Patents

Literature

93results about How to "Increased longitudinal stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

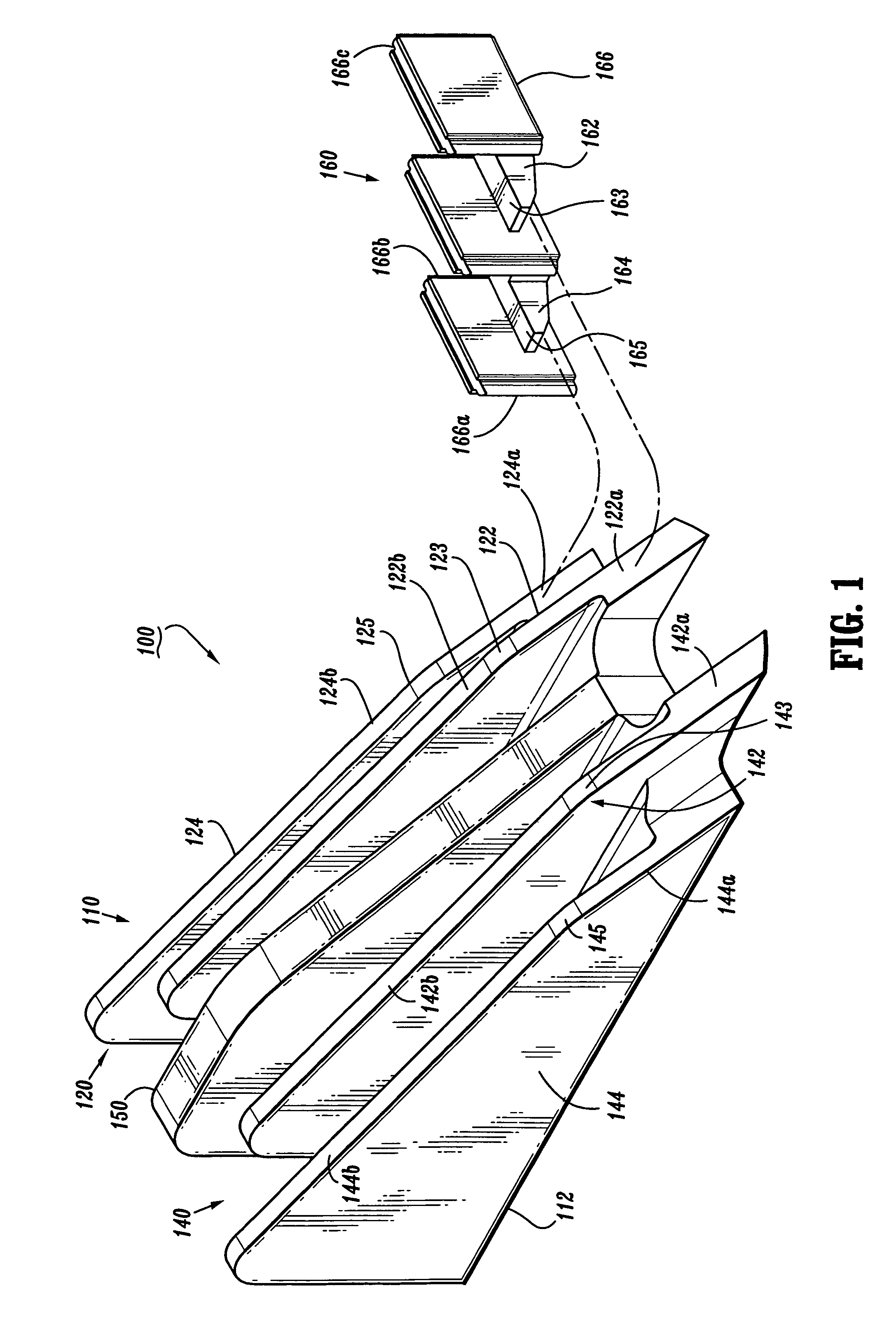

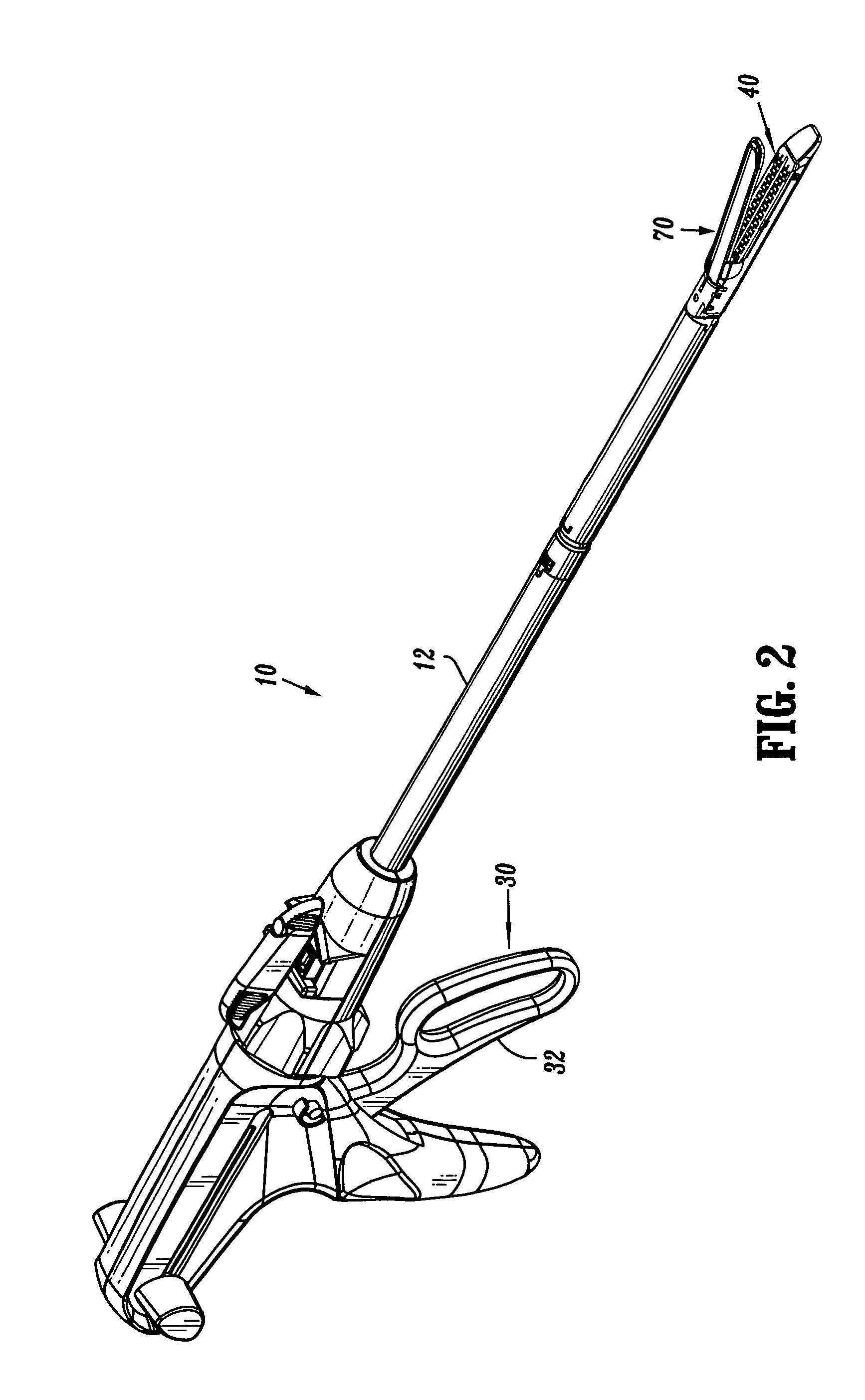

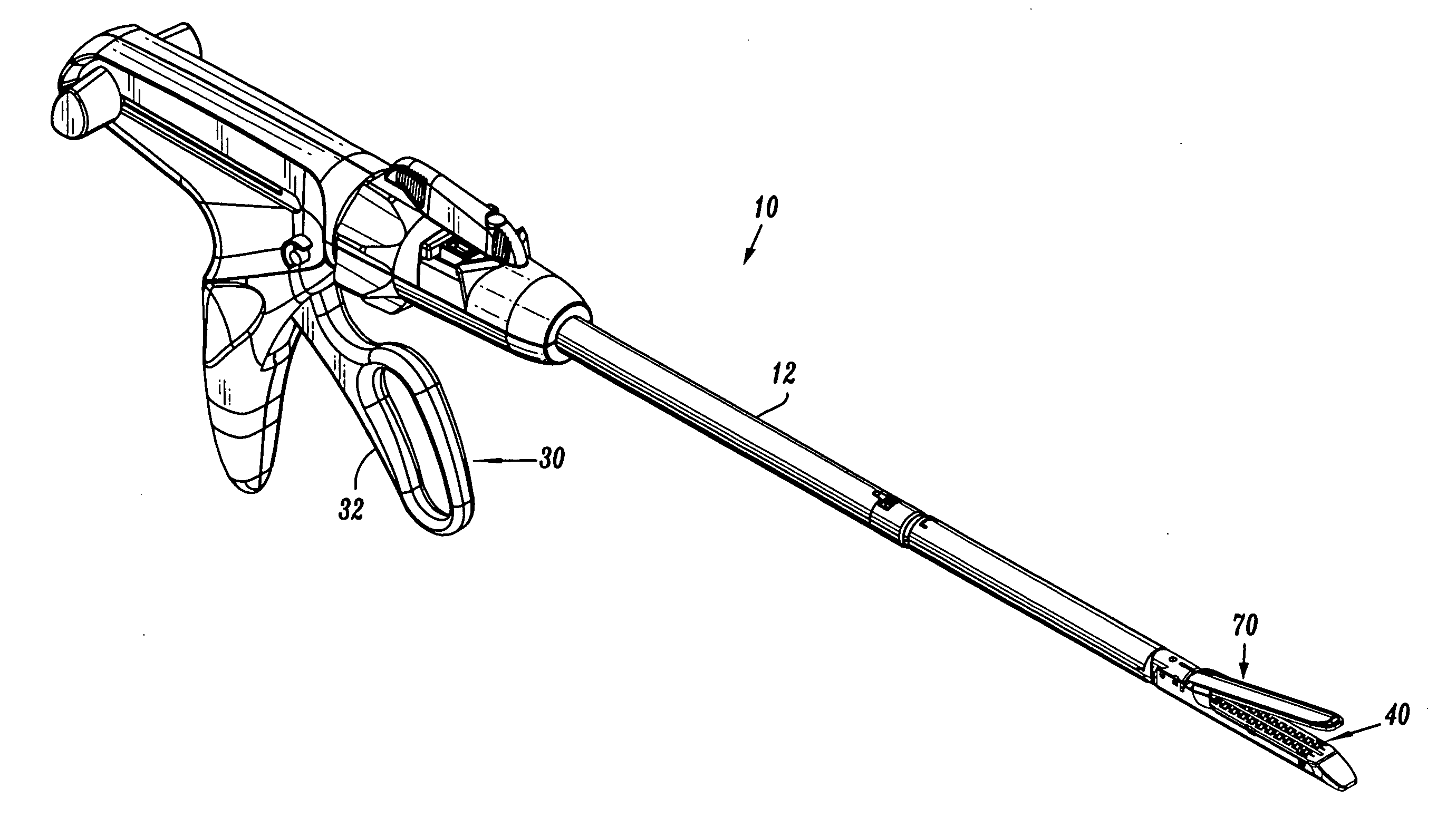

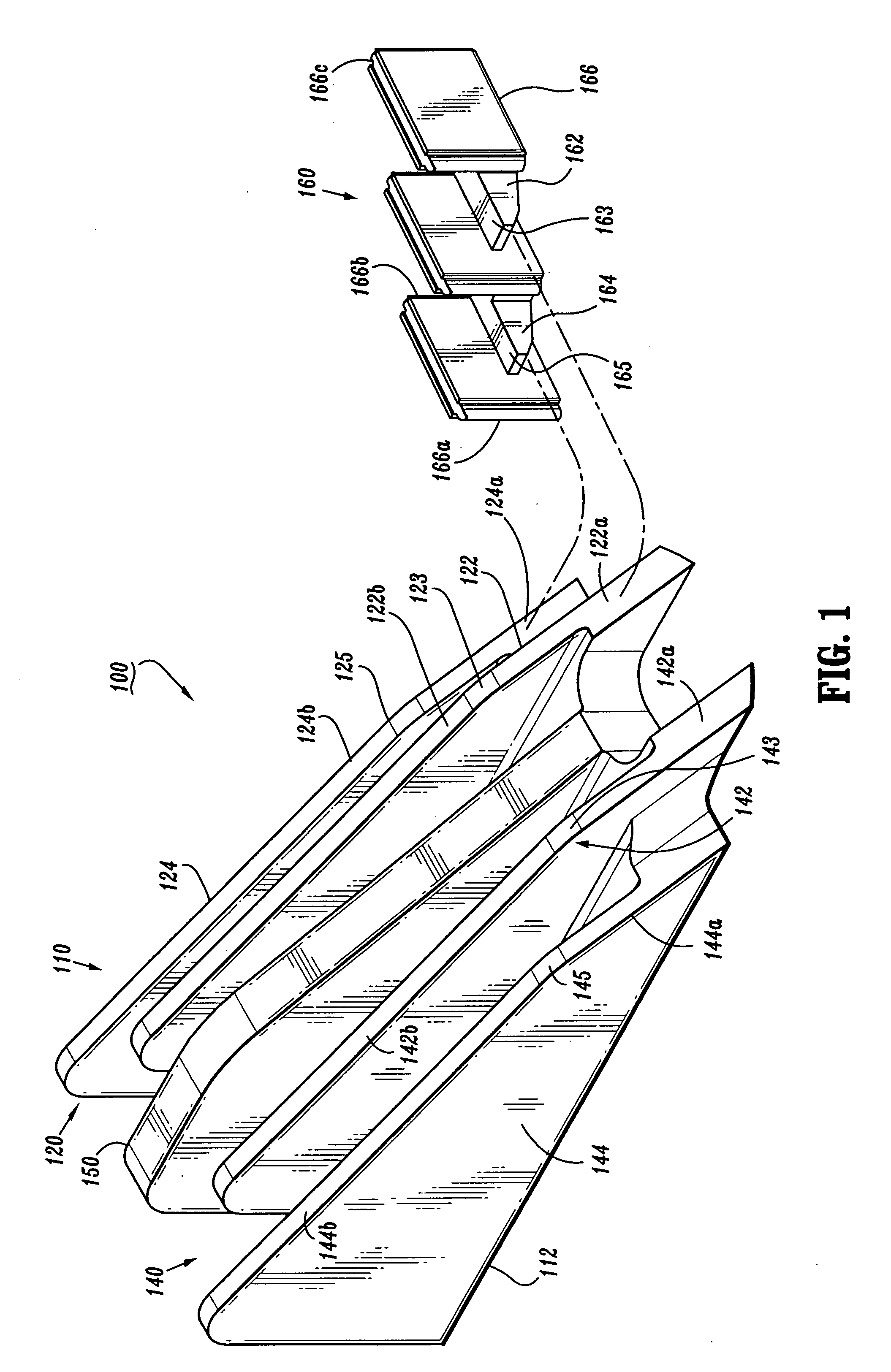

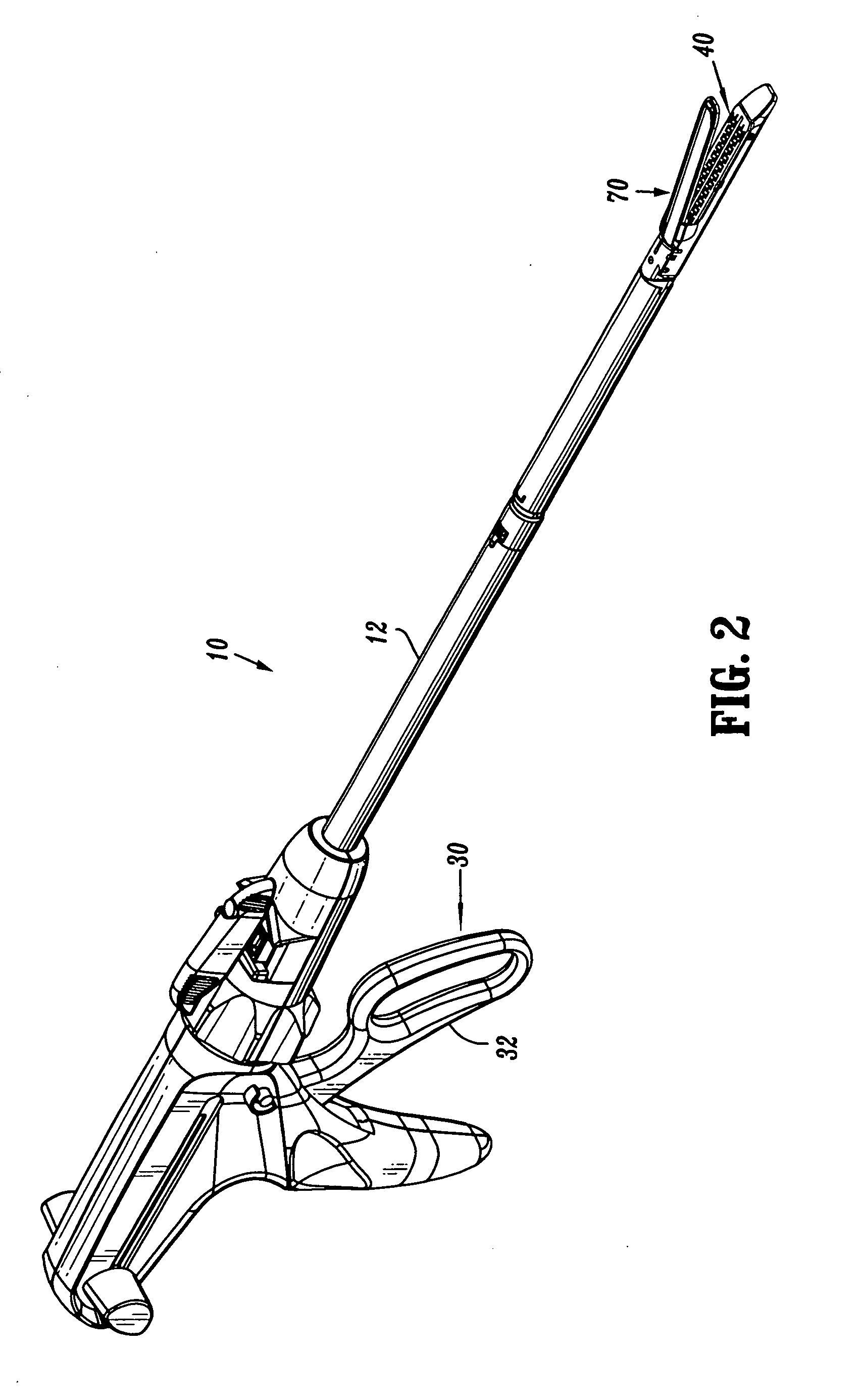

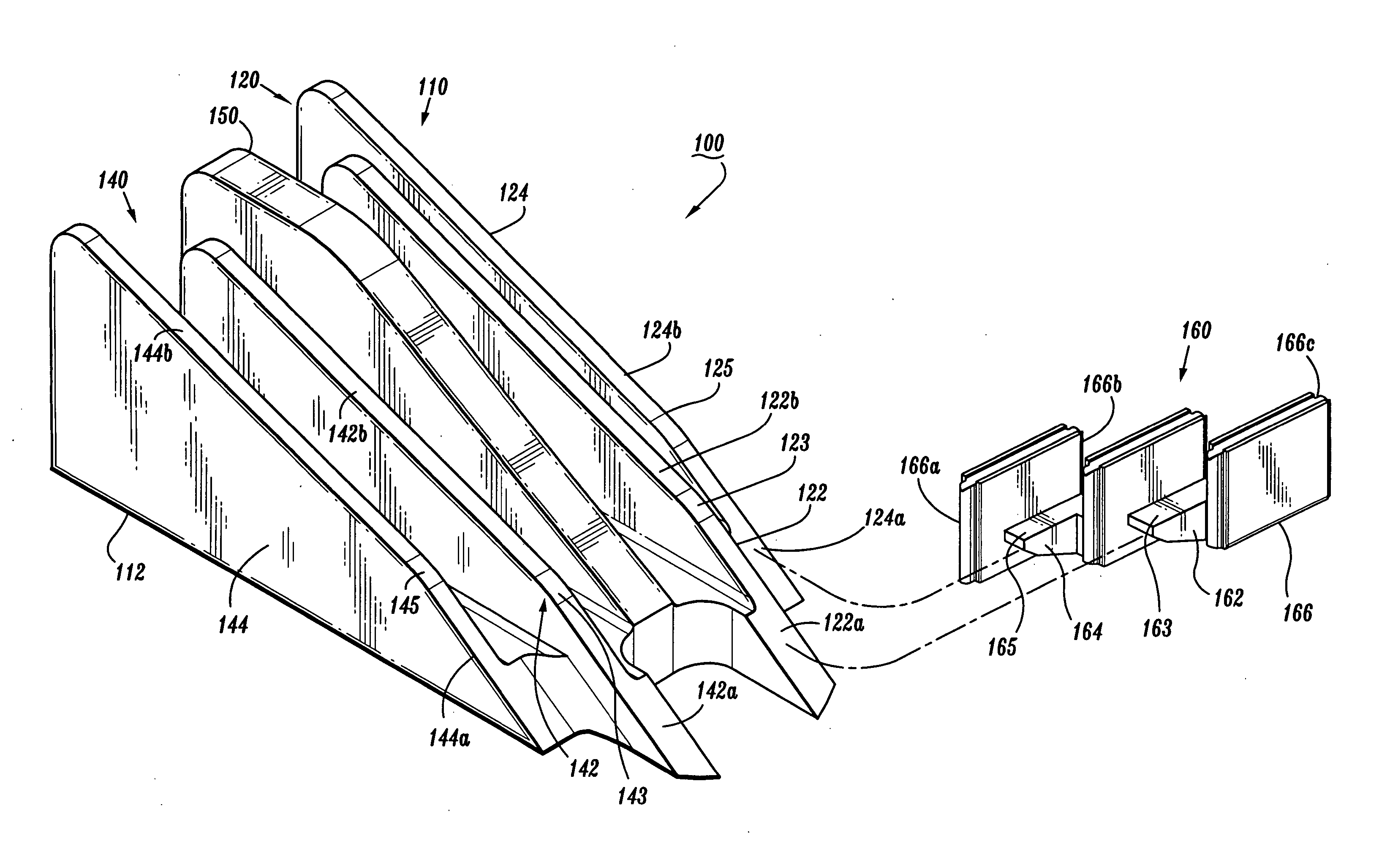

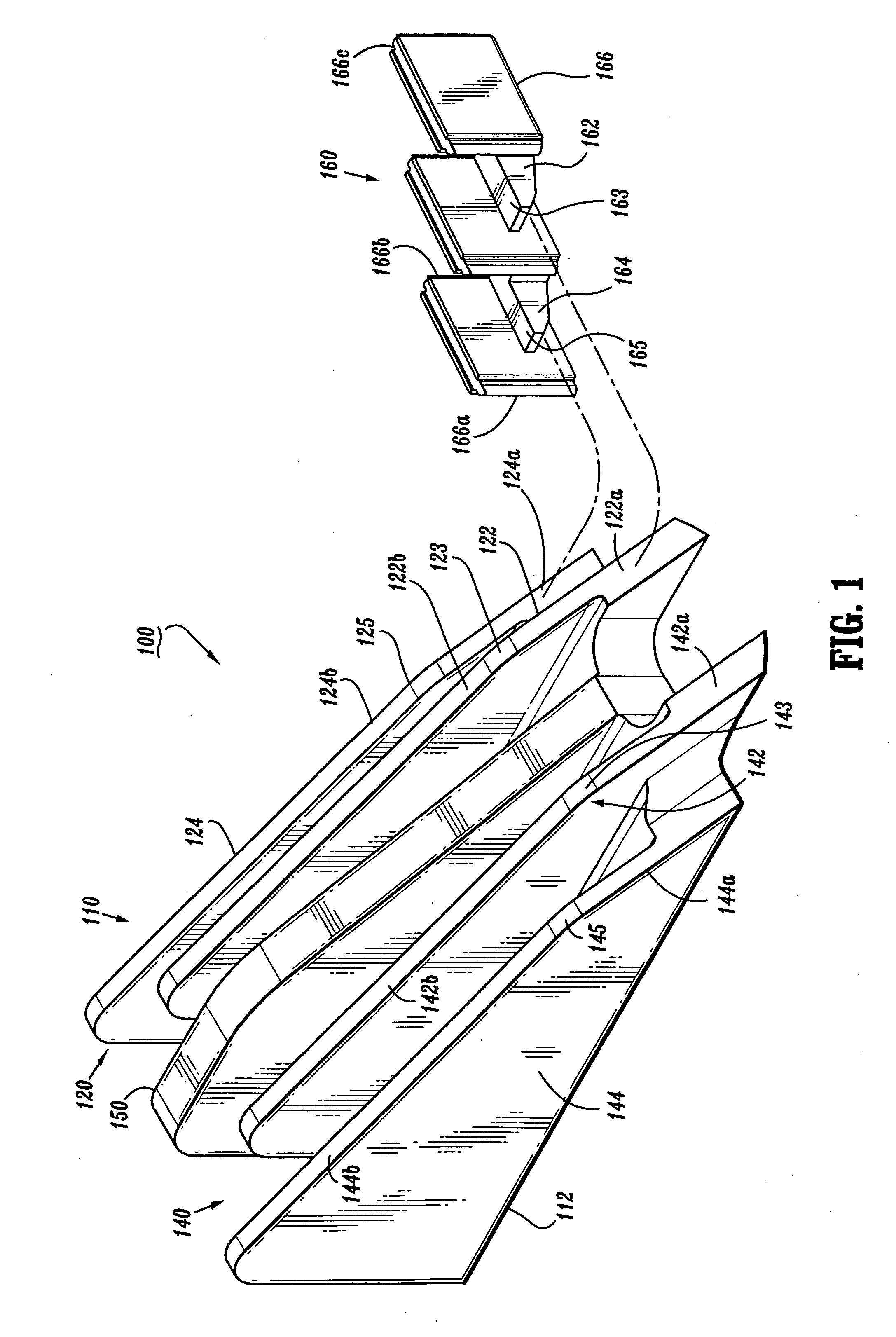

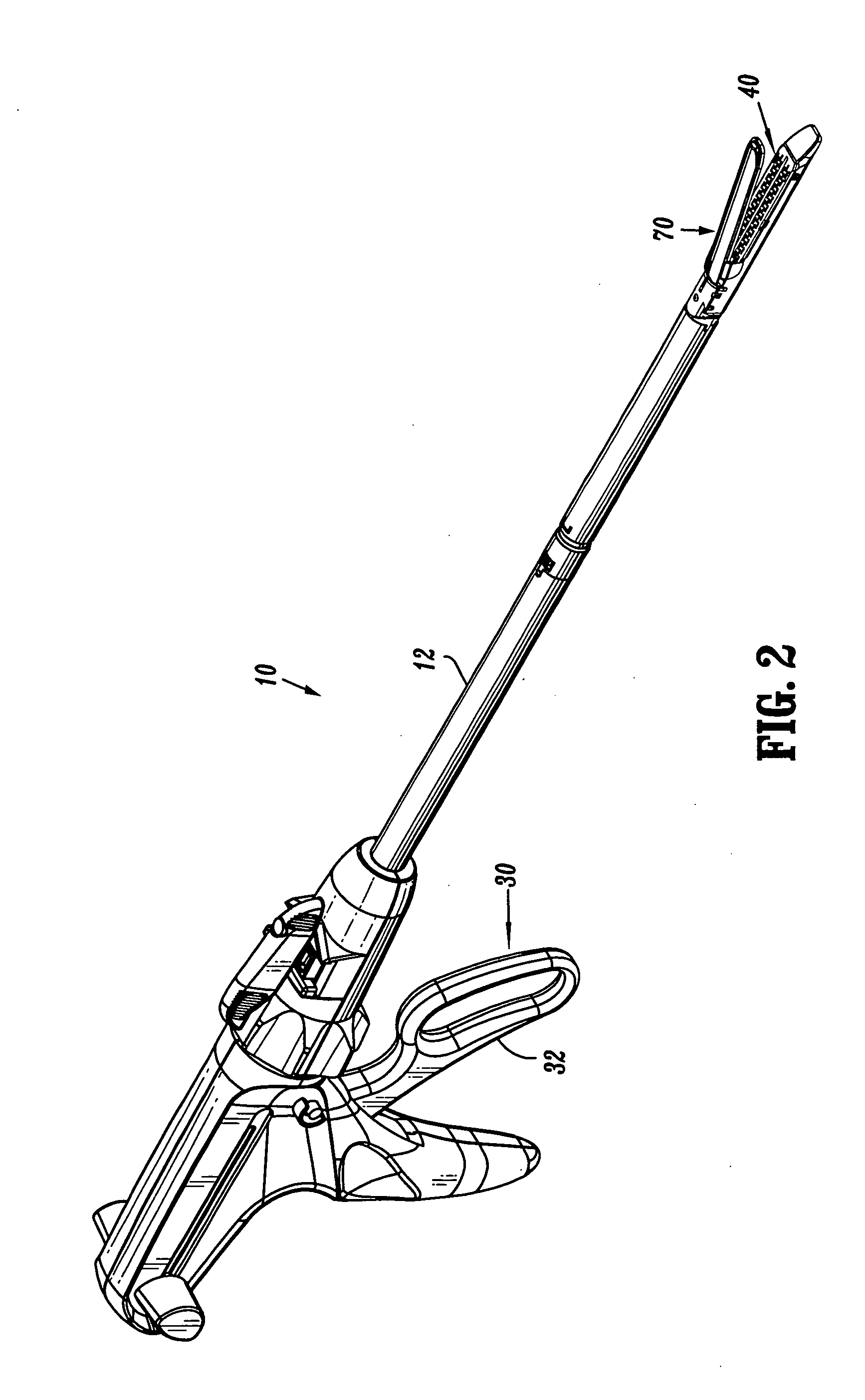

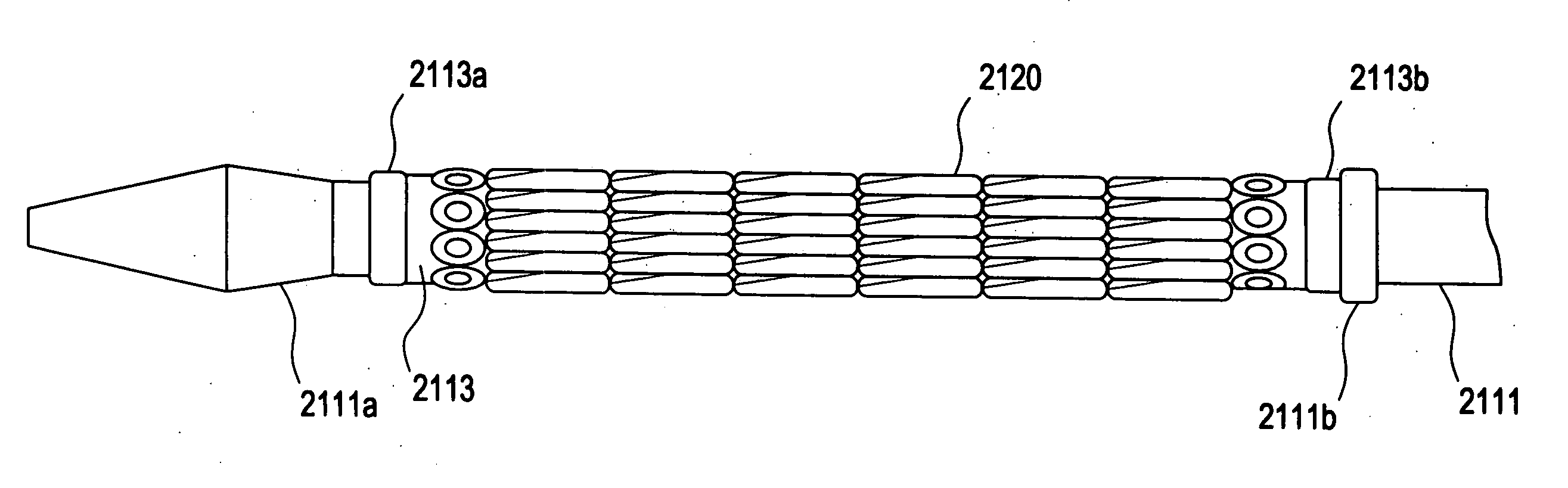

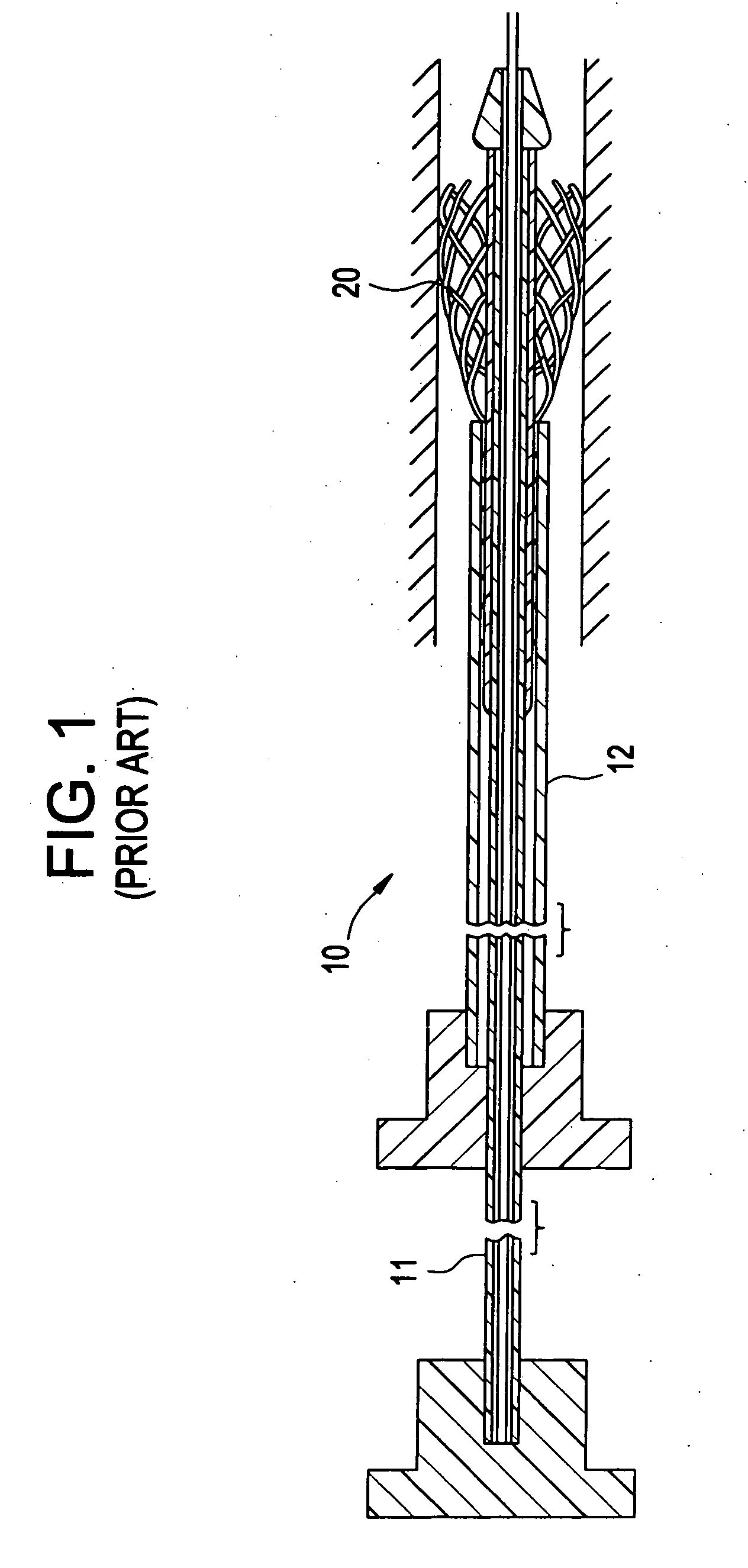

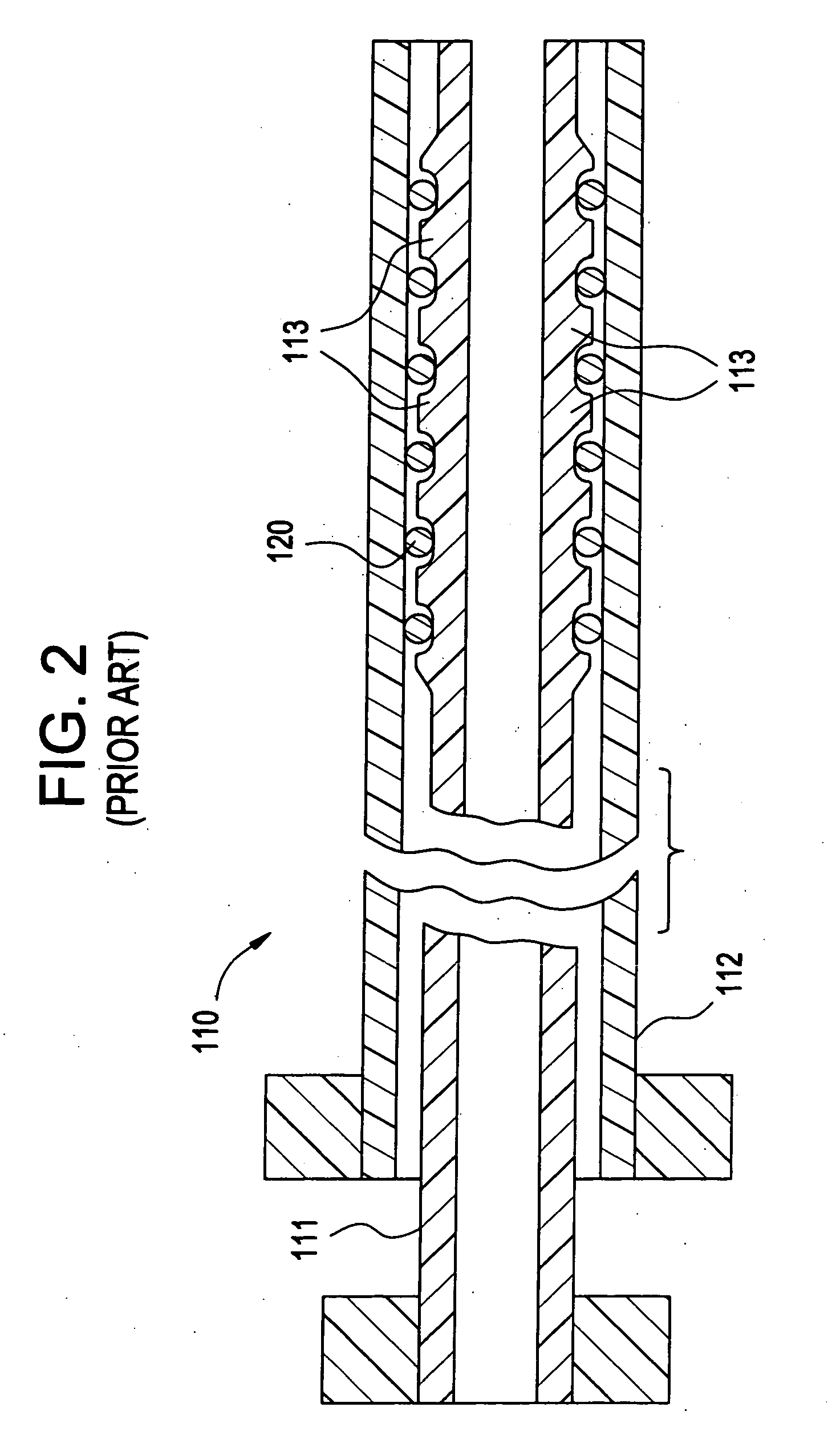

Staple drive assembly

ActiveUS7635074B2Maximizes longitudinal stabilityIncreased longitudinal stabilitySuture equipmentsStapling toolsMechanical engineering

