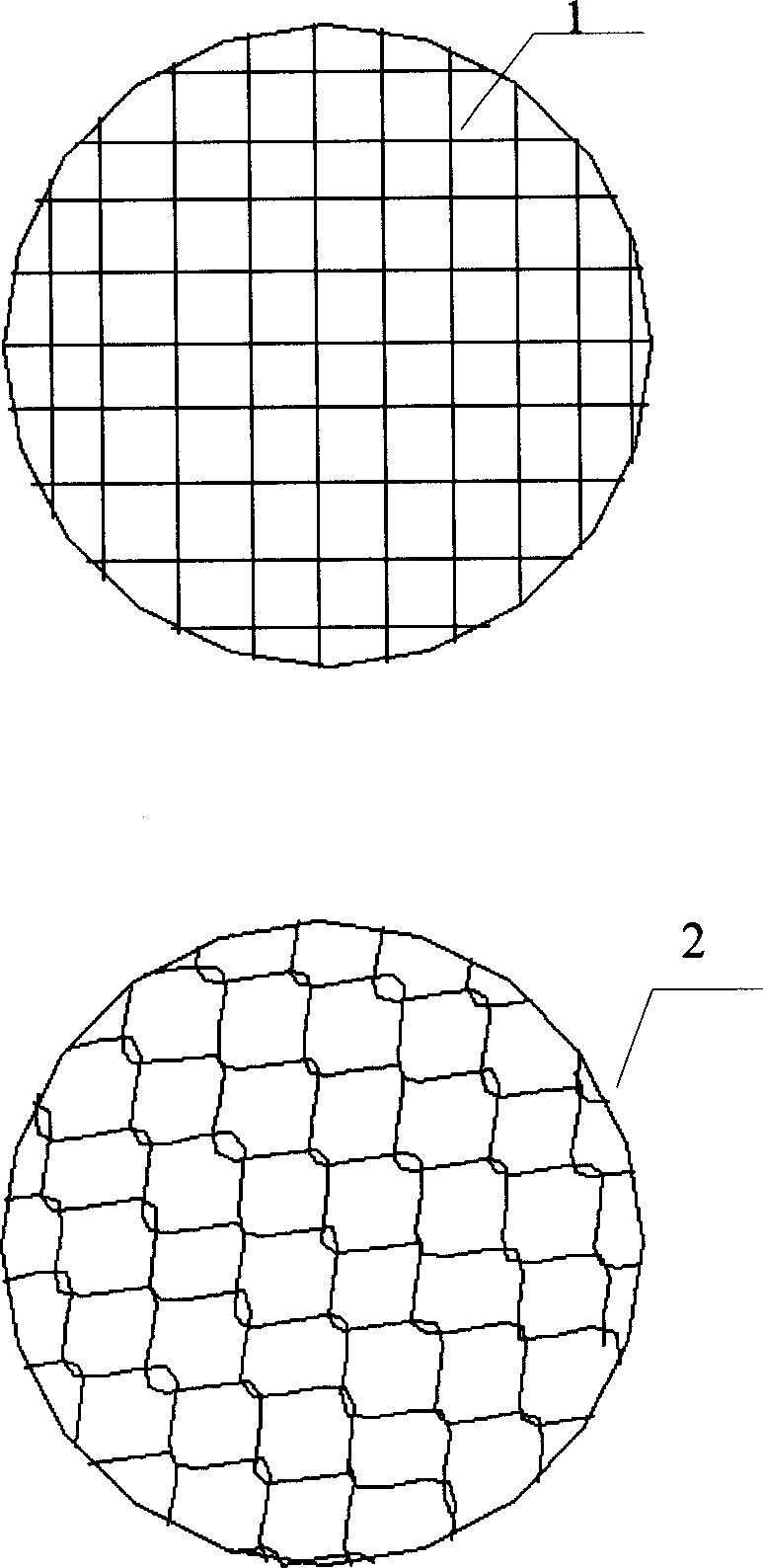

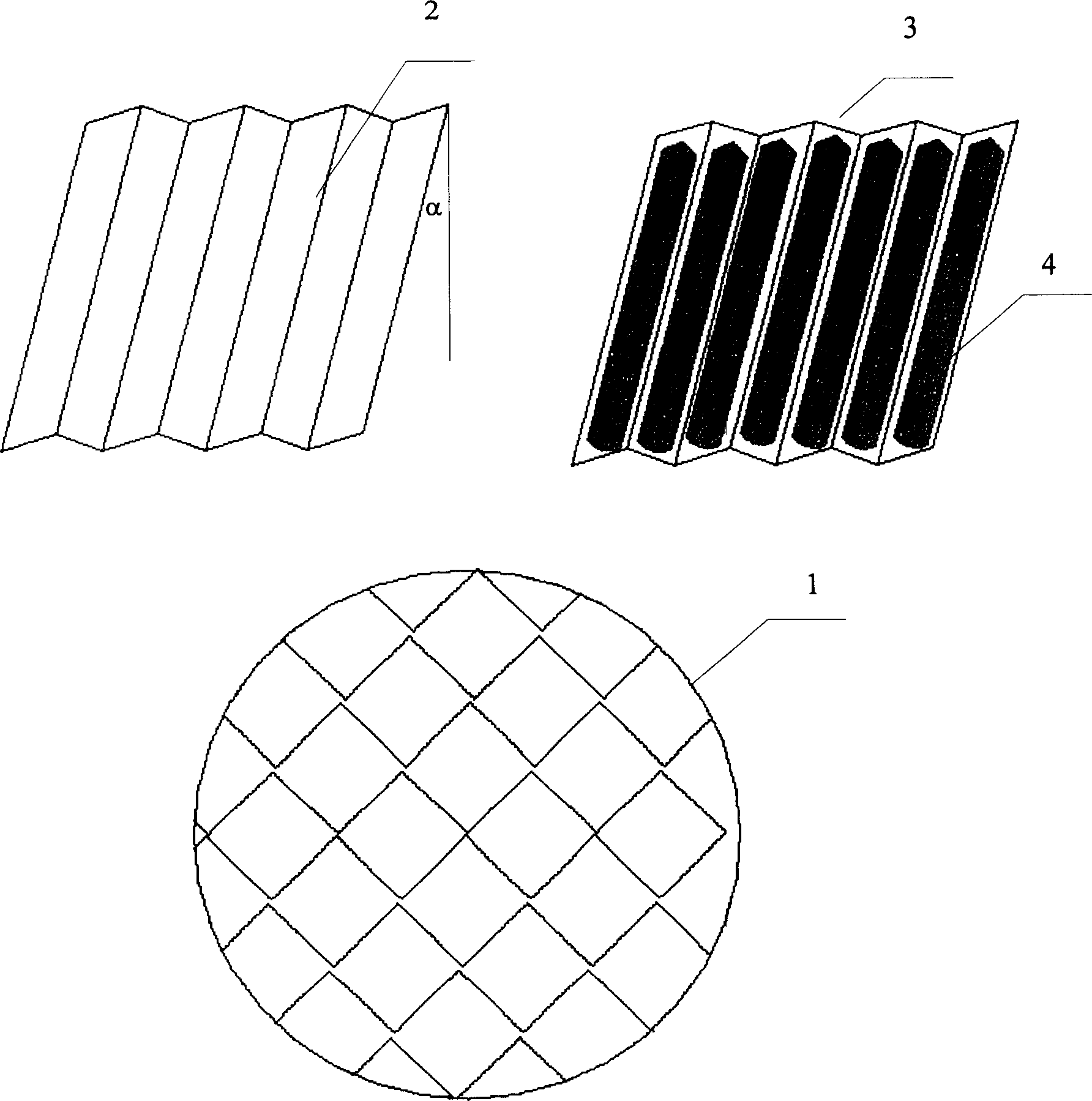

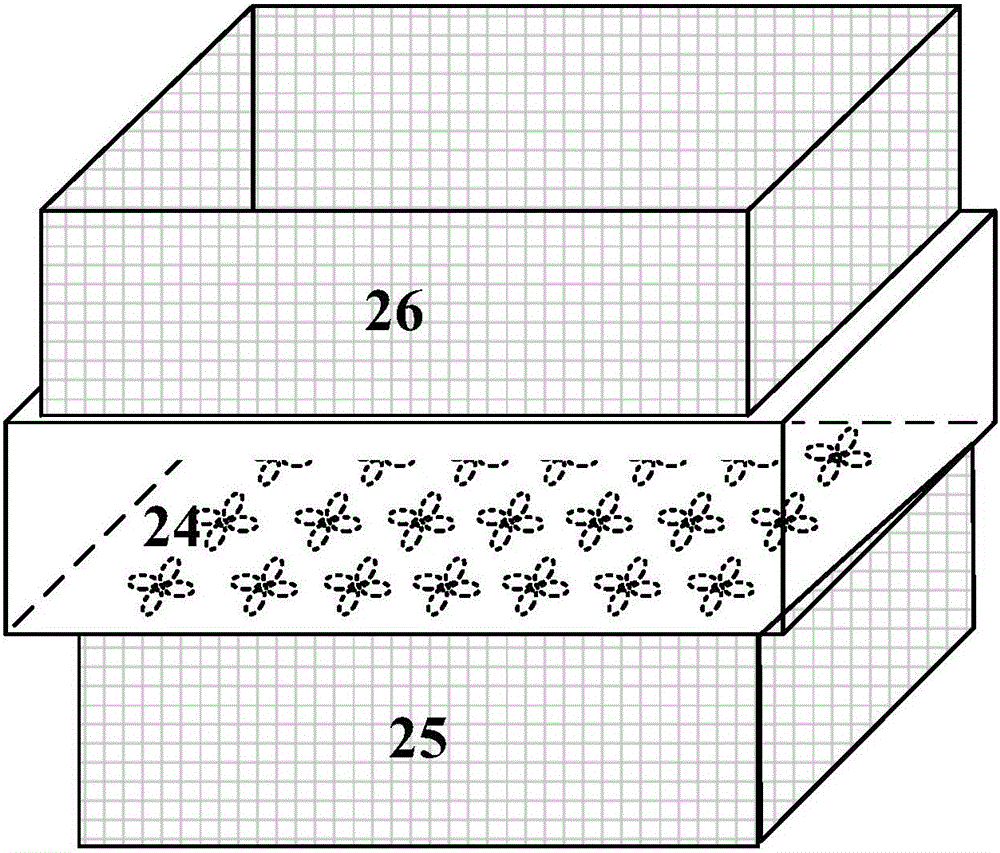

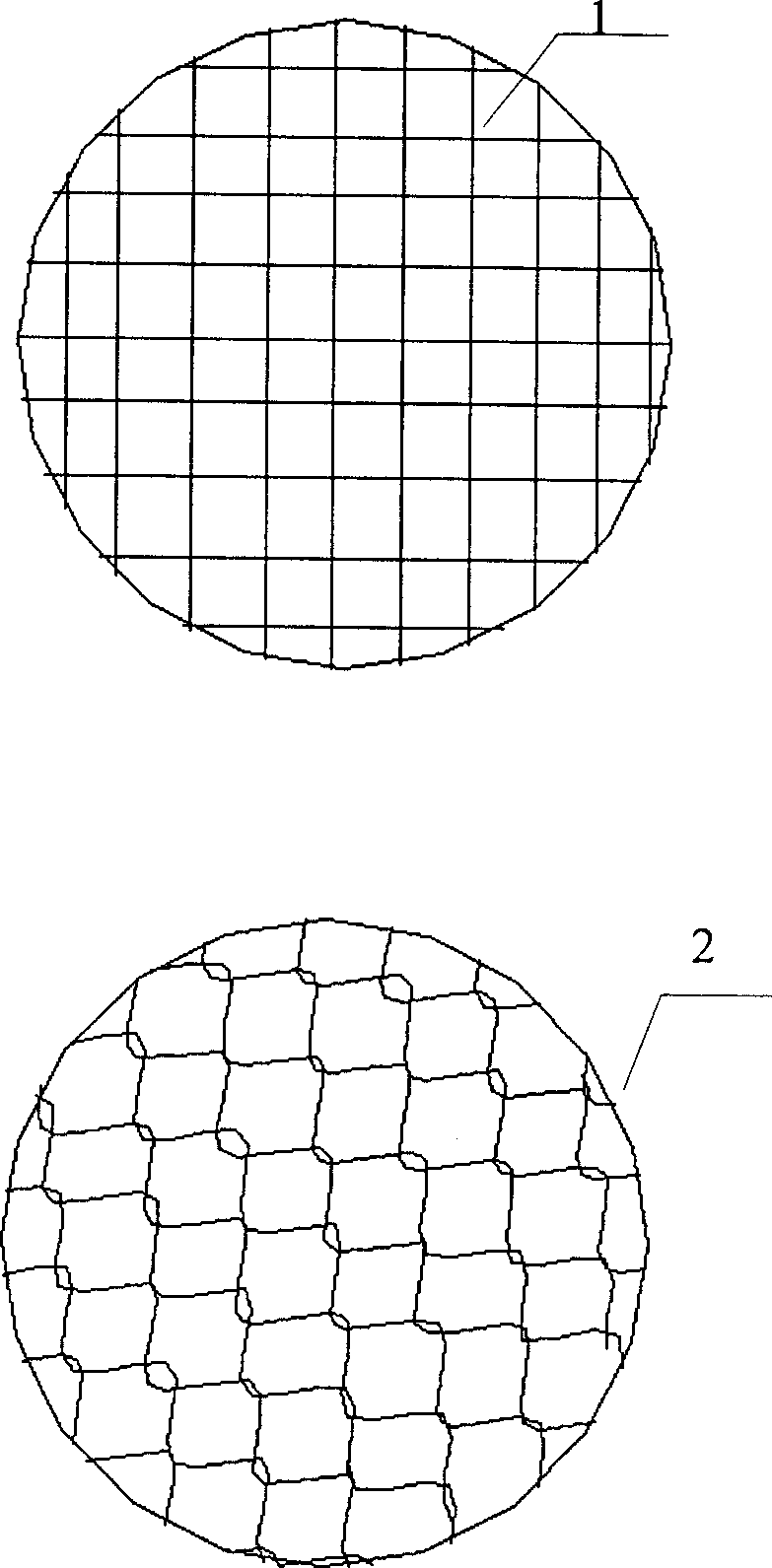

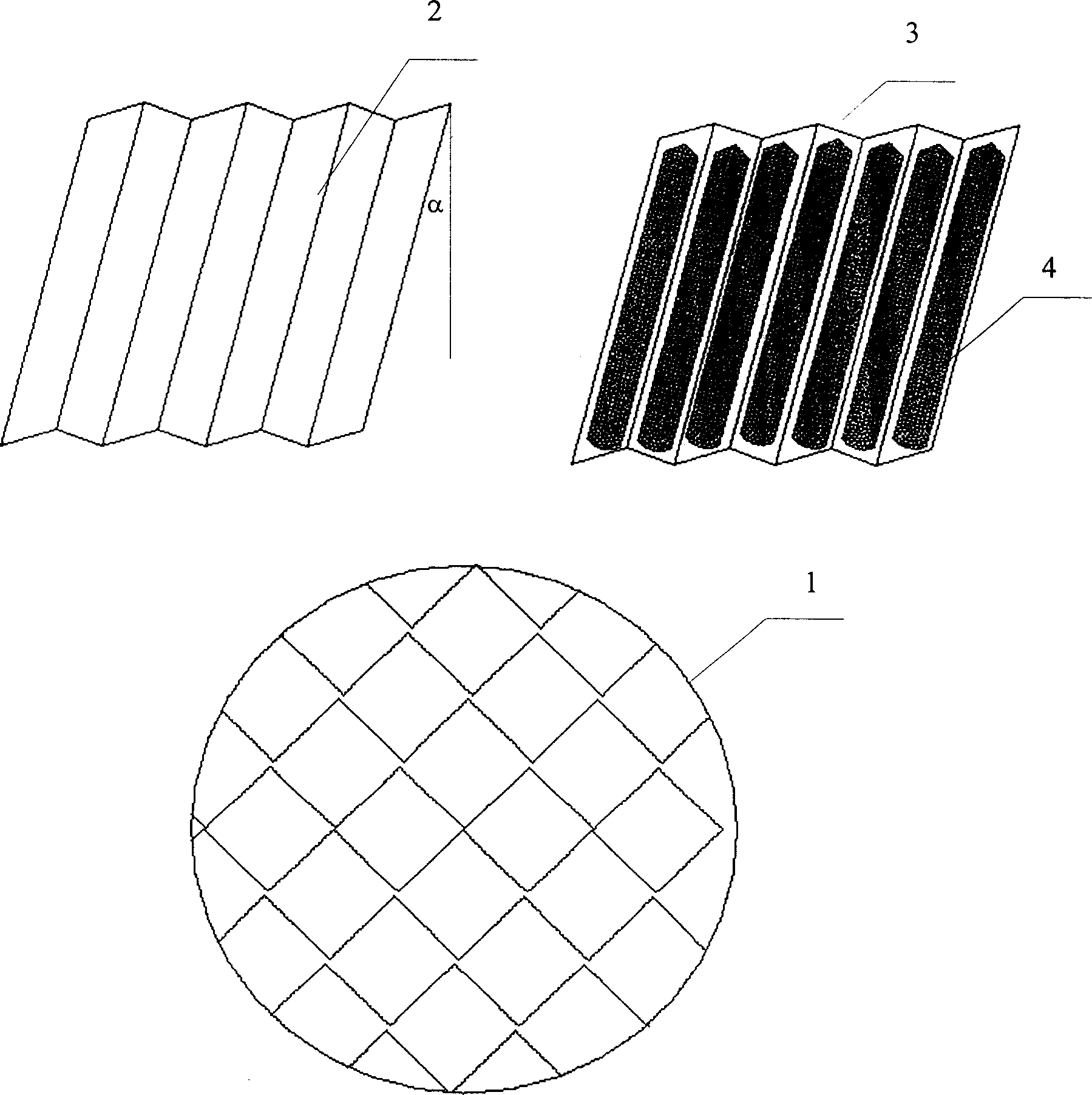

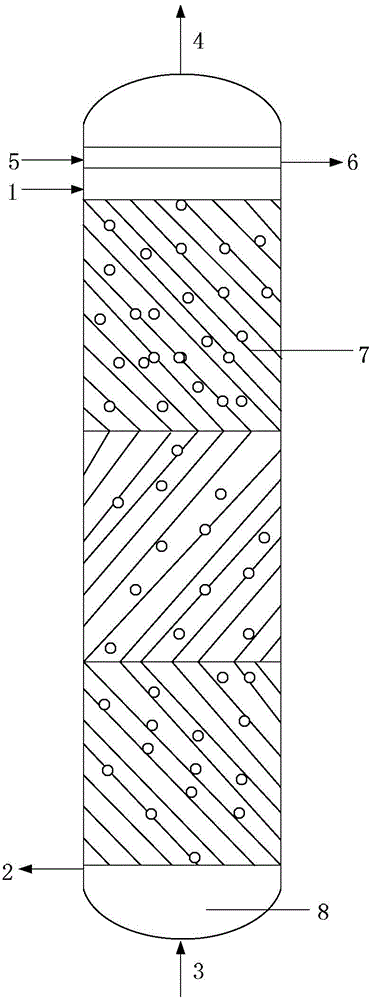

Catalyst distillation component and catalyst distillation method used said component

InactiveCN1602988AGood liquid redistribution abilityOvercome the defect of mass transfer effect declineChemical/physical processesFractional distillationCatalytic distillationReaction zone

The invention discloses a kind of catalyst distillation module and uses this module the catalyst distillation method.The invention catalyst distillation module includes the granules of catalyst, the silk screen vessel and the filler plate, its characteristic lies in, in the stated silk screen vessel which is used to load and fill granules of catalyst one by one or interval lays to the stated free channel which is formed by fold put the filler plate;Among them the stated filler plate is the corrugated sheet padding,open arbitrary shape holes on the corrugated sheet trough,remove the open hole part on the stated corrugated sheet, or divides the hole opened part into two parts along the ripple direction, then move upward or downward the formed two teeth pieces.The invention module has the force fluid redistribute ability, overcame the flaw that channel and so on cause the mass transfer effect droppes ; Lengthenes the fluid mobile way, increases the hold liquid volume of the reaction zone liquid.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic distillation assembly and catalytic distillation method using the same

InactiveCN1569301AImproved hydrodynamic propertiesSmall pressure dropChemical/physical processesFractional distillationVoid ratioGas phase

The invention relates to a catalyzing distillation component and a method. The component includes catalyst particles, silk network container and regulated fillers, its character lies in: the catalyst particles and other inertial particles are blended together and filled into the container, and the mentioned silk network containers are arranged in the regulated fillers one by one. The invention favors the transition of media to liquid phase in the gas phase reaction. It can make the reacting bed with large gap rate, and the catalyst is distributed in the whole reaction segment evenly.

Owner:CHINA PETROLEUM & CHEM CORP +1

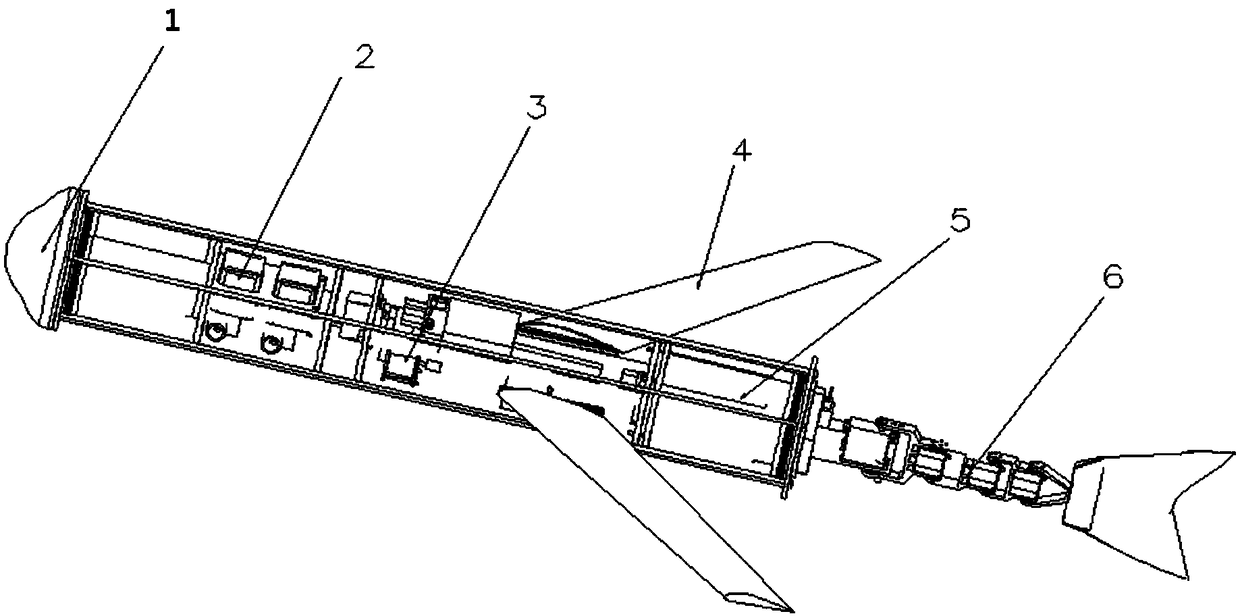

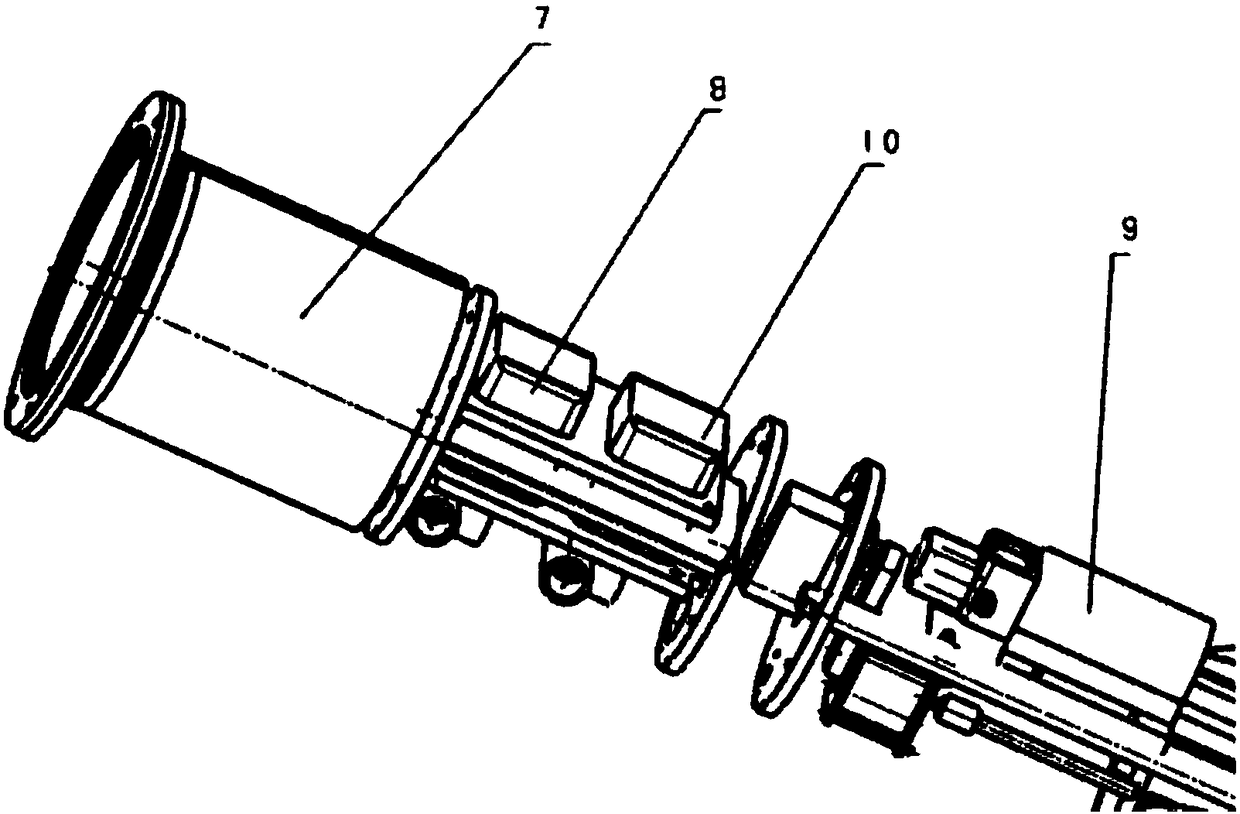

Underwater robot of bionic and gliding hybrid propulsion mode

InactiveCN108241179ARealize monitoringIncrease the voyageGeological measurementsPosition/course control in three dimensionsFiberCarbon fibers

The invention discloses an underwater robot of a bionic and gliding hybrid propulsion mode. The underwater robot comprises a head part, a sinking and floating adjustment mechanism, a center of gravityadjustment mechanism, a circuit compartment, a gliding wing and a tail part. The head part is composed of an image collection compartment. The sinking and floating adjustment mechanism includes an inner oil sac, a reversing valve, a hydraulic pump, a relief valve and an outer oil sac. The center of gravity adjustment mechanism includes a stepping motor driver, a stepping motor, a steering gear drive, a left and right center of gravity steering gear, a screw rod, a guide rail and a heavy block. The circuit compartment consists of a control system, including a moving layer, a sensing layer, a control layer, a communication layer and a monitoring layer. The gliding wing is made of epoxy carbon fiber material, with the advantages of high strength, light weight and so on. The tail part includes a four-joint bionic fishtail steering gear and a fishtail skeleton. The underwater robot of the bionic and gliding hybrid propulsion mode in the invention has the characteristics of large range, lownoise, low energy consumption, high concealment, small turning radius and so forth, and can improve the accuracy of measurement data and improve the working efficiency of measurement.

