Step composite ship form with retractable type hydrofoils

A technology of retractable and retractable hydrofoils, which is applied in the direction of hull, ship construction, ships, etc., can solve problems such as unacceptable, hydrofoils affecting docking, hydrofoils are easy to entangle, etc., to increase hydrodynamic force, improve longitudinal stability, excellent The effect of hydrodynamic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

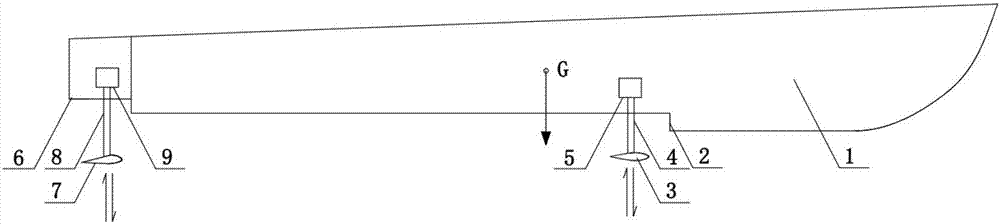

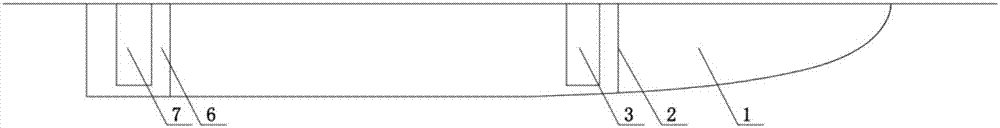

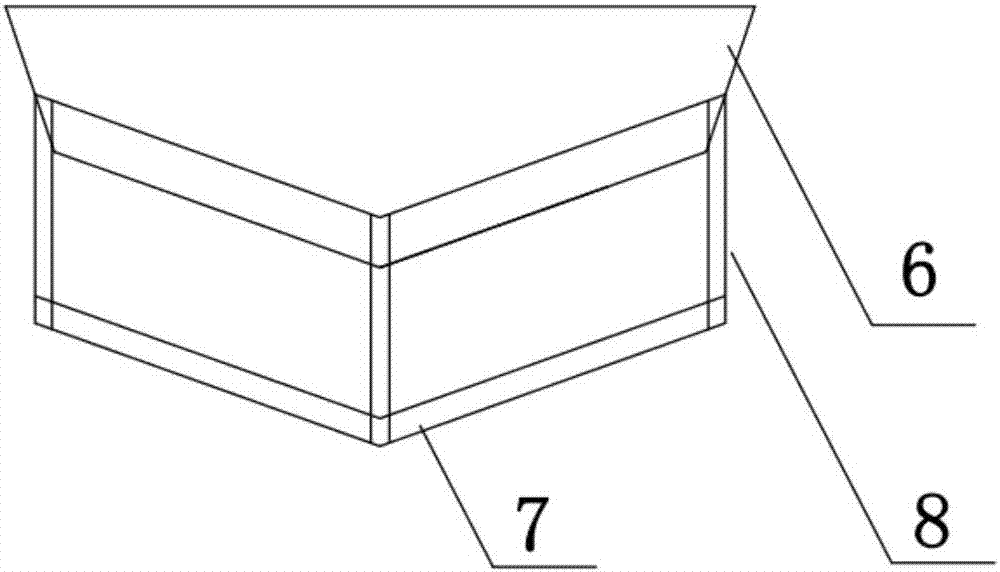

[0027] See Figure 1-Figure 9 , the present invention comprises a hull 1 (comprising a monohull or a catamaran), a false tail 6, a step 2 arranged at the bottom of the front body in the hull 1, a front hydrofoil 3 installed behind the step 2 through a front pillar 4, and the front The hydrofoil 3 and the front prop 4 are controlled by the front retractable device 5 to realize the retraction and release of the front hydrofoil, the rear hydrofoil 7 is installed under the false tail 6 through the rear prop 8, and the rear hydrofoil 7 and the rear prop 8 are retracted by the rear The unfolding device 9 is controlled to realize the retracting and releasing of the rear hydrofoil, and the front retracting device 5 and the rear retracting device 9 are installed inside the hull.

[0028] The mode of operation of the present invention is as follows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com