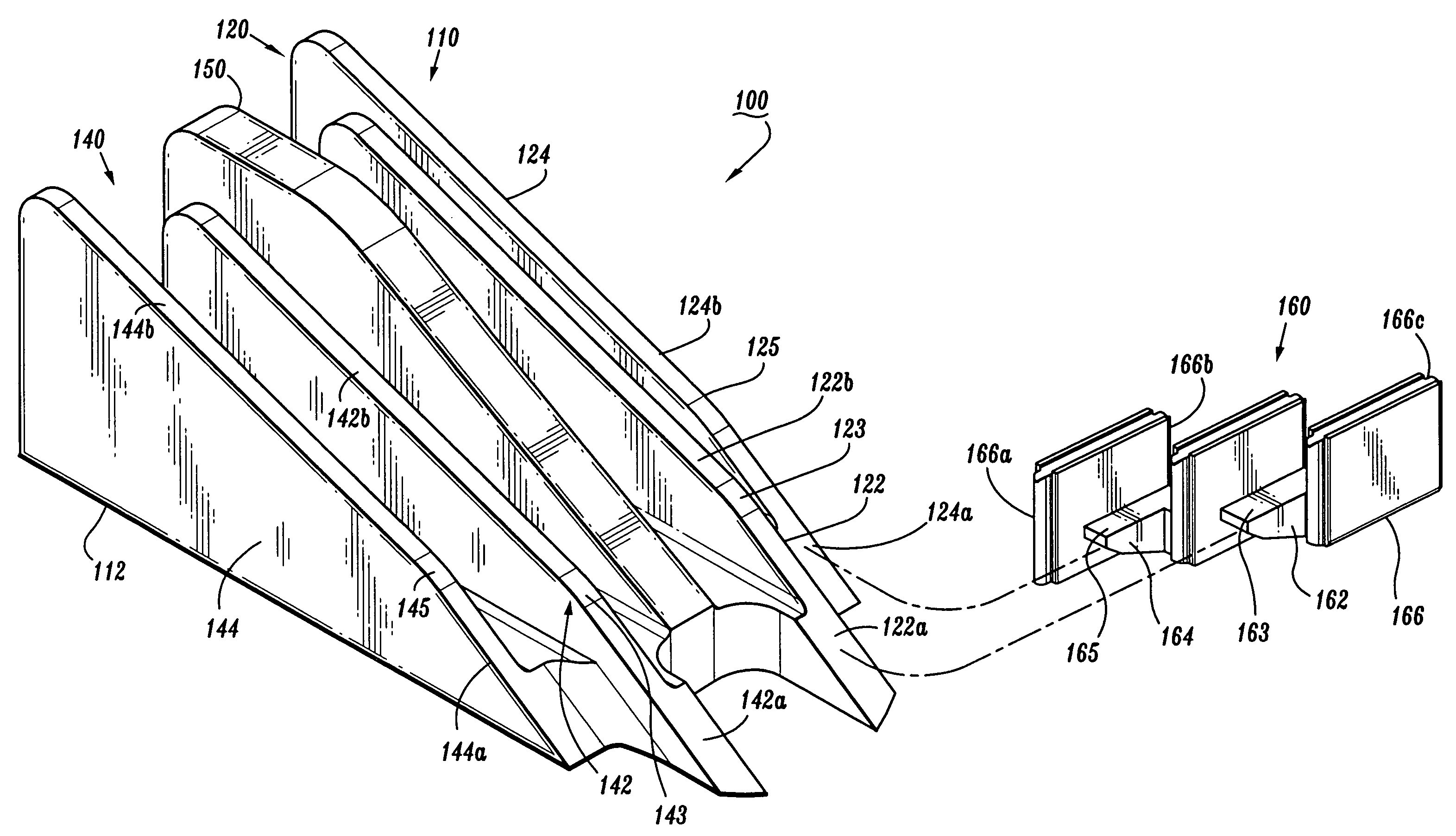

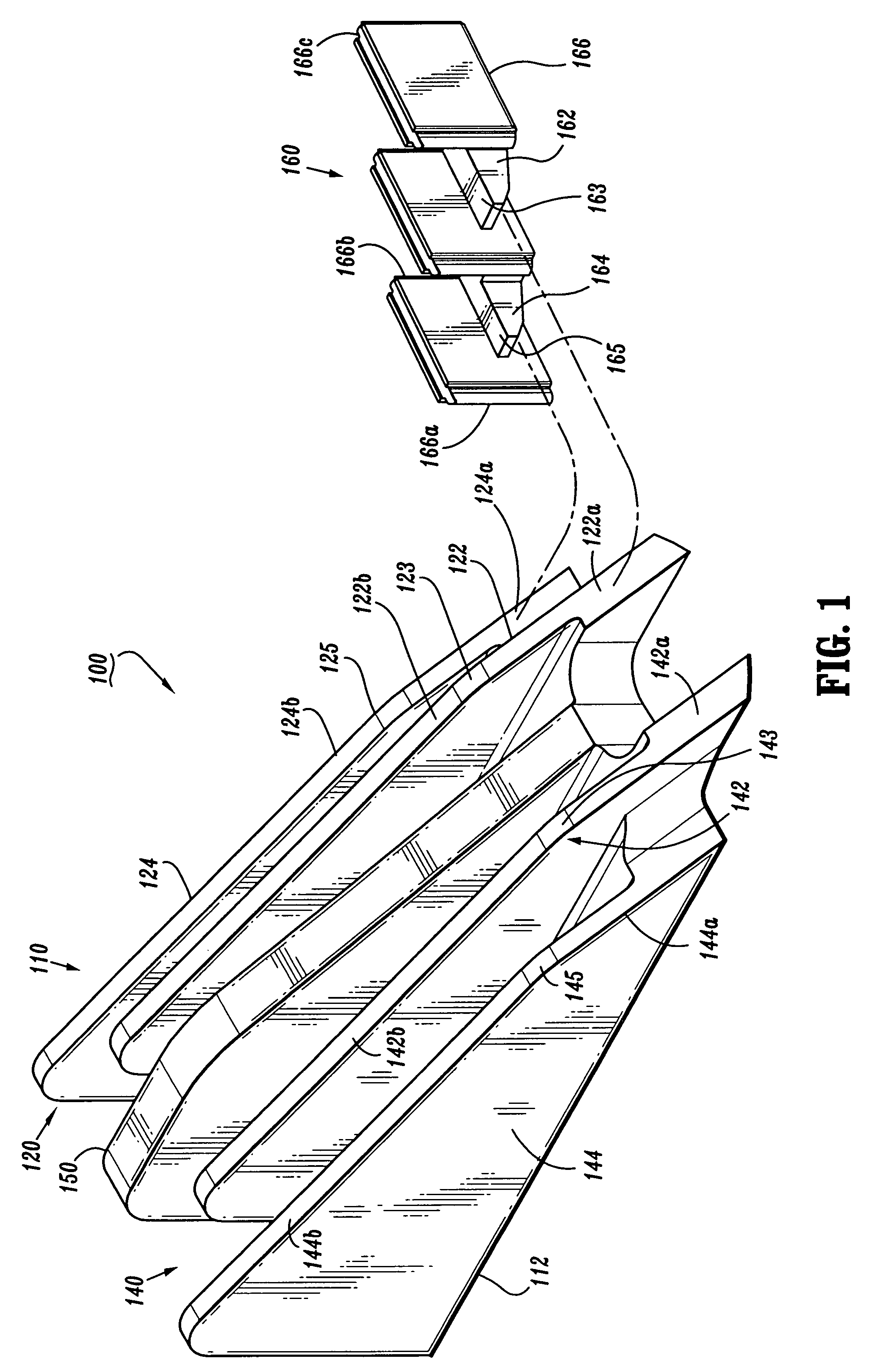

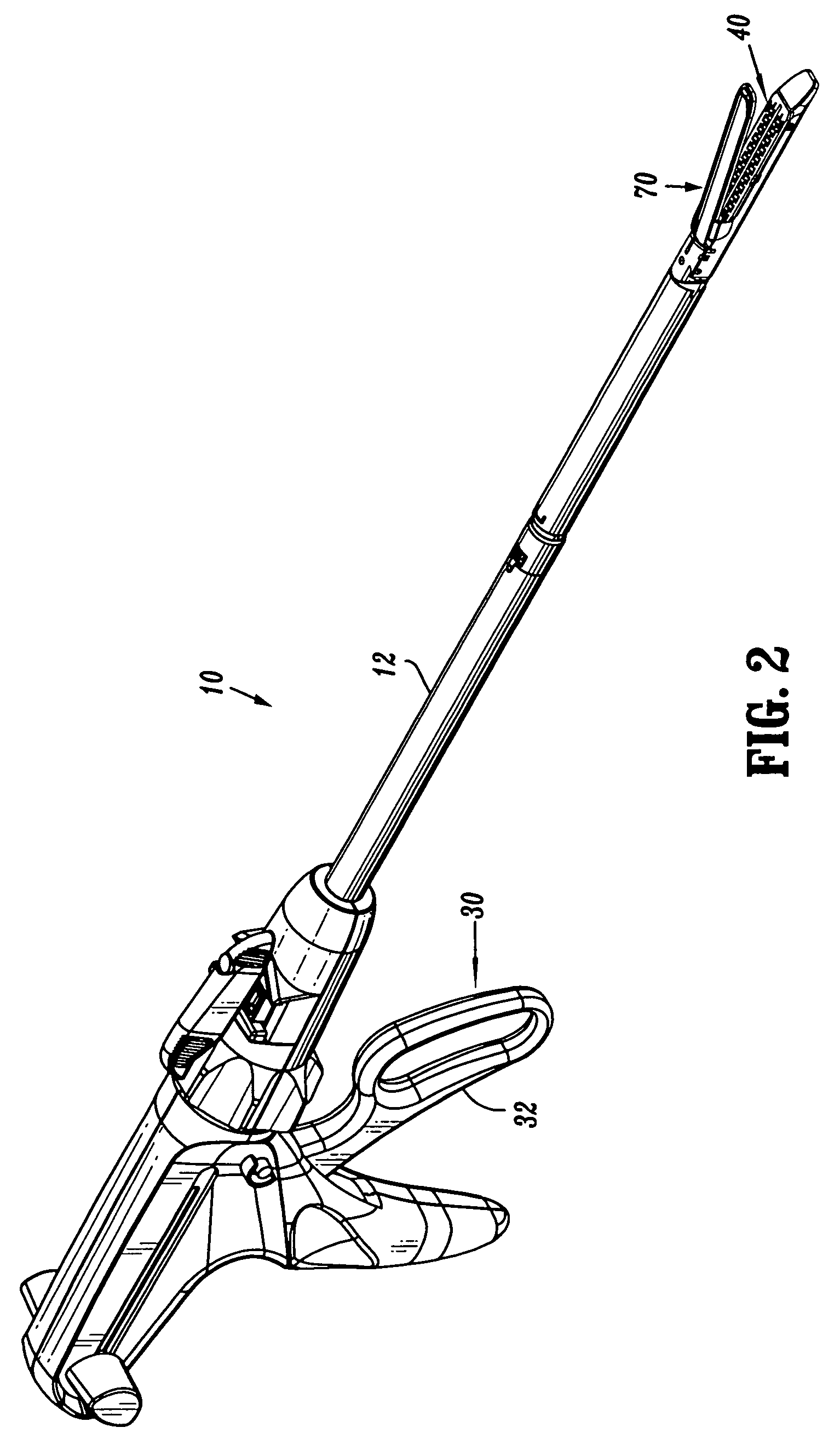

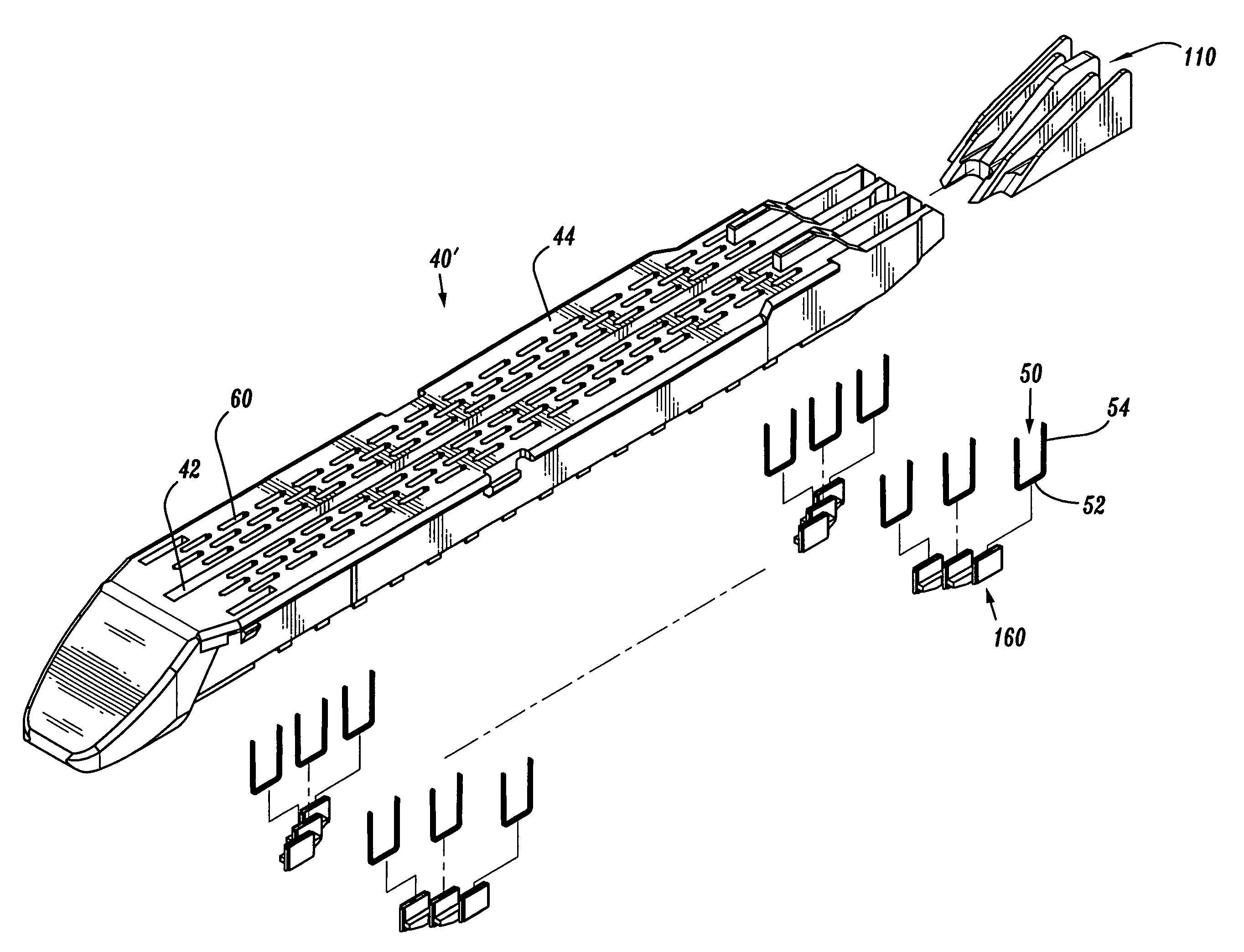

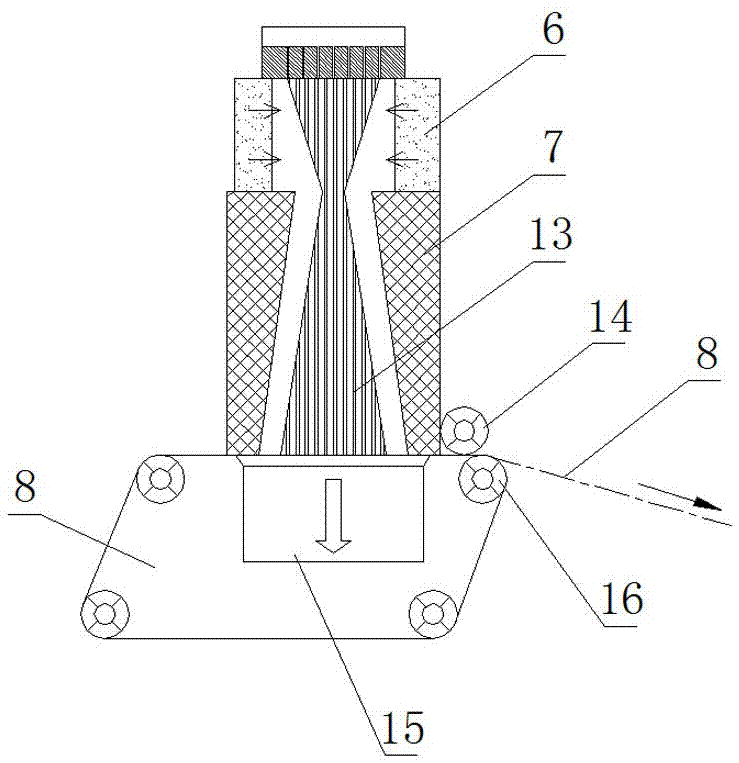

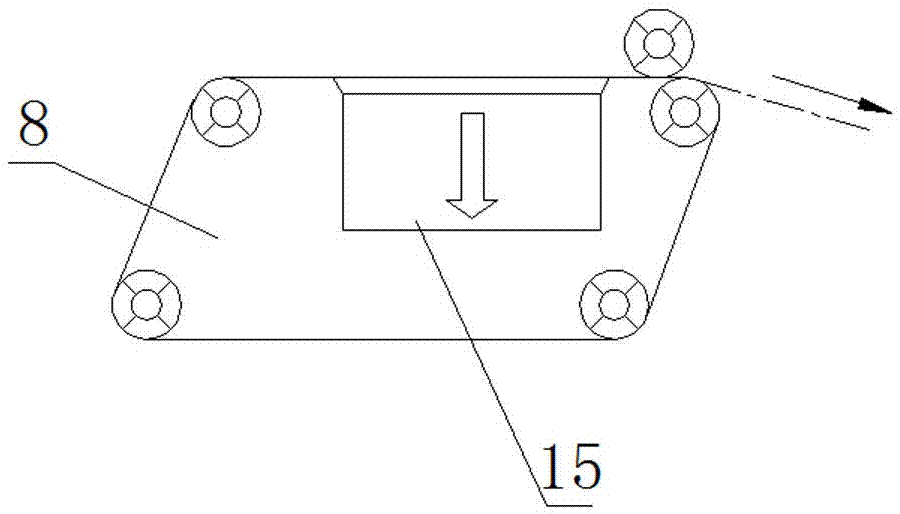

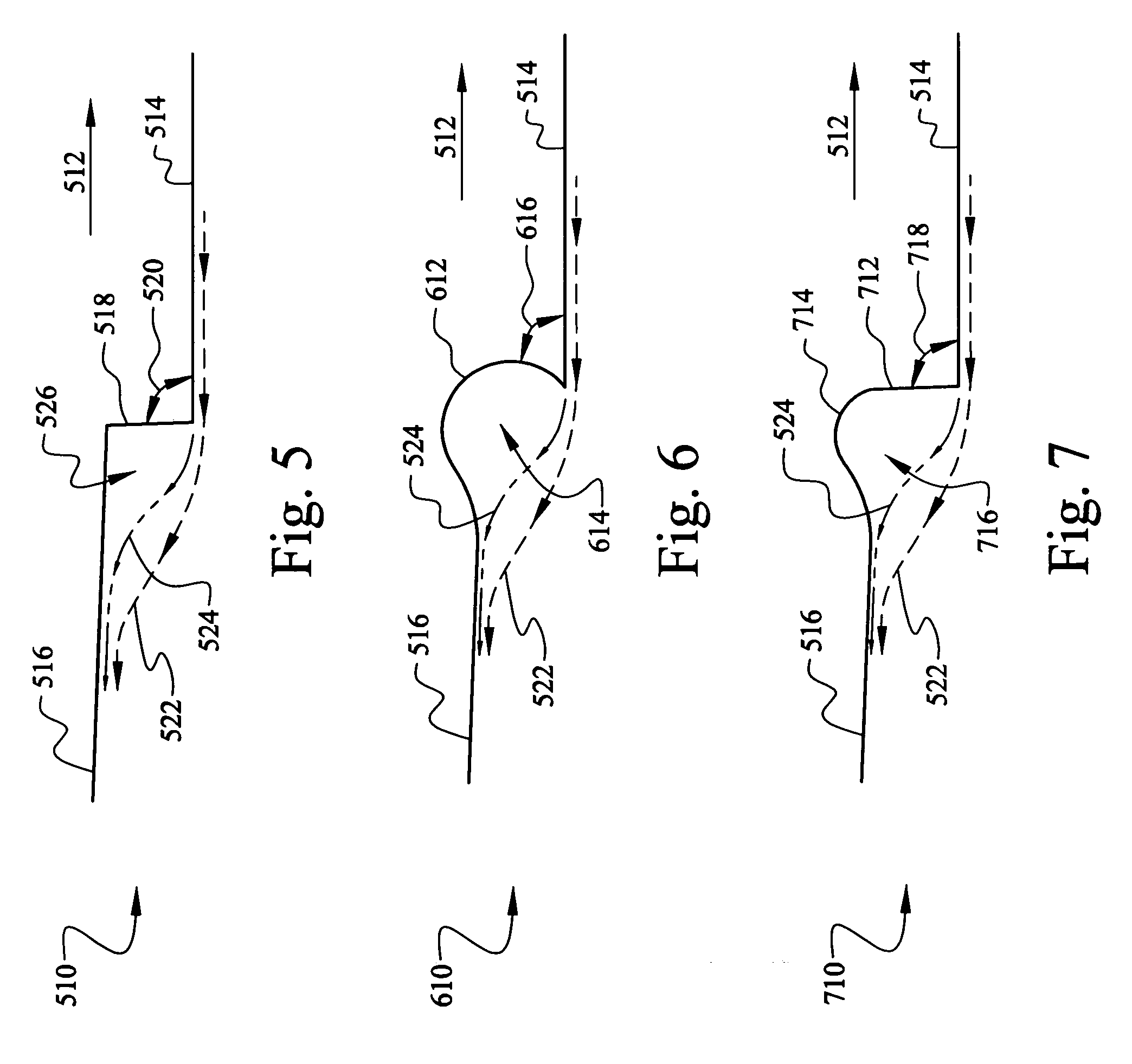

A staple drive assembly includes an actuation sled and at least one staple pusher. The staple drive assembly is adapted to fit within a staple cartridge having a plurality of staples and a corresponding number of retention slots. The at least one staple pusher includes at least one pusher plate for releasably engaging a backspan of a staple. The staple pusher may include a plurality of pusher plates that may be laterally and longitudinally spaced apart. An actuation member has at least one angled camming surface for engaging a complimentary angled surface of the at least one staple pusher. Camming engagement between the actuation member and the at least one staple pusher causes vertical movement of the at least one staple pusher. Lateral and longitudinal offset of the actuation member camming surfaces and the corresponding staple pusher following surfaces improves stability and control of the staple pusher during firing.

Owner:TYCO HEALTHCARE GRP LP

Staple drive assembly

ActiveUS7641091B2Maximizes longitudinal stabilityIncreased longitudinal stabilitySuture equipmentsStapling toolsEngineeringMechanical engineering

A staple drive assembly includes an actuation sled and at least one staple pusher. The staple drive assembly is adapted to fit within a staple cartridge having a plurality of staples and a corresponding number of retention slots. The at least one staple pusher includes at least one pusher plate for releasably engaging a backspan of a staple. The staple pusher may include a plurality of pusher plates that may be laterally and longitudinally spaced apart. An actuation member has at least one angled camming surface for engaging a complimentary angled surface of the at least one staple pusher. Camming engagement between the actuation member and the at least one staple pusher causes vertical movement of the at least one staple pusher. Lateral and longitudinal offset of the actuation member camming surfaces and the corresponding staple pusher following surfaces improves stability and control of the staple pusher during firing.

Owner:COVIDIEN LP

Staple drive assembly

ActiveUS20080023522A1Controlled driving can be maximizedMaximizes longitudinal stabilitySuture equipmentsStapling toolsMechanical engineering