Owner:NANJING INST OF TECH

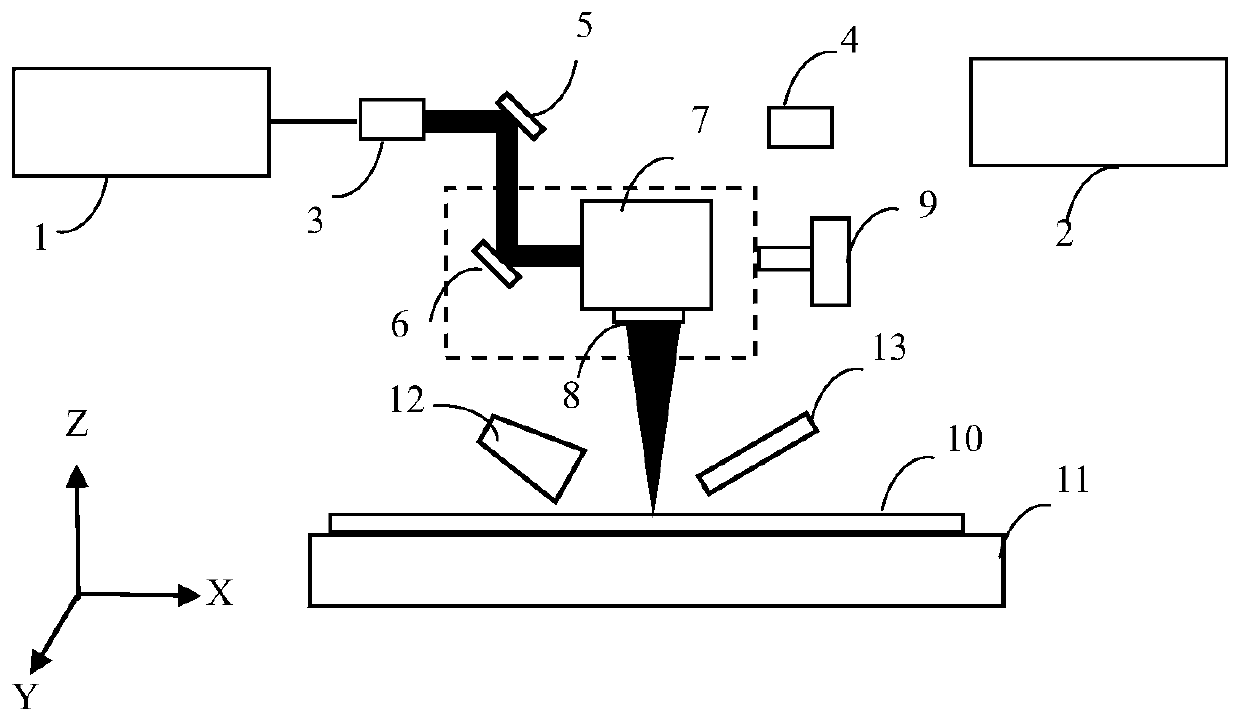

Method and device for preparing antifouling and drag-reducing material by laser treatment

PendingCN110340536AAdaptableReduce contact surfaceLaser beam welding apparatusMicro nanoOptoelectronics

The invention belongs to the technical field of laser machining, and discloses a method and a device for preparing an antifouling and drag-reducing material by laser treatment. The device mainly comprises a picosecond laser emitting assembly, a femtosecond laser emitting assembly and a scanning focusing assembly, wherein the femtosecond laser emitting assembly is used for emitting femtosecond laser, so that a micro-nano mixing structure with super hydrophobic performance is formed on the surface of a to-be-treated material; and the picosecond laser emitting assembly is used for emitting picosecond laser, so that the surface of the to-be-treated material forms a super hydrophilic region. According to the invention, the structure of the assemblies in the device and an arrangement mode thereof, the corresponding machining method and the like are improved, and the super hydrophilic-super hydrophobic (hydrophilic-super hydrophobic and hydrophobic-super hydrophobic) material surface topography is formed by utilizing the comprehensive action of the picosecond laser and the femtosecond laser, so that the composite wettability is realized, the drag of the to-be-treated material in water canbe reduced, the antifouling effect is achieved at the same time, and the problems that a traditional electrochemical corrosion method cannot achieve the micro-nano structure of the composite wettability and the environmental pollution is large and the like can be effectively solved.

Owner:HUAZHONG UNIV OF SCI & TECH

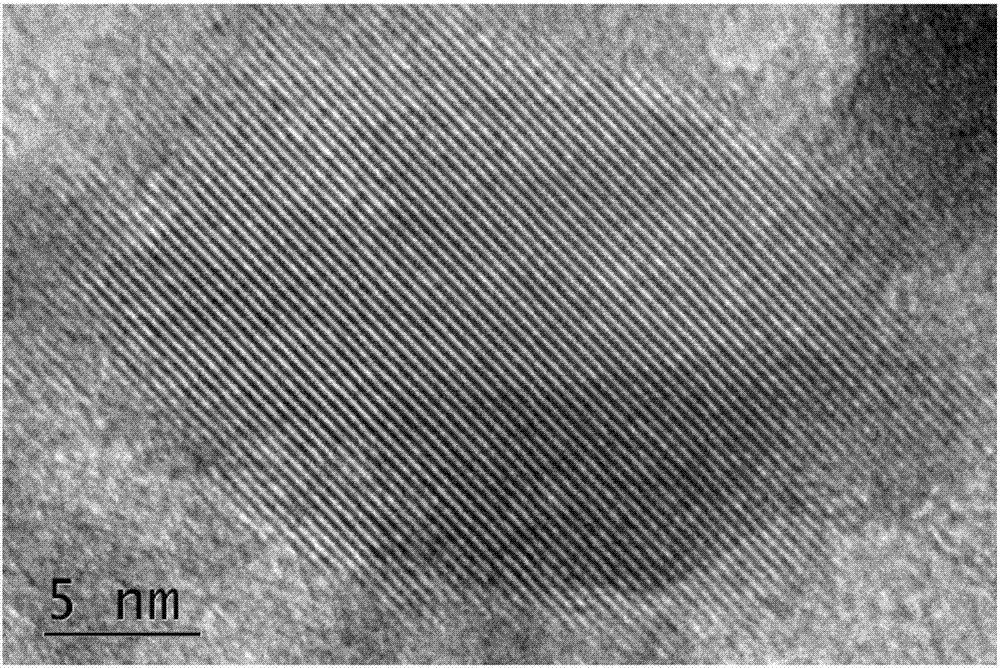

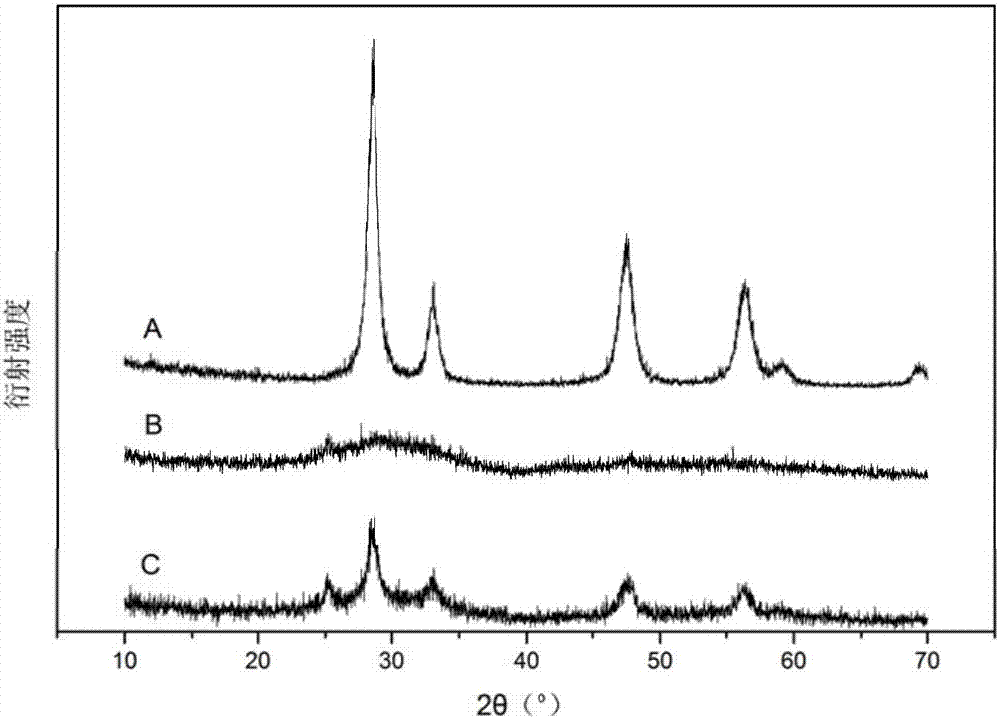

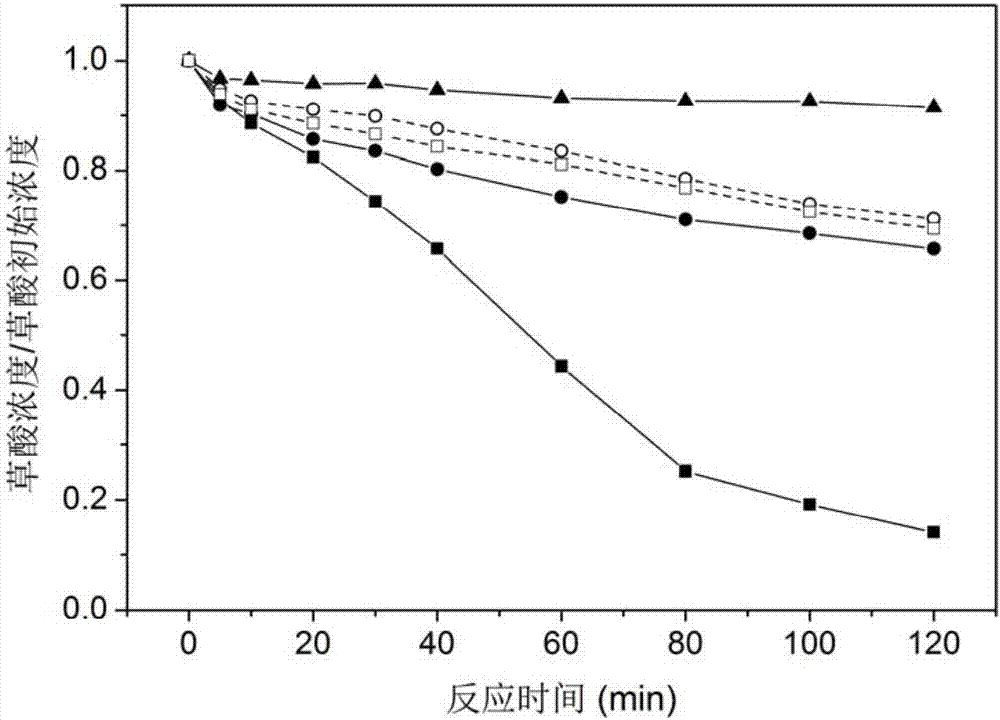

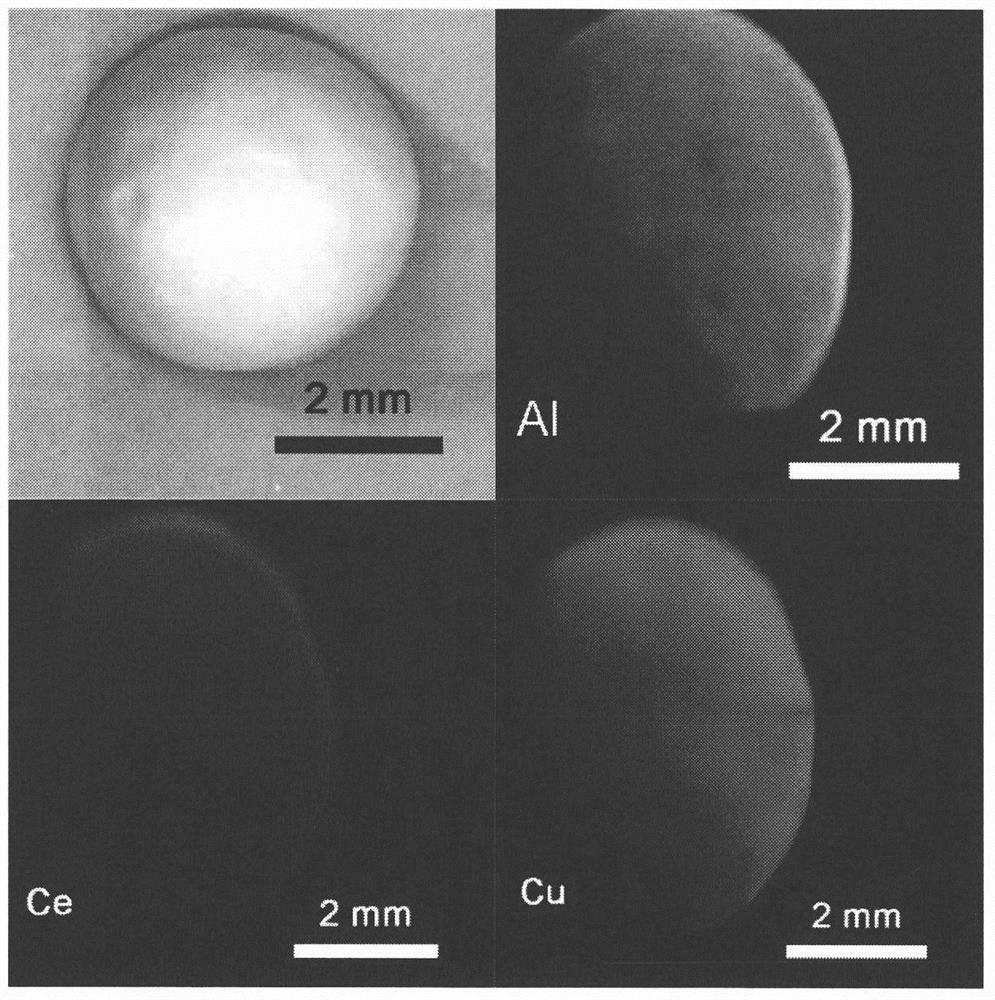

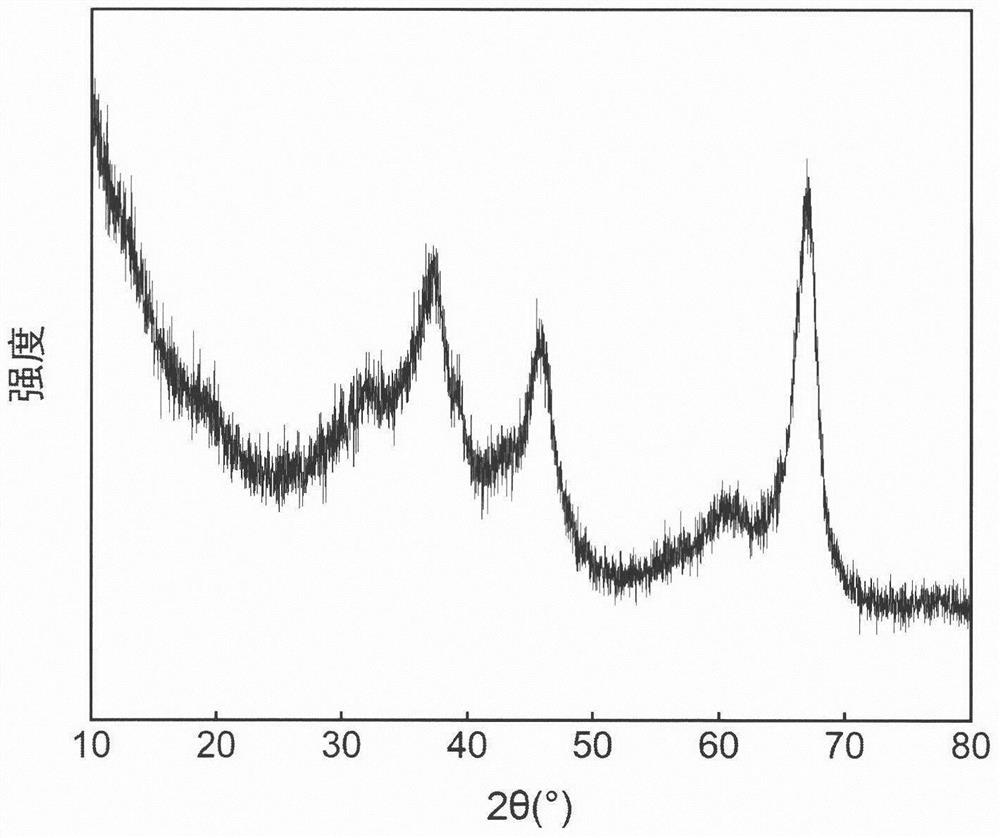

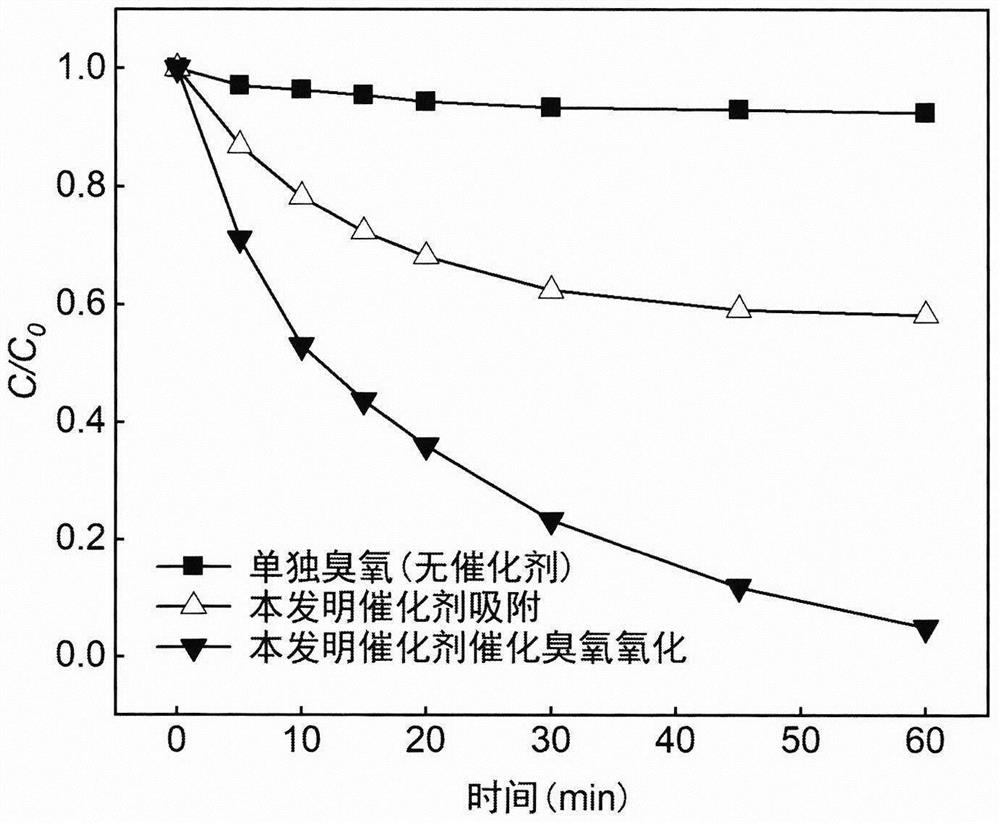

Millimeter level mesoporous ozone oxidation catalyst and preparation and application method thereof

ActiveCN106944027AHigh catalytic activityGood long-lasting activitySpecific water treatment objectivesWater contaminantsMicrosphereTitanium zirconium

The invention discloses a millimeter level mesoporous ozone oxidation catalyst and preparation and an application method thereof, belongs to the technical field of water processing, and aims to solve the problems that the hydrodynamic performance of a conventional ozone oxidation catalyst is bad, the catalytic efficiency is low, and the stability is insufficient. The millimeter level mesoporous ozone oxidation catalyst comprises cerium, titanium, zirconium, and oxygen, is a millimeter level mesoporous spherical particle, has a unique crystal structure, at the same time, has the advantages of durable and stable catalytic activity, excellent hydrodynamic characteristics and pore structure, high compression strength, acid / alkali resistance, ligand stability, oxidation resistance, and thermal stability, and can prominently improve the mineralization degree of ozone oxidation. The valence composition of active components is not changed after repeated use. The preparation method comprises the following steps: preparing millimeter level mesoporous titanium-zirconium composite microspheres by a calcium alginate template method, and then combining cerium and the titanium-zirconium compound by an impregnation method. The provided catalyst can be applied to fixed bed reactor / fluidized bed reactor wastewater treatment, and can be thermally regenerated when pollutants are accumulated on the catalyst.