A staple drive assembly includes an actuation sled and at least one staple pusher. The staple drive assembly is adapted to fit within a staple cartridge having a plurality of staples and a corresponding number of retention slots. The at least one staple pusher includes at least one pusher plate for releasably engaging a backspan of a staple. The staple pusher may include a plurality of pusher plates that may be laterally and longitudinally spaced apart. An actuation member has at least one angled camming surface for engaging a complimentary angled surface of the at least one staple pusher. Camming engagement between the actuation member and the at least one staple pusher causes vertical movement of the at least one staple pusher. Lateral and longitudinal offset of the actuation member camming surfaces and the corresponding staple pusher following surfaces improves stability and control of the staple pusher during firing.

Owner:TYCO HEALTHCARE GRP LP

Staple drive assembly

ActiveUS20070075115A1Controlled driving can be maximizedMaximizes longitudinal stabilitySuture equipmentsStapling toolsEngineeringMechanical engineering

A staple drive assembly includes an actuation sled and at least one staple pusher. The staple drive assembly is adapted to fit within a staple cartridge having a plurality of staples and a corresponding number of retention slots. The at least one staple pusher includes at least one pusher plate for releasably engaging a backspan of a staple. The staple pusher may include a plurality of pusher plates that may be laterally and longitudinally spaced apart. An actuation member has at least one angled camming surface for engaging a complimentary angled surface of the at least one staple pusher. Camming engagement between the actuation member and the at least one staple pusher causes vertical movement of the at least one staple pusher. Lateral and longitudinal offset of the actuation member camming surfaces and the corresponding staple pusher following surfaces improves stability and control of the staple pusher during firing.

Owner:TYCO HEALTHCARE GRP LP

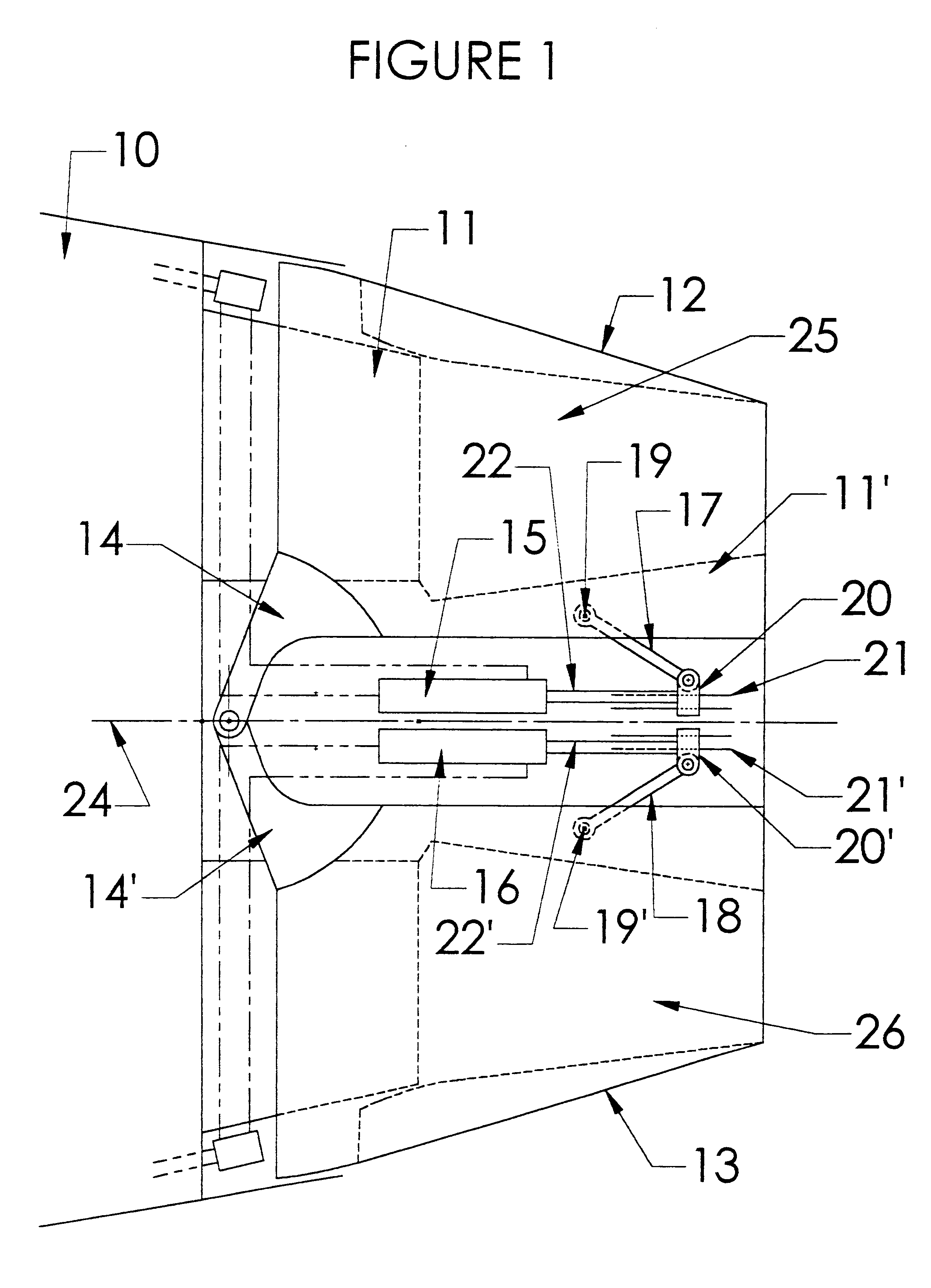

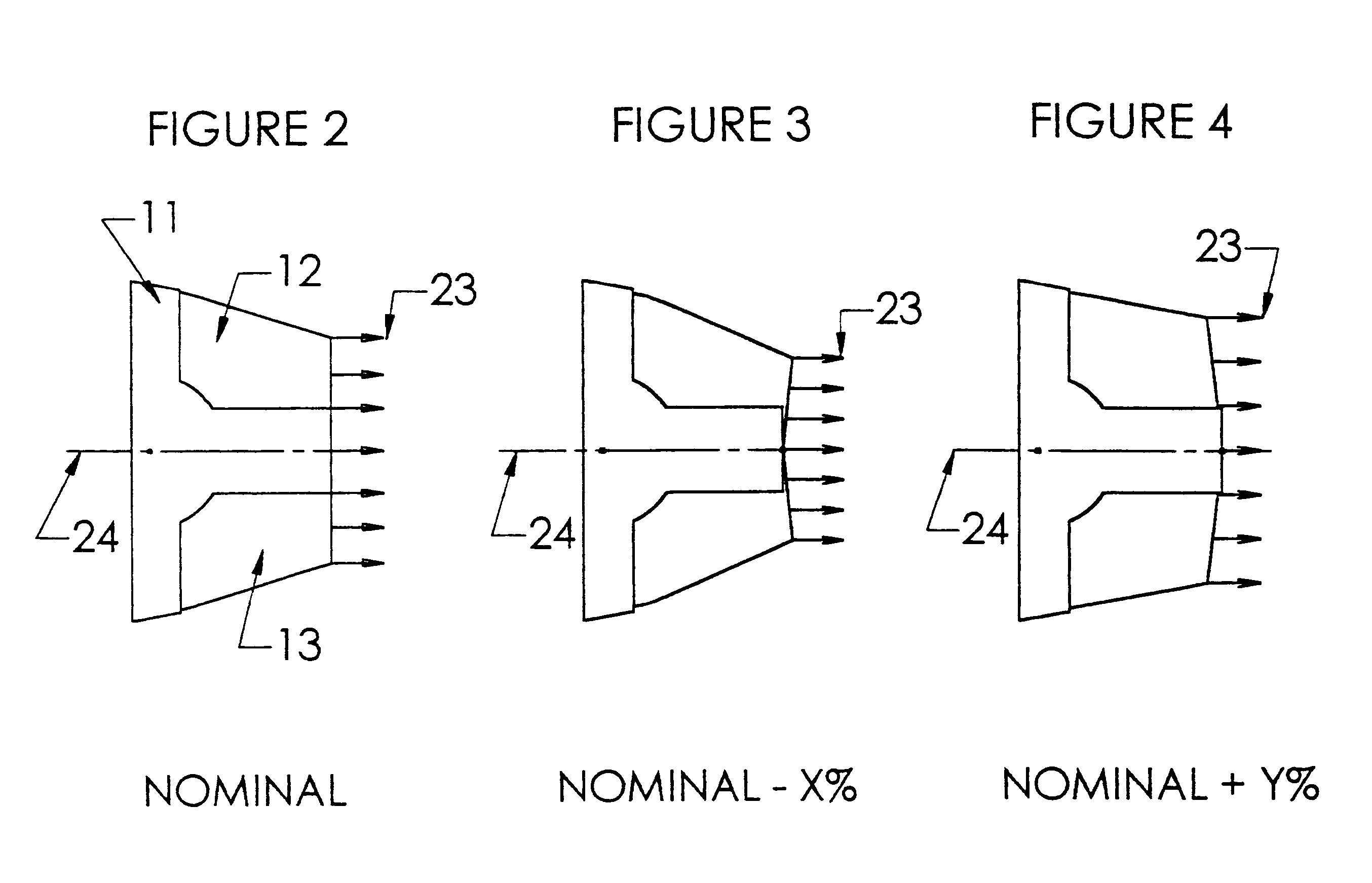

Thrust vectoring and variable exhaust area for jet engine nozzle

InactiveUS6938408B2Increased longitudinal stabilitySlow down the landing speedAircraft navigation controlSpraying apparatusJet engineThrust vectoring

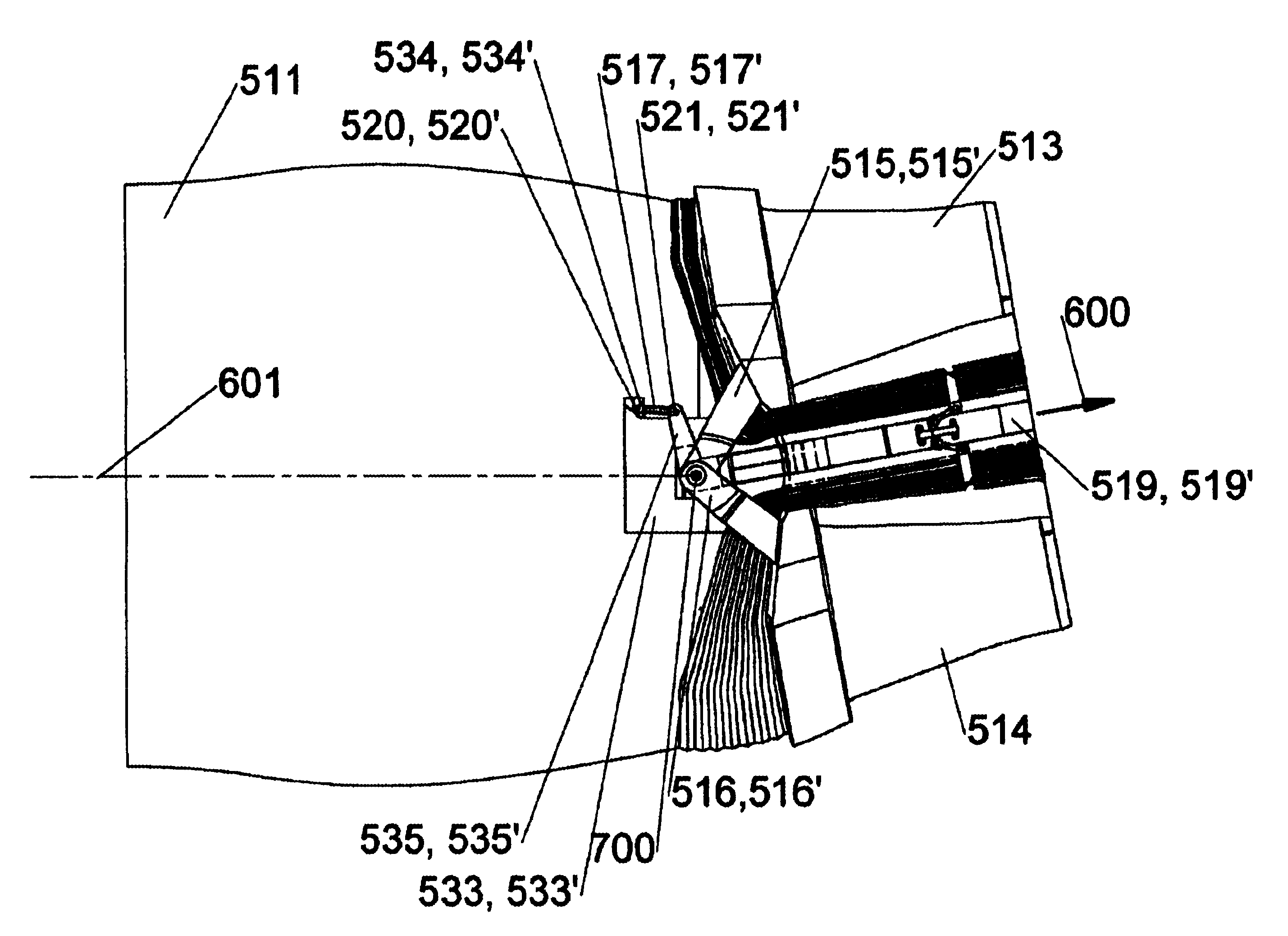

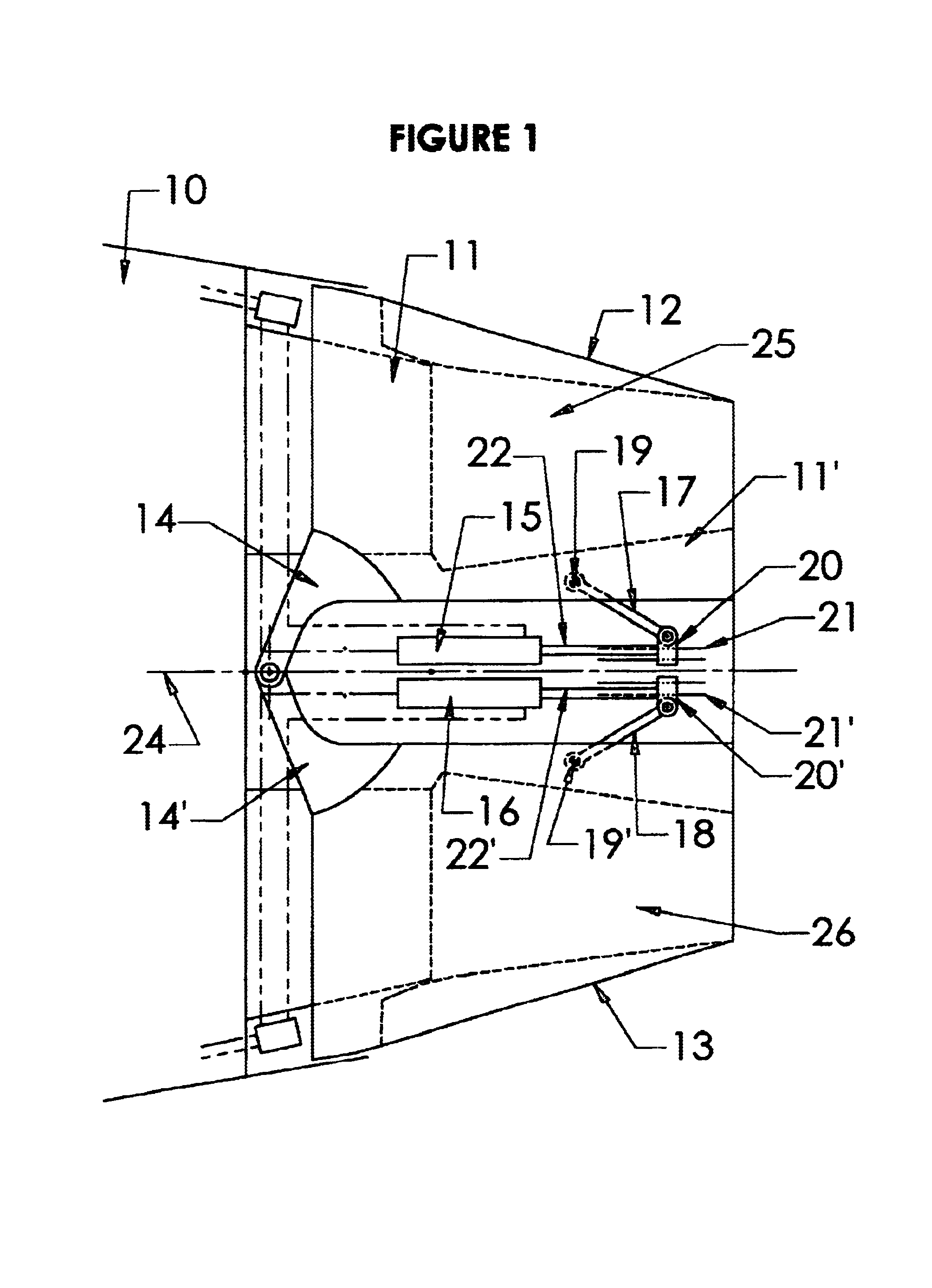

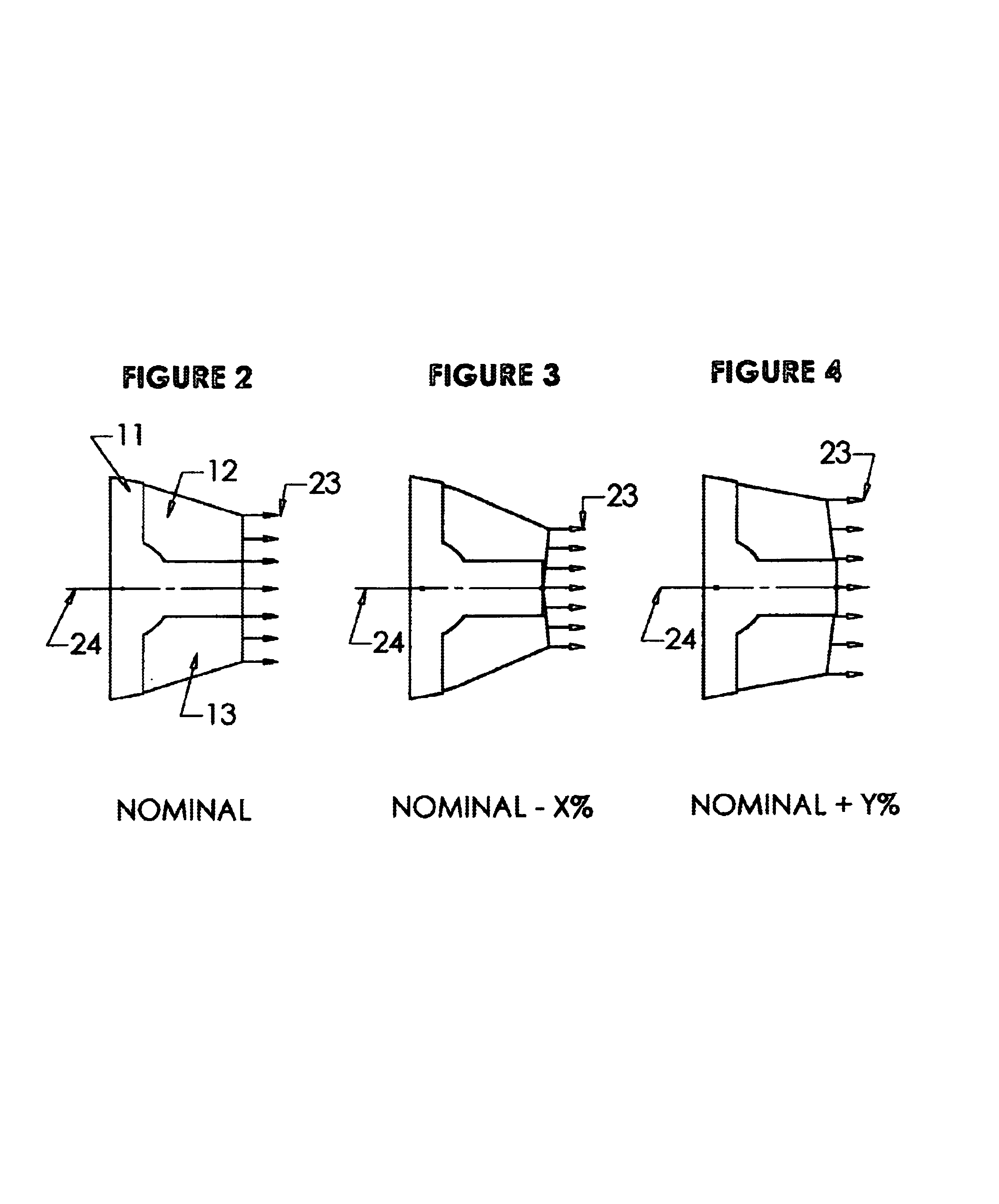

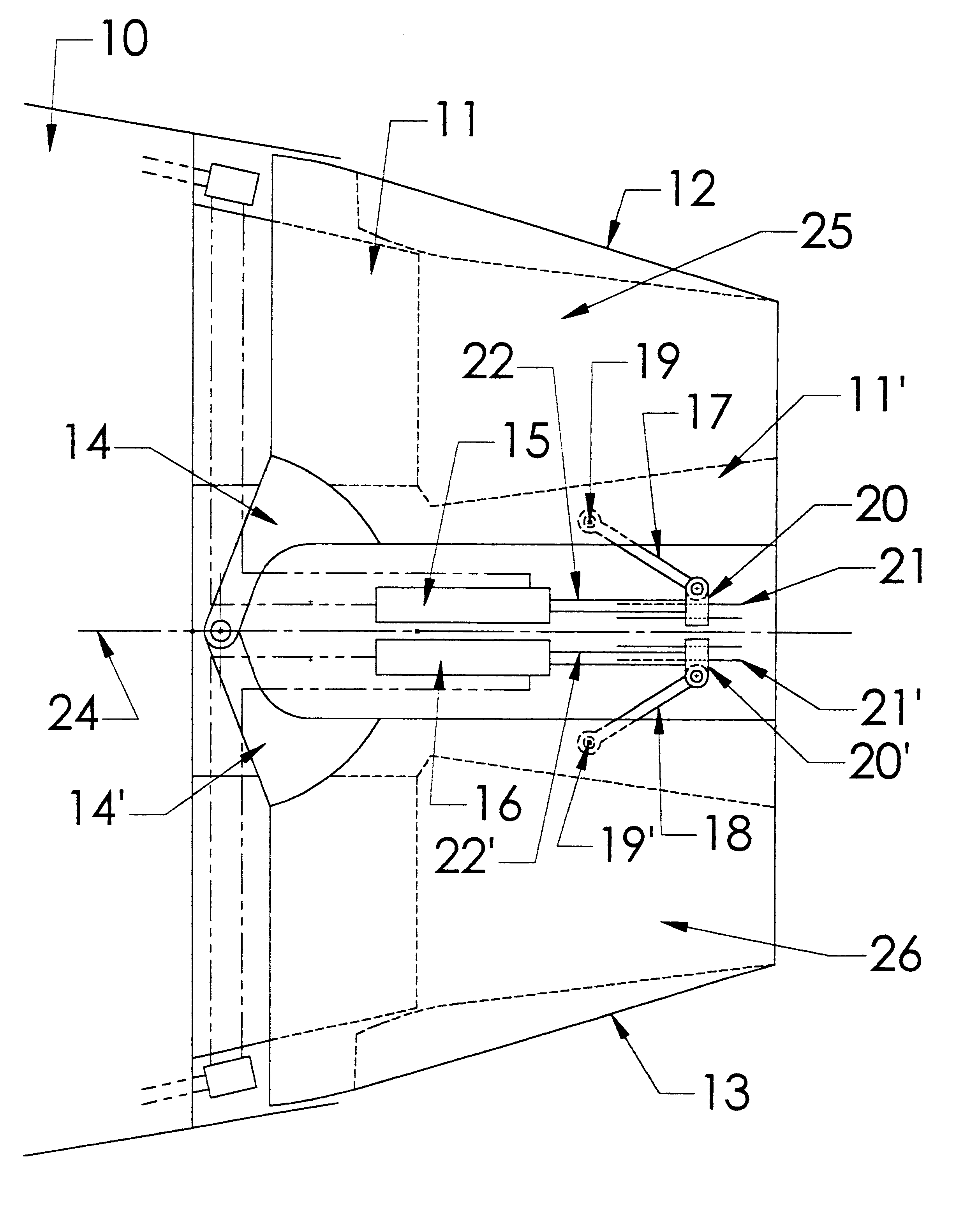

A jet engine nozzle having a pair of pivoting extension arms and a pair of pivoting shells connected to a jet pipe is provided. The first extension arm is pivotally connected to the jet pipe at a first location, while the second extension arm is pivotally connected to the jet pipe at a second location. Each shell is pivotally connected at both the first and second locations. An axis of rotation associated with the first location is coaxial to an axis of rotation associated with the second location. Independent actuation means are provided to rotate the extension arms and the shells, thereby enabling adjustment of the thrust-vector angle or the exhaust area of the nozzle.

Owner:PROPULSION VECTORING

Jet engine nozzle with variable thrust vectoring and exhaust area

InactiveUS6546716B2Variable exhaust areaLess-expensiveAircraft navigation controlSpraying apparatusNacelleJet engine

Owner:PROPULSION VECTORING

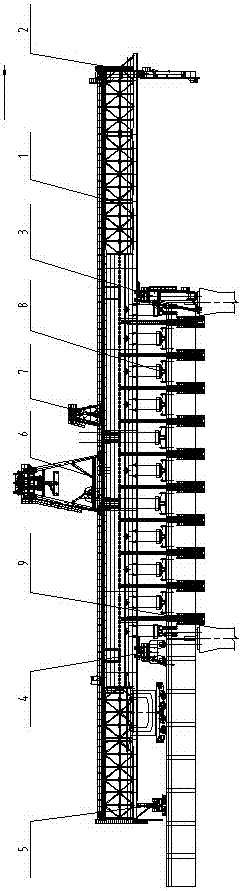

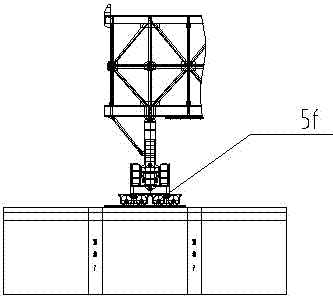

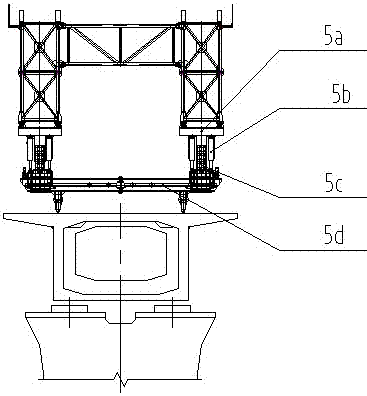

Bridge erecting machine for precast segmental beam span by span construction and construction method thereof

ActiveCN107059640ASmooth rotationNo need for staggered placementBridge erection/assemblyArchitectural engineeringHeavy load

The invention discloses a bridge erecting machine for precast segmental beam span by span construction and a construction method thereof. The bridge erecting machine for the precast segmental beam span by span construction comprises a main frame, a support leg system, a hanging system, a wet joint template system and an overhead travelling crane system. The support leg system comprises a number one support leg, a number two support leg, a number three support leg and a number four support leg, which sequentially arranged at the lower portion of the main frame from front to back, wherein the number one support leg and the number four support leg are located on two ends of the main frame as a auxiliary supporting support leg correspondingly, the number two support leg and the number three support leg are used as a heavy load supporting support leg, the hanging system is connected to the bottom of the main frame, the wet joint template system is connected to the outside of the main frame, the overhead travelling crane system is arranged on a longitudinal moving rail at the top of the main frame; and the construction method of the bridge erecting machine for precast segmental beam span by span construction comprises beam erecting process of the bridge erecting machine and bridge erecting machine through-hole process. The bridge erecting machine for the precast segmental beam span by span construction and the construction method thereof have the advantages that the construction demands of the precast segmental beam of high speed railway are met, the construction efficiency is high, and the construction is convenient and highly efficient.

Owner:ZHENGZHOU NEW DAFANG HEAVY IND & TECH

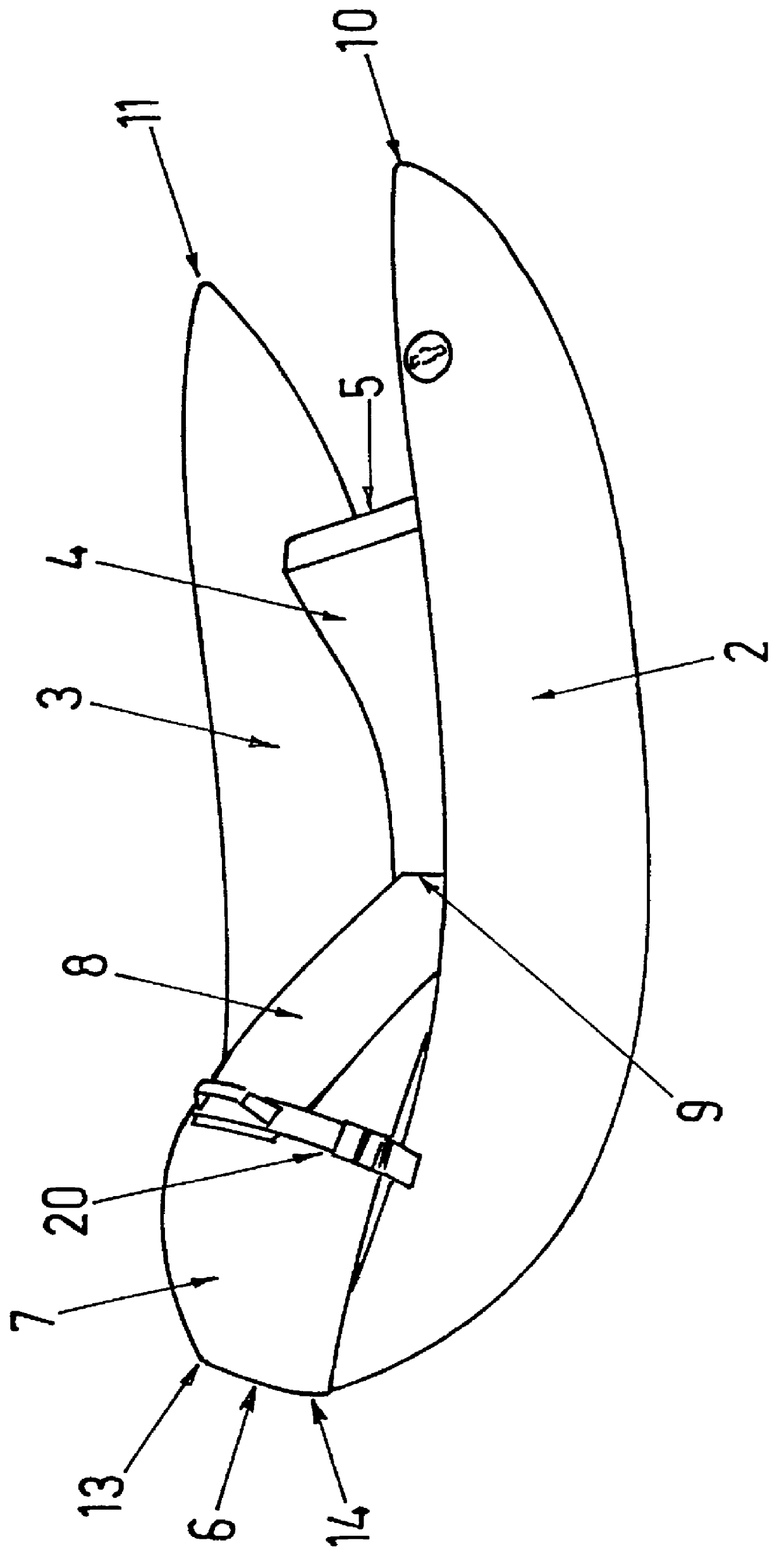

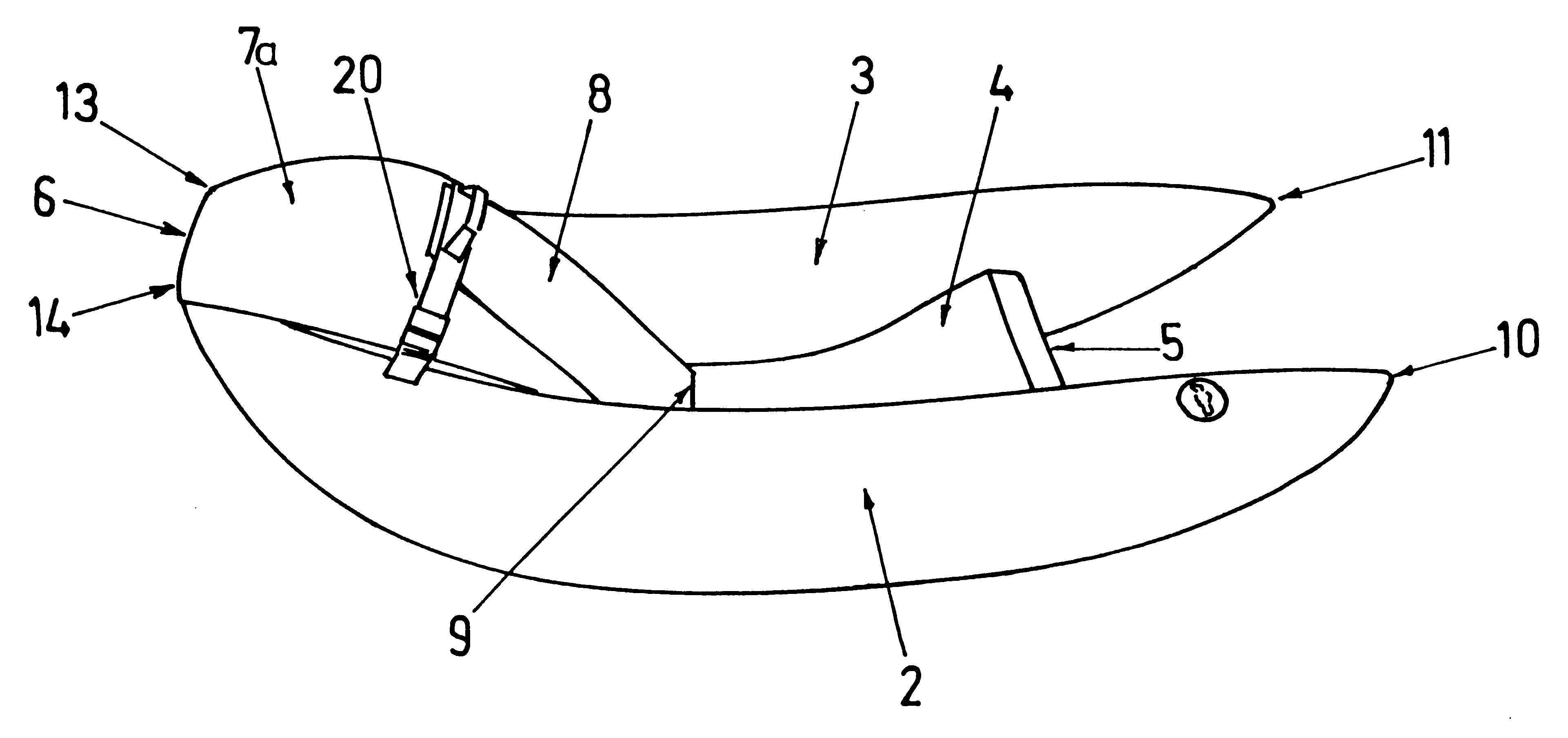

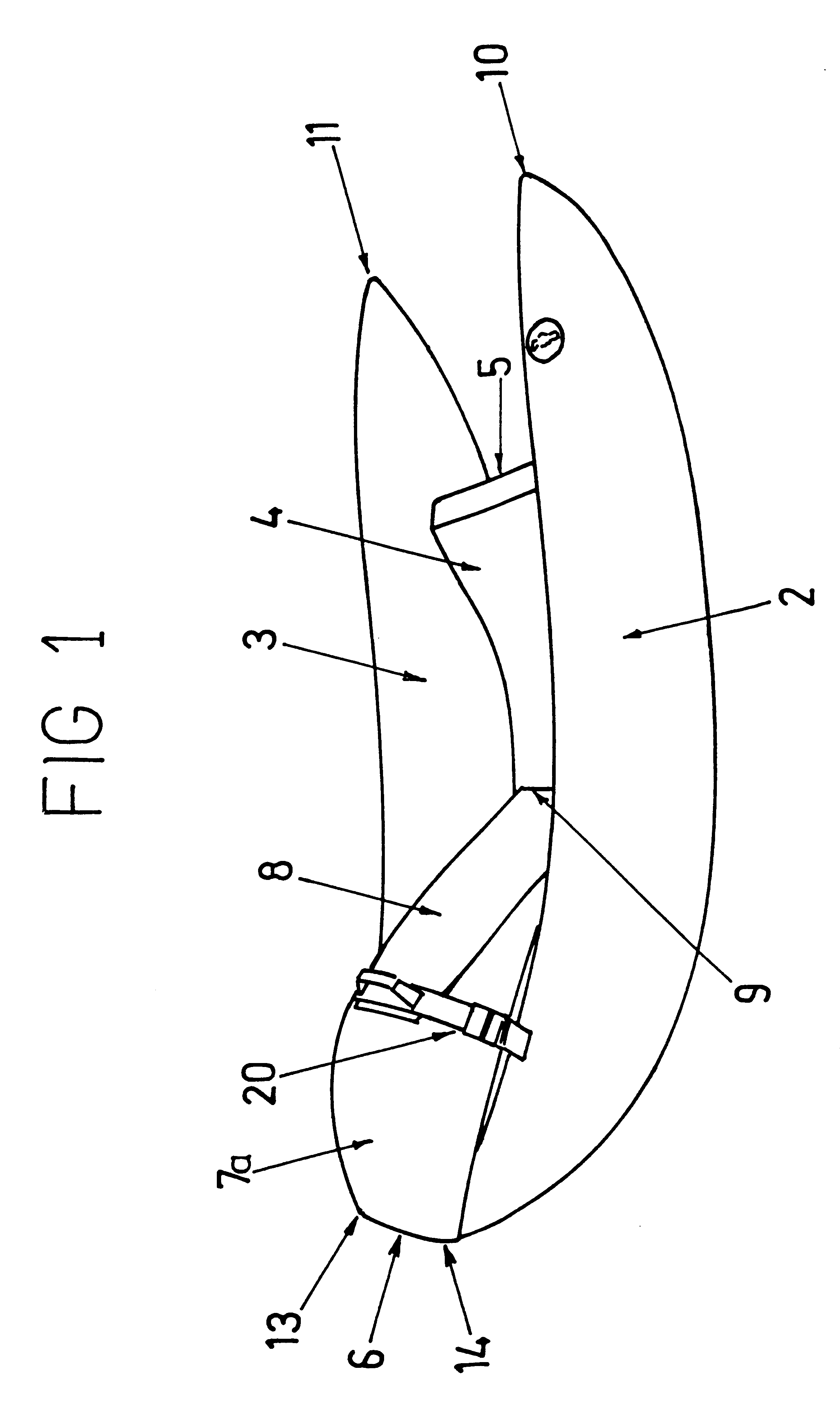

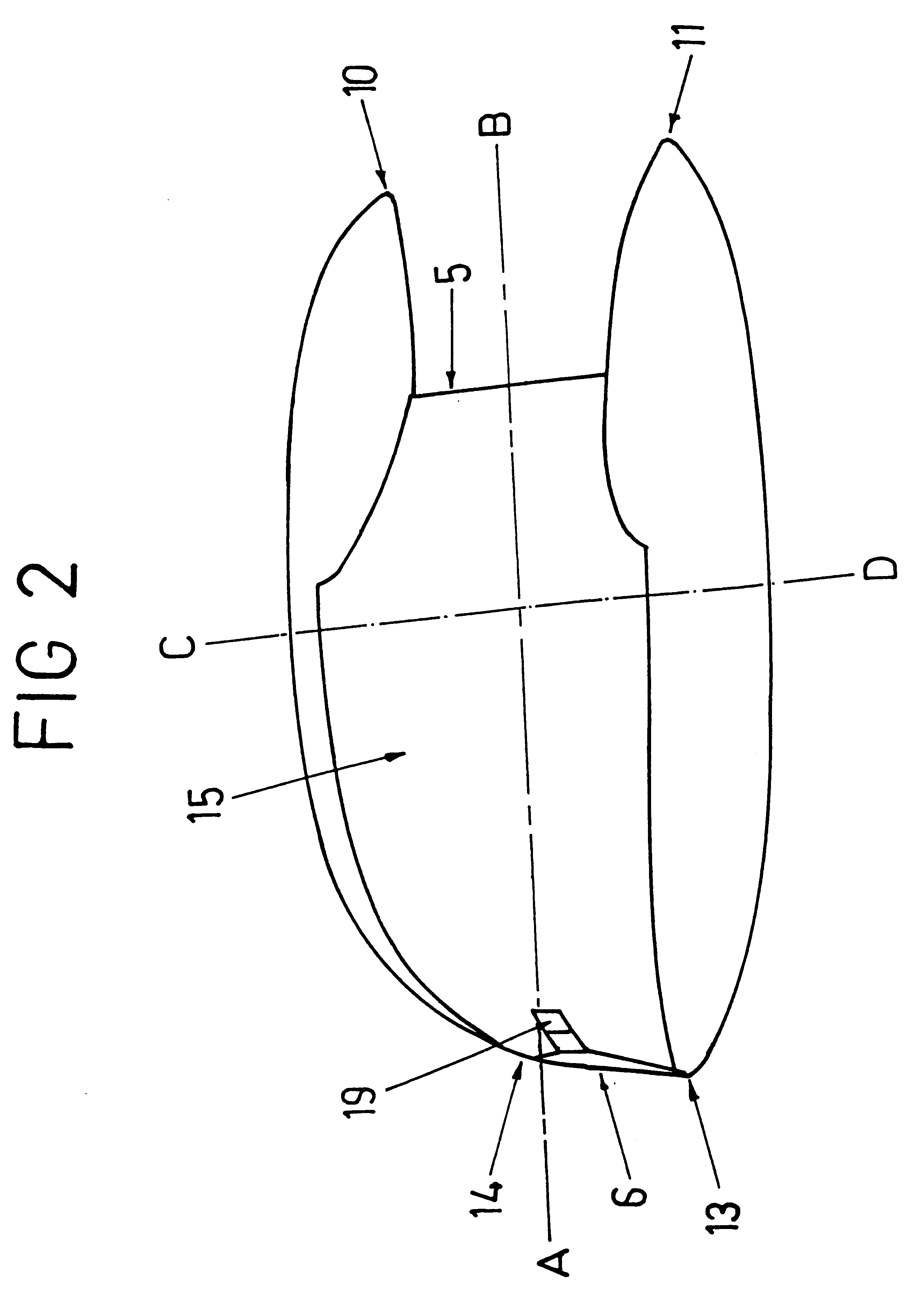

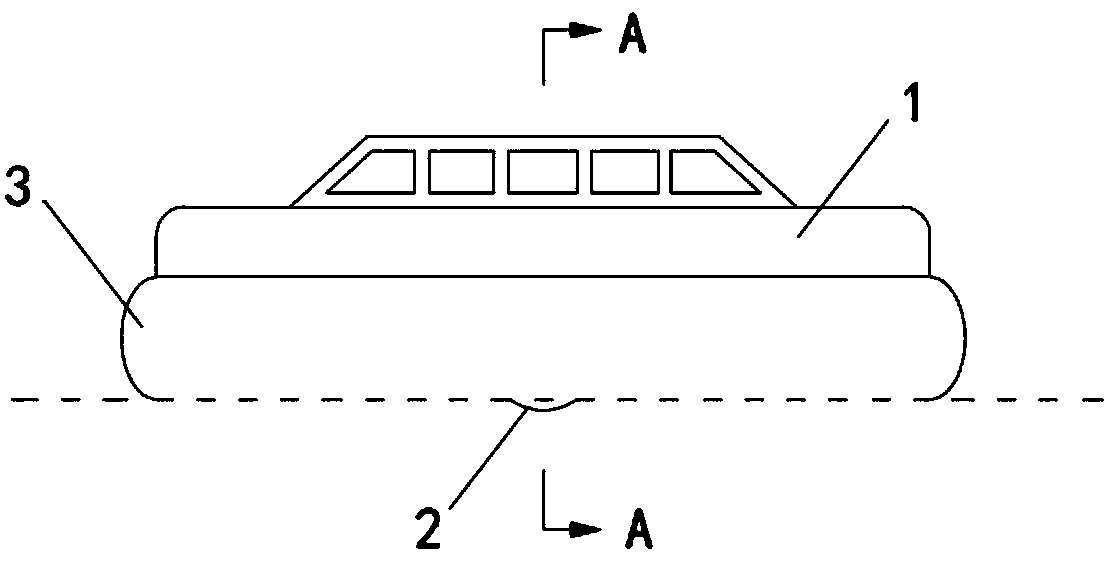

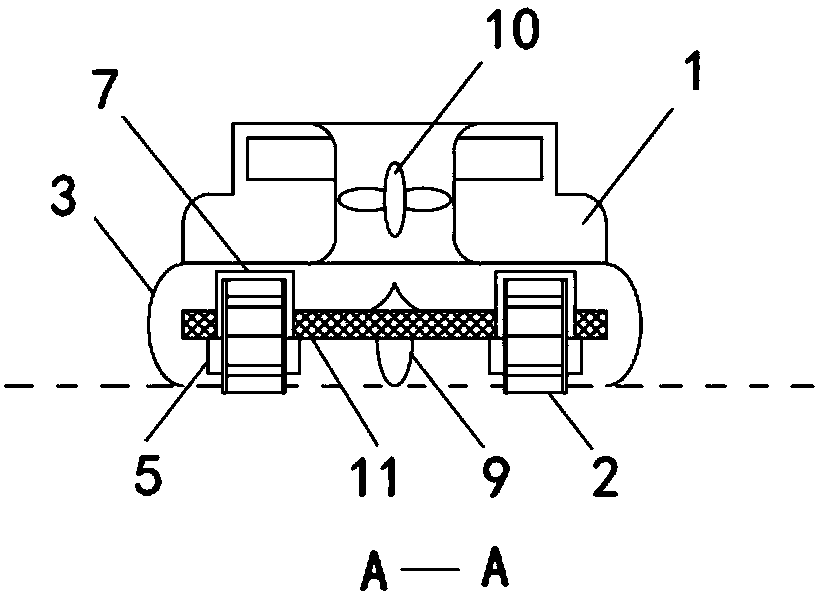

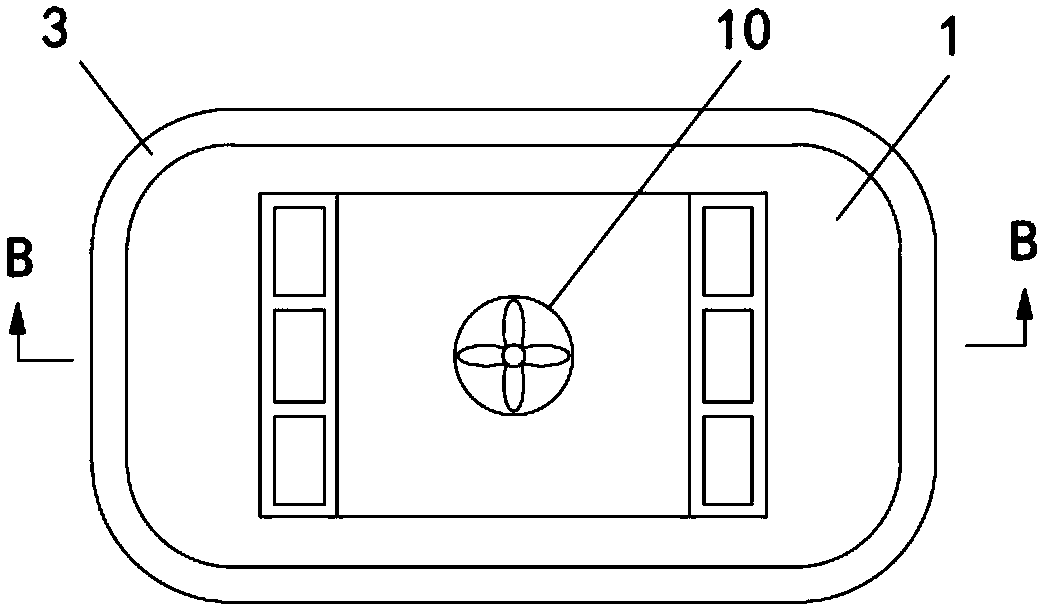

Flotation device

InactiveUS6155899AEfficient propulsionMinimise riskLife-buoysWater sport boardsEngineeringMechanical engineering

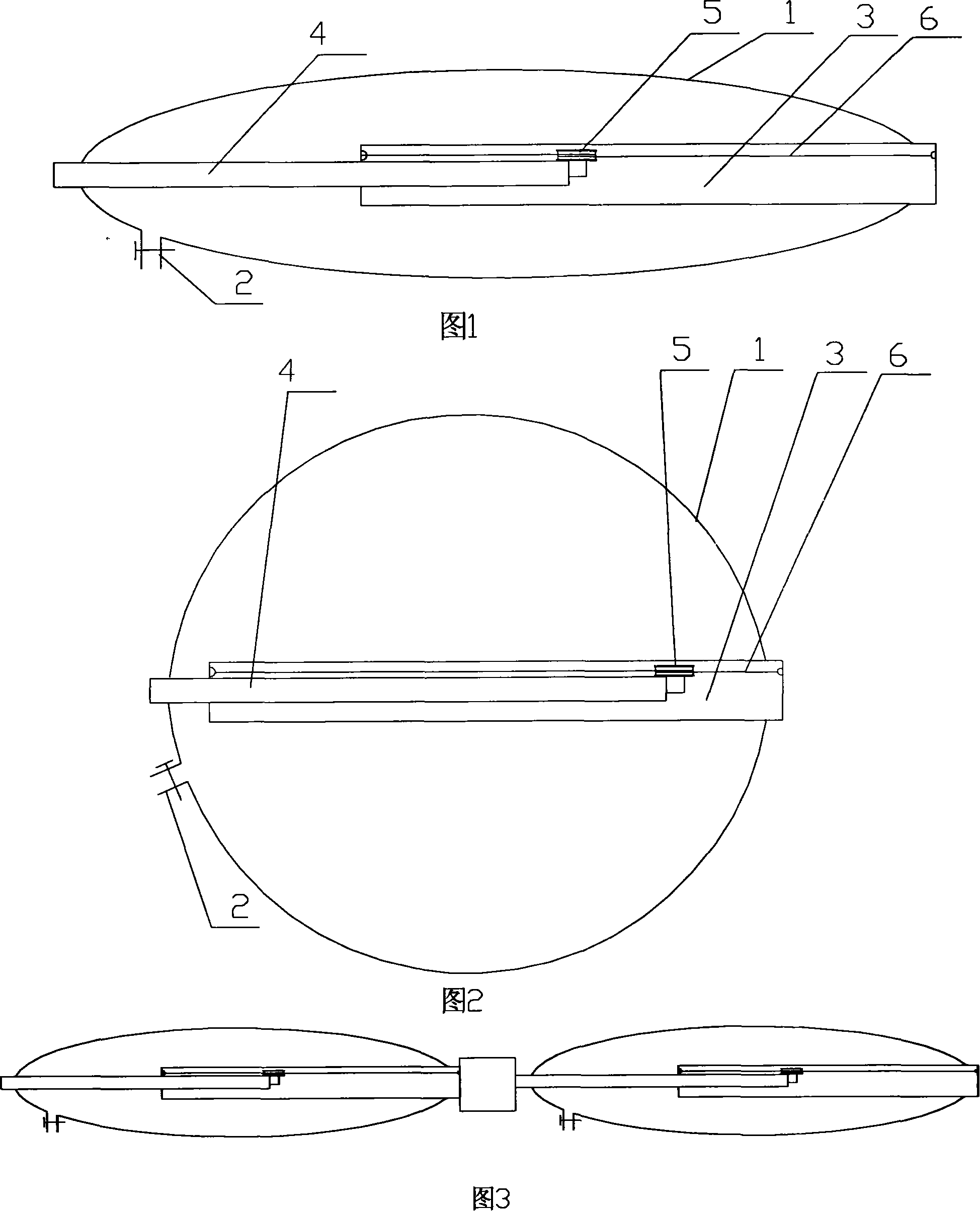

PCT No. PCT / NZ97 / 00113 Sec. 371 Date Mar. 8, 1999 Sec. 102(e) Date Mar. 8, 1999 PCT Filed Sep. 12, 1997 PCT Pub. No. WO98 / 10981 PCT Pub. Date Mar. 19, 1998An inflatable chair suitable for white-water use consisting of two inflatable floats (2, 3), rigid / semi-rigid seat base (4), bow hull floor section (12) an adjustable seat back (8) and a waterproof covering (7). The two inflatable floats (2, 3) are circular in cross section and taper at both ends to conical points (10, 11) at the stern and (13, 14) at the bow (6). The floats (2, 3) are separated by a rigid / semi-rigid central section (15) comprised of the seat base (4), bow hull floor section (12) which extends from the bow (6) for a majority of the chair's length, and together with the seat back (8) providing a semi-reclining body position enabling the user to use hands and / or legs for propulsion / manoeuvring.