Owner:NANJING UNIV

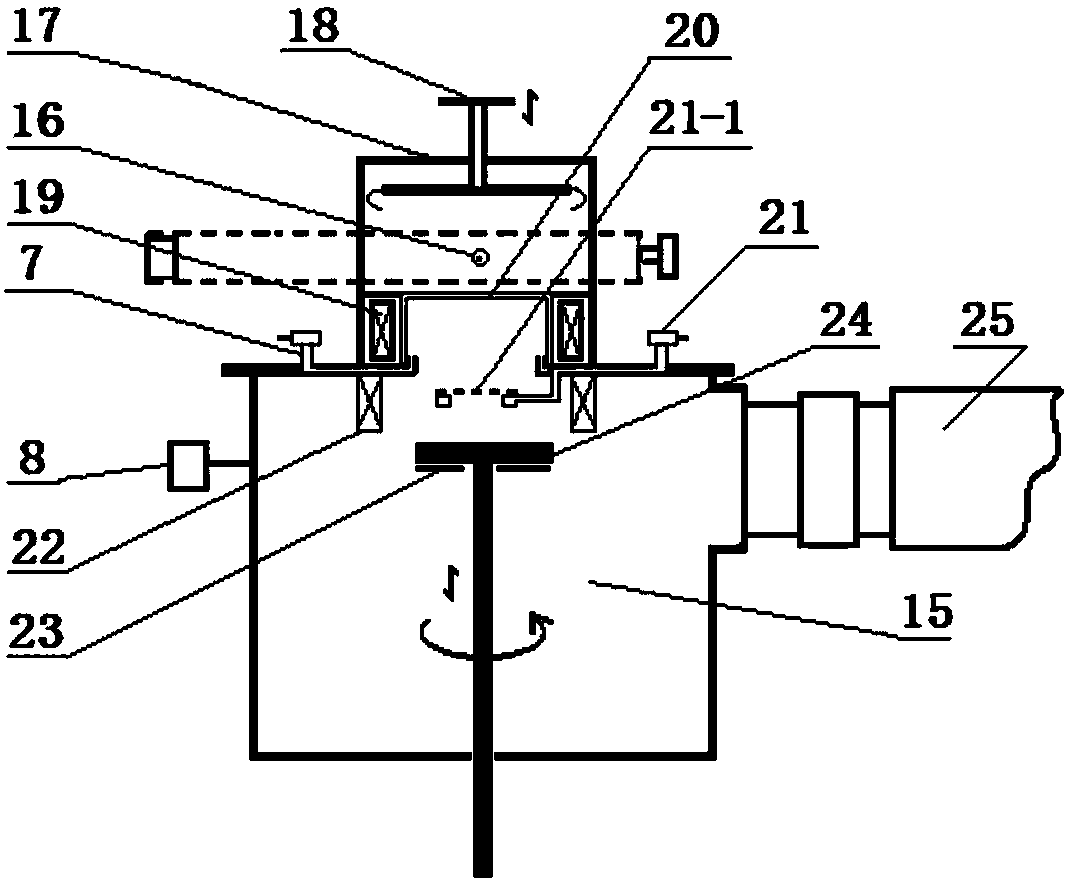

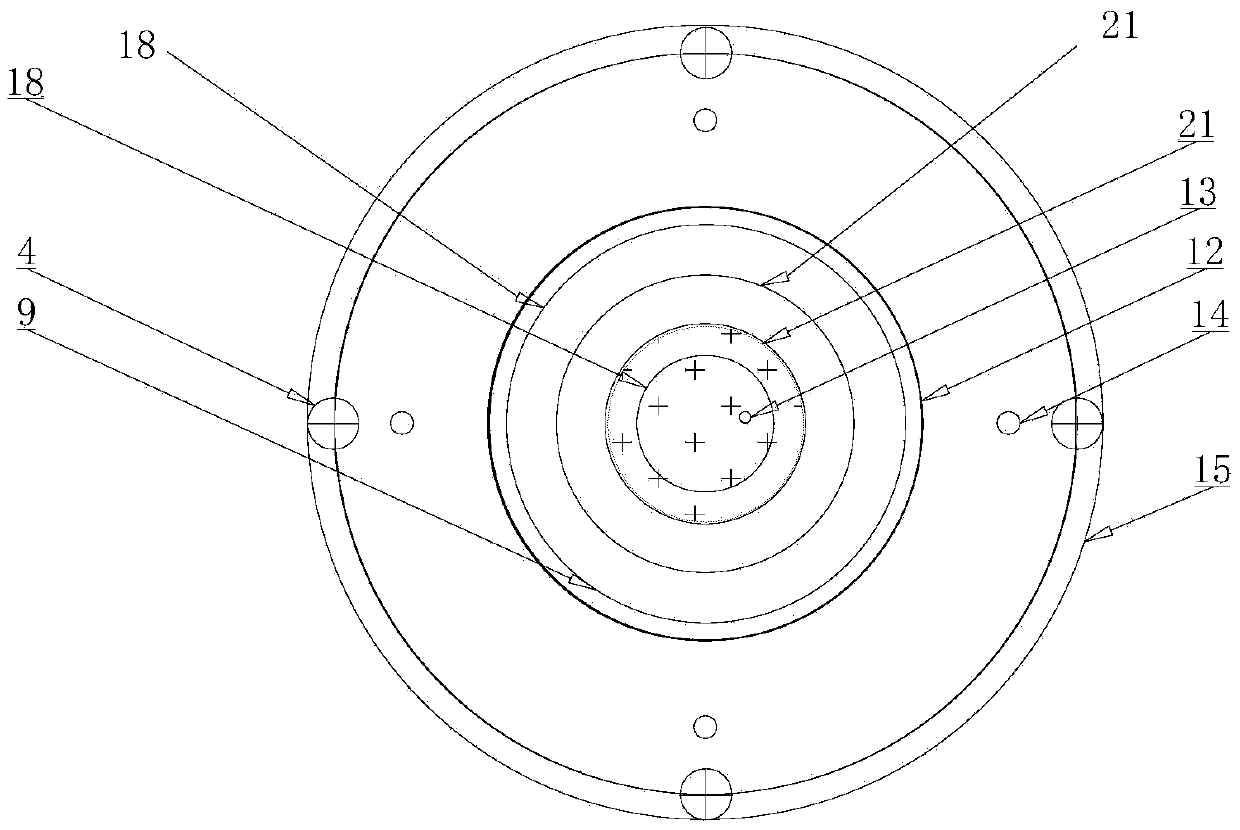

Magnetic driven rotation gas distribution device in gas-fluid etc. heterogeneous system

InactiveCN1795973AChange speedWide distributionMixing methodsChemical/physical/physico-chemical stationary reactorsEngineeringTower

The invention relates to a magnetic driving rotary gas distributor equipment of gas-liquid multi-phase system. It includes a tower device with magnetic driving device, the rotary-type gas distributor can be directly rotated in the tower bottom to make gas distribution. The gas distributor is driven by rotary permanent magnetic field produced by magnetic driving device and rotated so as to implement goal of rotary gas distribution. In the supporting disk of the gas distributor a gas ingress pipe hole is set, and the ring-shaped gas distribution cavity chamber in the supporting disk and the gas-feeding circular hole on the rotary hollow shaft can be used for making gas distribution, in the bottom end of the rotary hollow shaft a cleaning pollution-discharging valve is mounted.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

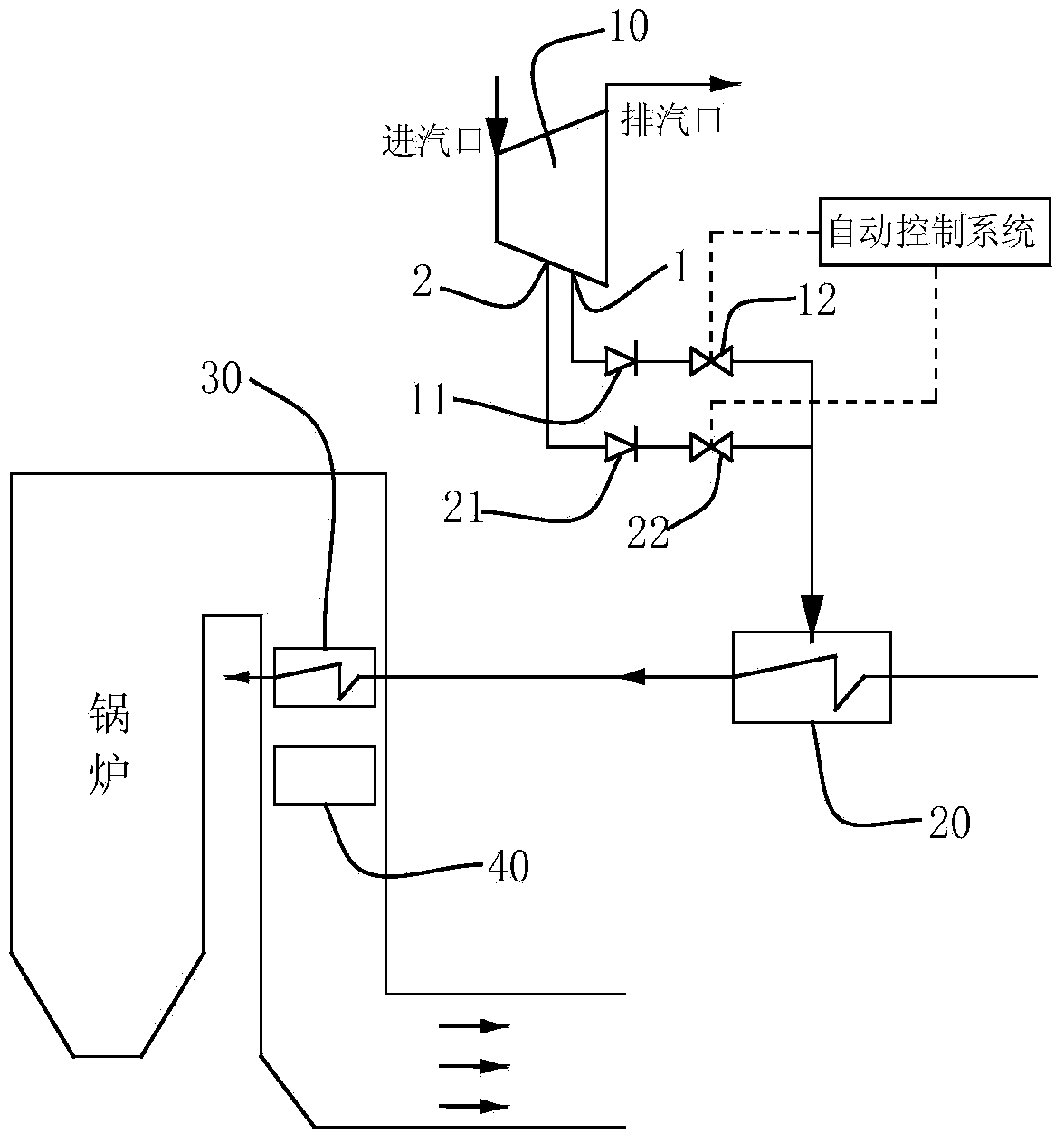

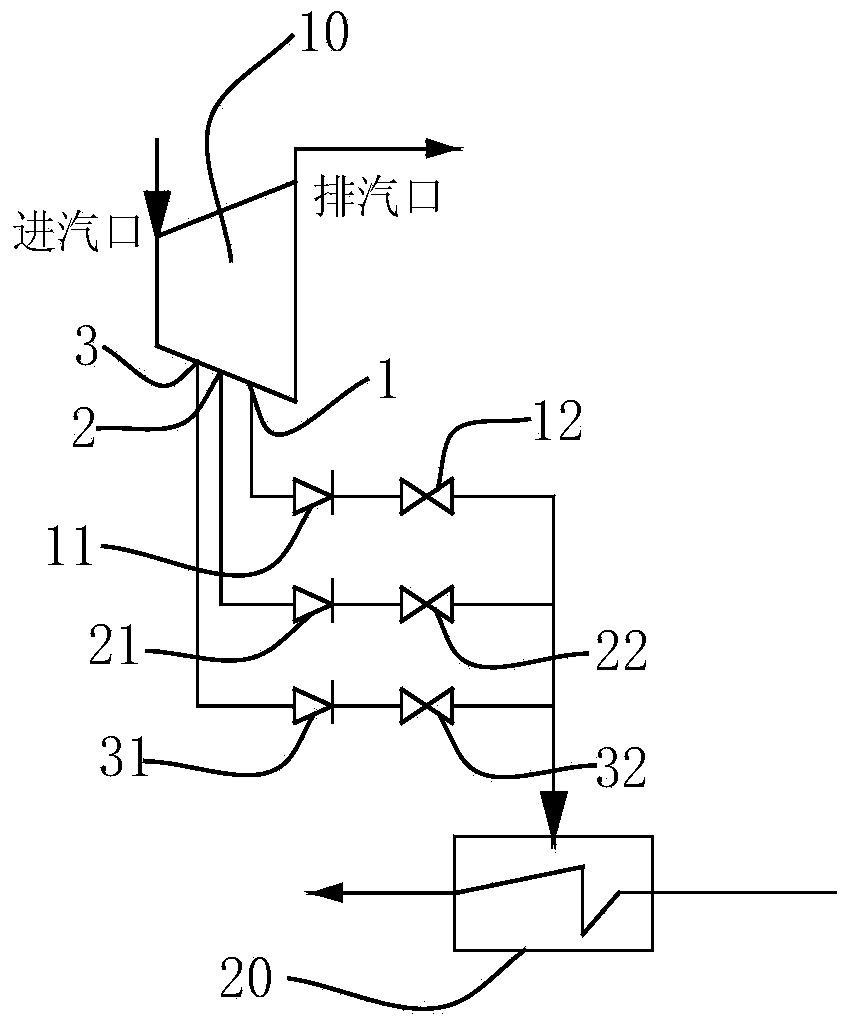

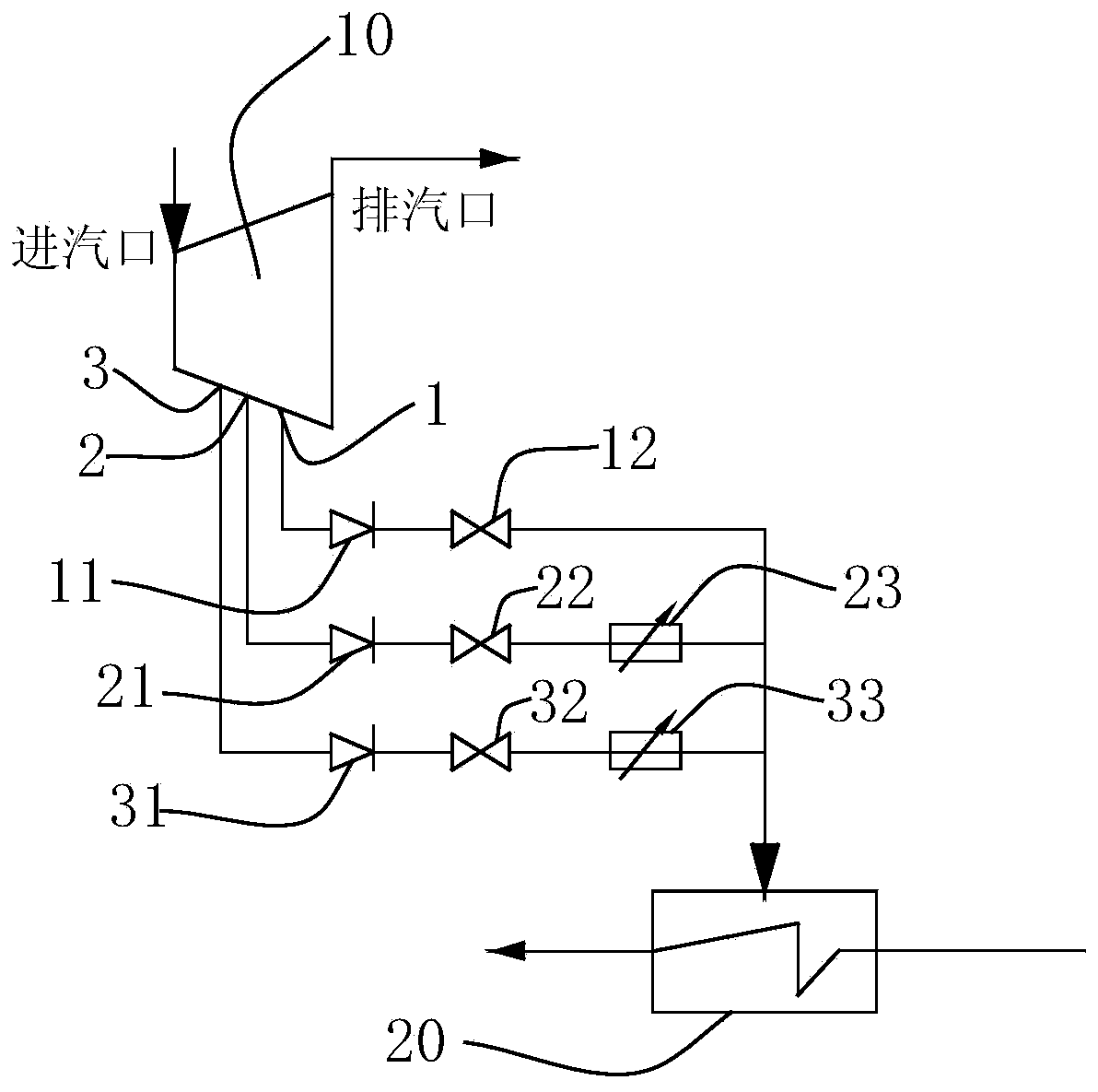

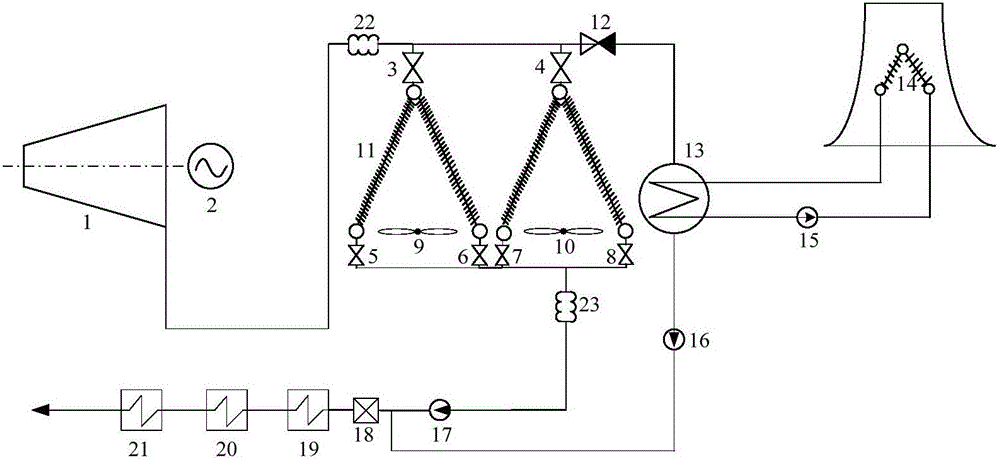

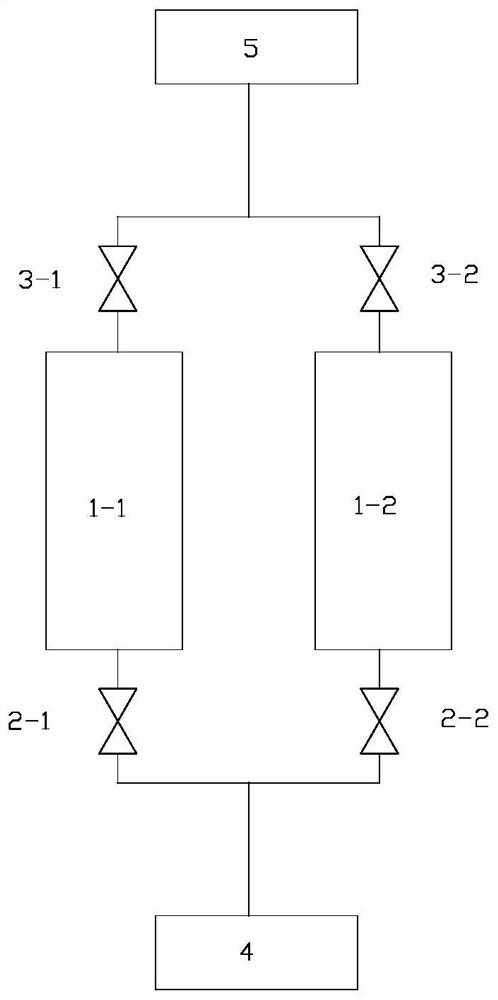

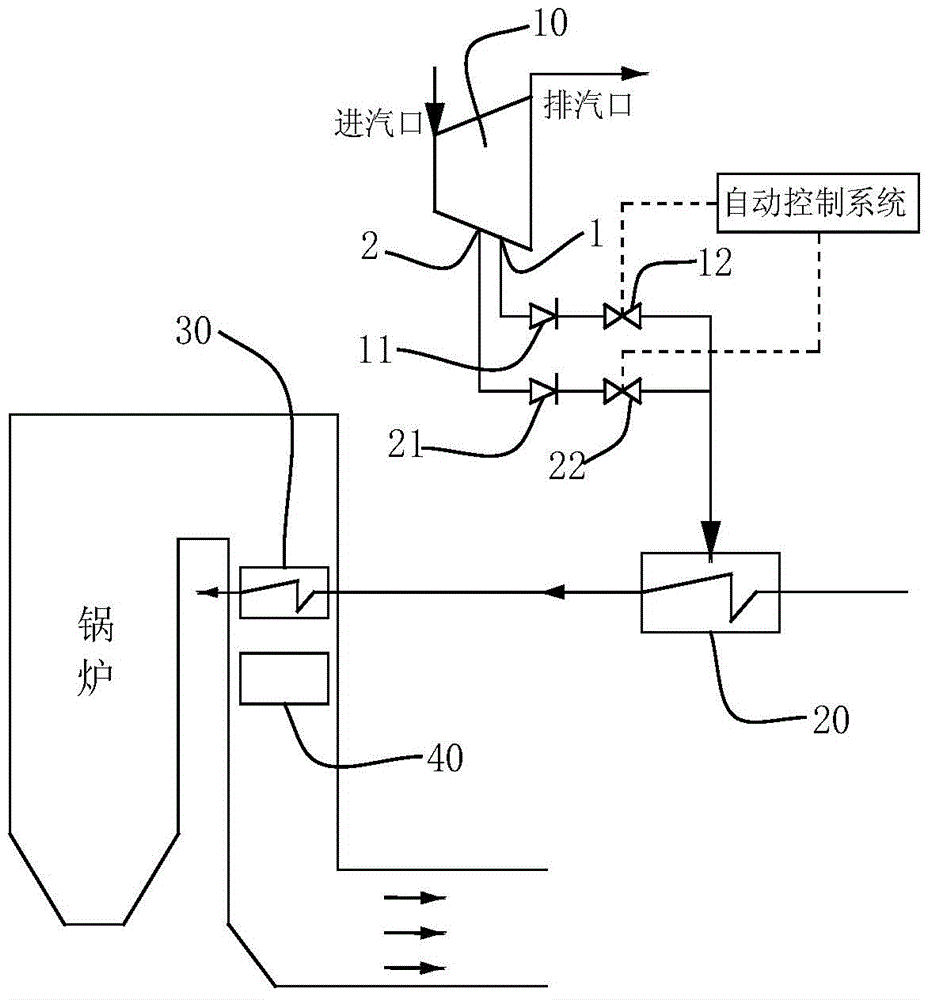

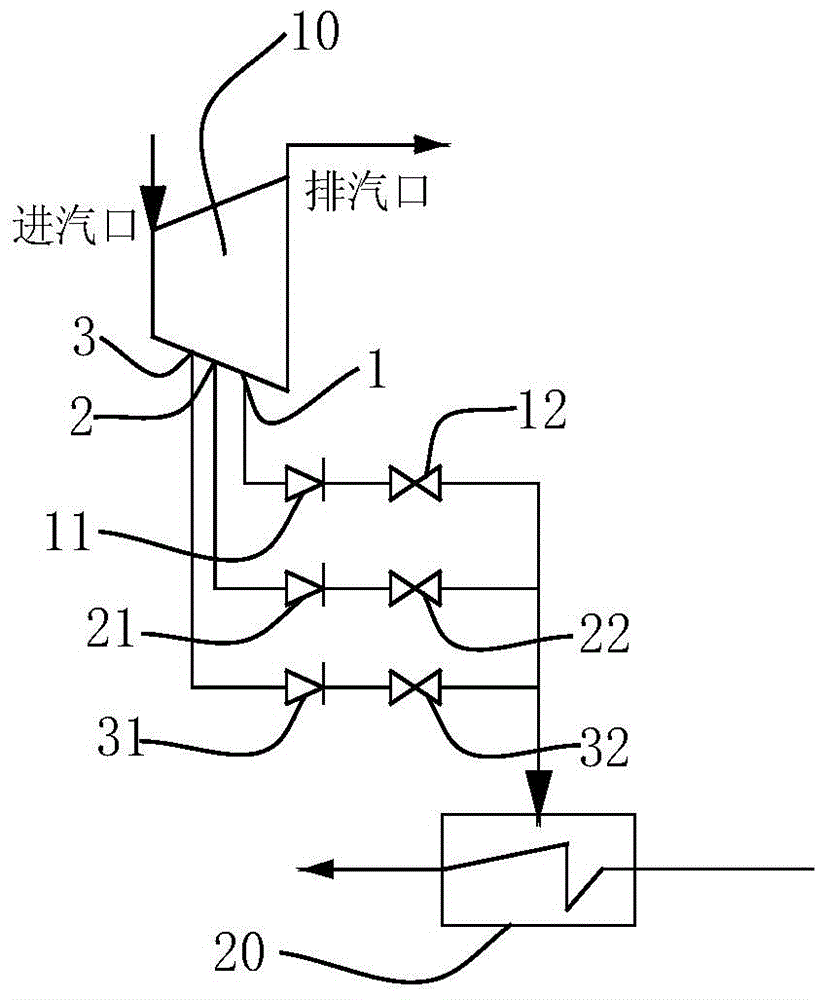

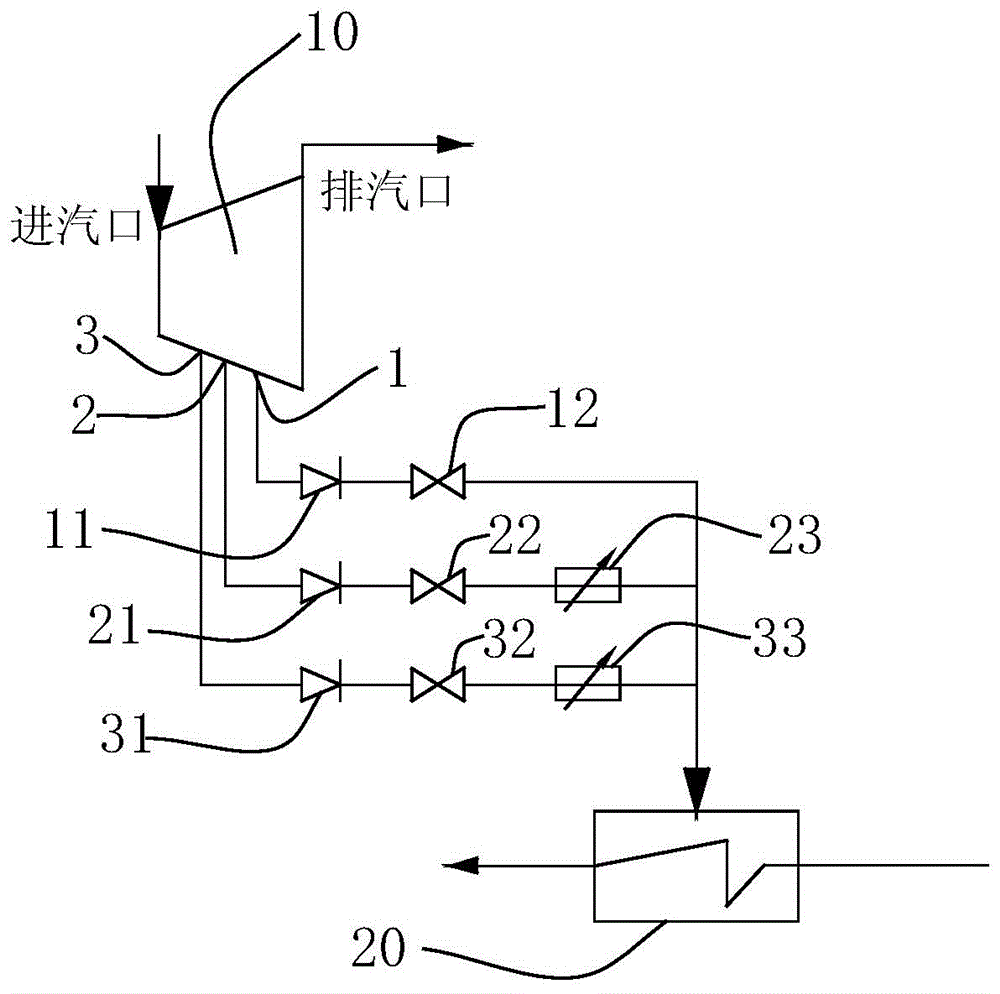

Regenerative system of turbogenerator unit and operation method thereof

ActiveCN103644005ASolve environmental problems that cannot be put into operationIncrease feed water temperatureSteam useFeed-water heatersEngineeringHigh pressure

The invention discloses a regenerative system of a turbogenerator unit and an operation method thereof. The system comprises a high-pressure cylinder and a high-pressure heater, wherein an steam exhaust port and a plurality of high-pressure steam extraction ports whose steam extraction pressure is increased sequentially are formed in the high-pressure cylinder, the high-pressure steam extraction ports are connected with the same high-pressure heater through high-pressure steam extraction pipelines, and an extraction check valve and an isolated valve are arranged on each high-pressure steam extraction pipeline. When the turbogenerator unit operates at a rated load, a first high-pressure steam extraction port with the lowest steam extraction pressure supplies steam for the high-pressure heater, and the steam extraction pressure at the time is set to be P0; when the turbogenerator unit operates in a state lower than the rated load, a high-pressure steam extraction port with steam extraction pressure less than or equal to P0 or closer to P0 is selected to supply steam for the high-pressure heater, and the isolated valves on other high-pressure steam extraction pipelines are switched off. According to the regenerative system of the turbogenerator unit and the operation method thereof, a denitration system can operate normally when the unit operates at a low load, the boiler feeding temperature is increased, and the thermodynamic cycle efficiency of the unit is improved accordingly.