Owner:BODDY GRAEME JAMES

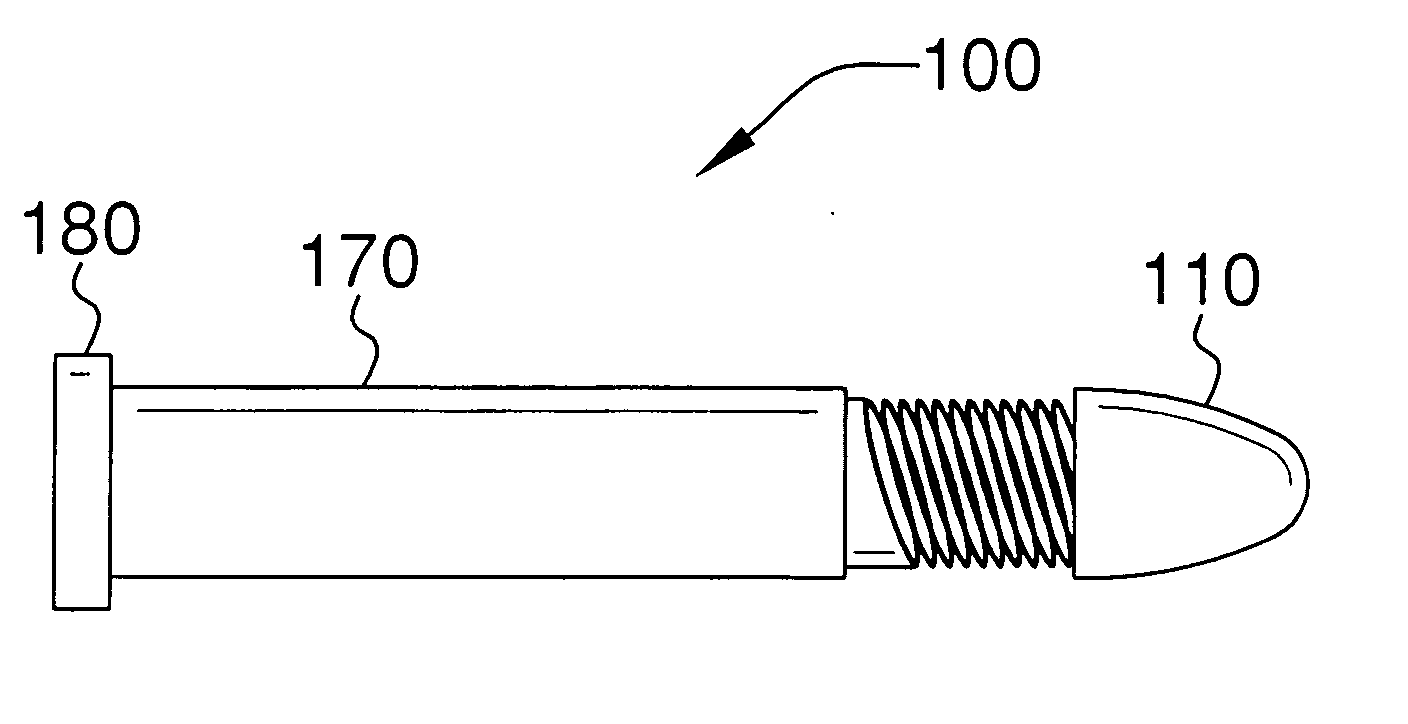

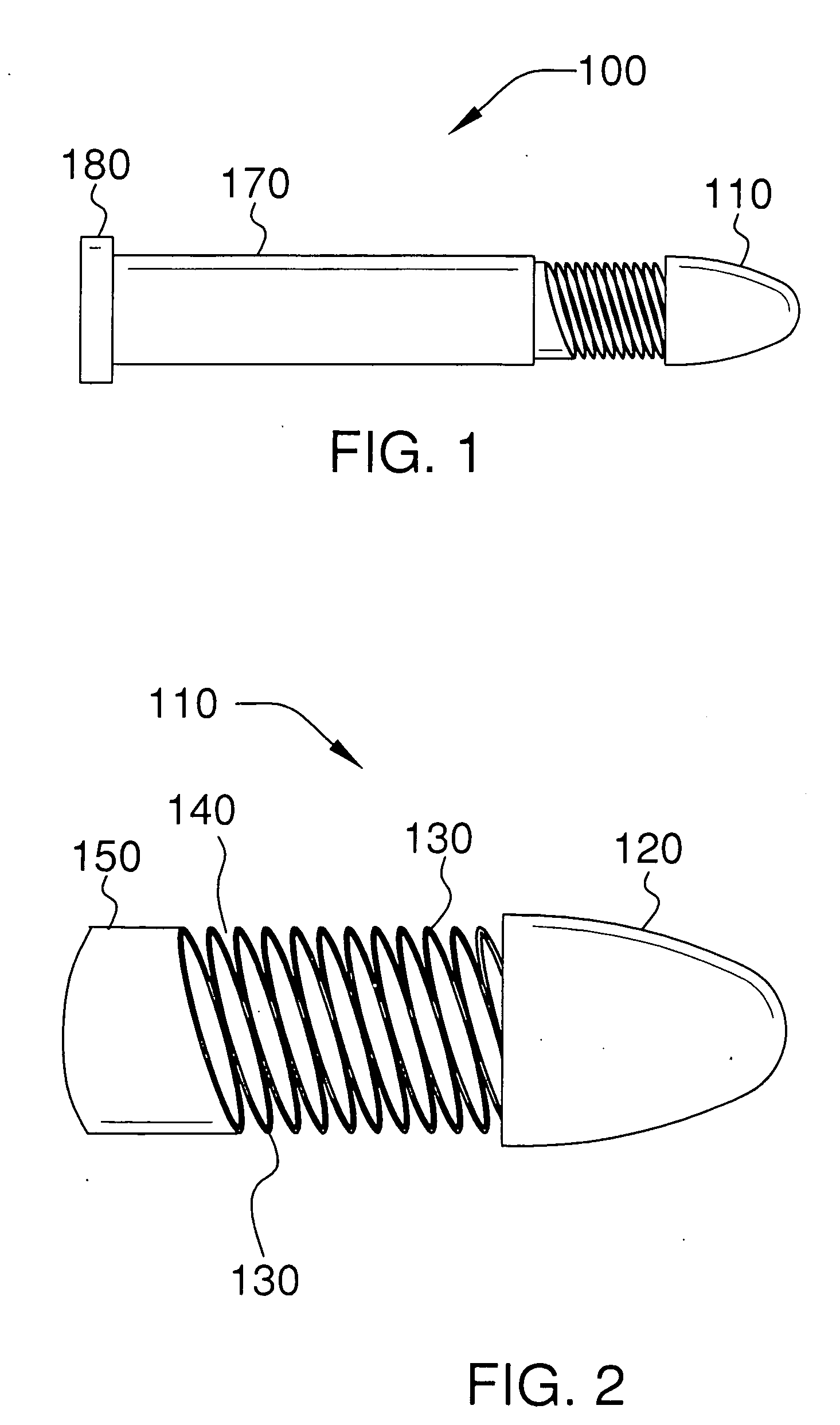

Deployment system for an intraluminal medical device

InactiveUS20070106364A1Extended shelf lifeUndesirable and premature delaminationStentsBlood vesselsStent graftingInsertion stent

An intraluminal medical device delivery system that distributes forces more uniformly across an intraluminal medical device during loading and delivery of the device to an intended treatment site. A support member provided on an inner member of a catheter delivery system helps to more uniformly distribute forces across the device by crimping the device over the support member so as to place the support member in a mechanically compressed state during delivery of the device to the intended treatment site. The support member is preferably comprised of a material having a modulus of elasticity that increases when the material is compressed. The mechanical nature of the support member provides increased stability to the device during loading and delivery thereof without providing heat or other preformed or additional mechanical members to the support member. Repositioning of the device is available due to the stability of the device when mounted on the support member. The intraluminal medical device can be a stent, a stent graft, segments thereof, or a series of such stents, stent grafts, or segments thereof.

Owner:CORDIS CORP

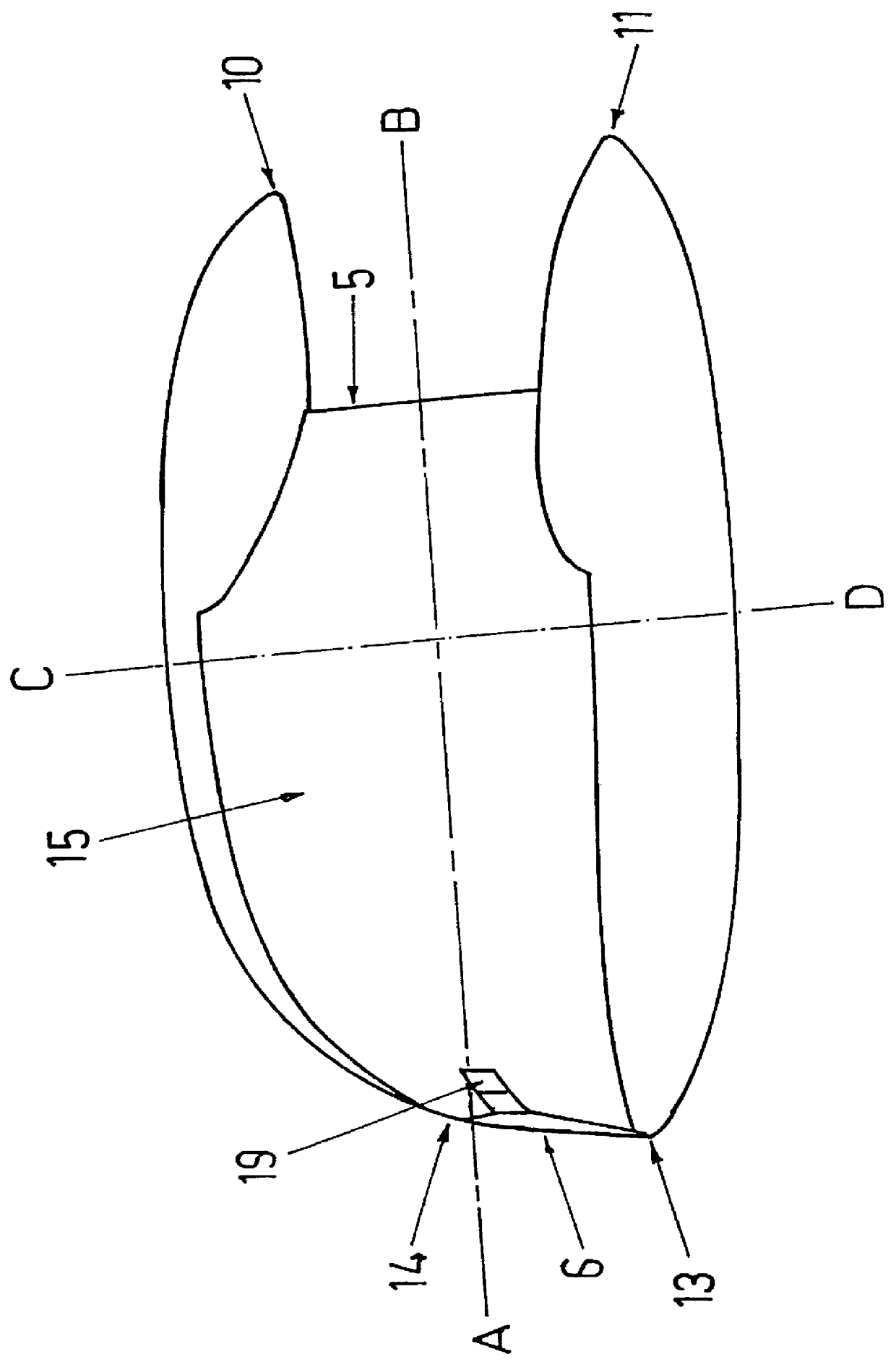

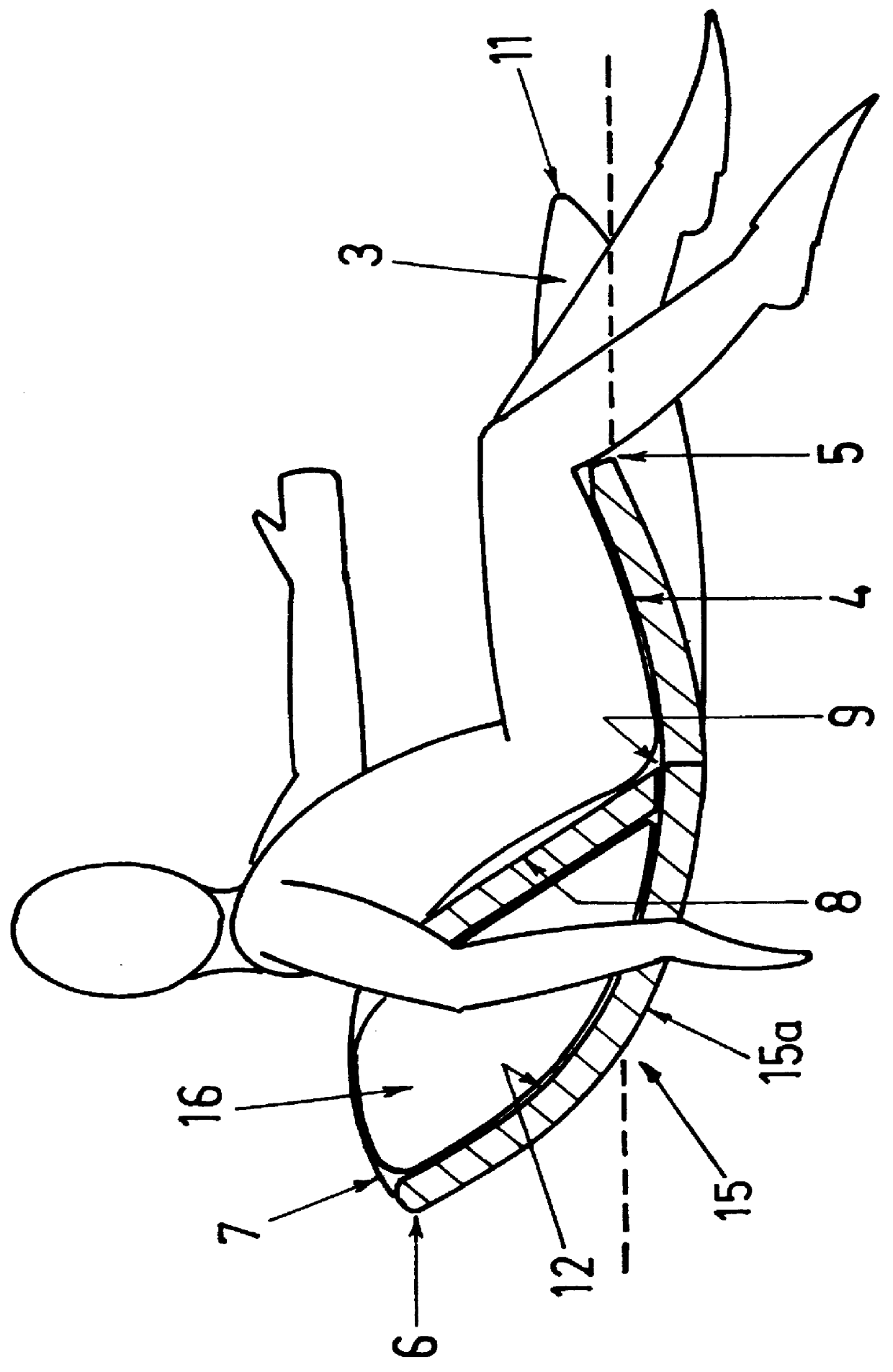

Flotation device

InactiveUS6227925B1Efficient propulsionRisk minimizationWater sport boardsLife-buoysBody positionsBack rests

A substantially rigid or semi-rigid chair suitable for white-water use with a hydrodynamically efficient underwater profile, capable of efficient human propulsion, using hands and / or legs, which supports the user in a semi-reclining position and which is sufficiently maneuvrable, in both forward and reverse direction, to enable the user to engage in white-water river use. In one embodiment, the chair consisting of two floats (2, 3), rigid / semi-rigid seat base (4), bow hull floor section (12) an adjustable seat back (8) and a waterproof covering (7). The floats (2, 3) are separated by a rigid / semi-rigid central section (15) comprised of the seat base (4), bow hull floor section (12) which extends from the bow (6) for a majority of the chair's length, and together with the seat back (8) providing a semi-reclining body position enabling the user to use hands and / or legs for propulsion / maneuvring.