Owner:王振宇

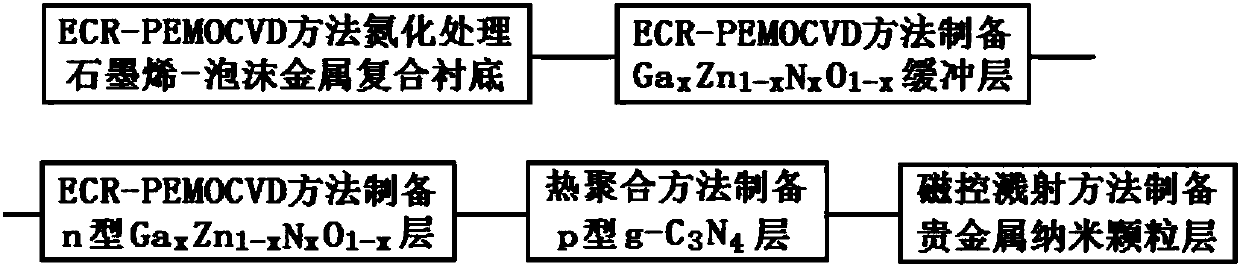

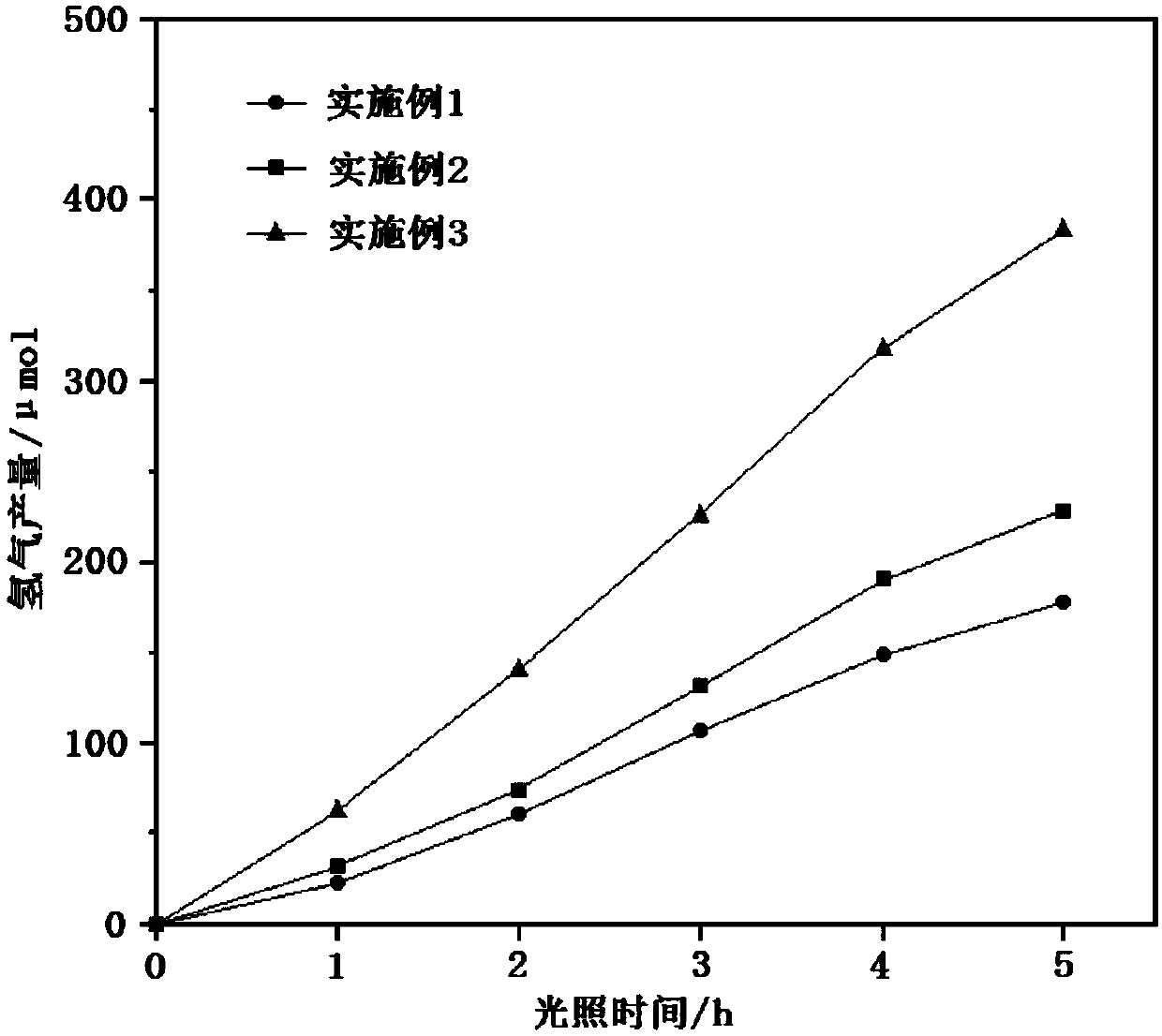

Photocatalytic thin film on foam metal-graphene composite substrate and preparation method

InactiveCN107649165AImprove mechanical propertiesUniform pore structureCatalyst activation/preparationHydrogen productionCvd grapheneNitrogen treatment

The invention belongs to the technical field of photocatalytic thin film manufacturing, and provides a photocatalytic thin film on a foam metal-graphene composite substrate and a preparation method. Concretely, the preparation method comprises the steps of taking a foam metal-graphene composite material as a substrate, firstly using an electron cyclotron resonance-plasma enhancing metal organic matter CVD (chemical vapor deposition) method to successively perform nitrogen treatment of the foam metal-graphene composite substrate, preparation of a GaxZnl-xNxO1-x buffer layer and preparation of an n-type GaxZn1-xNxO1-x layer, then using a thermal polymerization method to prepare a p-type g-C3N4 layer, and finally using a magnetron sputtering method to prepare a precious metal nanometer granular layer. The prepared photocatalytic thin film has a very good visible light photocatalysis effect, can be used for photolyzing water to produce hydrogen, degrading organic pollutant in waste water,removing harmful gas and purifying air, and has a broad application prospect.

Owner:秦永泽

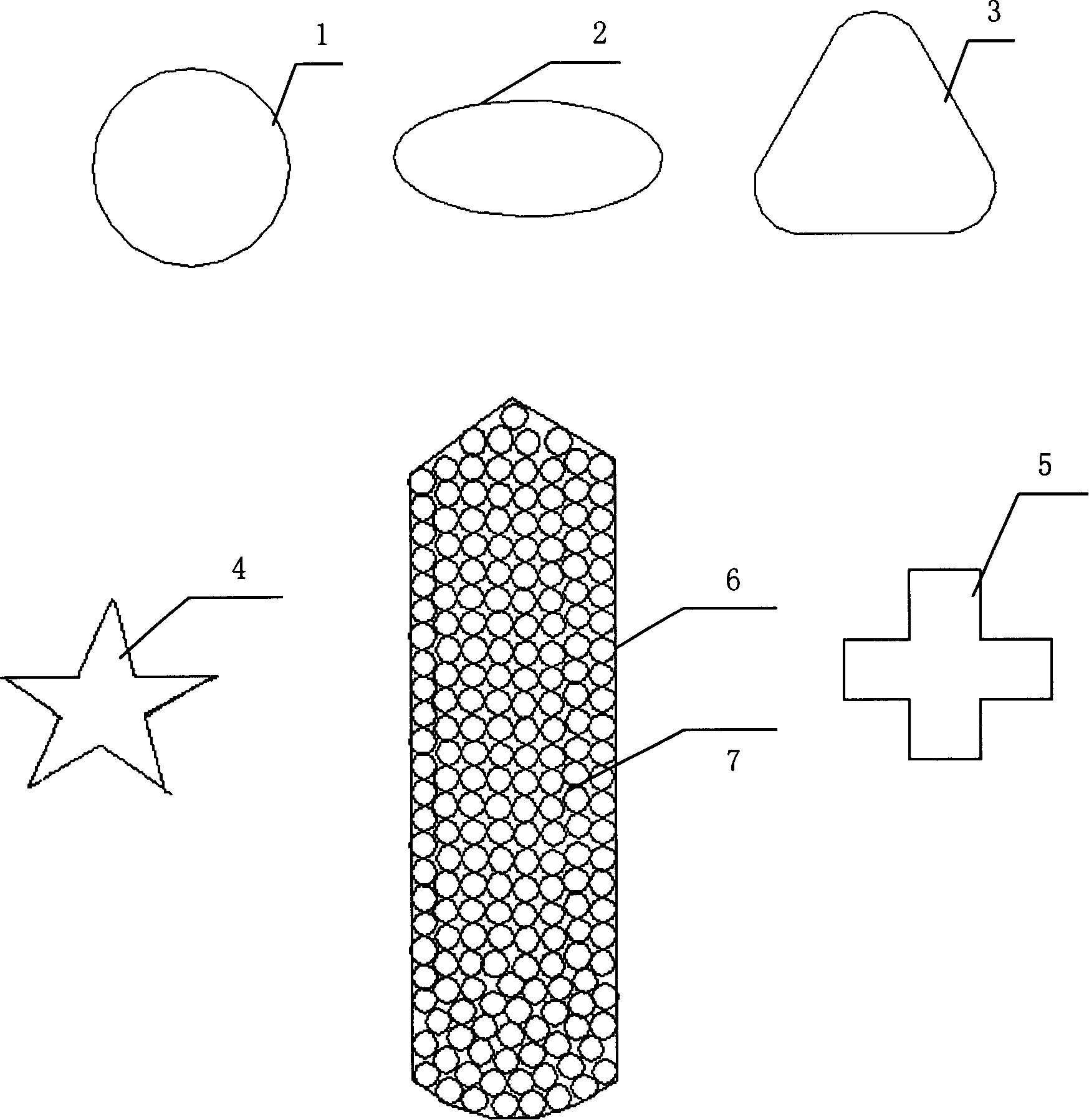

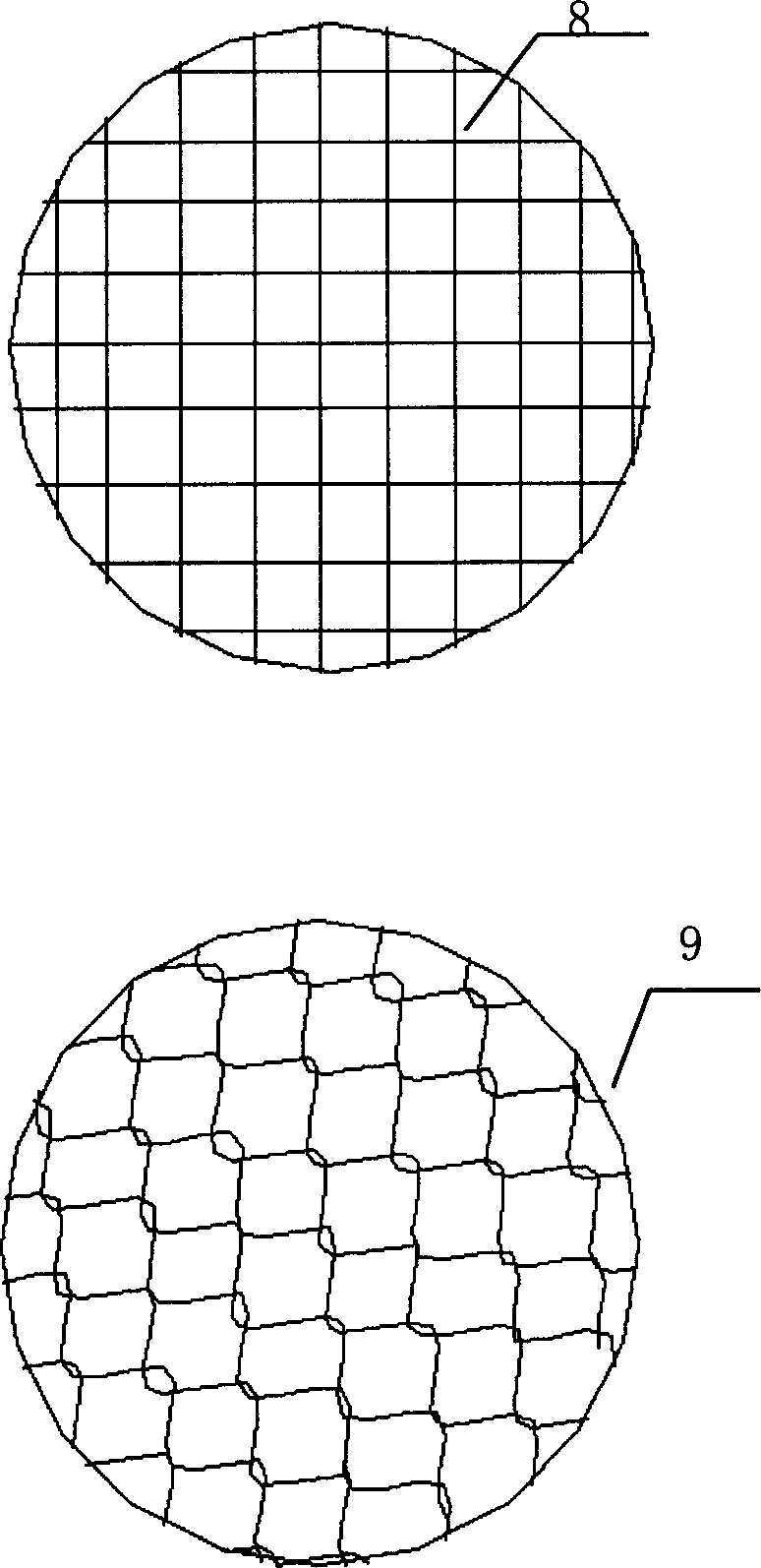

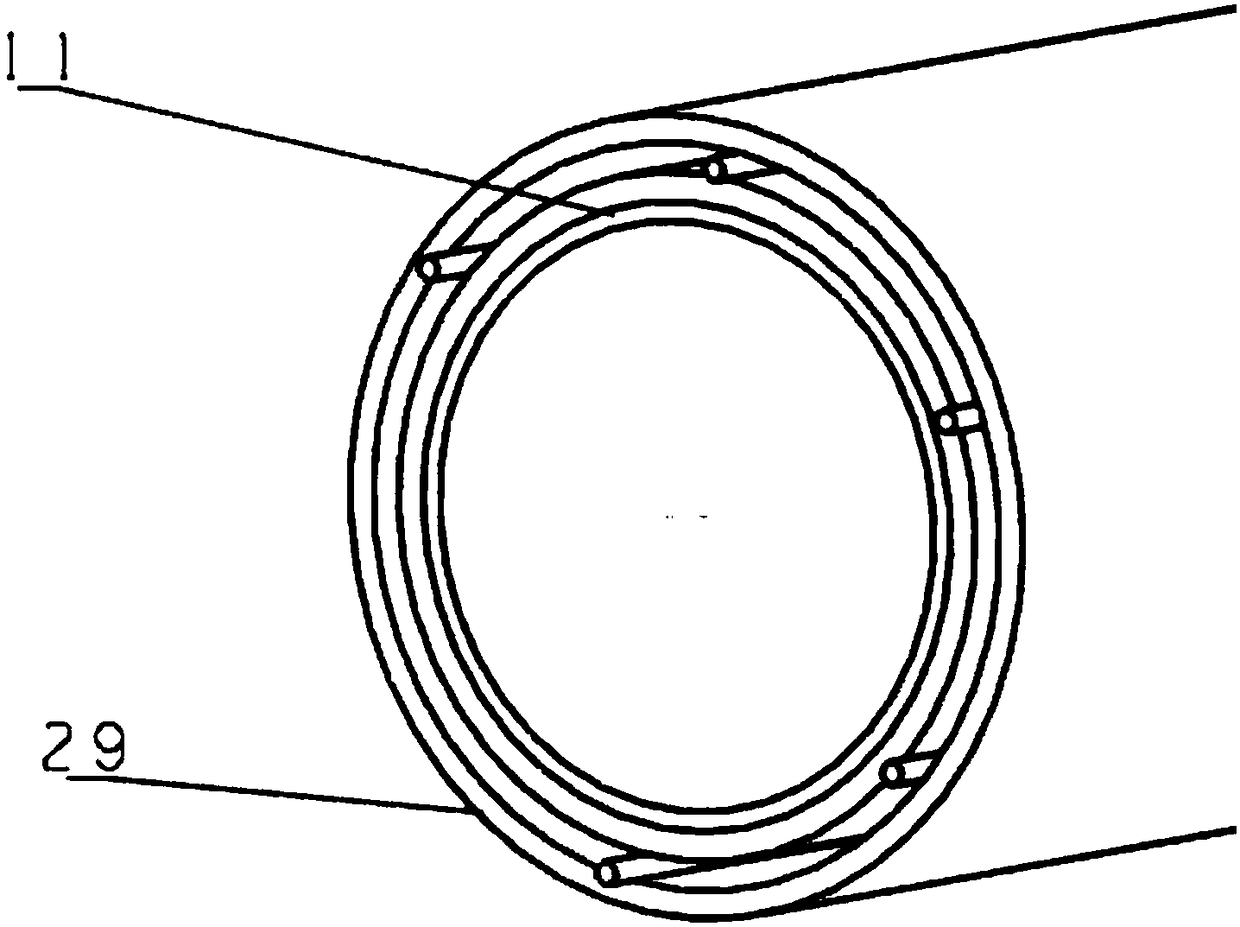

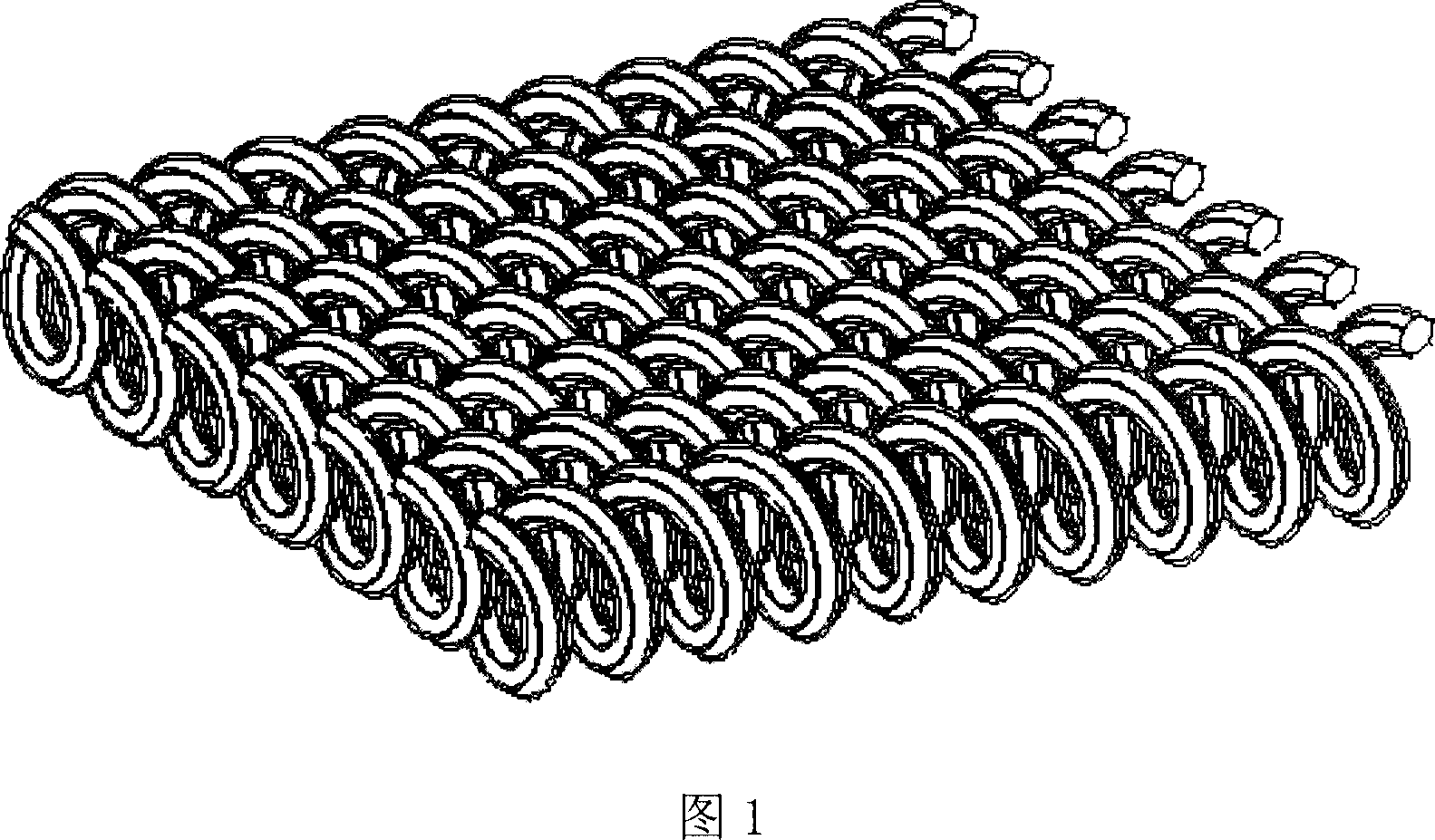

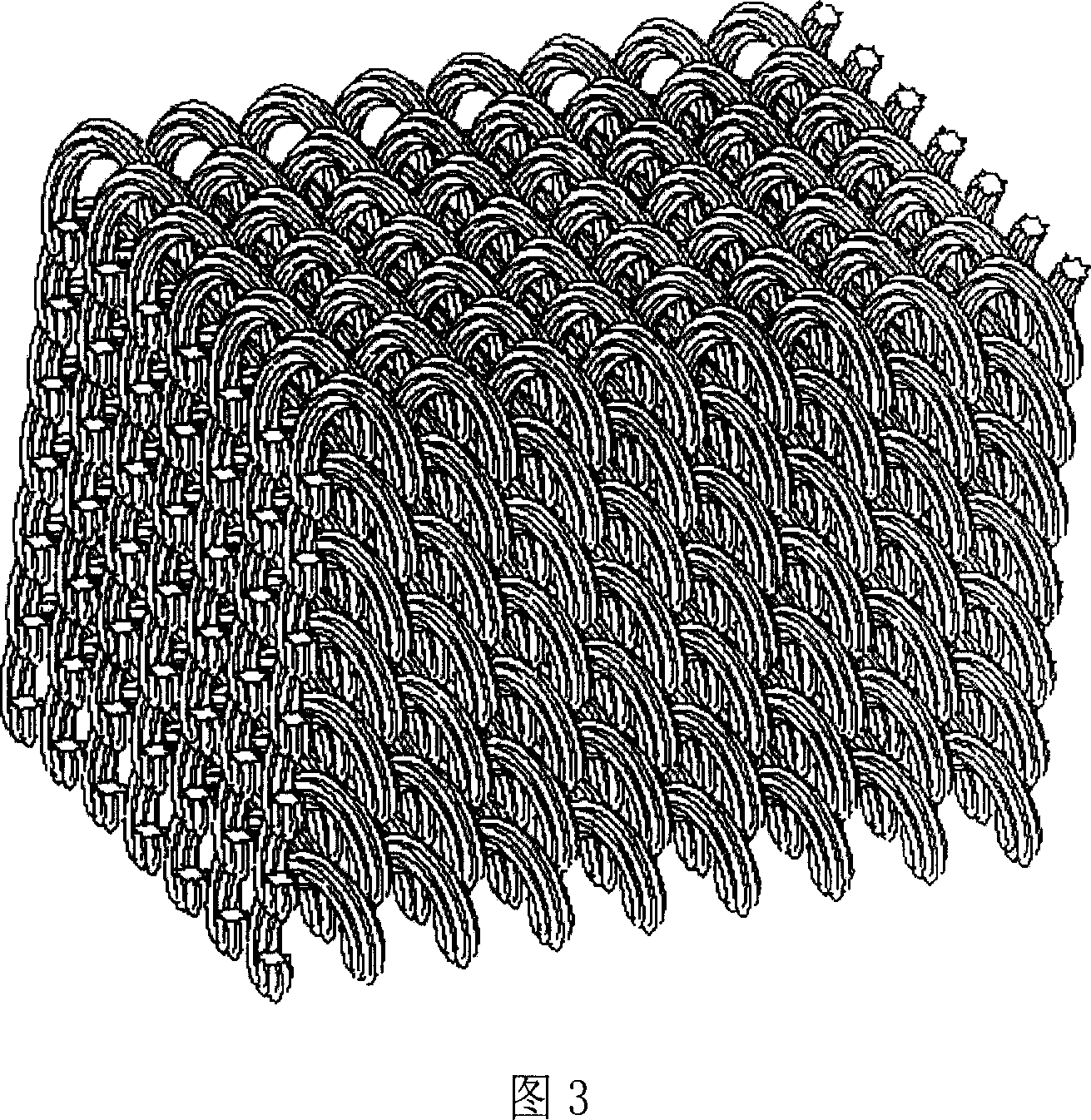

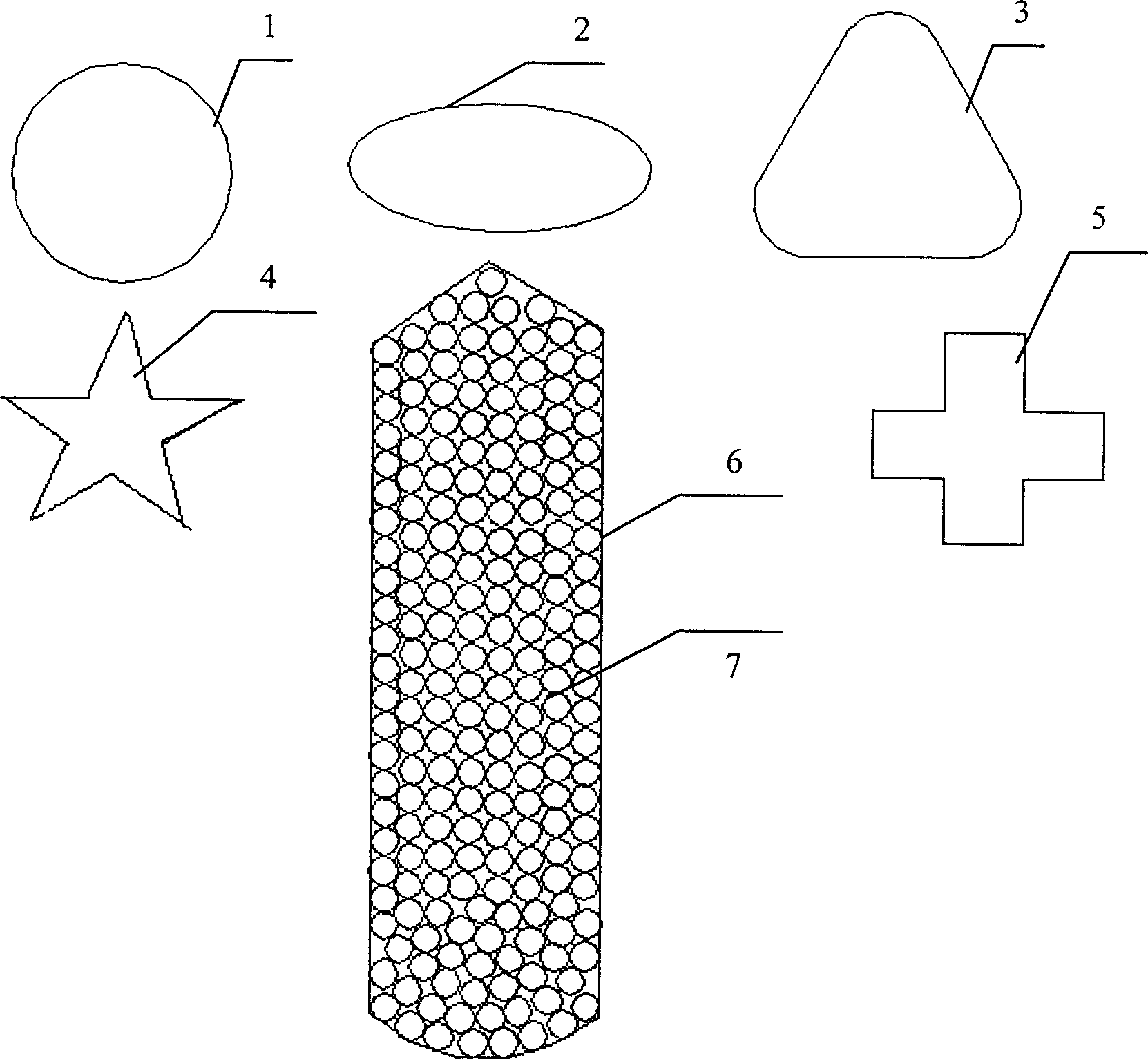

Suspended biological carrier adapted to microbial bodies, and preparation method

InactiveCN1958474AIncrease the effective surface areaImprove degradabilitySustainable biological treatmentBiological water/sewage treatmentSpray nozzleRough surface

This invention relates to a biological carrier for water treatment, more specifically, a suspended microbe carrier and its preparation method. The method adopts a polymer extruder, whose spray nozzle is equipped with a mold with a groove at the section and rough inner surface. The mold can extrude filamentous polymer with convex section and rough surface. The diameters of the filaments are 1-3 mm. winding of several filaments of the filamentous polymer can form suspended microbe carrier with arbitrary structure. The helical diameters of the helically winding filamentous polymer are 6-8 mm, and the pitches are 4-7 mm. The suspended microbe carrier can match the sizes and physical structures of microbes in wastewater, and has such advantages as simple structure, easy preparation, and excellent hydrodynamic properties.

Owner:SOUTH CHINA UNIV OF TECH

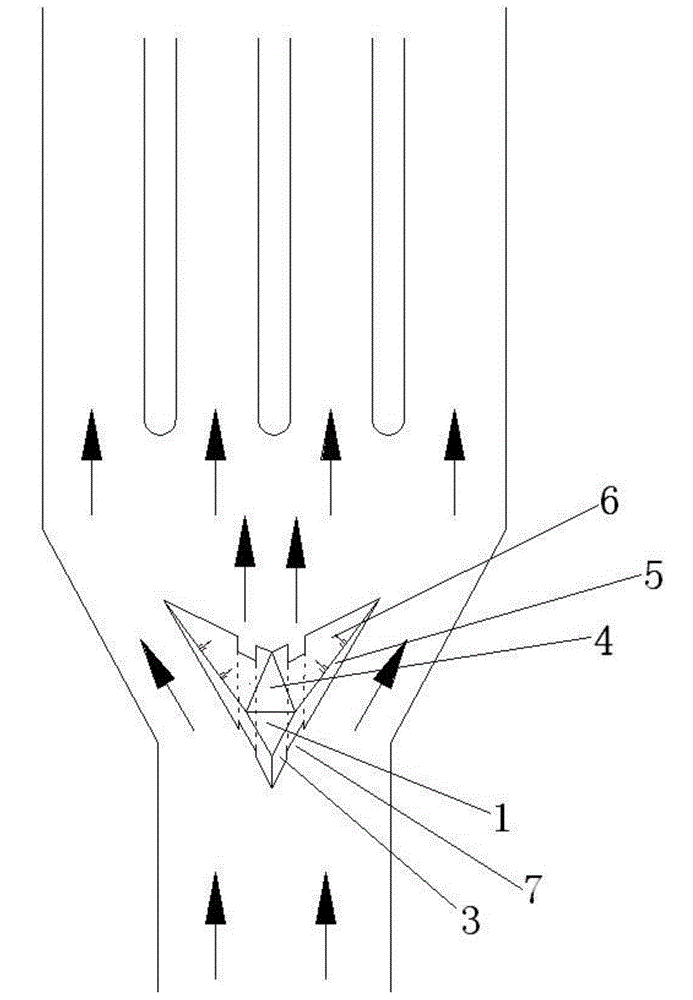

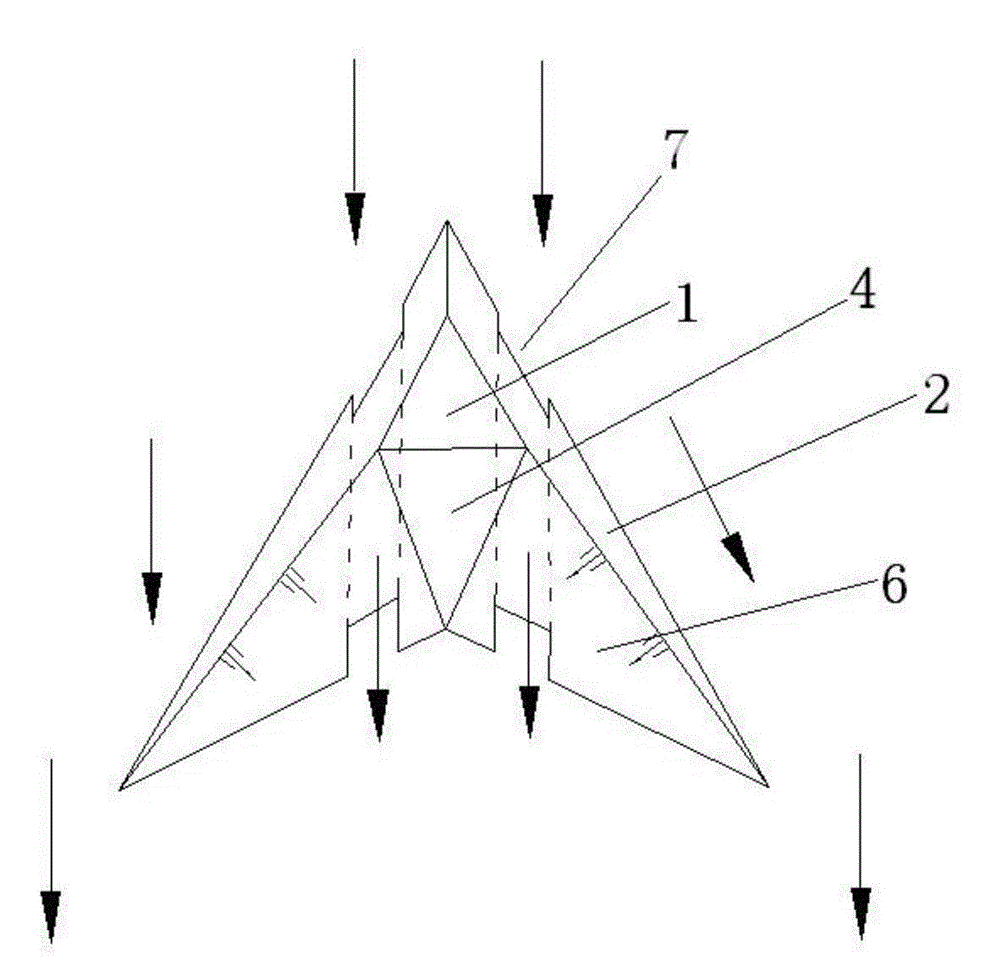

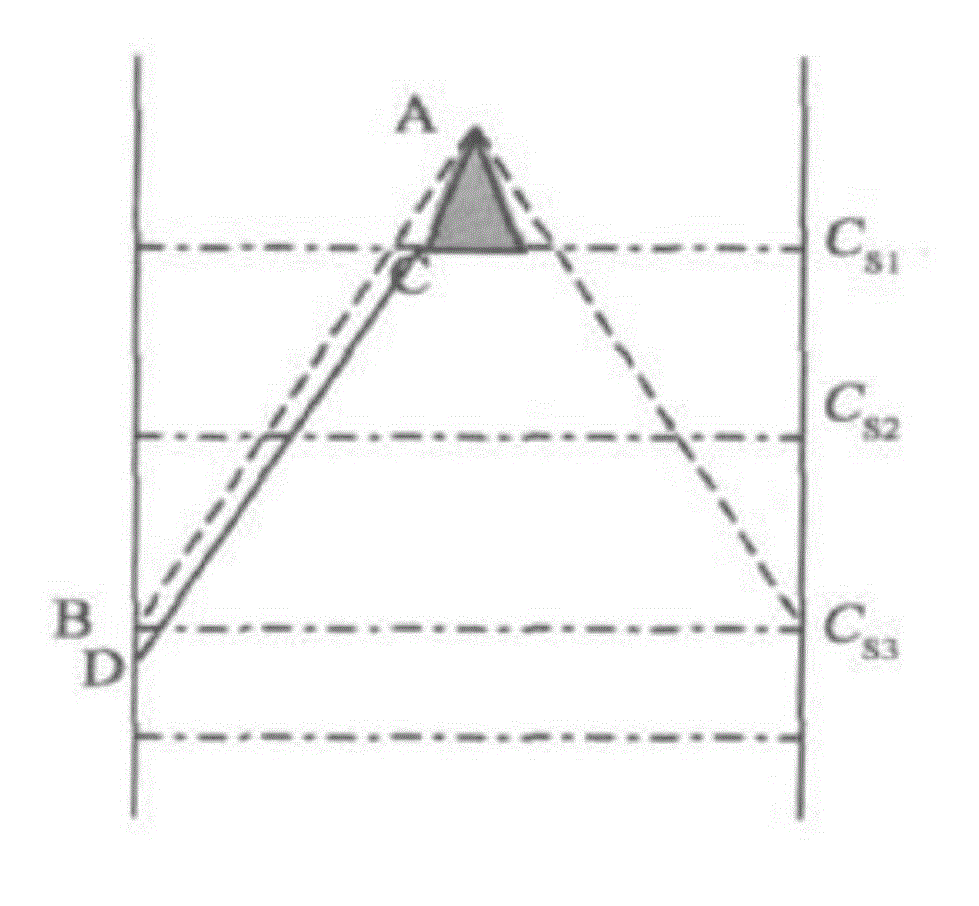

Open channel diffusion section flow-equalizing device and method for calculating placement position of open channel diffusion section flow-equalizing device

InactiveCN104652350AImprove hydrodynamic propertiesSimple structureArtificial water canalsHydraulic engineering apparatusShortest distanceWater flow

The invention discloses an open channel diffusion section flow-equalizing device and a method for calculating a placement position of the open channel diffusion section flow-equalizing device. The open channel diffusion section flow-equalizing device is characterized by comprising an isosceles triangular top plate (1), a dovetailed bottom plate (2), two upstream front slope plates (3), an isosceles-triangular upstream rear slope plate (4), a flank outer wall (5) and a flank inner wall (6), wherein the dovetailed bottom plate (2) is arranged parallel to the top plate (1); the two upstream front slope plates (3) are connected with the outer lateral edge of the top plate (1) and the outer lateral face of the bottom plate (2); the isosceles-triangular upstream rear slope plate (4) is superposed with the bottom of the top plate (1); the vertex angle of the isosceles-triangular upstream rear slope plate (4) inclines to the plane of the bottom plate (2); the flank outer wall (5) is connected with the rear lateral edges of the upstream front slope plates (3) and the tail end point of the bottom plate (2); the flank inner wall (6) is connected with the waist of the upstream rear slope plate (4) and the tail end point of the bottom plate (2). According to the open channel diffusion section flow-equalizing device and the method for calculating the placement position of the open channel diffusion section flow-equalizing device, the theoretical and technical problems of short-distance diffused water-flow smooth joint are solved through the flow division effect of two flanks of the flow-equalizing device.

Owner:HOHAI UNIV

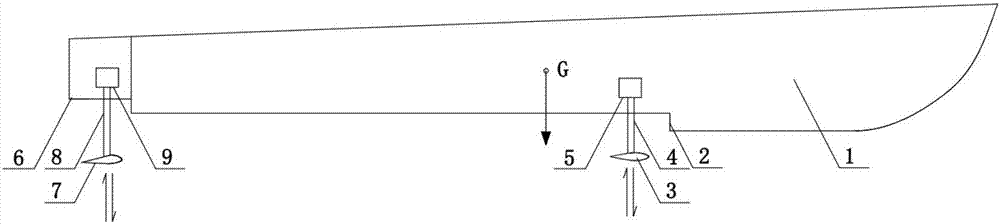

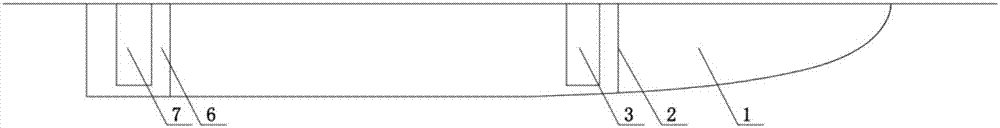

Step composite ship form with retractable type hydrofoils

InactiveCN107226169ASolving Recycling ProblemsIncrease hydropowerHydrodynamic/hydrostatic featuresMarine engineeringSelf stability

The invention provides a step composite ship form with retractable type hydrofoils. The step composite ship comprises a hull with a step and a fake tail, a front hydrofoil, a rear hydrofoil, supporting columns of the hydrofoils and devices for separately controlling the corresponding hydrofoil to extend / retract, wherein the front hydrofoil is located behind the step; the rear hydrofoil is located under the fake tail; the hydrofoil extending and retracting devices are arranged in the hull, and are used for extending / retracting the front hydrofoil and the rear hydrofoil; and when being unfolded, the hydrofoils are located under a baseline of the hull; and when the hydrofoils are retracted, the front hydrofoil is located behind the step, and the rear hydrofoil is located under the fake tail, and the front hydrofoil and the rear hydrofoil are close to the bottom of the hull. According to the step composite ship form with the hydrofoils which are additionally arranged disclosed by the invention, in an abyssal region, excellent hydrodynamic characteristics of the hydrofoils can be utilized to achieve the purposes of reducing resistance, increasing speed and saving energy, and the vertical damp of the hydrofoils and the longitudinal self-stability characteristic of a hydrofoil system can also be utilized to notably improve the movement performance of a ship and light boat; and in a shallow water region, after the front hydrofoil is retracted to the step, the rear hydrofoil can be retracted under the fake tail, so that the situation that the normal exerting of the functions of the ship and the light boat is influenced because the hydrofoils touch the ground is avoided.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

Joint air-cooling system and control method

InactiveCN105674760AReduce exhaust back pressureIncrease vacuumFeed water supplySteam/vapor condensersEngineeringAir cooling system

The invention provides a joint air-cooling system and a control method. The joint air-cooling system comprises a steam turbine, an indirect cooling condenser and a condensation water precision processing unit. A generator is connected to the steam turbine. A direct air-cooling unit is a direct air-cooling radiator. An inlet of the direct air-cooling radiator is connected with the steam turbine, and an outlet of the direct air-cooling radiator is connected with the condensation water precision processing unit. A multi-level heater is connected to the condensation water precision processing unit. An inlet of the indirect cooling condenser is connected with the steam turbine, and an outlet of the indirect cooling condenser is connected with the multi-level heater. The indirect cooling condenser is further connected with an indirect air-cooling unit. According to the joint air-cooling system and the control method, exhausted steam of the steam turbine is distributed, a part of the exhausted steam of the steam turbine enters a direct air-cooling condenser to be subjected to heat exchanging, and the other part of the exhausted steam of the steam turbine enters the indirect cooling condenser to be subjected to heat exchanging; the back pressure of the exhausted steam of the steam turbine can be further reduced through a composite circulation cooling system, the vacuum of a machine set is improved, and then the economy of the machine set is improved.