Owner:BODDY GRAEME JAMES

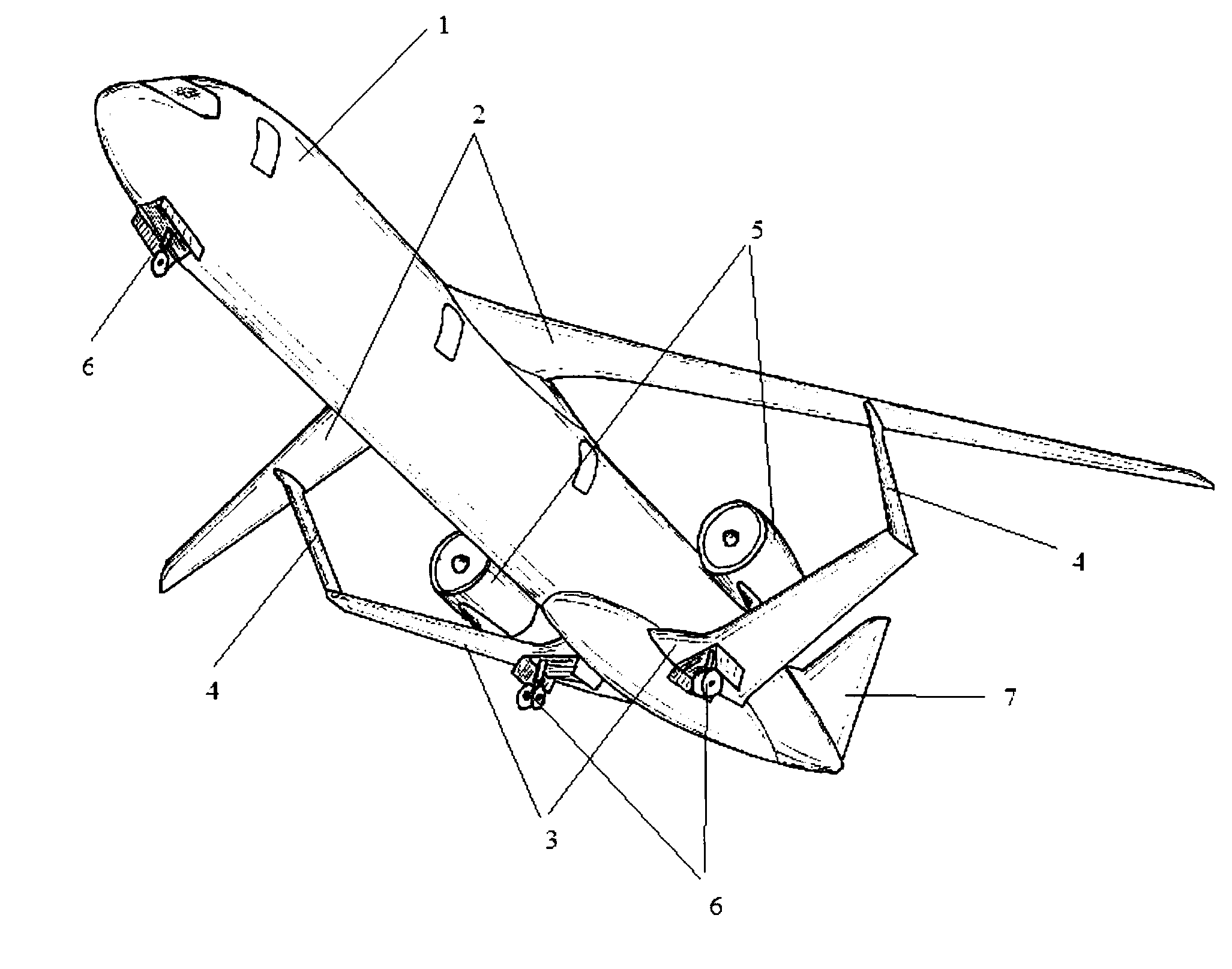

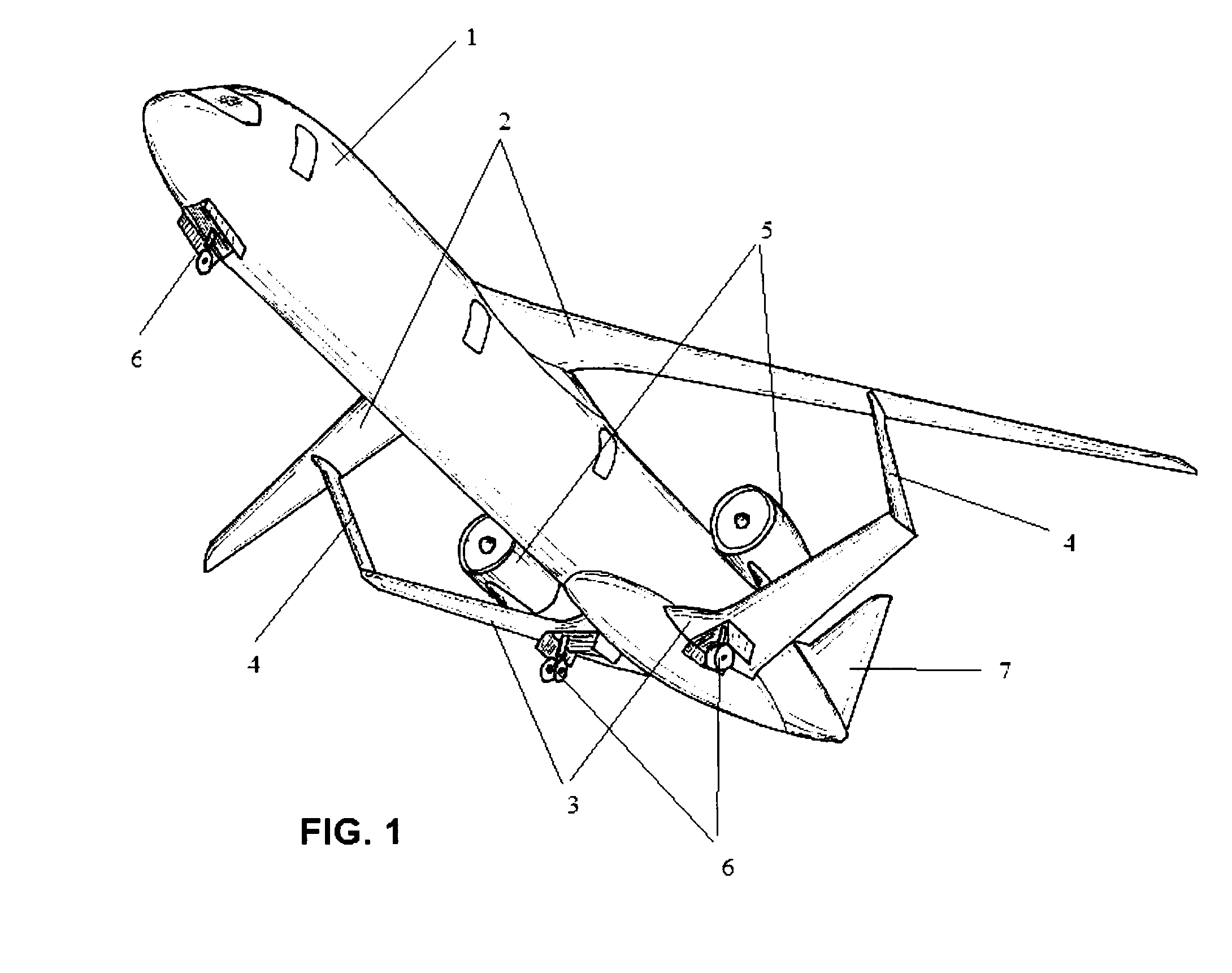

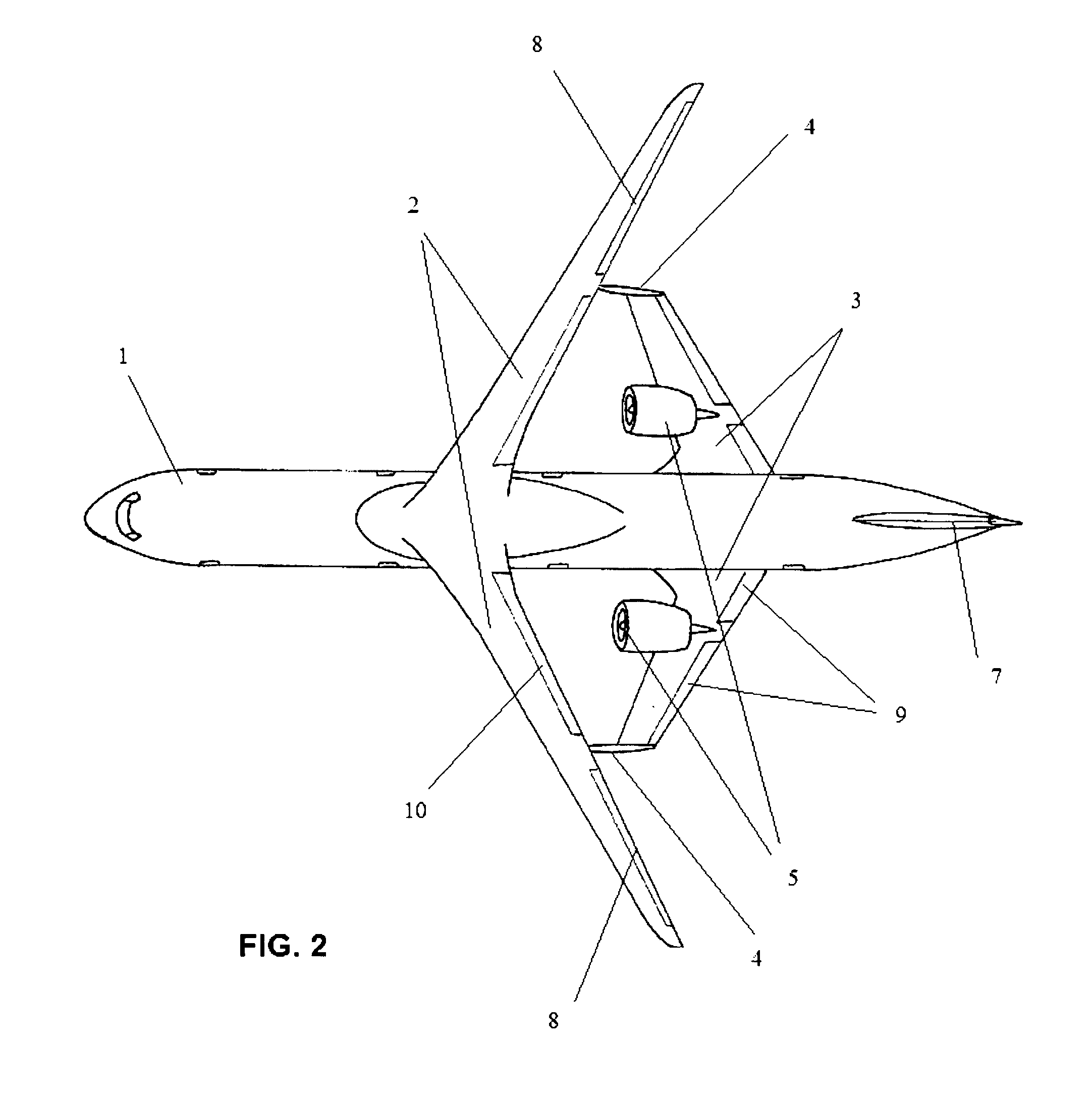

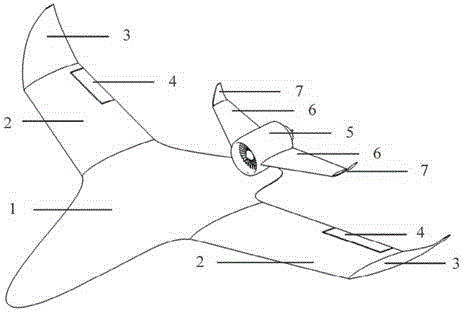

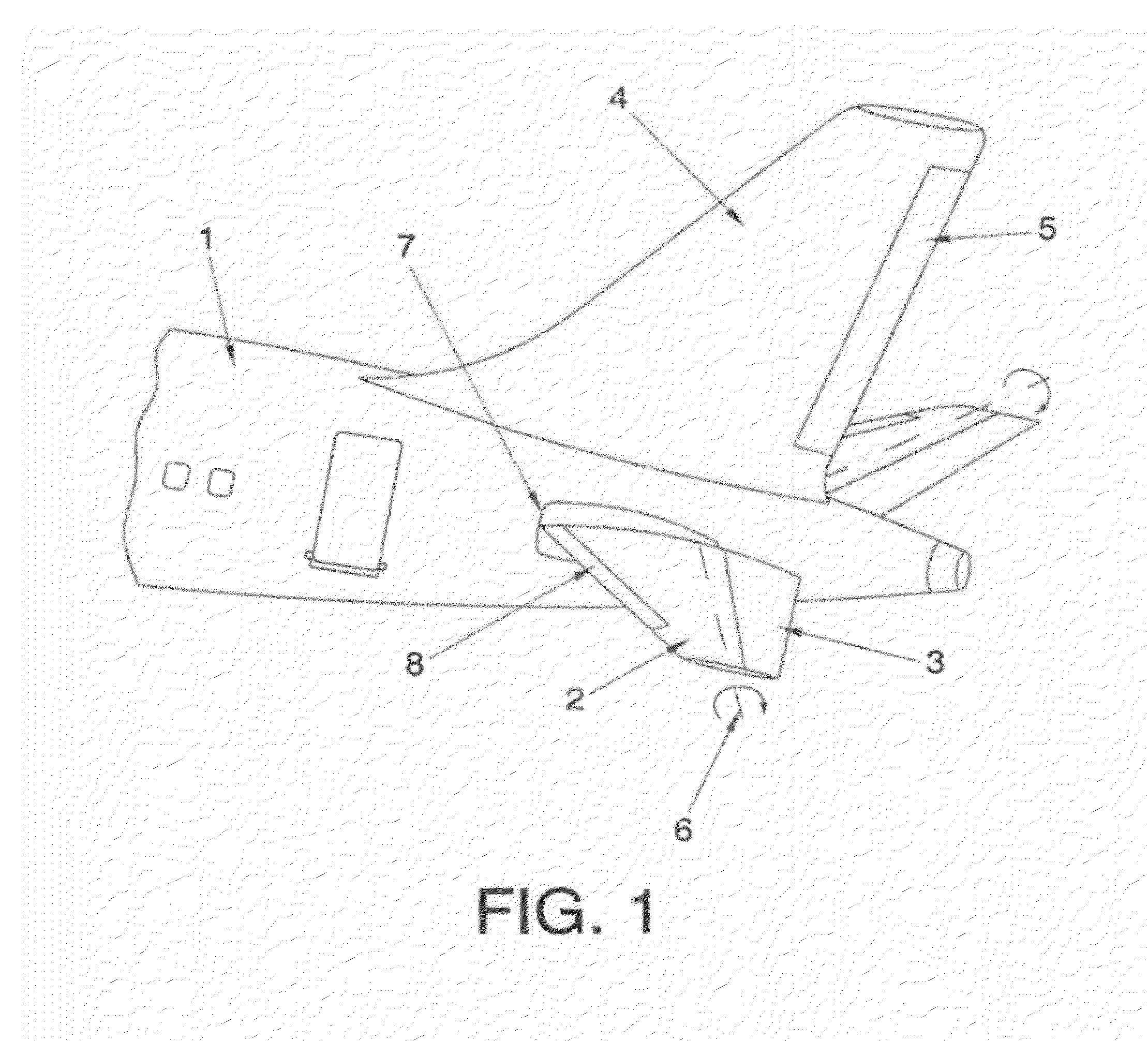

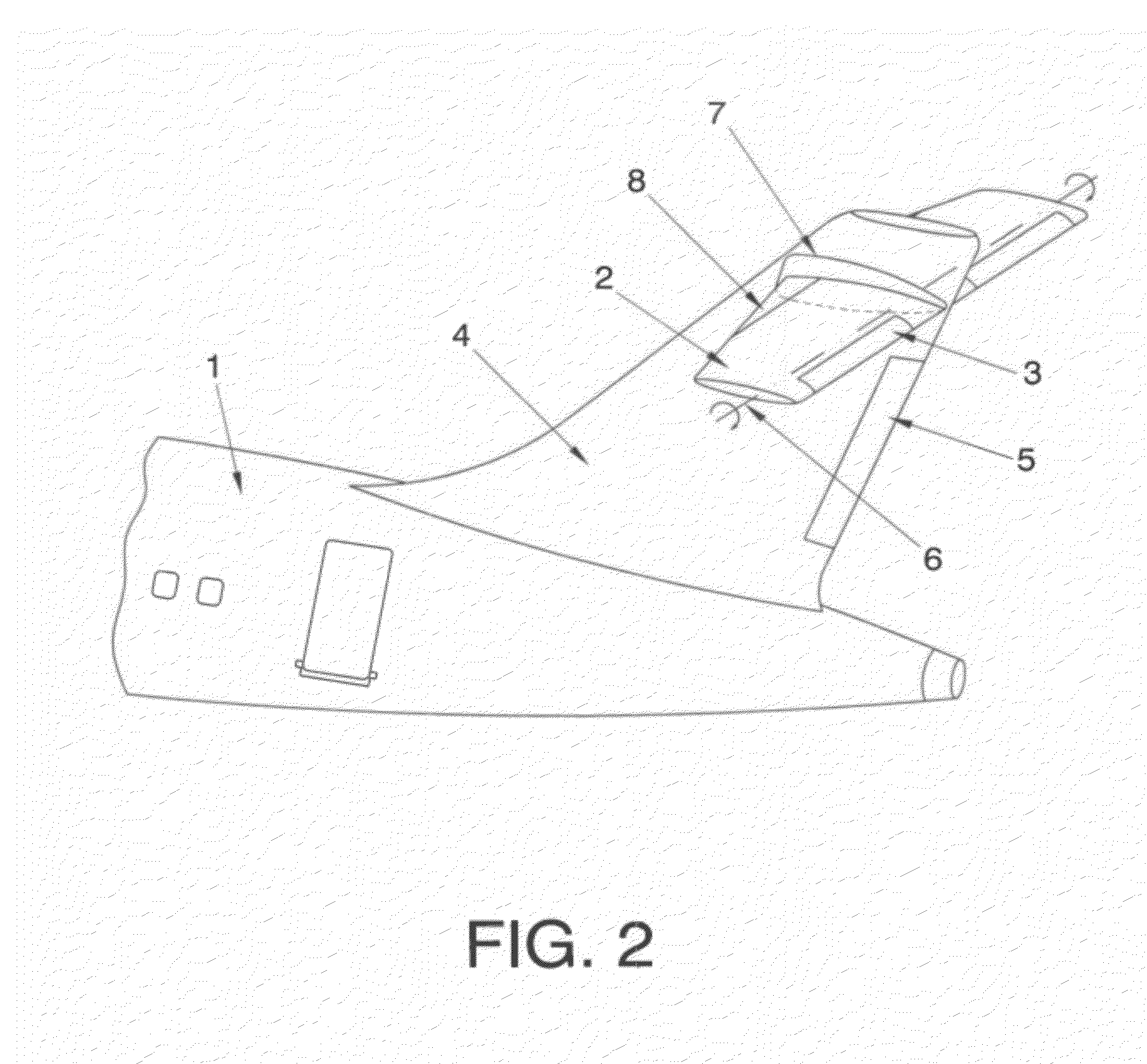

Aircraft having a lambda-box wing configuration

ActiveUS20110180660A1Reducing compressible dragImprove stabilityFuselage insulationWing adjustmentsWing configurationIntermediate point

Aircraft having a lambda-box wing configuration, comprising a fuselage (1), a propulsion system (5), a first pair of swept-back airfoils (2), connected to the top forward portion of the fuselage (1), a second pair of swept-forward airfoils (3), connected to the lower rear portion of the fuselage (1) at a point of the said fuselage (1) aft of the connection of the swept-back airfoils (2), and a third pair of substantially vertical airfoils (4), the tips of the swept-forward airfoils (3) being connected to the lower side of the swept-back airfoils (2) at an intermediate point of the span of the said swept-back airfoils (2), by means of the substantially vertical airfoils (4), the swept-back airfoils (2) having a higher aspect ratio than that of the swept-forward airfoils (3), which makes the swept-back airfoils (2) have a reduced induced drag without penalizing their weight.

Owner:AIRBUS OPERATIONS SL

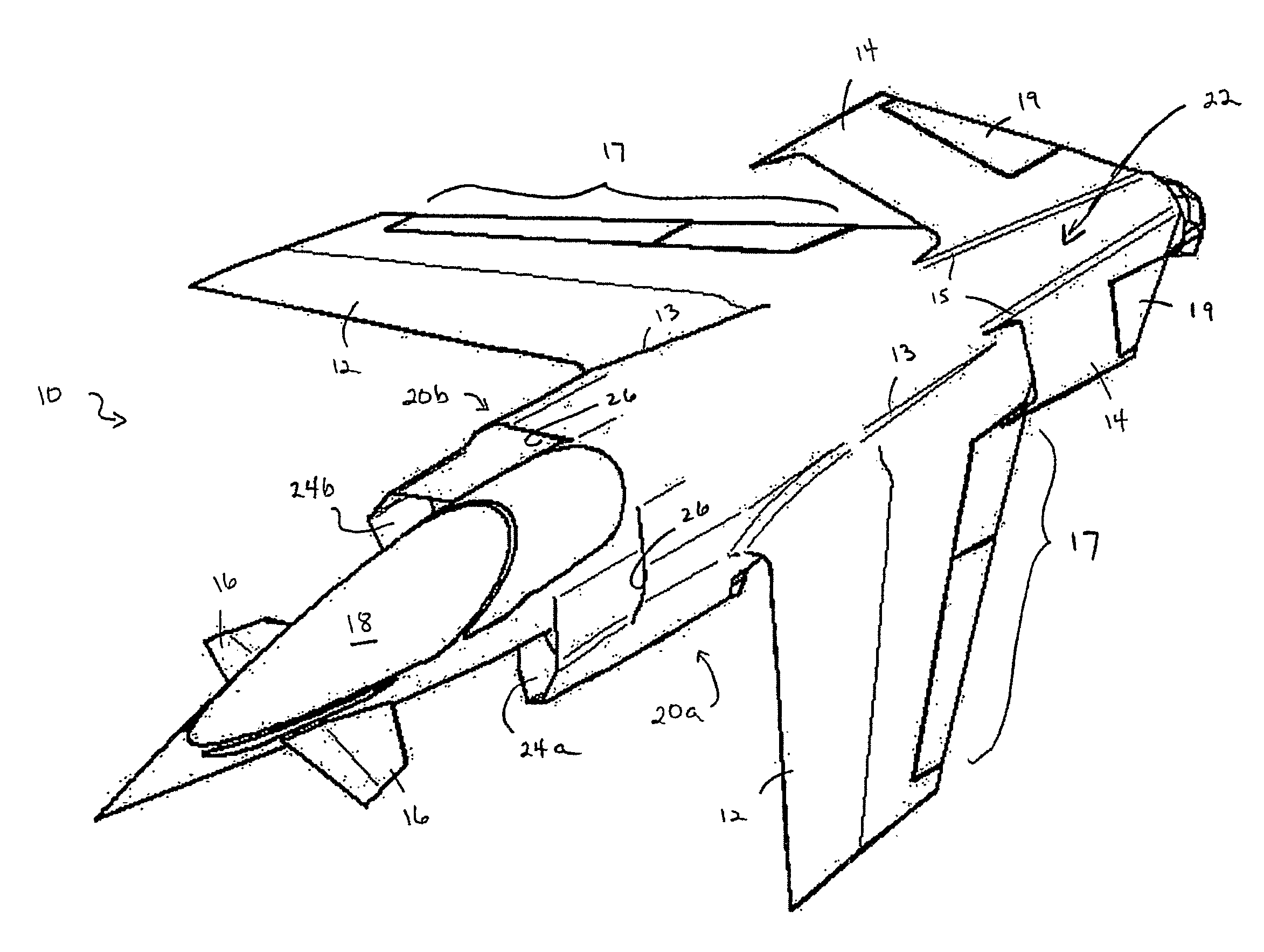

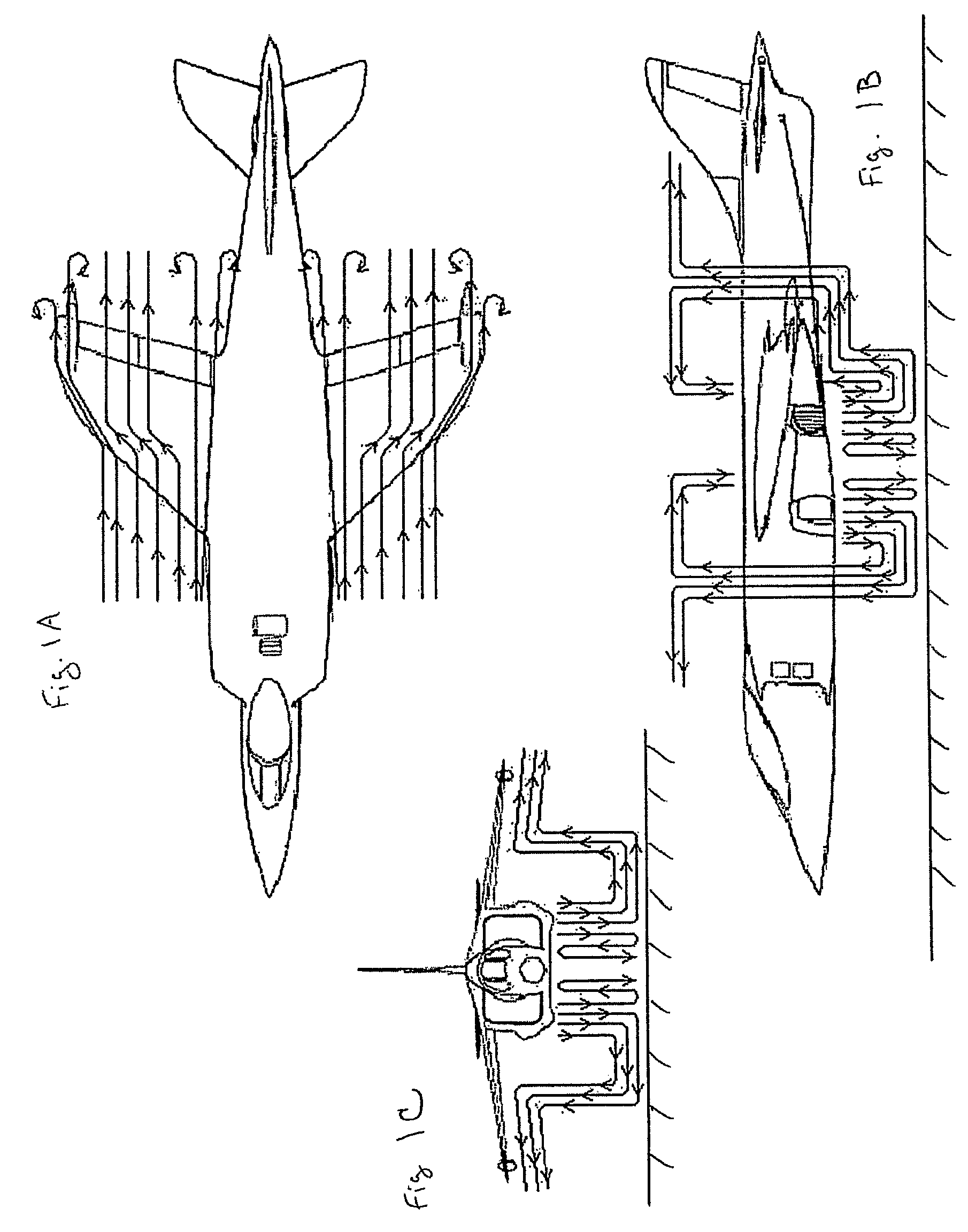

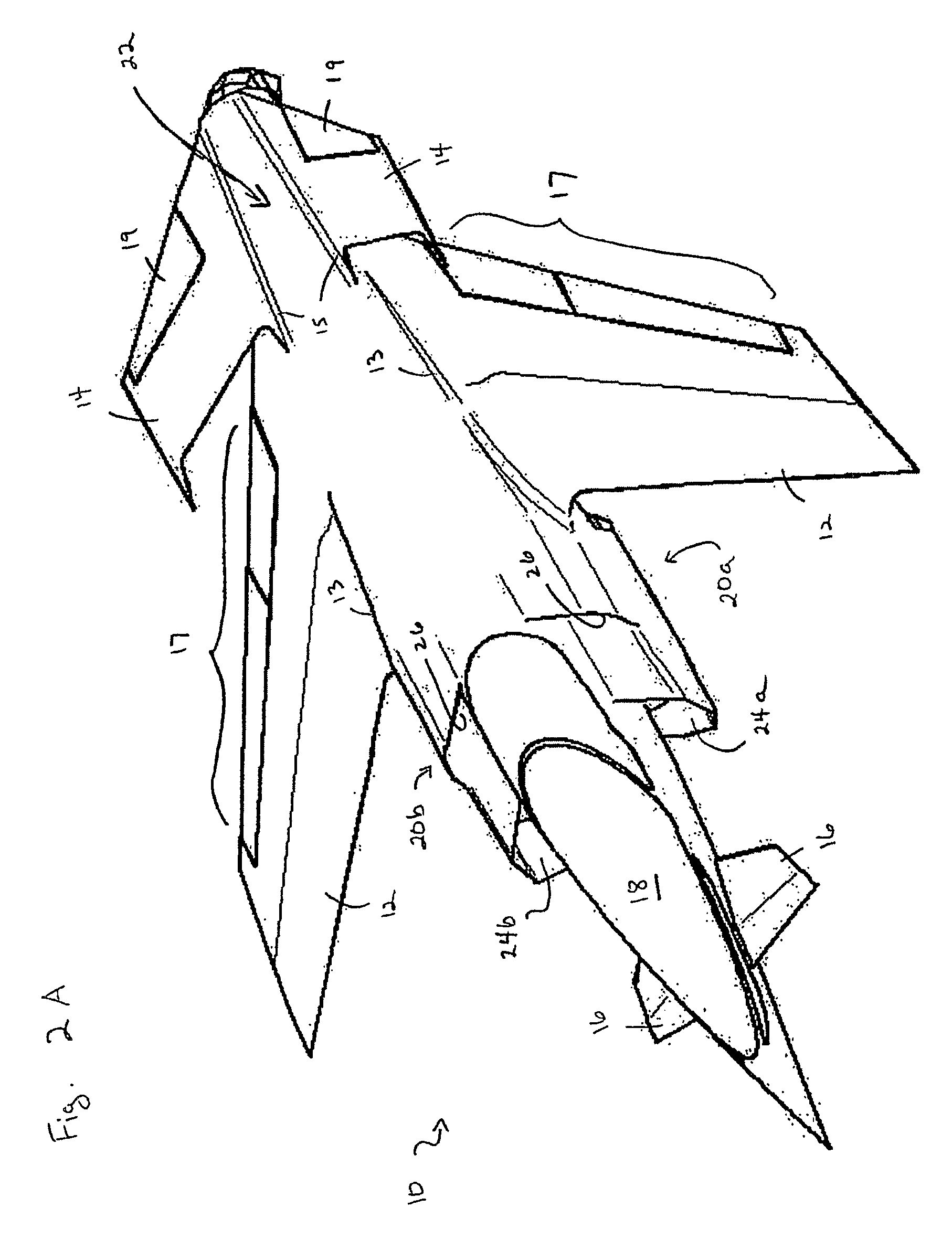

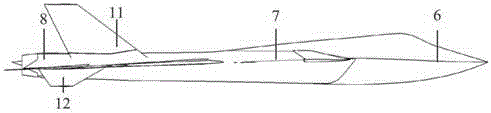

VTOL aircraft with forward-swept fixed wing

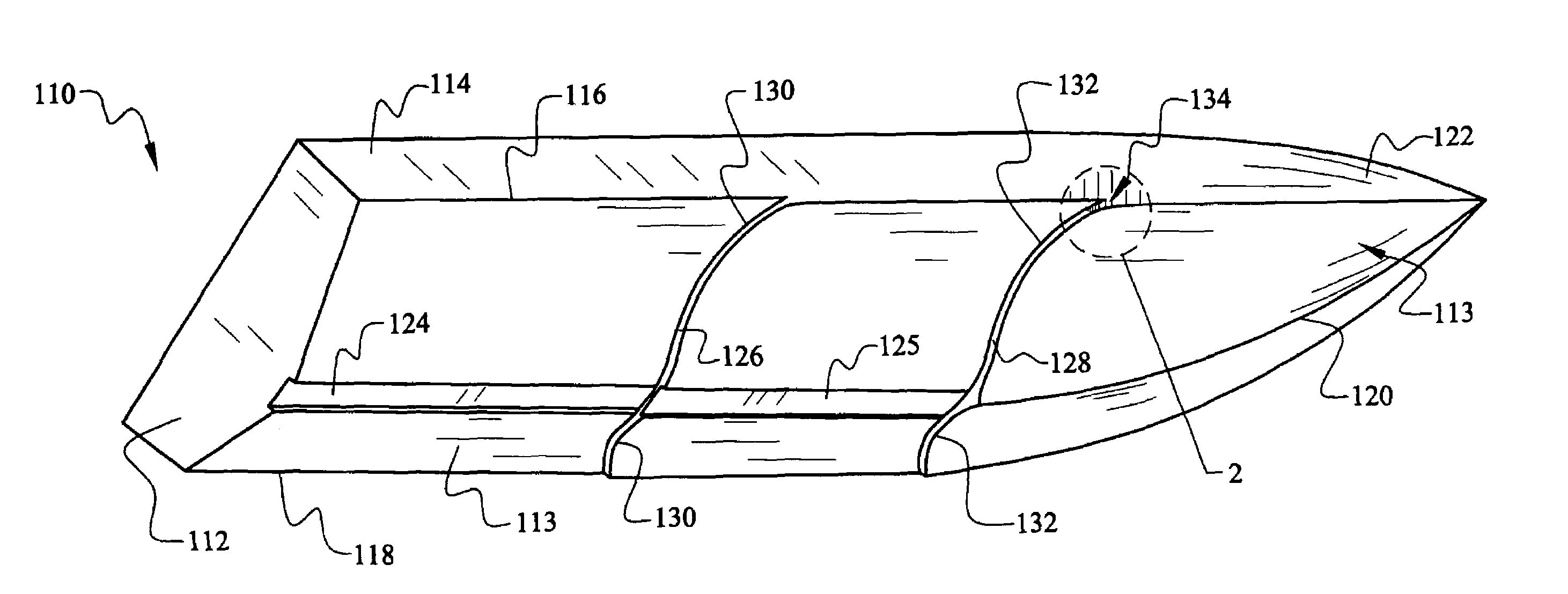

InactiveUS7735774B2Increased longitudinal stabilityEliminates or significantly reduces “suckdown”Aircraft navigation controlAircraft stabilisationJet aeroplaneFixed wing

A fixed-wing VTOL aircraft features a forward-swept wing configuration coupled with a tripod arrangement of the engines (two forward, one rear), a forward-swept empennage or tail assembly, and a forward canard. The engines and wings / empennage are located relative to each other such that the engine outlet nozzles, which pivot downwardly to provide lift-off thrust, are minimally covered by the wings / empennage, if at all. The wings and empennage may include lifting fans to supplement lift and provide pitch and / or roll control.