Owner:XIAN THERMAL POWER RES INST CO LTD

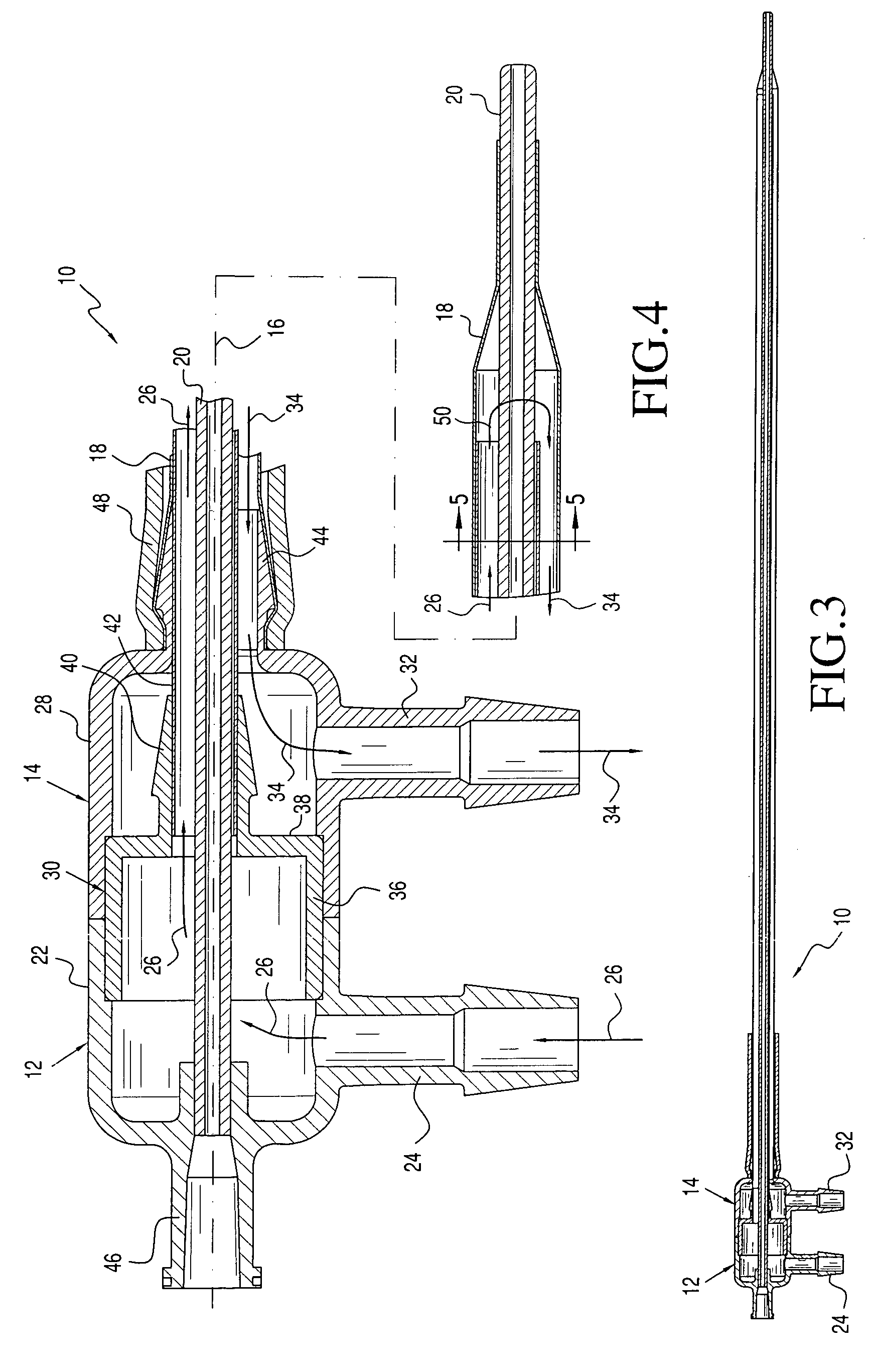

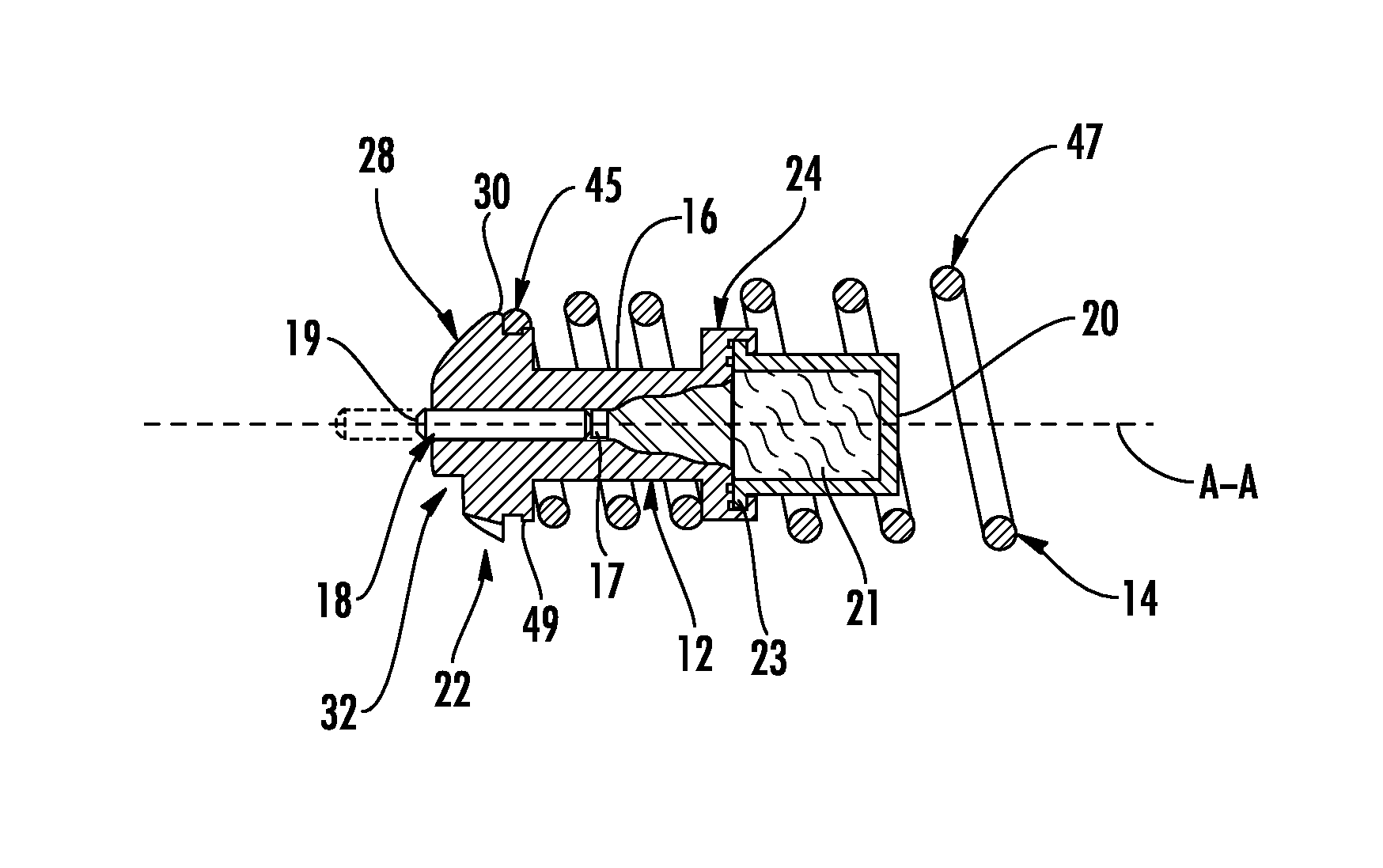

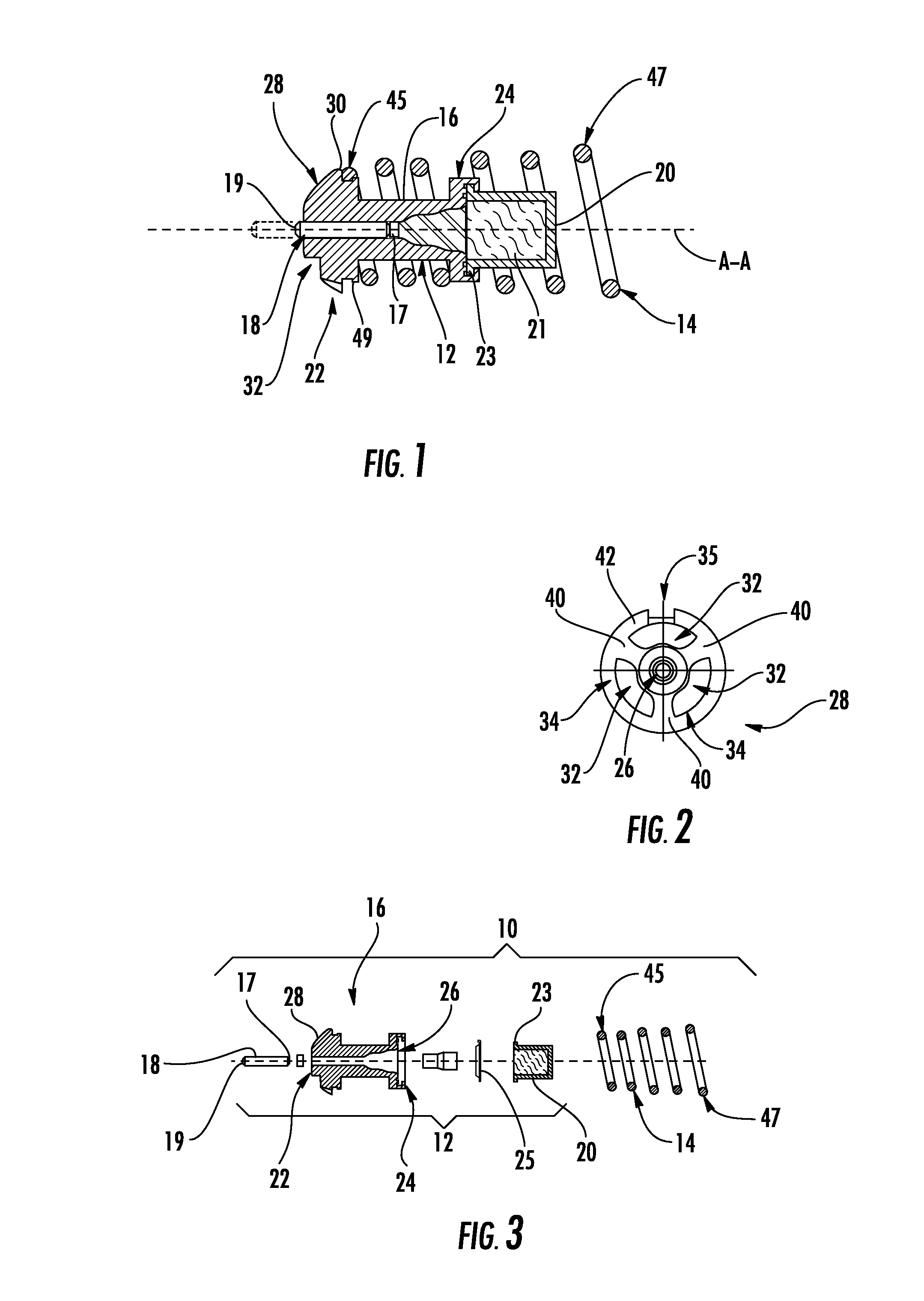

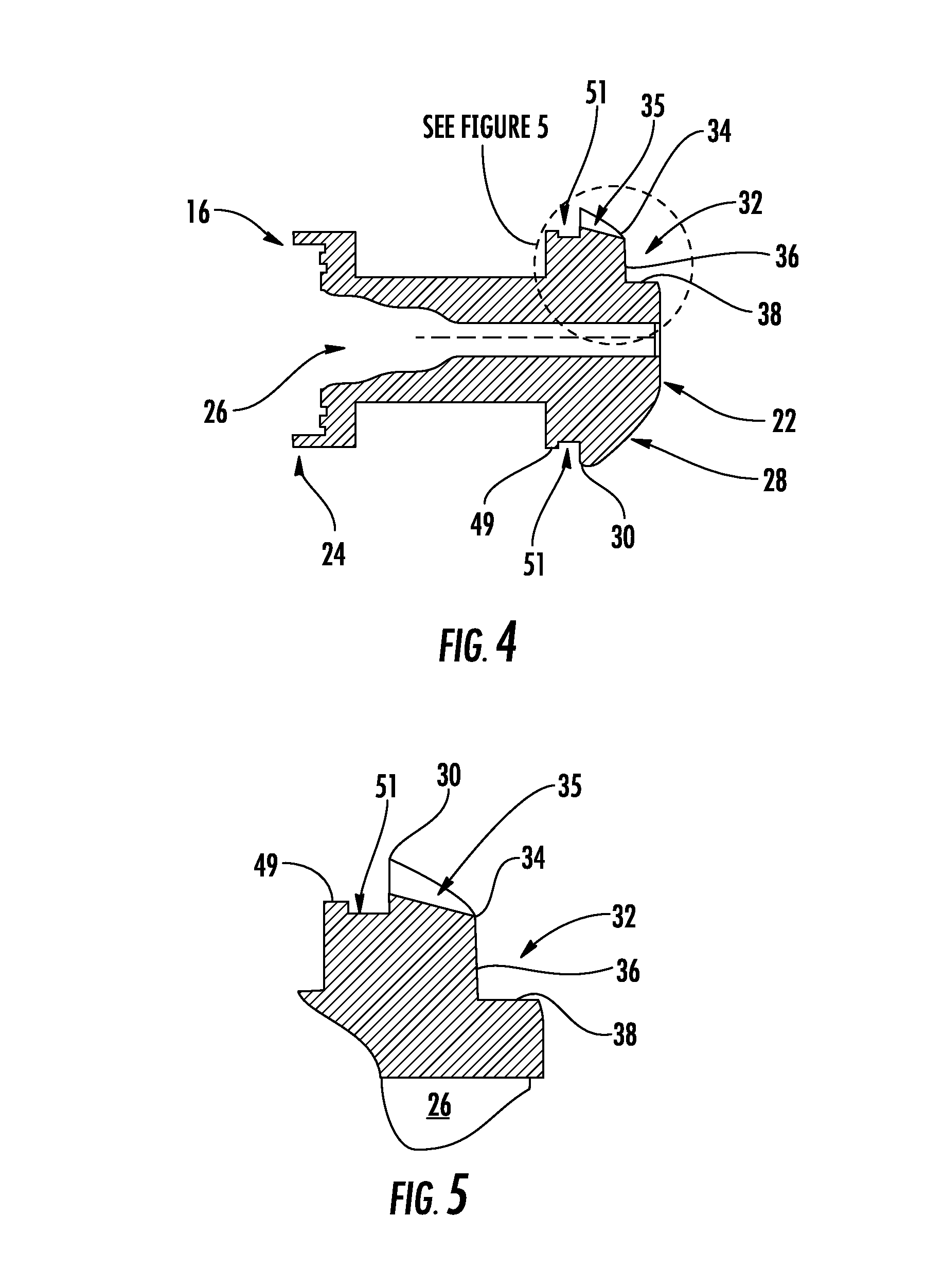

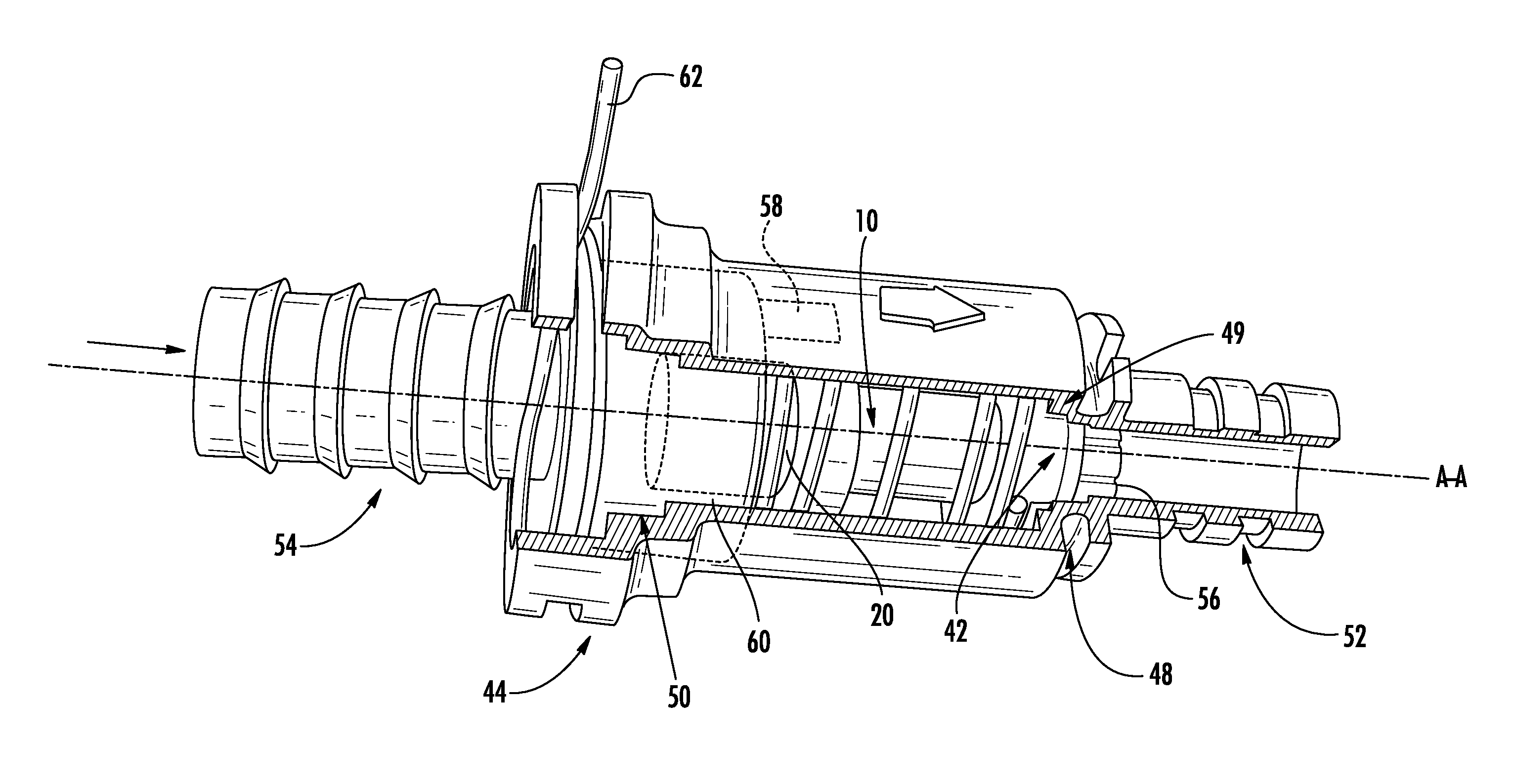

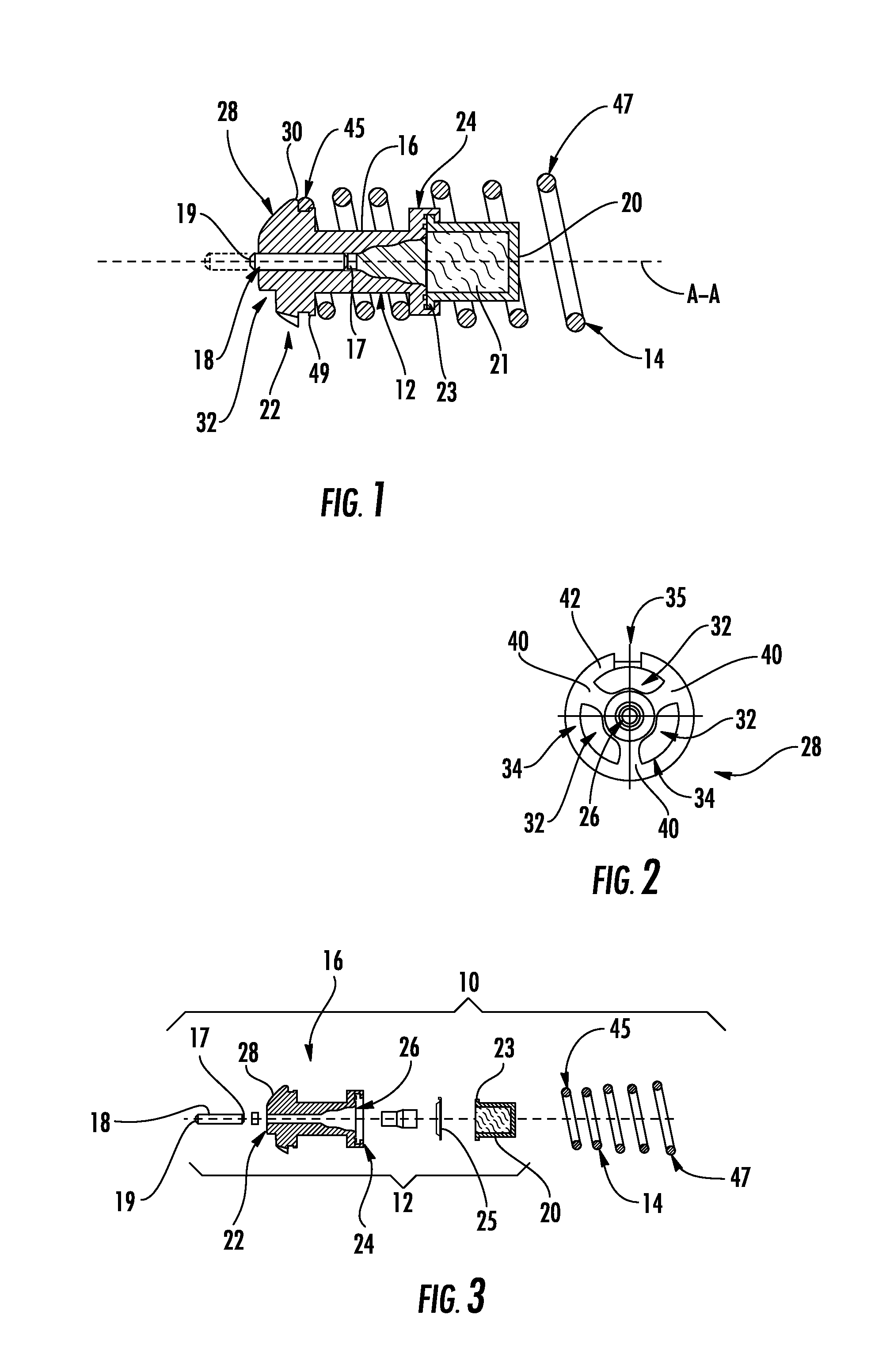

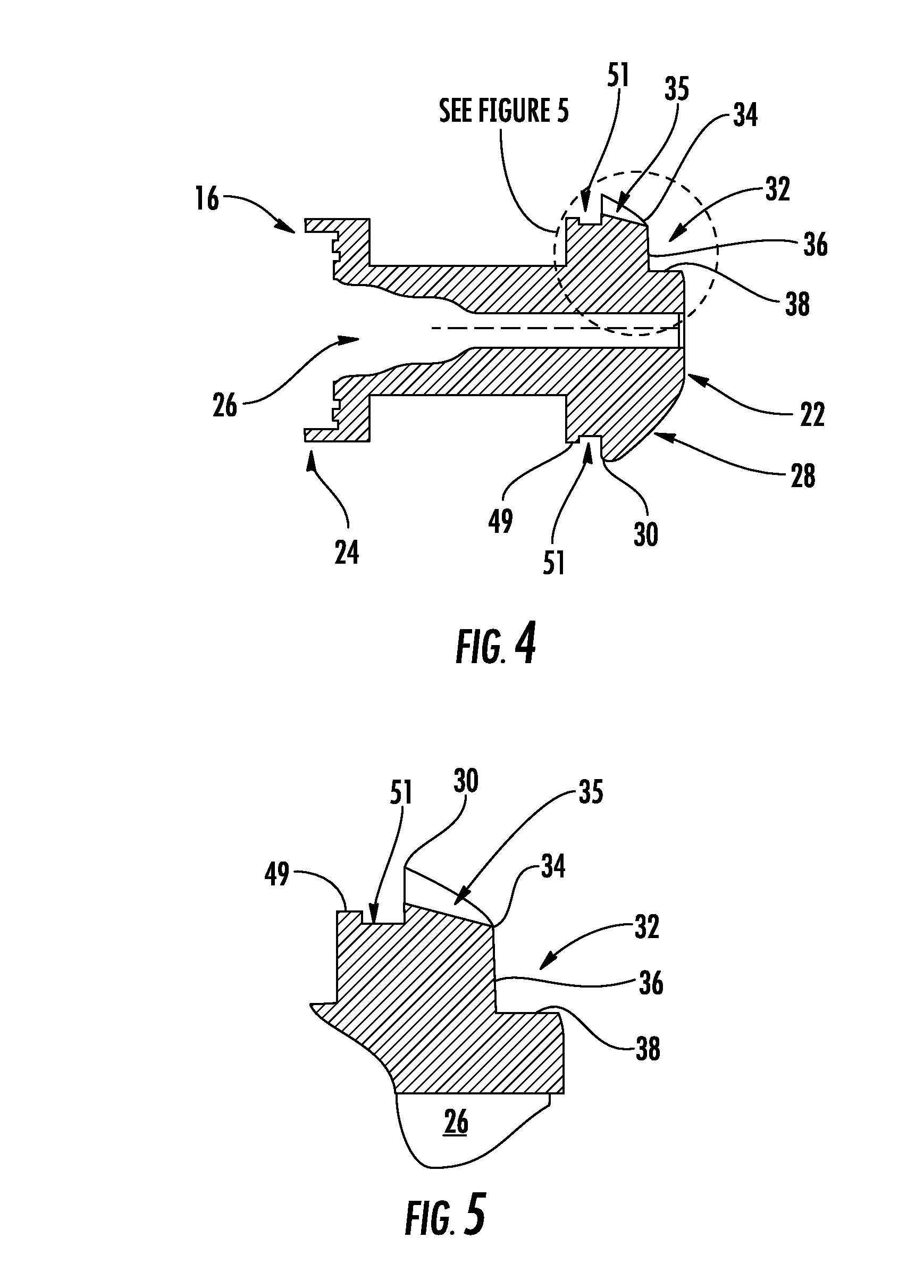

Thermally actuated power element with integral valve member

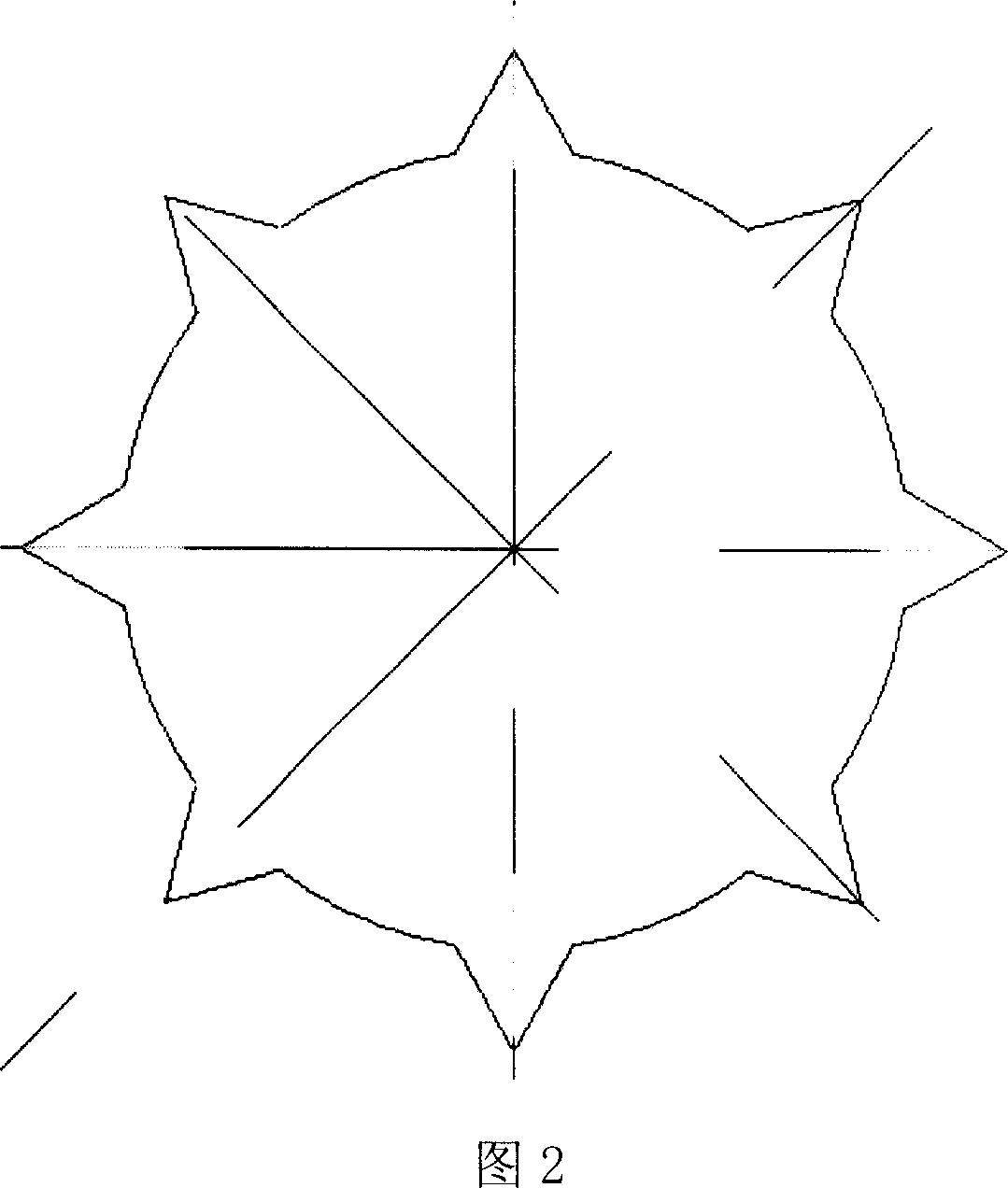

ActiveUS9298195B2Improved hydrodynamic propertiesIncrease pressureTemperature control without auxillary powerTemperature control with auxillary non-electric powerEngineeringActuator

A thermally actuated power element comprising an actuator having a guide, defining a generally cylindrical bore extending between first and second guide ends. The guide first end has a generally convex valve member projecting radially between the bore and a valve member periphery, defining a plurality of substantially identical flow depressions. The flow depressions are configured radially intermediate the cylindrical bore and the periphery, while an annular valve member seal surface extends between a radial boundary of the flow depressions and the periphery. A piston having axially opposed first and second piston ends is partially received in the generally cylindrical cavity. A generally concave cup defines a cavity and contains a thermally active pellet, and a diaphragm is received in the guide second end intermediate the cup and said piston. A generally cylindrical return member engages the guide adjacent the periphery.

Owner:ROSTRA VERNATHERM

Thermally Actuated Power Element with Integral Valve Member

ActiveUS20140131460A1Disrupt sealImproved hydrodynamic propertiesTemperature control without auxillary powerTemperature control with auxillary non-electric powerActuatorPiston

A thermally actuated power element comprising an actuator having a guide, defining a generally cylindrical bore extending between first and second guide ends. The guide first end has a generally convex valve member projecting radially between the bore and a valve member periphery, defining a plurality of substantially identical flow depressions. The flow depressions are configured radially intermediate the cylindrical bore and the periphery, while an annular valve member seal surface extends between a radial boundary of the flow depressions and the periphery. A piston having axially opposed first and second piston ends is partially received in the generally cylindrical cavity. A generally concave cup defines a cavity and contains a thermally active pellet, and a diaphragm is received in the guide second end intermediate the cup and said piston. A generally cylindrical return member engages the guide adjacent the periphery.

Owner:ROSTRA VERNATHERM

Catalytic distillation assembly and catalytic distillation method using the same

InactiveCN1241667CImproved hydrodynamic propertiesSmall pressure dropChemical/physical processesFractional distillationVoid ratioGas phase

The invention relates to a catalyzing distillation component and a method. The component includes catalyst particles, silk network container and regulated fillers, its character lies in: the catalyst particles and other inertial particles are blended together and filled into the container, and the mentioned silk network containers are arranged in the regulated fillers one by one. The invention favors the transition of media to liquid phase in the gas phase reaction. It can make the reacting bed with large gap rate, and the catalyst is distributed in the whole reaction segment evenly.