Owner:SONIC BLUE AEROSPACE

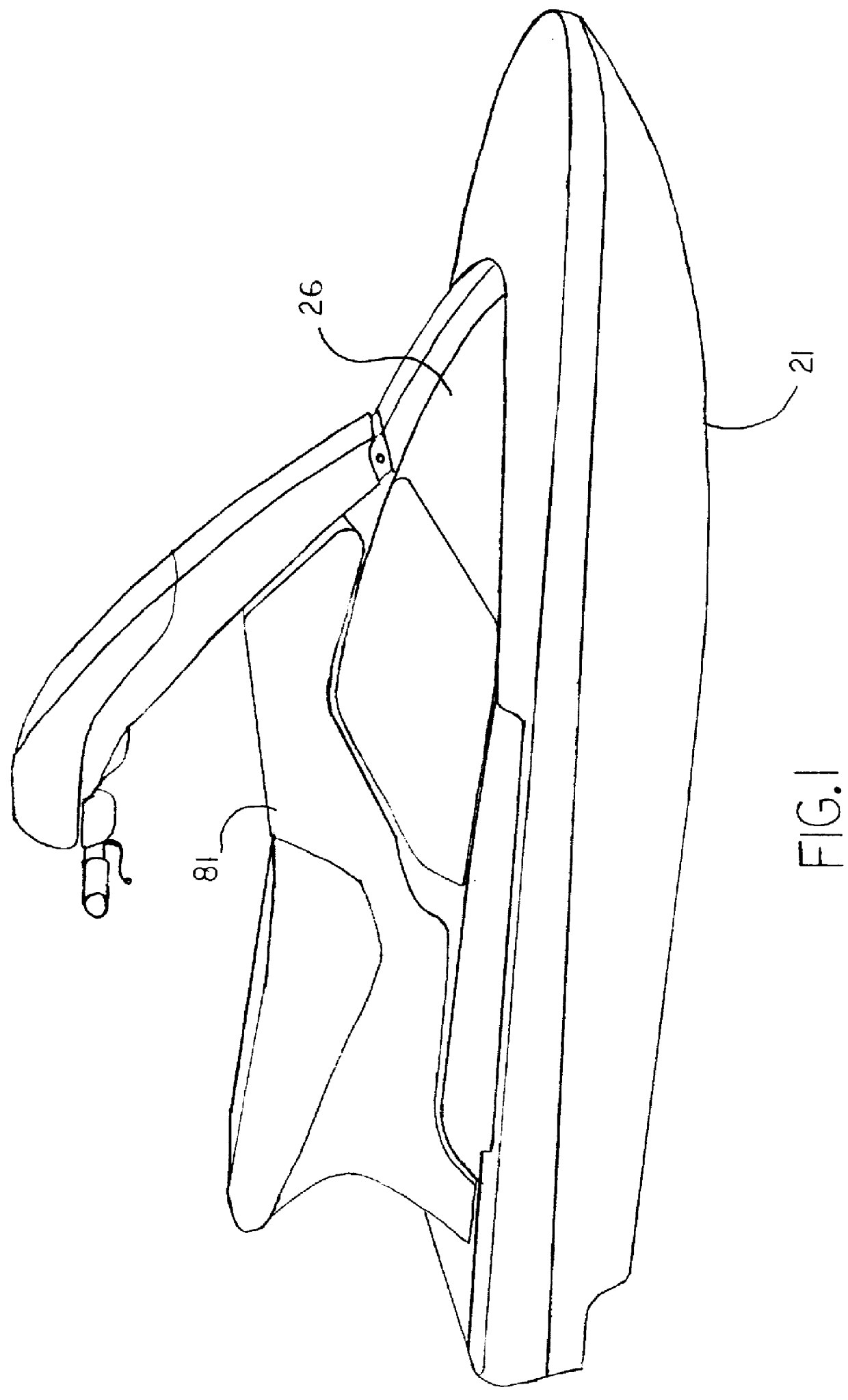

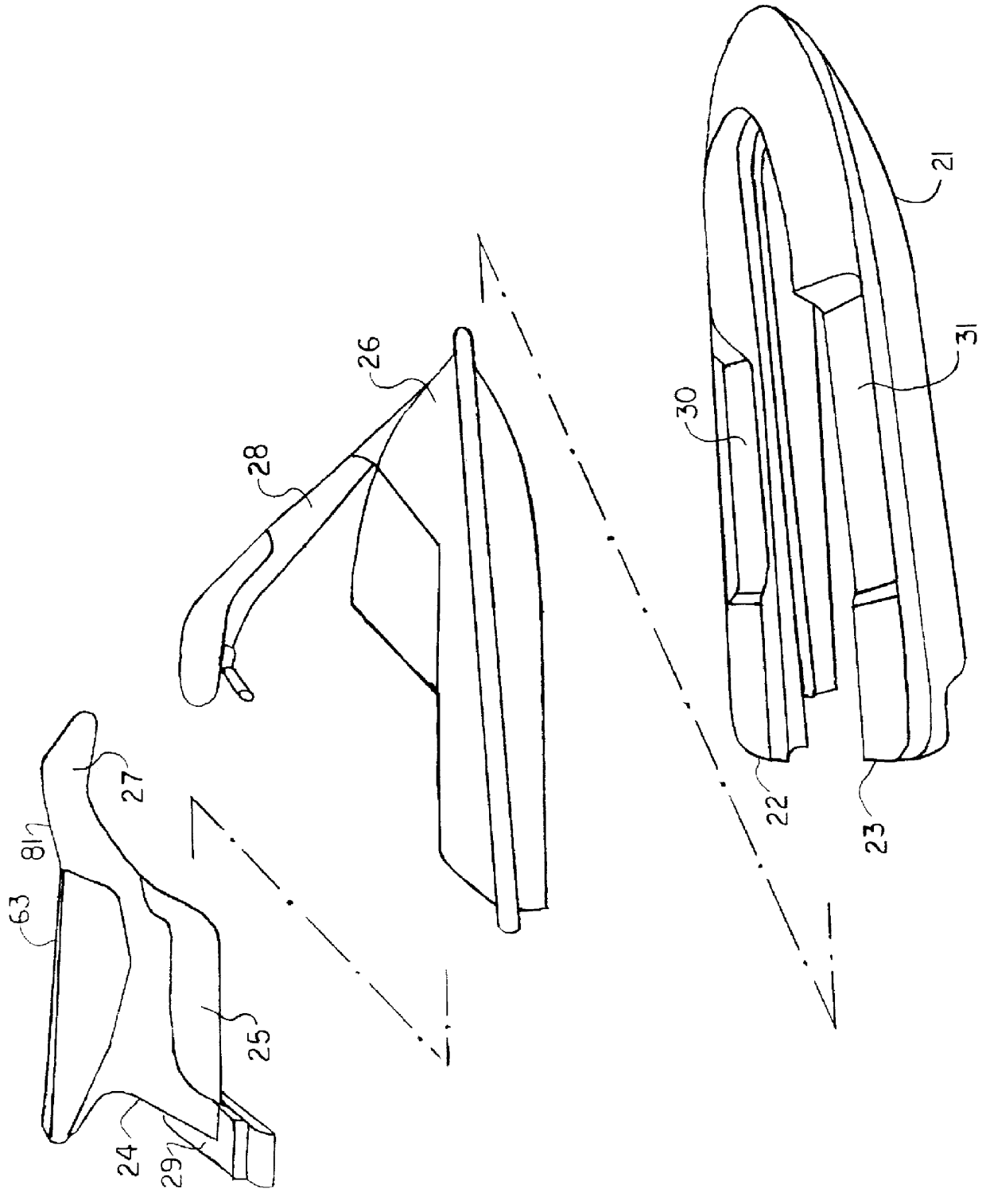

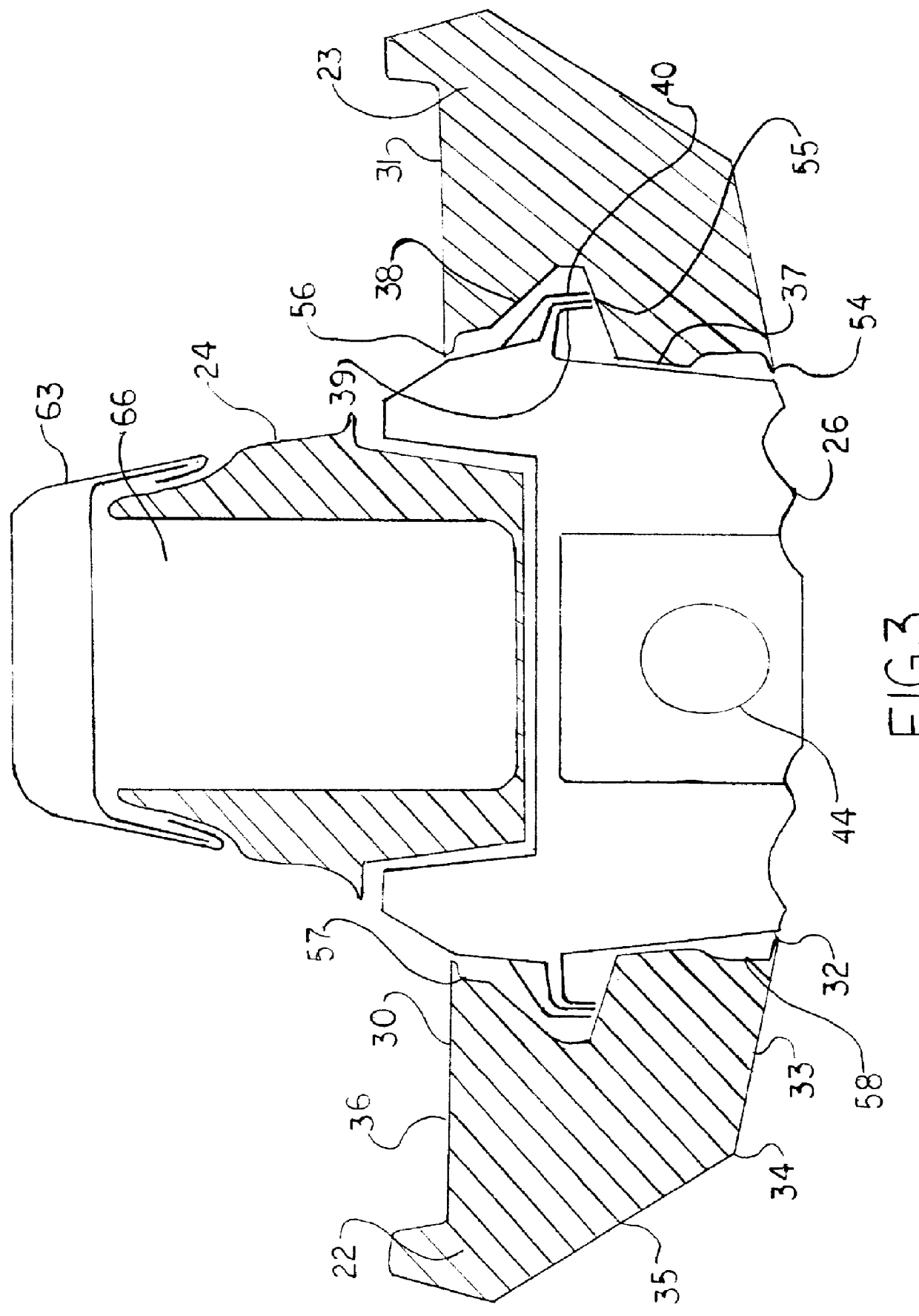

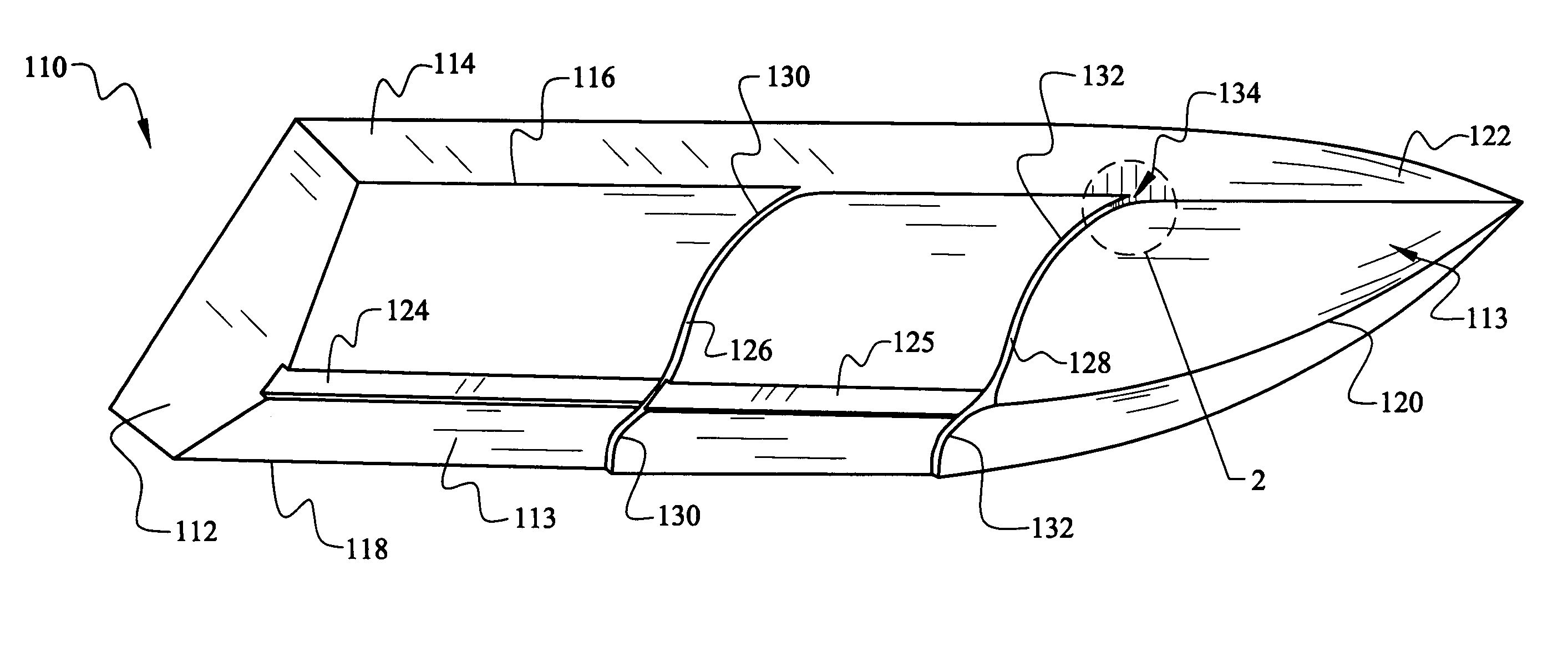

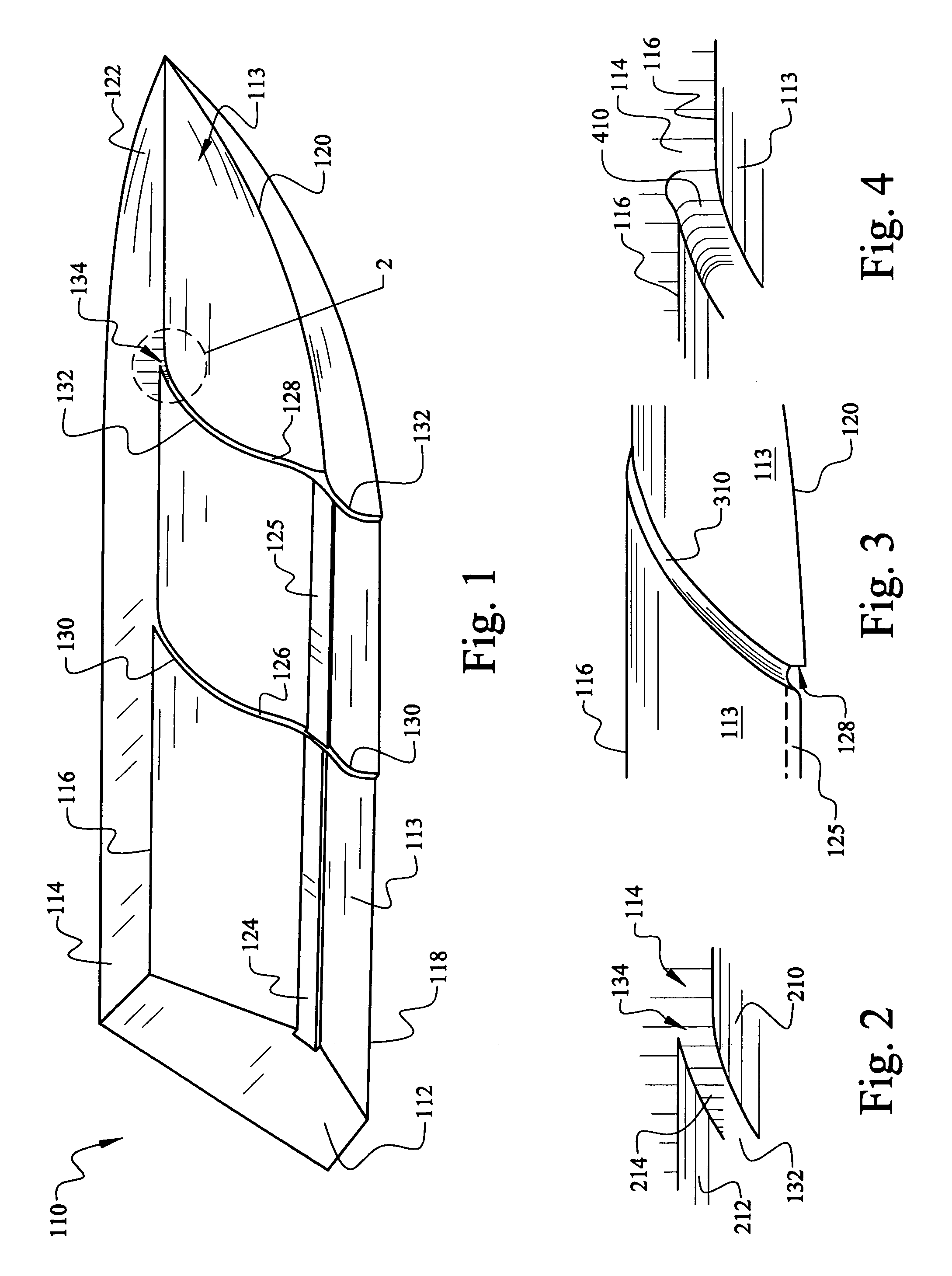

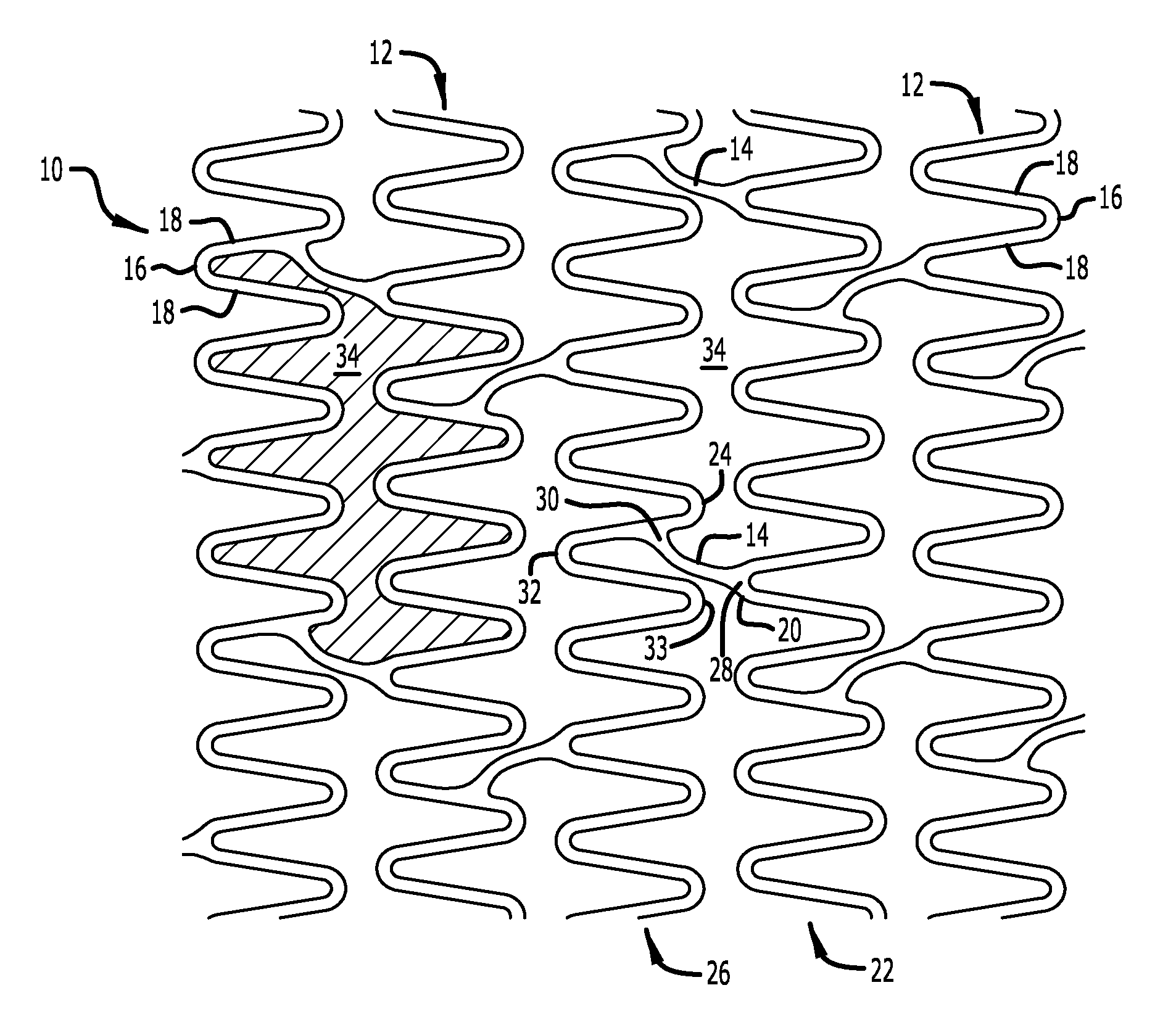

Kit for non-permanently converting a stand up PWC into a sit down

InactiveUS6135047AEasy to installIncrease buoyancyTowing/pushing equipmentMarine vessel transportationMarine engineeringBuoyancy

A hull and seat assembly configured to be easily installed, secured and operated on production stand up PWC. The hull assembly (21) increases buoyancy and stability sufficient for multi-rider sit down operation while maintaining peak performance geometry. The arrangement of the hull provides rider foot wells (30,31), allows it to be fabricated and installed in one piece, and provides unobstructed water jet flow and turning capability. The seat assembly (81) provides a tandem seat for multiple riders, positions the handle pole and provides a platform (29) that eases boarding from deep water. The seat assembly fills the stand up foot well and extends rear of the transom for increased longitudinal stability. Storage space is provided in both the hull (53) and seat assemblies (66). The connection strategy concurrently secures the hull (21), seat (81) and PWC (26) together with one releasable fastener (70) and is arranged to be fail safe.

Owner:MILLER SCOTT A

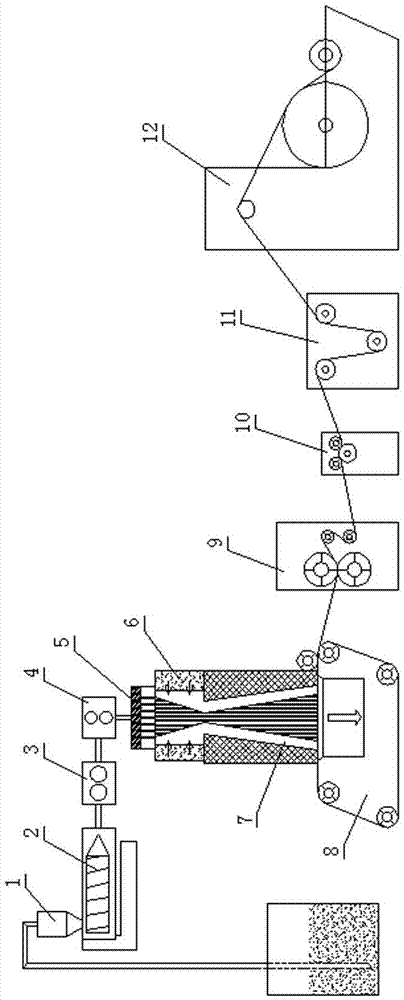

Method for producing non-woven cloud cotton fabric with spun-bonded method

ActiveCN107237048AWide variety of sourcesSource shortHeating/cooling textile fabricsConjugated synthetic polymer artificial filamentsCold airMolding machine

The invention provides a method for producing non-woven cloud cotton fabric with a spun-bonded method, and belongs to the technical field of non-woven fabric. The method comprises the steps of mixing and stirring low-melting-index raw materials; conveying stirred raw material to a screw rod through a feeding system to be extruded and melted to obtain hot melts; conducting spinning on the hot melts, and cooling spun silk with side cold air to obtain initial filaments; pulling the initial filaments, and obtaining fibers with a certain fineness; dividing the fibers and conducting lapping to obtain fiber nets; obtaining non-woven fabric after the fiber nets are hot-rolled; stretching the non-woven fabric several times by the speed difference between a rolling mill, a finishing machine and a winder, wherein stretched non-woven fabric materials are preheated through hot air and high temperature in the stretching process to make products fluffy and soft, and have transverse micro-elasticity, and then winding the stretched non-woven fabric materials to form the non-woven cloud cotton fabric after the materials are molded through a cooling molding machine. Through the adoption of the method for producing the non-woven cloud cotton fabric with the spun-bonded method, the production efficiency,, the production speed and the yield are high, the production process is simple, and the production is quickly and conveniently completed at a time.

Owner:山东恒鹏卫生用品有限公司

Airship pneumathode with alterable bulk

InactiveCN101157384ASimple structureAppropriate aerodynamic shapeGas-bag arrangementsRelative pressureSurgery

The invention relates to an airship balloon, the capability of the airship balloon is variable, and consists of a balloon (1), an inflation mouth (2) and a balloon telescopic device which can be used for stretching the balloon in axial direction. the balloon telescopic device is arranged in the balloon (1); the air outlet of the inflation mouth (2) is communicated with the inner cavity of the balloon (1); the invention has the advantages that due to the balloon telescopic device which can be used for stretching the balloon in axial direction, when the airship climbs up to high, and when the relative pressure in the balloon is increasing, the balloon telescopic device can shorten the balloon in axial direction, and the capacity in the balloon is enlarged accordingly to reduce the stress of the balloon wall, thereby achieving the purpose of preventing the balloon wall from being damaged; at the same time, the aerodynamic appearance of the balloon which is in proper stiffness, and can be kept to help fly.

Owner:周雷

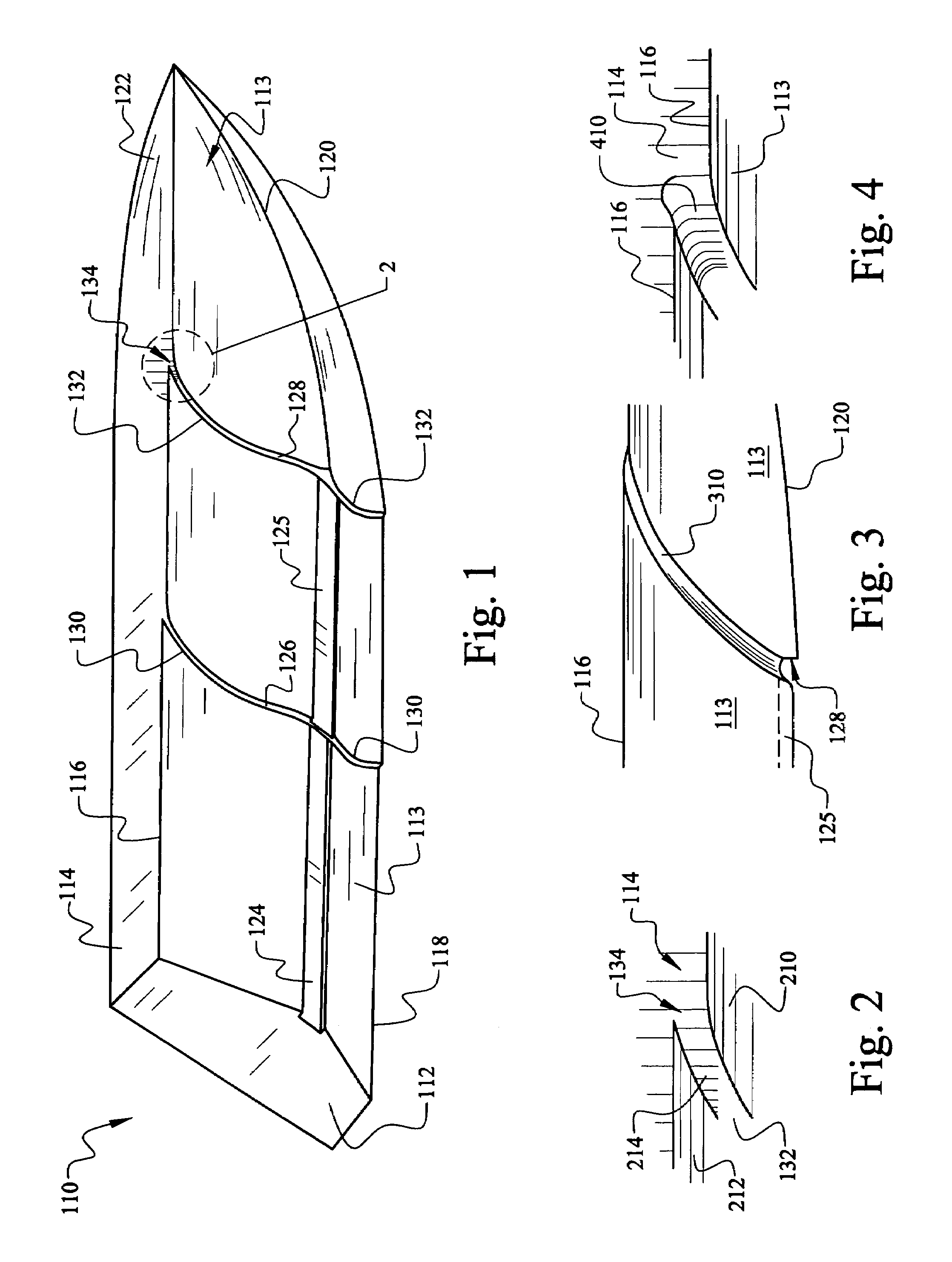

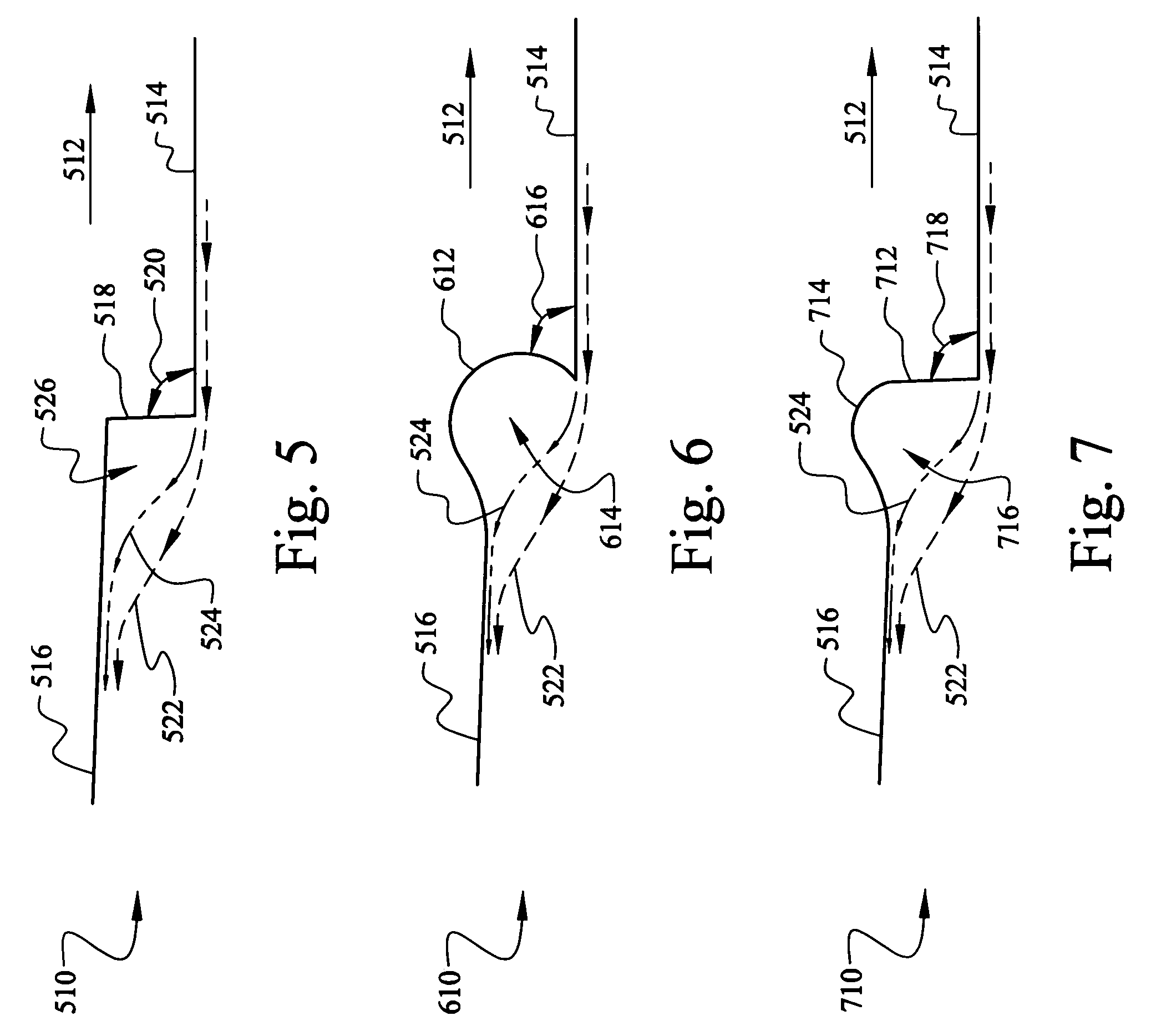

Slot-V hull system

InactiveUS7677192B2Good draftIncreased longitudinal stabilityFloating buildingsHydrodynamic/hydrostatic featuresMarine engineeringLandform

Owner:SCISM RANDY +1

Slot-V hull system

InactiveUS20070245944A1Reduction in overall vessel costLess demand in propulsion powerFloating buildingsHydrodynamic/hydrostatic featuresMarine engineeringLandform

The present invention comprises systems and methods of utilizing hull arrangements that combine aerodynamic and hydrodynamic effects to provide marine vessels with broader ranges of performance capabilities. The combination hull arrangements variously combine V-hulls, slot aspects, topographic features, and other hull characteristics that enable a vessel to retain the primary performance benefits of conventional V-hulls and achieve assorted improvements. Embodiments of the slot-V hull system employ specifically shaped hull characteristics to influence the manners in which water, air, and air / water spray mixtures interact with the vessel's hull. One principal operative effect can enable a vessel with the slot-V hull system to achieve a planing attitude more rapidly and efficiently than a standard V-hull.