Owner:CHINA PETROLEUM & CHEM CORP +1

Device and method for separating long chain hydrocarbon in chemical wastewater from methanol to olefin

ActiveCN104129825AImproved hydrodynamic propertiesIncrease chances of mergerHydrocarbon purification/separationHydrocarbonsOrganic solventSolvent

The invention discloses a device and method for separating long chain hydrocarbons in chemical wastewater from methanol to olefins. The device includes a solvent air floatation tower and a hydrophobic coalescence board assembly; the wall of the solvent air floatation tower is provided with a wastewater inlet, a wastewater outlet, a gas inlet, a gas outlet, a solvent inlet and a solvent outlet; the position of the wastewater inlet is higher than that of the wastewater outlet; the position of the gas inlet is lower than that of the wastewater outlet; the position of the gas outlet is higher than that of the gas inlet; the solvent inlet and solvent outlet are higher than the wastewater inlet; the hydrophobic coalescence board assembly is arranged in the solvent air floatation tower, and between the wastewater inlet and the wastewater outlet. By setting the hydrophobic coalescence board assembly in the solvent air floatation tower, the increases invention coalescence opportunity of the droplets with long chain hydrocarbon organic solvent, reduces backmixing of water and solvents, improves the fluid mechanical characteristics in the solvent air floatation tower, simplifies the wastewater treatment process, reduces the energy consumption and improves the separation efficiency.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Ozone oxidation catalyst for wastewater treatment and application method thereof

ActiveCN114011426AIncrease the areaLarge hole volumeWater contaminantsMetal/metal-oxides/metal-hydroxide catalystsPtru catalystPhosphite salt

The invention relates to an ozone oxidation catalyst for wastewater treatment and an application method thereof, and belongs to the technical field of water treatment. The catalyst provided by the invention has efficient and stable catalytic activity, excellent fluid mechanical properties, rich pore structures, relatively high mechanical strength, proper variable valence activity, adsorption activity, catalytic ozonolysis activity and catalytic ozonolysis degradation activity, is suitable for reactors such as a bubble tower, and can be produced on a large scale. Compared with single ozone oxidation or ceramsite-based catalysts, the catalyst has the advantages that the actual wastewater organic pollutant degradation efficiency is greatly improved, the catalyst can be used for strengthening complex-state heavy metal ozone oxidation complex breaking and free heavy metal release, the efficiency of converting organophosphorus, hypophosphite, phosphite and the like into orthophosphate through ozone oxidation can be improved, the operation effect is stable, and the catalyst is suitable for advanced treatment of industrial wastewater and industrial park wastewater.

Owner:NANJING UNIV

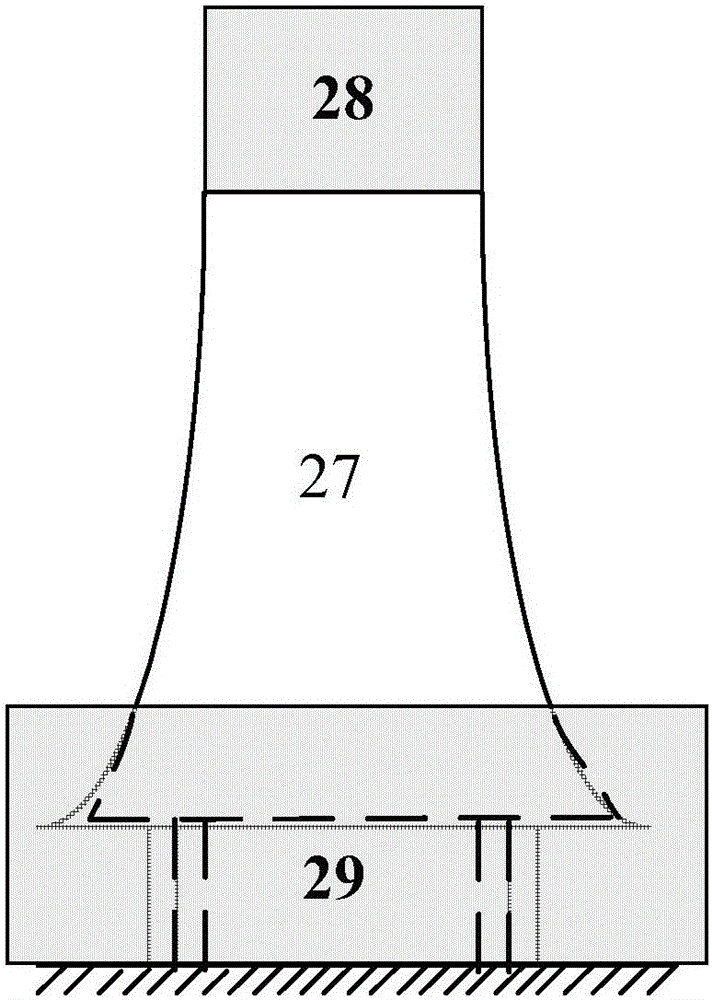

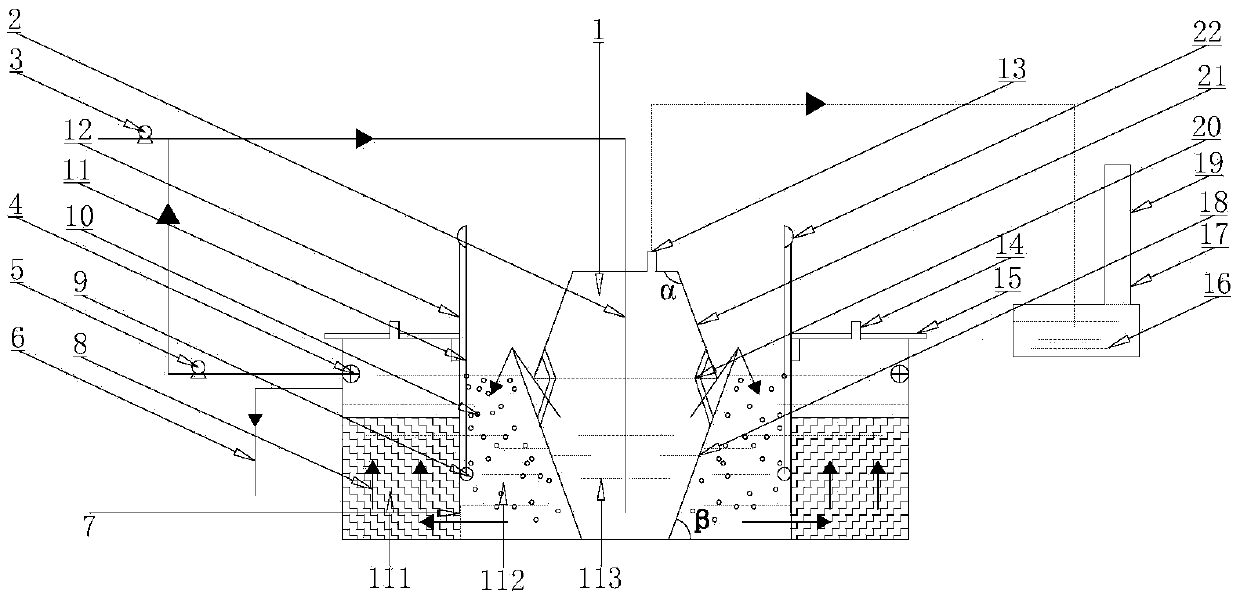

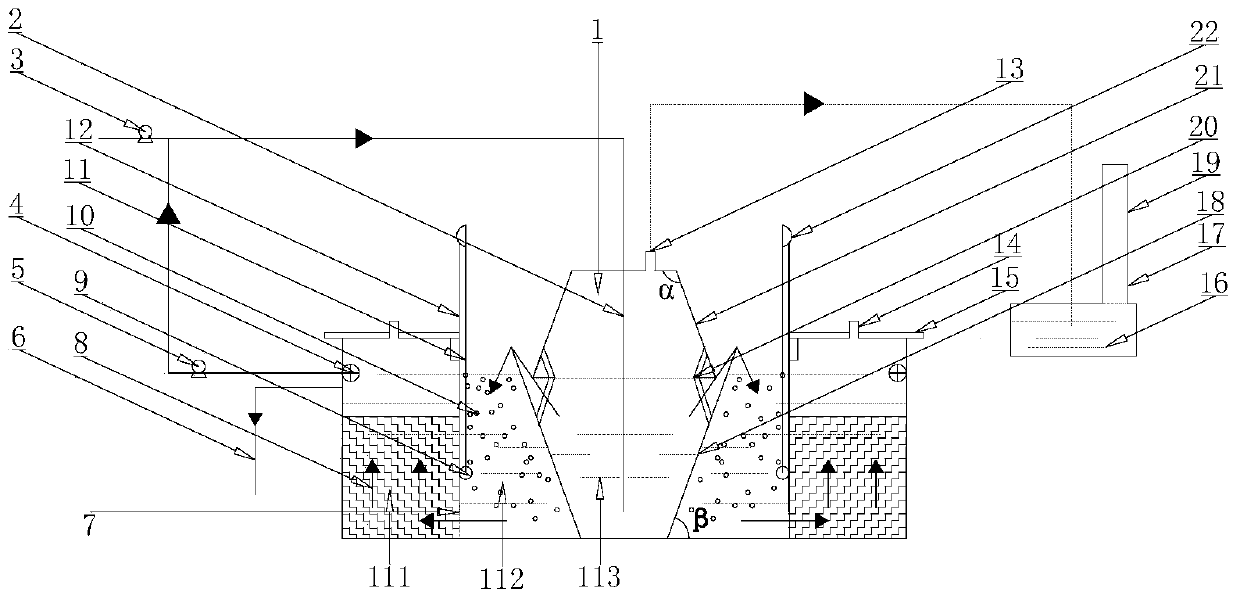

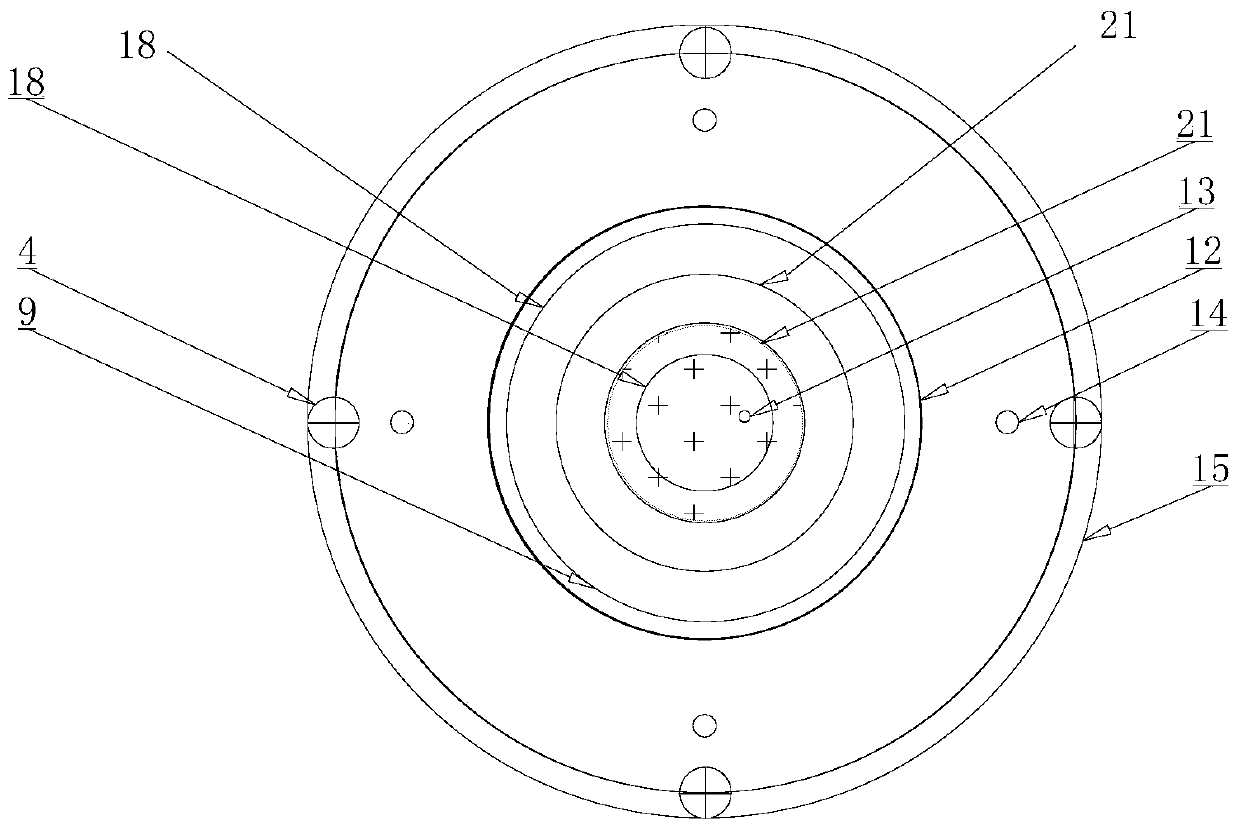

Tricyclic type synchronous carbon removal and denitrification biological reactor

ActiveCN105366808AImprove processing efficiencyReduce energy consumptionWater contaminantsTreatment with aerobic and anaerobic processesPollutantWater pipe

A tricyclic type synchronous carbon removal and denitrification biological reactor includes a reactor body and a water inlet pipe; the inner bottom plating of the reactor body is provided with an inverted circular truncated cone-shaped separator plate and a cylinder separator plate from the inside to the outside to divide the reactor cavity into a tricyclic type structure; the inverted circular truncated cone-shaped separator plate is used as an anaerobic zone; the region between the inverted circular truncated cone-shaped separator plate and the cylinder separator plate is used as an aerobic zone; the region between the cylinder separator plate and the side wall of the reactor body is used as an anoxic zone; the top of a three-phase separator is provided with a first gas vent; the aerobic zone is provided with an annular aeration device; the water outlet of the anoxic zone is equipped with a water outlet device; and the inlet end of the water inlet pipe is connected to the liquid outlet of a raw water adjusting pump, and the outlet end is let in the anaerobic zone. The invention has the beneficial effects that the reactor can remove carbon and nitrogen pollutants at the same time, and recover methane gas to turn waste into treasure; the reactor is provided with different zones to improve the hydromechanical properties and create the best conditions for microbe growth; and multi-level treatment of pollutants within the same reactor is achieved.

Owner:HANGZHOU NORMAL UNIVERSITY

Steam-water system arrangement structure of deep peak regulation double-hearth power station pulverized coal boiler

PendingCN112963819AOptimize layoutSave spaceSteam separation arrangementsPulverulent fuel combustion burnersIsolation valvePower station

The invention discloses a steam-water system arrangement structure of a deep peak regulation double-hearth power station pulverized coal boiler. The structure comprises a first hearth water-cooling wall (1) and a second hearth water-cooling wall (2) which are coupled with a hearth structure, and economizers (4) at the upstream of inlet headers of the first hearth water-cooling wall (1) and the second hearth water-cooling wall (2) are arranged in a combined manner; and superheaters (5) at the downstream of outlet headers of the first hearth water-cooling wall (1) and the second hearth water-cooling wall (2) are arranged in a combined manner. Aiming at different systems in a steam-water flow, a manner of combining split parallel arrangement and a combined structure is adopted, meanwhile, isolation valves are arranged to ensure that all the systems are independent and communicated, the operation manner is flexible, the hydrodynamic characteristics in a low-load interval are stable, and the steam-water system arrangement manner is closely attached to the design concept of a double-hearth boiler; and the deep peak regulation capability of the double-hearth boiler can be better exerted.

Owner:XIAN THERMAL POWER RES INST CO LTD

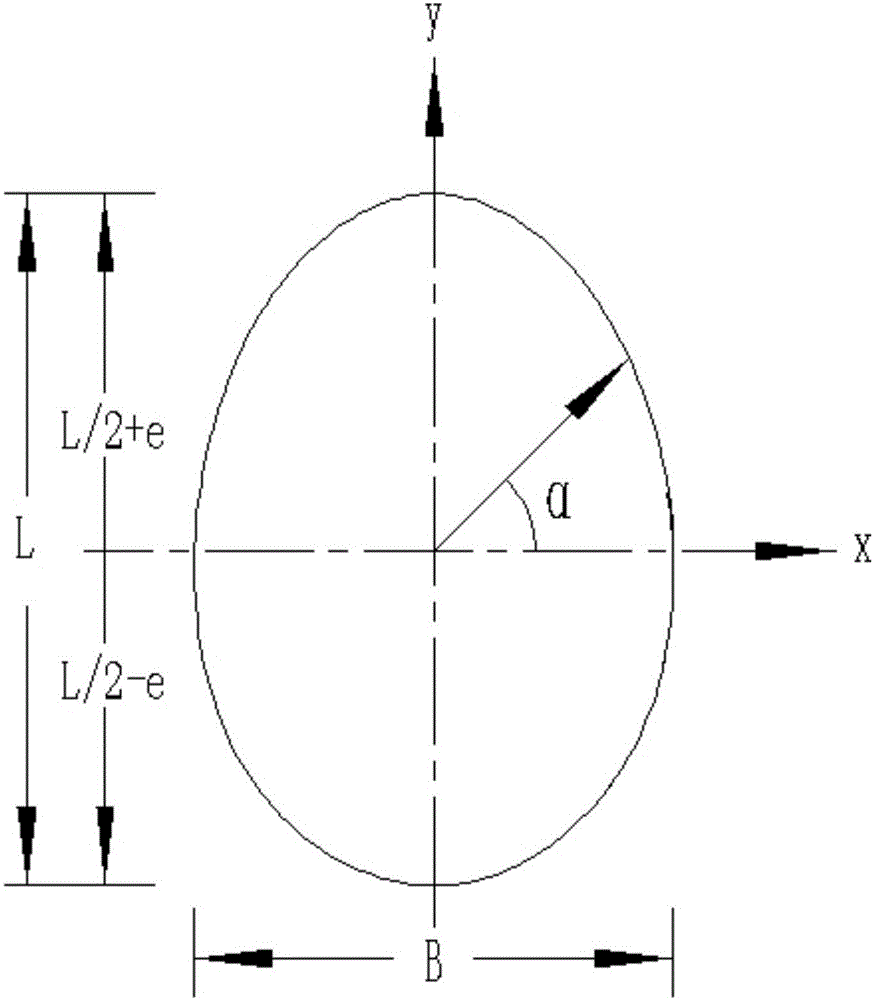

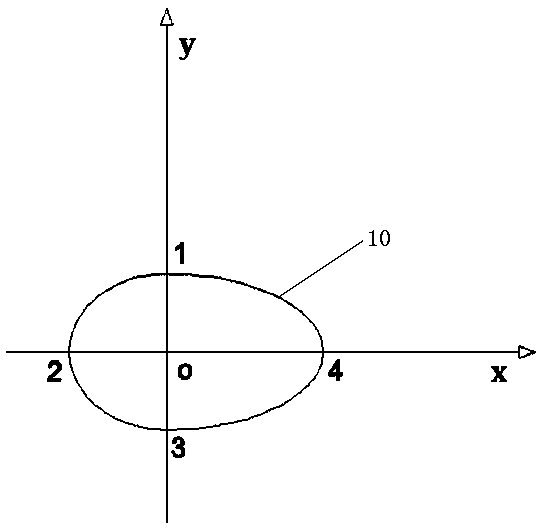

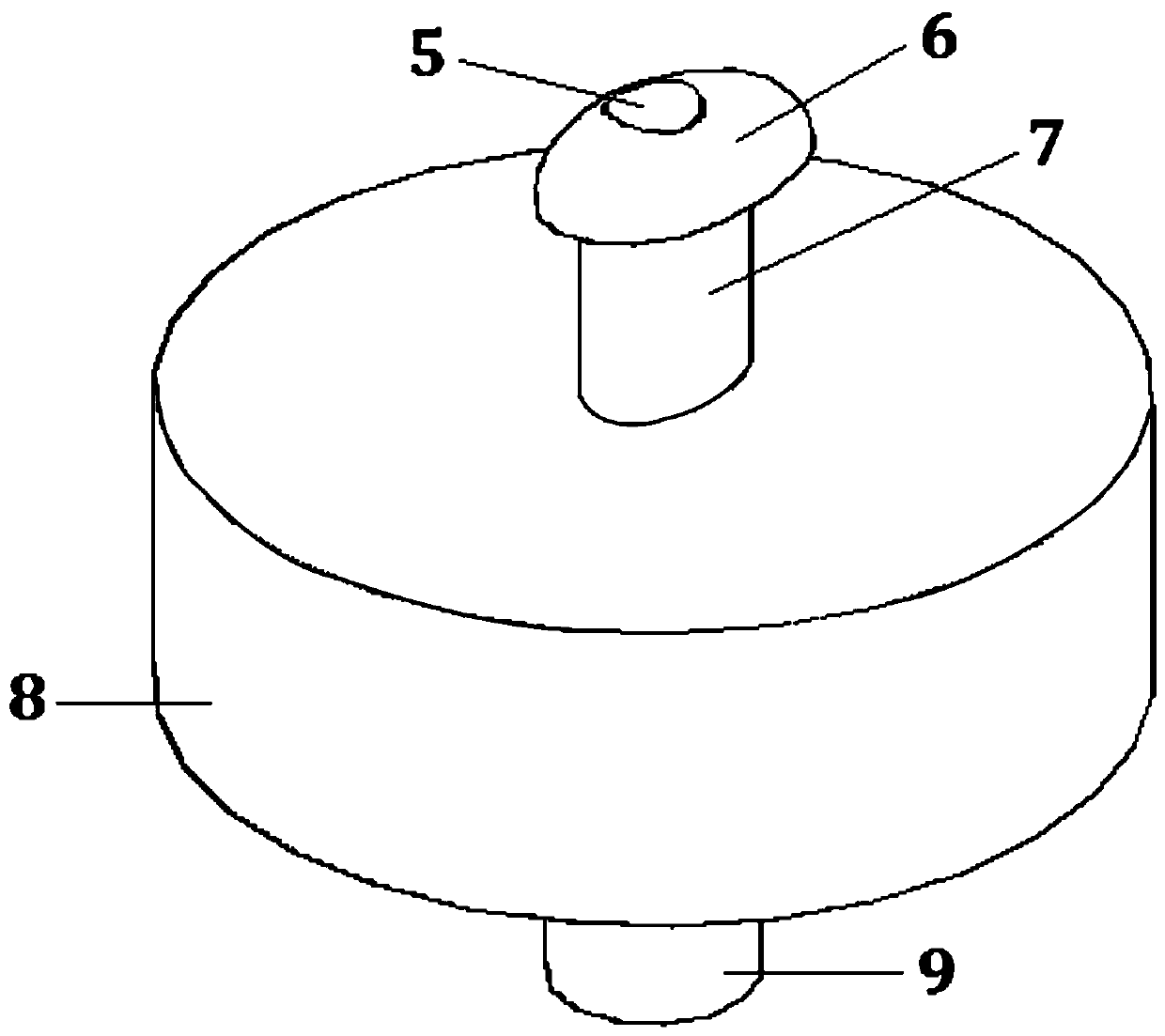

Double-ellipsoidal streamlined rotator irrigation emitter plug and mounting method thereof

ActiveCN110419417ASmooth flow separationReduced shape resistanceWatering devicesCultivating equipmentsIrrigationEngineering

A double-ellipsoidal streamlined rotator irrigation emitter plug comprises a plug back taper. A plug water inlet is formed in the upper end face of the plug back taper, the lower surface of the plug back taper is sequentially communicated with a plug taper neck, a dropper cavity and a dropper water outlet pipe from top to bottom, the contour line of the cross section of the plug back taper is a double-ellipsoidal streamlined curve, the contour line of the cross section of the plug taper neck is a double-ellipsoidal streamlined curve, and the area of the double-ellipsoidal streamlined curve ofthe upper end face is as same as that of the double-ellipsoidal streamlined curve of the lower end face. According to the double-ellipsoidal streamlined rotator irrigation emitter plug and a mountingmethod thereof, the problem of great local head loss can be solved, and the plug form resistance of an irrigation emitter is maximally reduced.

Owner:CHINA THREE GORGES UNIV

A three-ring synchronous carbon and nitrogen removal bioreactor

ActiveCN105366808BAchieve turbulenceImproved hydrodynamic propertiesWater contaminantsTreatment with aerobic and anaerobic processesNitrogen removalTime function

A three-ring synchronous decarbonization and denitrification bioreactor, comprising a reactor body and a water inlet pipe, the inner bottom plate of the reactor body is arranged with an inverted truncated truncated baffle plate and a cylindrical baffle plate from the inside to the outside to separate the inner cavity of the reactor body into two parts. Three-ring structure, the inner cavity of the inverted truncated truncated baffle plate is used as an anaerobic zone, the area between the inverted truncated truncated truncated baffle plate and the cylindrical baffle plate is used as an aerobic zone, and the space between the cylindrical baffle plate and the side wall of the reactor body is used as an aerobic zone. The top of the three-phase separator is provided with a first exhaust hole; the aerobic zone is provided with an annular aeration device; the water outlet of the anoxic zone is equipped with a water outlet; the water inlet end of the water inlet pipe is connected to The liquid outlet of the raw water regulating pump, and the outlet end leads to the anaerobic zone. The beneficial effects of the invention are: simultaneous removal of carbon and nitrogen pollutants; methane gas can be recovered to realize turning waste into treasure; different zones are arranged in the reactor to improve the hydrodynamic properties and create optimal conditions for the growth of functional microorganisms; the same The multi-level treatment of pollutants is realized in the reactor.

Owner:HANGZHOU NORMAL UNIVERSITY

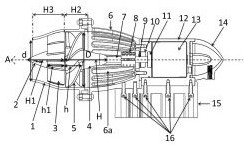

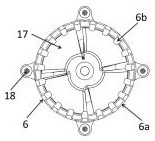

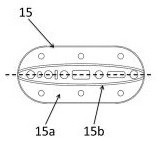

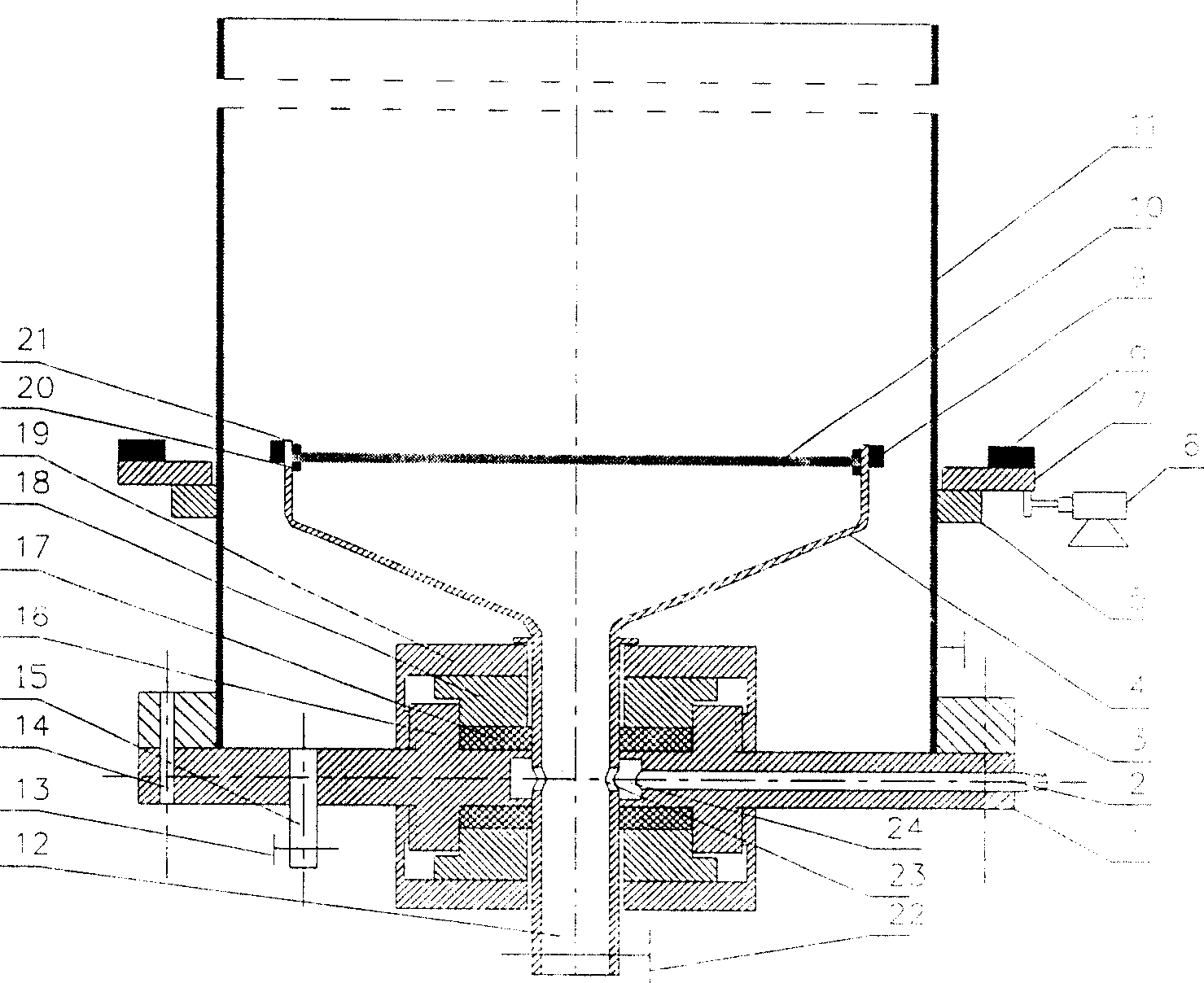

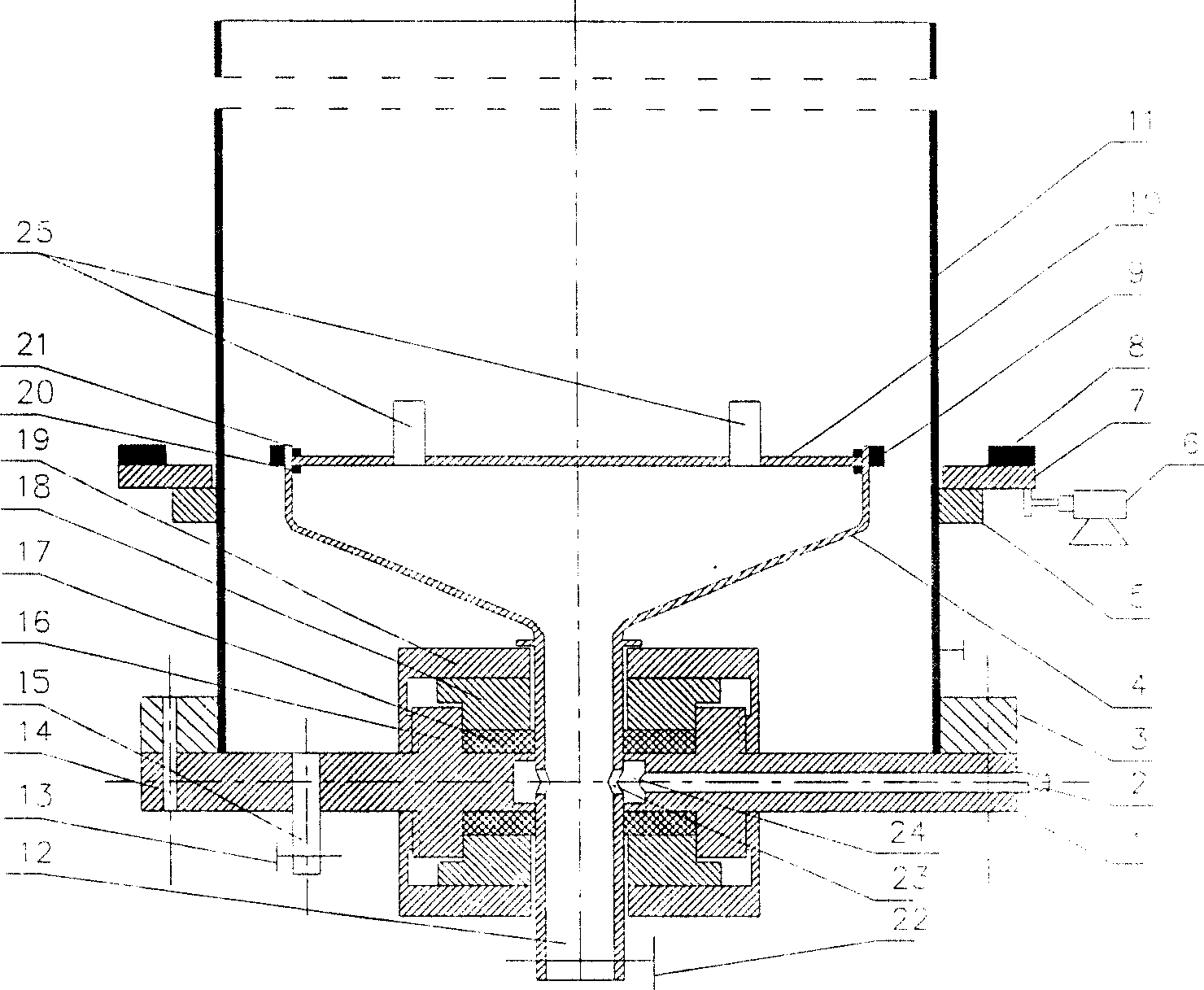

Pod type electric jet propeller

InactiveCN111924080AEliminate swirlsEliminate riskPropulsive elementsPropulsive transmissionImpellerCoupling

The invention relates to the field of shipbuilding industry, and aims to provide a pod-mounted water surface or underwater vehicle, which enables production of a pod type electric jet propeller to bepossible. The motor and the jet pump body are assembled into a whole. Moreover, the front rectification technology and the rear rectification technology of the jetpump are fully utilized, and the advancing function and the reversing function are achieved under the condition that an auxiliary device is not used. The efficiency of the propeller is improved, and manufacturing is more convenient due tothe small number of structural components. The jet propeller power assembly has the engineering advantages that the drive motor and the jet pump are designed into the jet propeller power assembly which can be assembled into a whole, and the jet propeller power assembly is installed at the bottom of a ship through the wing-shaped lazy arm. The pod typejet propeller comprises a compression cavity,an impeller,a rectifying body,a drive motor,an impeller shaft and a coupling, and aconical inflow body. According to a model test result, the technical effect of the pod type electric jet propeller isincreased by 25-50% in the aspect of propulsion efficiency characteristics.

Owner:韩玉军

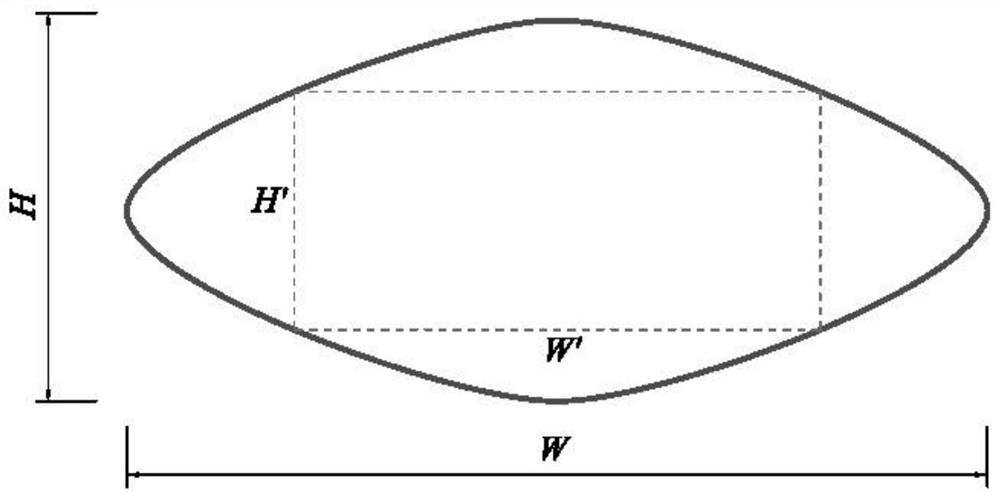

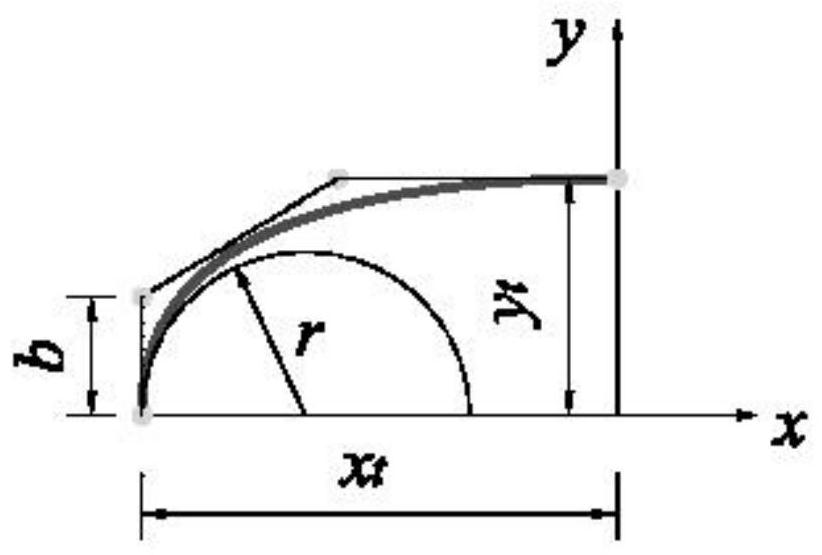

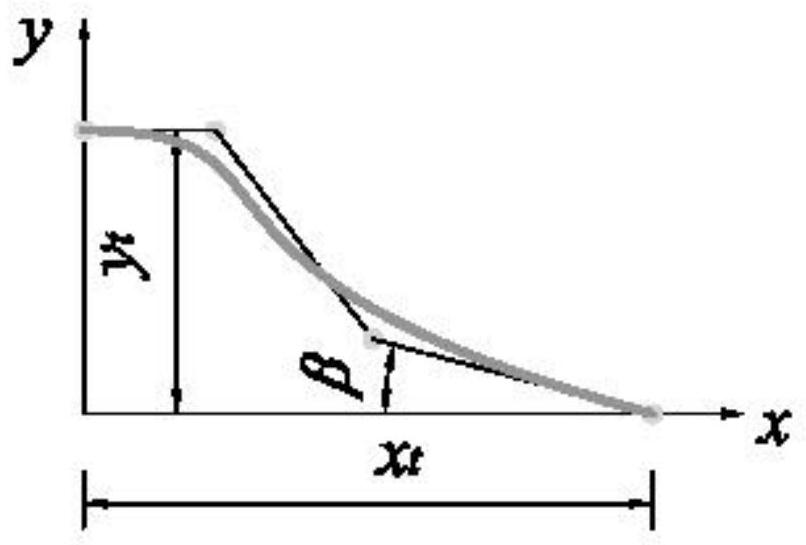

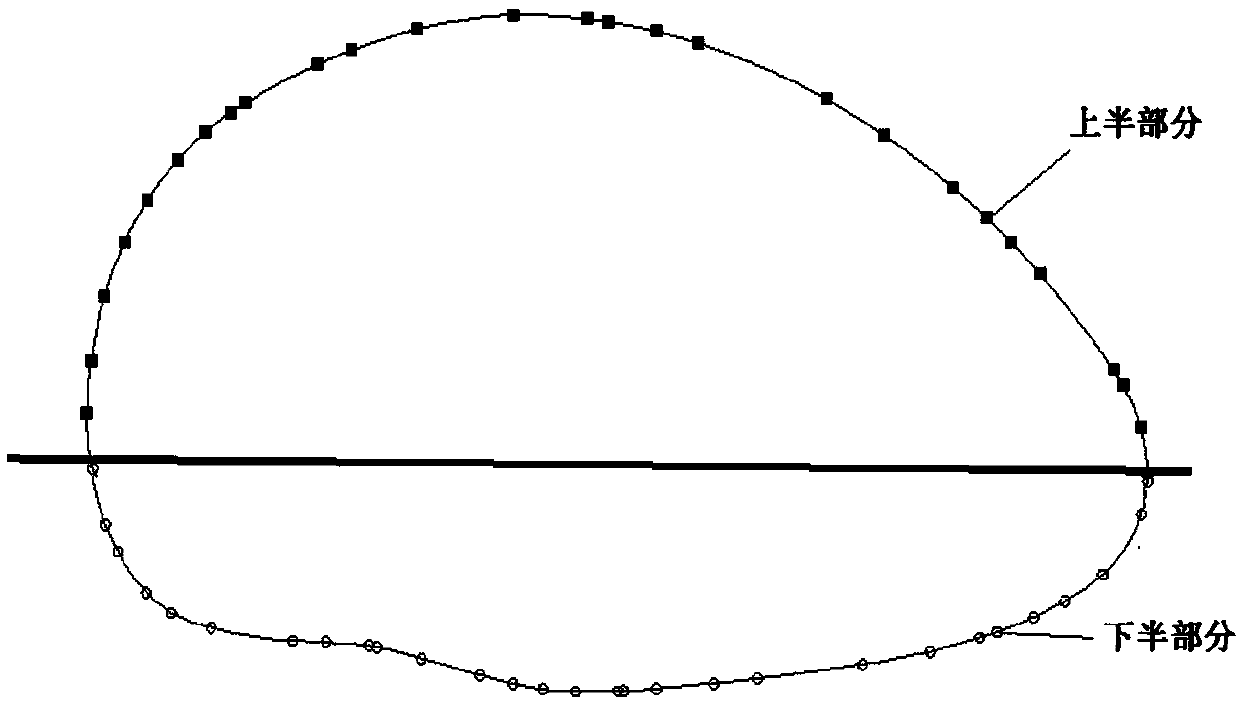

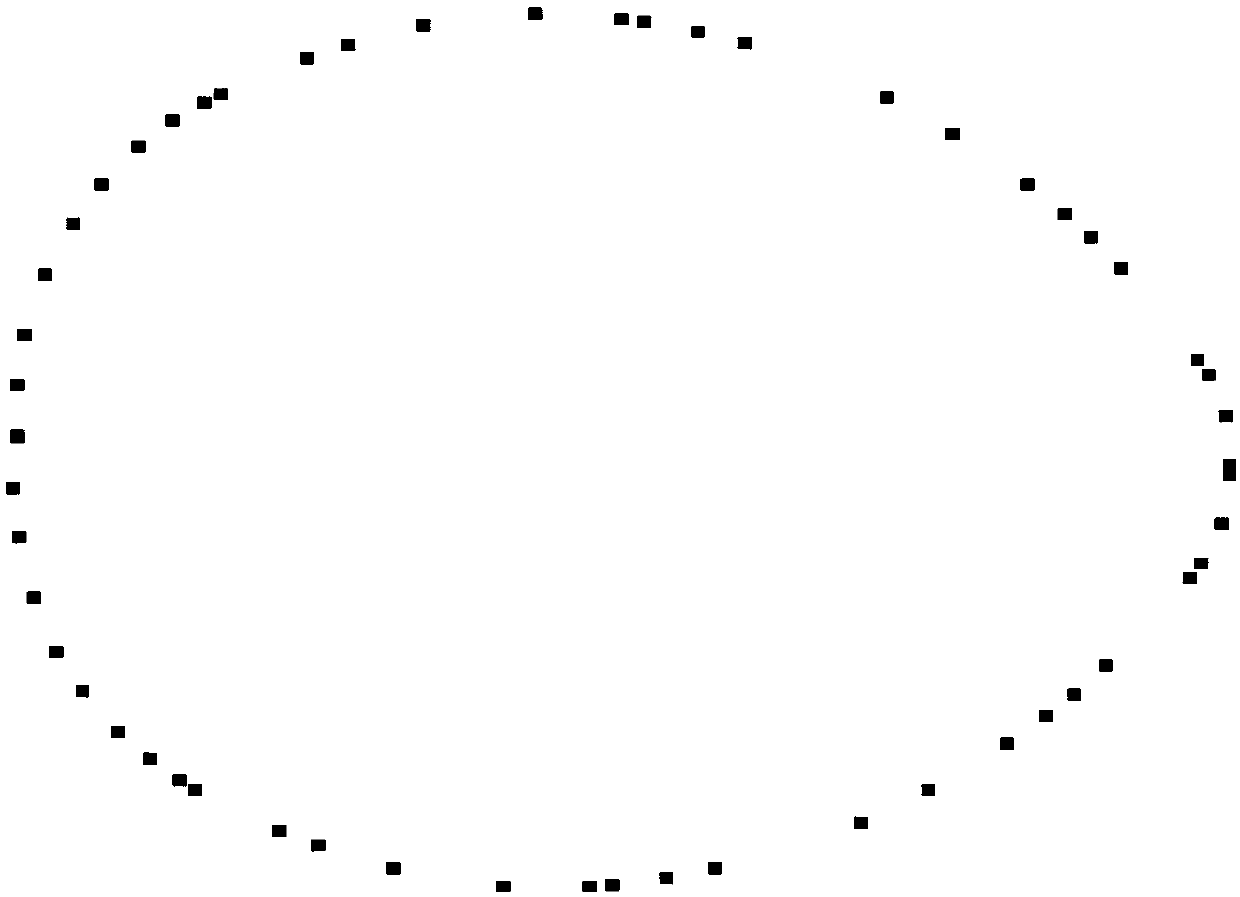

Geometrical optimization shape and parameter optimization algorithm for parameterized cross section of floating tunnel

ActiveCN111709079AGood hydrodynamic performanceLow fluid resistanceGeometric CADBiological neural network modelsEngineeringStructural engineering

Owner:CCCC FHDI ENG

Magnetic driven rotation gas distribution device in gas-fluid multi-phase system

InactiveCN100496685CReduce sizeWide distributionMixing methodsChemical/physical/physico-chemical stationary reactorsTowerDistributor

The invention relates to a magnetic driving rotary gas distributor equipment of gas-liquid multi-phase system. It includes a tower device with magnetic driving device, the rotary-type gas distributor can be directly rotated in the tower bottom to make gas distribution. The gas distributor is driven by rotary permanent magnetic field produced by magnetic driving device and rotated so as to implement goal of rotary gas distribution. In the supporting disk of the gas distributor a gas ingress pipe hole is set, and the ring-shaped gas distribution cavity chamber in the supporting disk and the gas-feeding circular hole on the rotary hollow shaft can be used for making gas distribution, in the bottom end of the rotary hollow shaft a cleaning pollution-discharging valve is mounted.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Regenerative system of turbogenerator unit and operation method thereof

ActiveCN103644005BSolve environmental problems that cannot be put into operationIncrease feed water temperatureSteam useFeed-water heatersEngineeringHigh pressure

The invention discloses a regenerative system of a turbogenerator unit and an operation method thereof. The system comprises a high-pressure cylinder and a high-pressure heater, wherein an steam exhaust port and a plurality of high-pressure steam extraction ports whose steam extraction pressure is increased sequentially are formed in the high-pressure cylinder, the high-pressure steam extraction ports are connected with the same high-pressure heater through high-pressure steam extraction pipelines, and an extraction check valve and an isolated valve are arranged on each high-pressure steam extraction pipeline. When the turbogenerator unit operates at a rated load, a first high-pressure steam extraction port with the lowest steam extraction pressure supplies steam for the high-pressure heater, and the steam extraction pressure at the time is set to be P0; when the turbogenerator unit operates in a state lower than the rated load, a high-pressure steam extraction port with steam extraction pressure less than or equal to P0 or closer to P0 is selected to supply steam for the high-pressure heater, and the isolated valves on other high-pressure steam extraction pipelines are switched off. According to the regenerative system of the turbogenerator unit and the operation method thereof, a denitration system can operate normally when the unit operates at a low load, the boiler feeding temperature is increased, and the thermodynamic cycle efficiency of the unit is improved accordingly.

Owner:王振宇

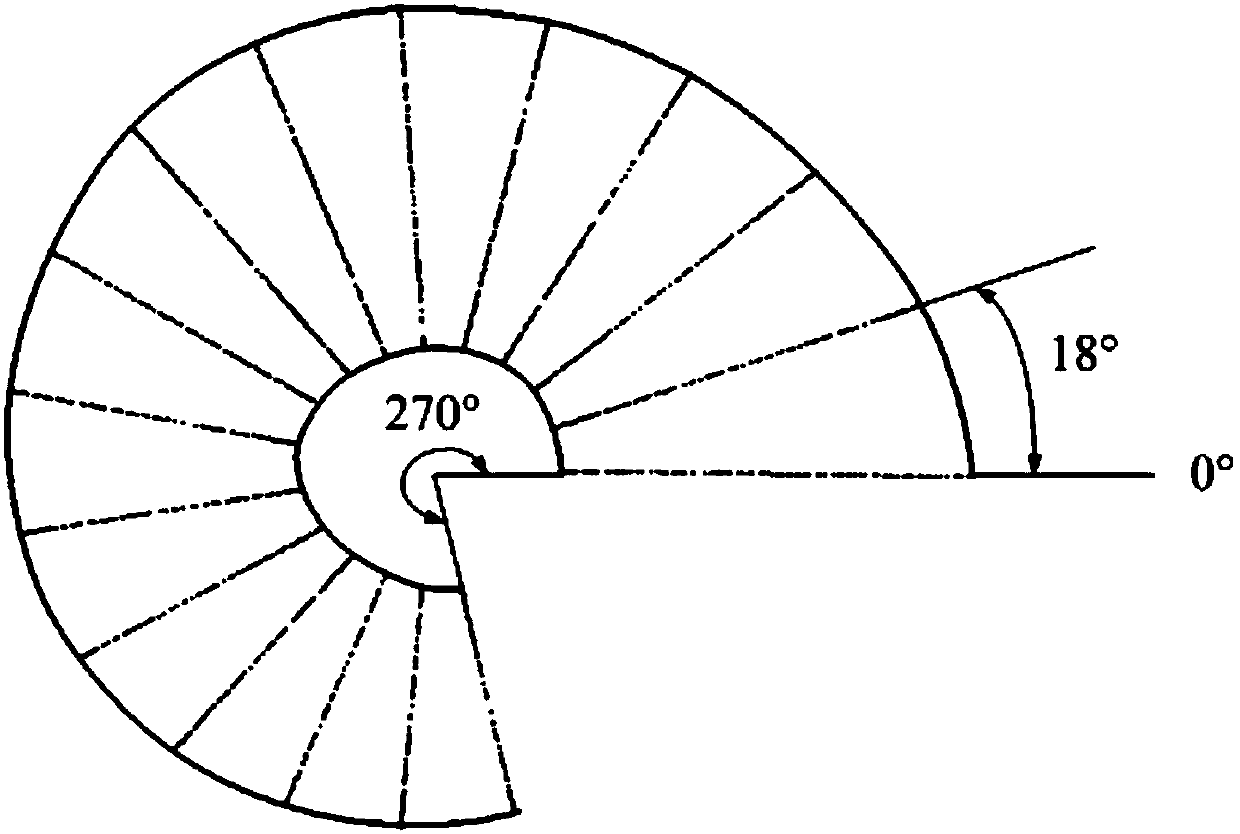

A Bionic Design Method of Turbocharger Volute

ActiveCN108304673BImprove performanceAchieve flow optimizationGeometric CADSpecial data processing applicationsBionicsEngineering

The invention relates to a bionics design method for a supercharger volute. The good hydrodynamic characteristics of a spiral shell contour curve are utilized for conducting supercharger volute passage cross section line design. The method comprises the following steps that 1, by means of a reverse engineering technology, a spiral shell inner cavity surface model is digitized, and quantification and reconstruction of a spiral shell inner surface hook face are achieved by means of processing of software; 2, the obtained volute passage cross section curves are spread and arranged according to the areas from small to large, and supercharger volute passage cross section line design is achieved; 3, lofting is conducted by means of a cross section contour line to generate a volute hook face, thehook face at an outlet of the passage and the volute passage hook face are in tangent transition, and thickening is conducted according to the engineering requirements. Accordingly, flow optimizationof the supercharger volute can be better achieved, the air injection efficiency and linear changes under all rotating speeds are improved, the supercharger property is improved, and the overall efficiency of a compressor is improved. A new idea and method are provided for current supercharger volute design.

Owner:SHANDONG JIAOTONG UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com