Owner:SCISM RANDY +1

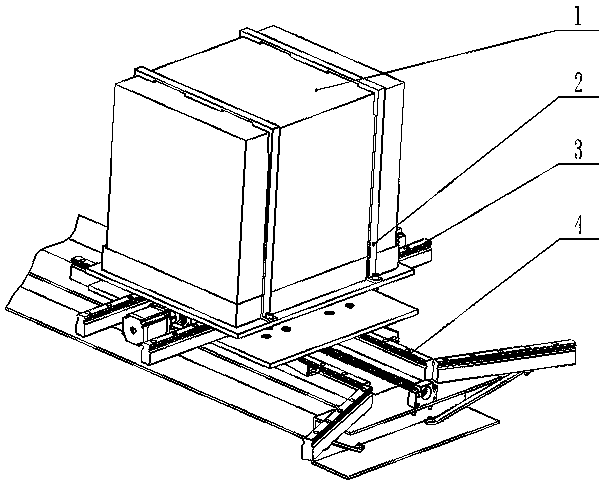

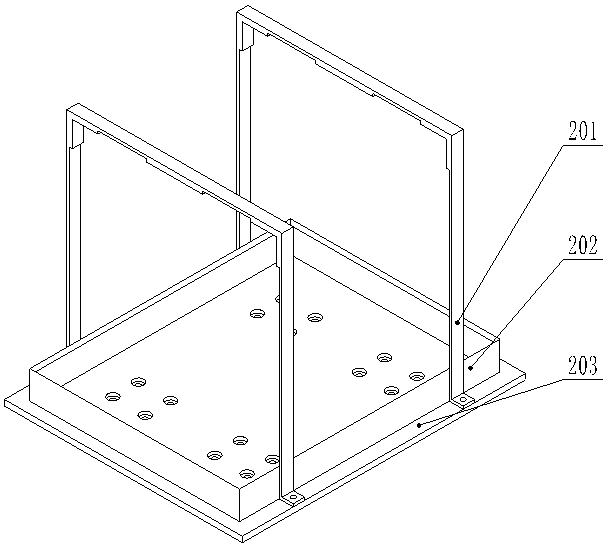

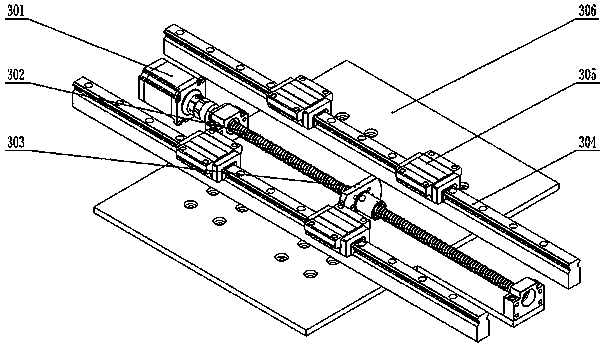

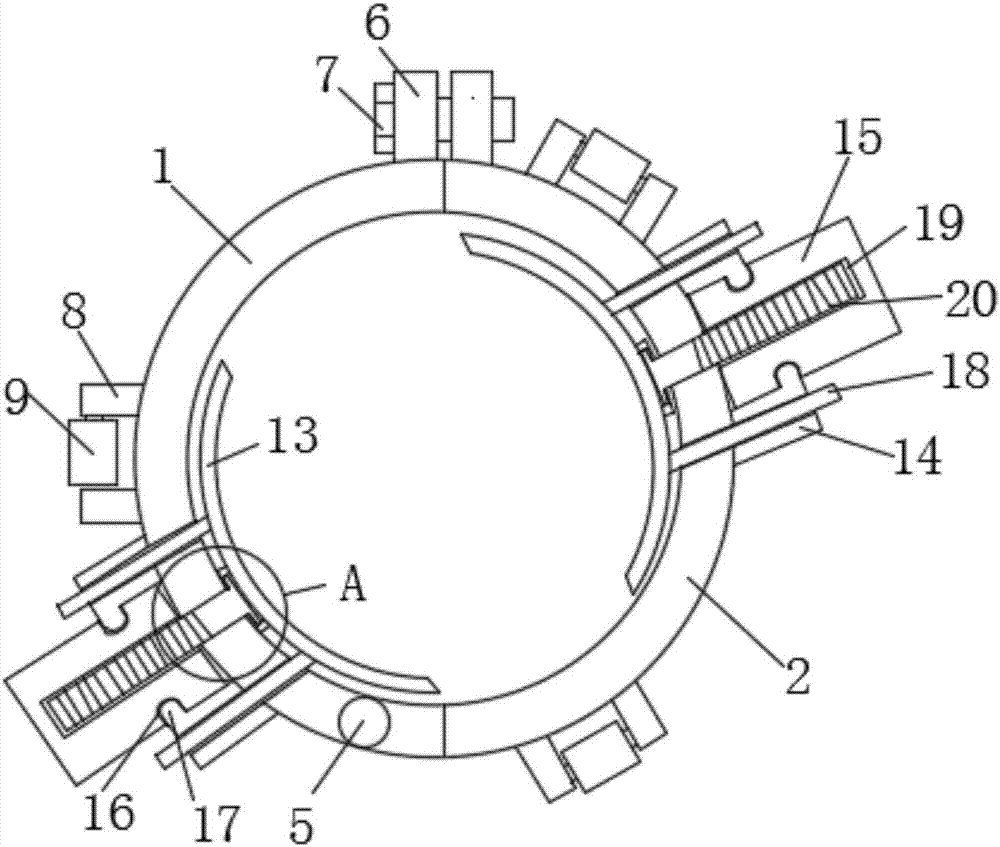

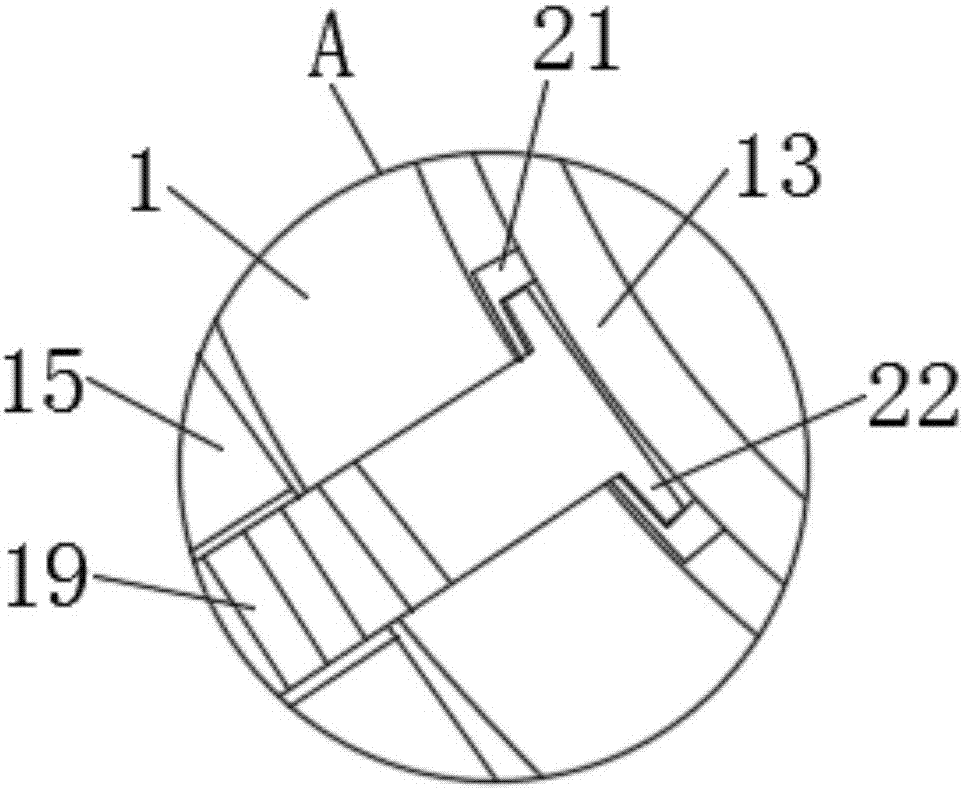

Electric tractor gravity center adjusting device

PendingCN110254202AReduce lossExtended service lifeElectric propulsion mountingPower batteryEngineering

The invention provides an electric tractor gravity center adjusting device which comprises a power battery, a power battery bracket, a gravity center horizontal-adjusting mechanism and a gravity center longitudinal-adjusting mechanism. The power battery is used for providing gravity required for gravity center adjusting; the power battery bracket is used for installing and fixing the power battery and providing anti-collision protection for the power battery; the gravity center horizontal-adjusting mechanism located below the power battery bracket is used for adjusting a gravity center of an electric tractor in a horizontal direction; and the gravity center longitudinal-adjusting mechanism located below the gravity center horizontal-adjusting mechanism is used for adjusting the gravity center of the electric tractor in a longitudinal direction. According to the electric tractor gravity center adjusting device provided by the invention, the characteristic of large weight of an electric tractor battery can be fully utilized, gravity center adjusting can be carried out in the horizontal direction and the longitudinal direction without extraly adding balancing weight blocks, the gravity center adjusting range is wide, the precision is high, the tractive efficiency and the stability of the electric tractor can be improved, the energy can be saved, and the environment can be protected.

Owner:NORTHWEST A & F UNIV

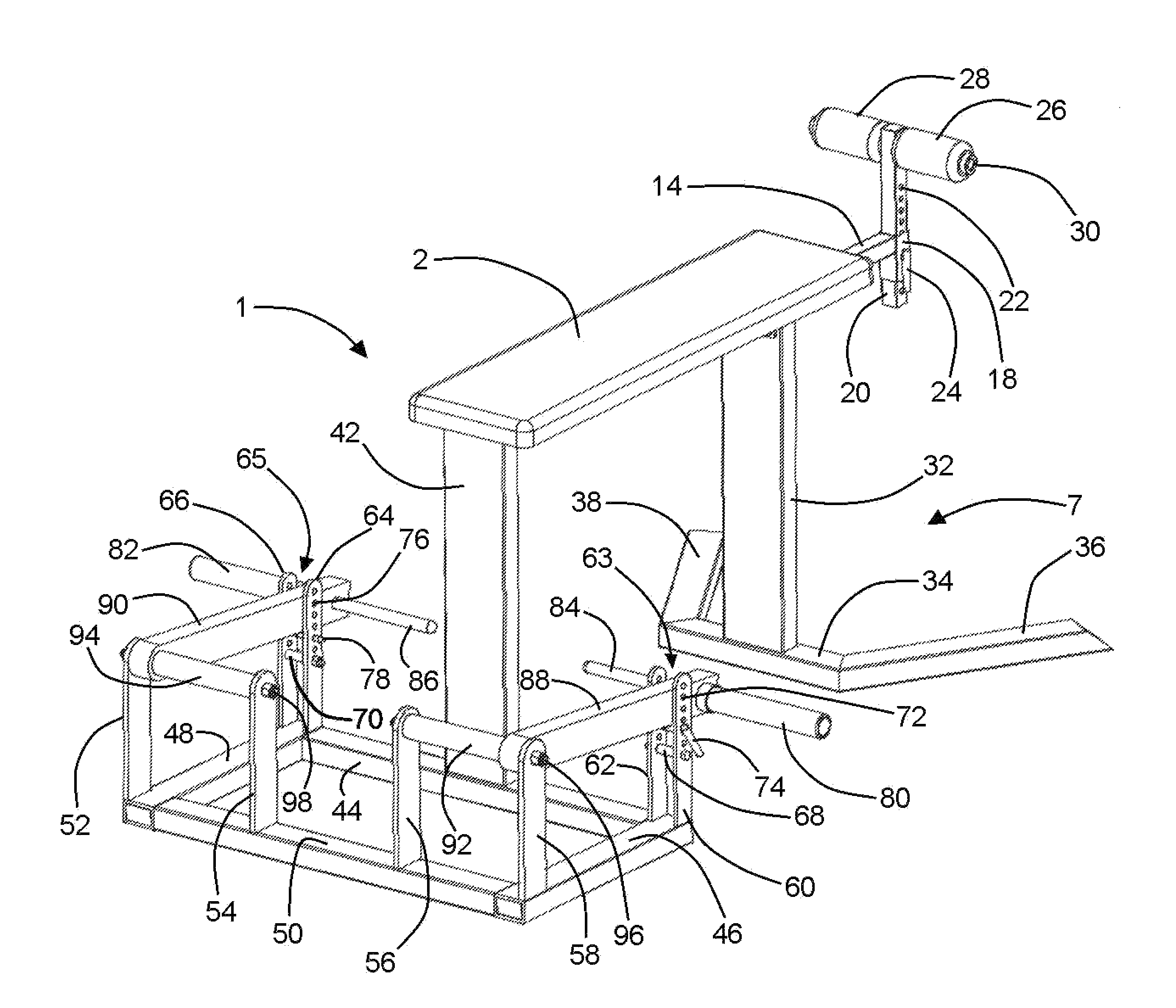

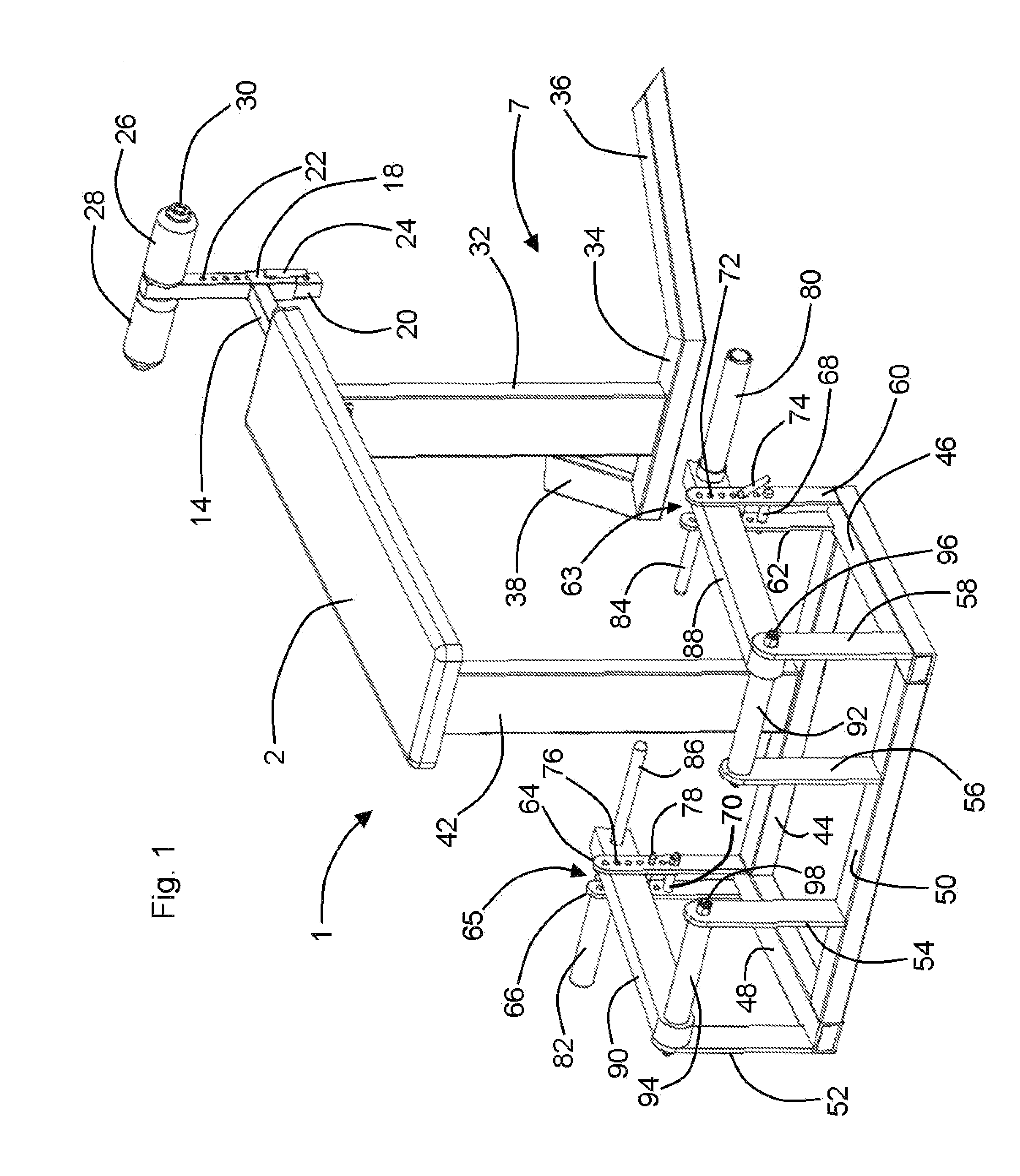

Exercise machine

An exercise machine having a bench top having a right side, a left side, a forward end, a rearward end, and having an upper support surface; the exercise machine further having a rear leg fixedly attached to and extending downwardly from the bench top's rearward end; the exercise machine further having a “J” leg having a stem section and a tail section, the “J” leg's stem section having an upper end fixedly attached to the bench top's forward end, the “J” leg's tail section having a distal end; the exercise machine further having at least a first arm, the at least first arm having a proximal end and a distal end, the proximal end of the at least first arm being pivotally attached to the distal end of the “J” leg's tail section; the exercise machine further having a first handle fixedly attached to the at least first arm's distal end; and the exercise machine further having a first free weight bar fixedly attached to the at least first arm's distal end.

Owner:HALL ANTONY A +1

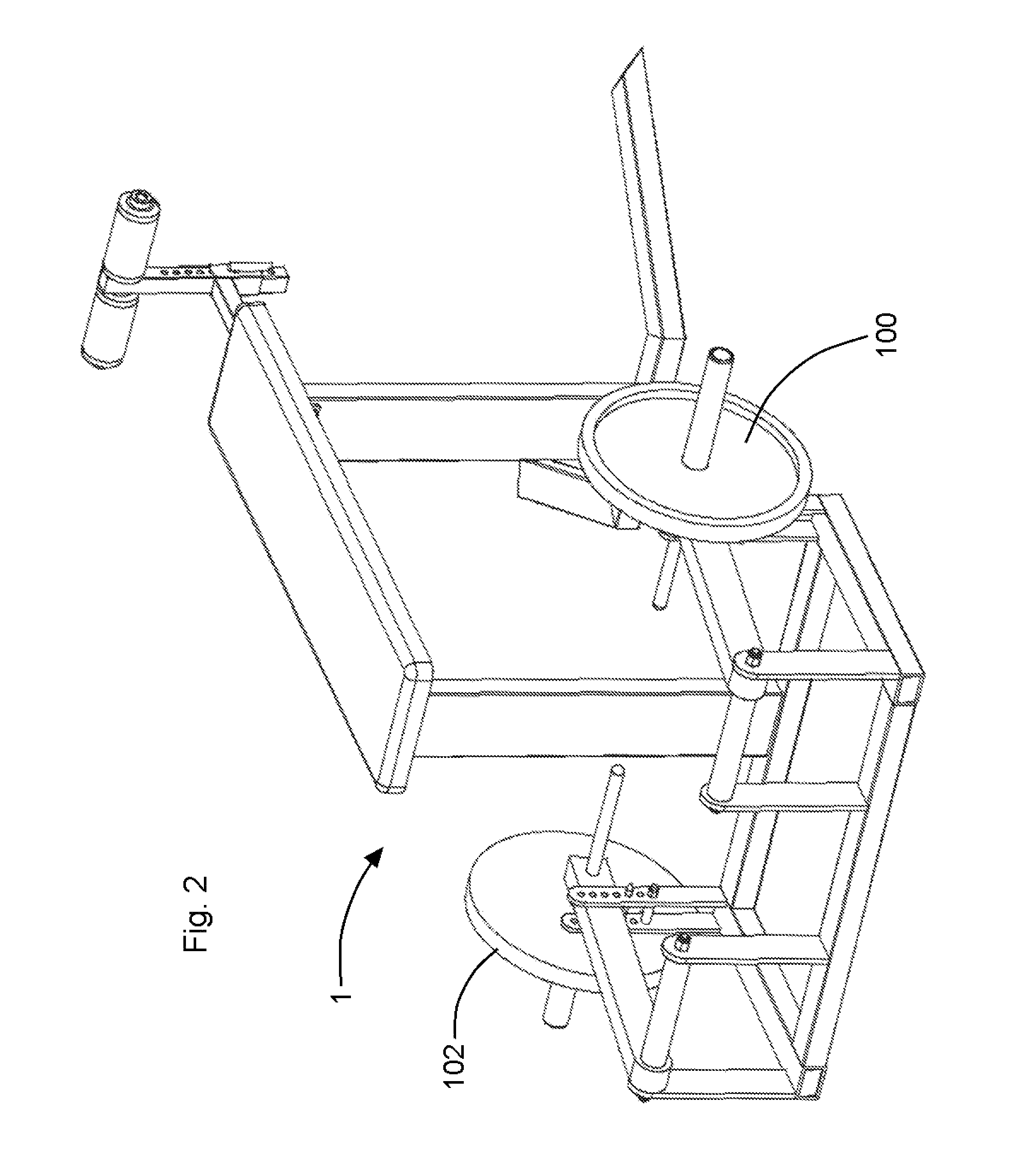

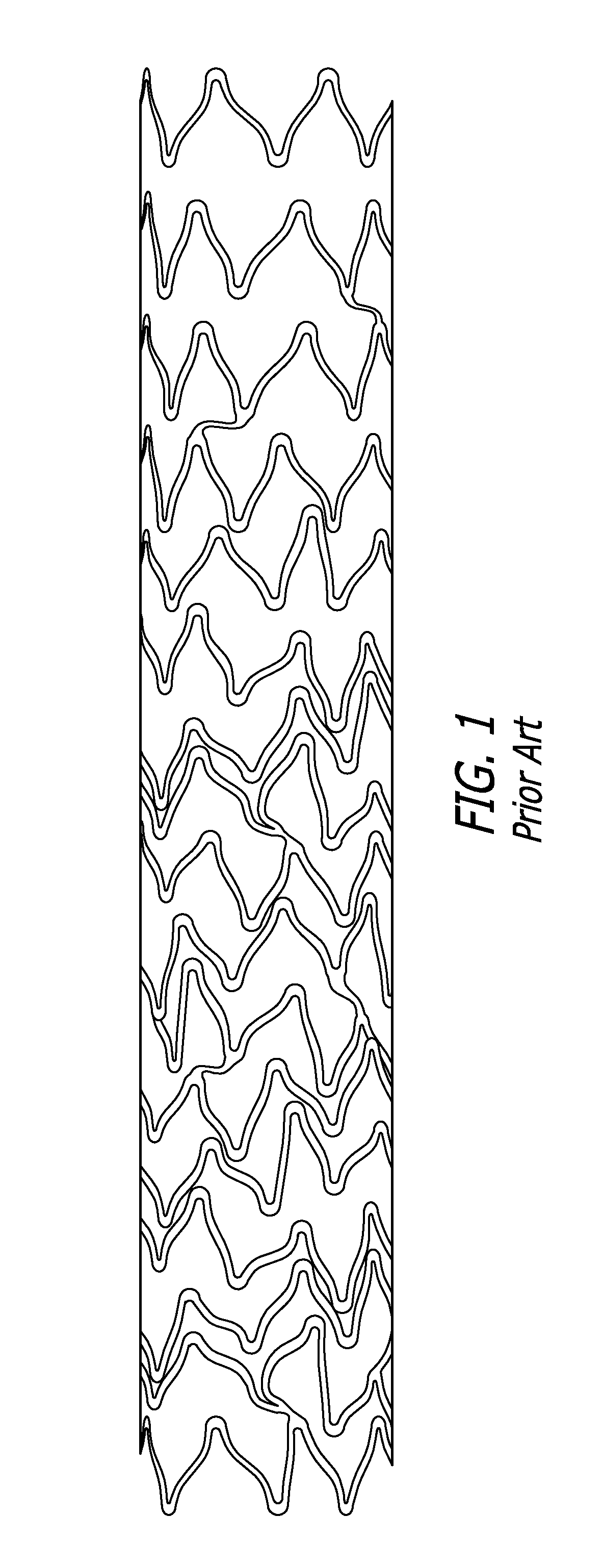

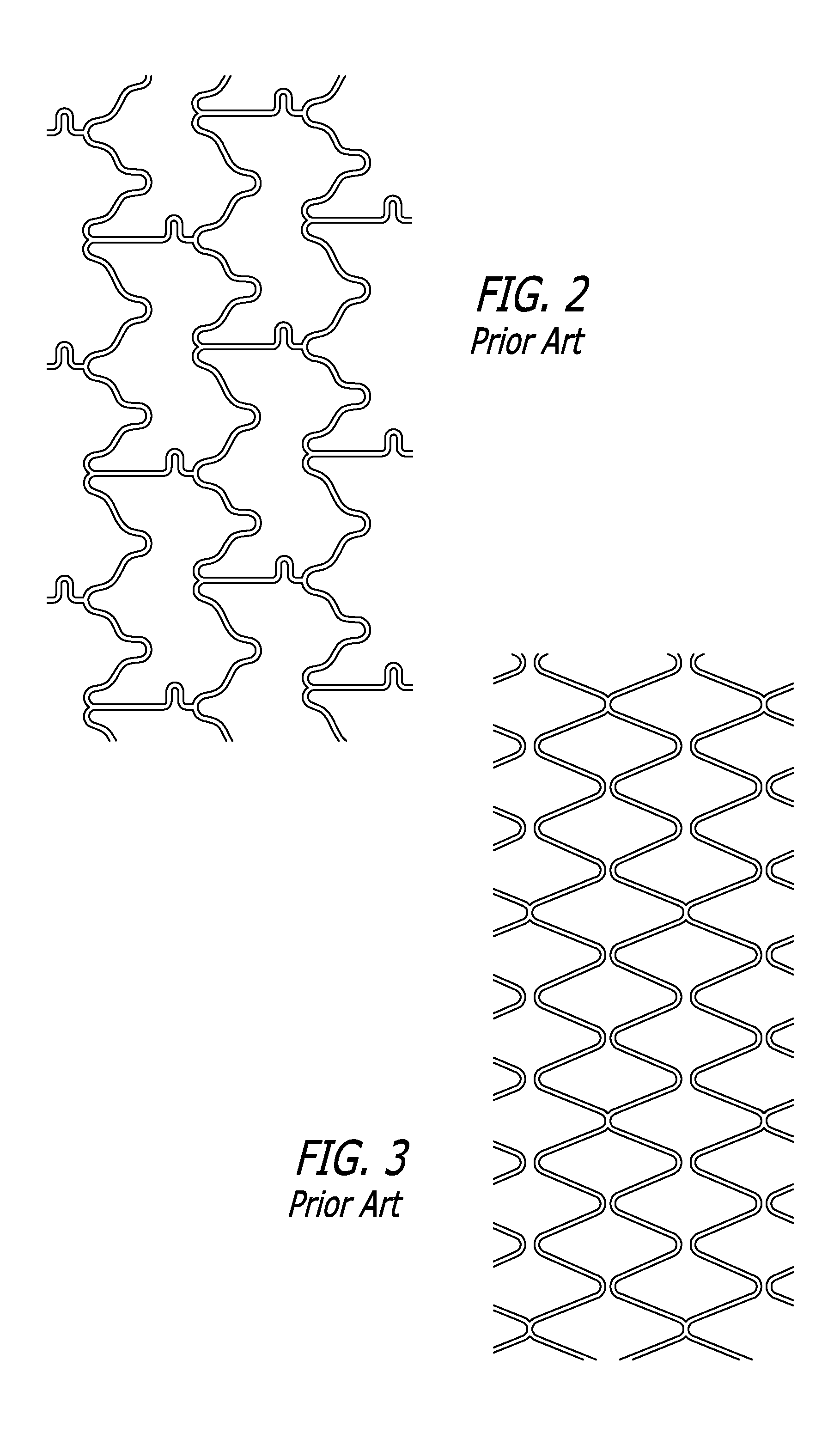

Offset peak-to-peak stent pattern

InactiveUS20130123905A1Low profilePrevent movementStentsBlood vesselsCoronary arteriesInsertion stent

The invention is directed to an expandable stent for implanting in a body lumen, such as a coronary artery, peripheral artery, or other body lumen. The invention provides for an intravascular stent having a plurality of cylindrical rings connected by links. The links between adjacent rings provide axial strength when subjected to longitudinal compressive forces.

Owner:ABBOTT CARDIOVASCULAR

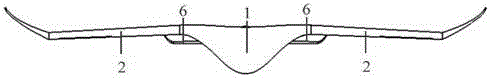

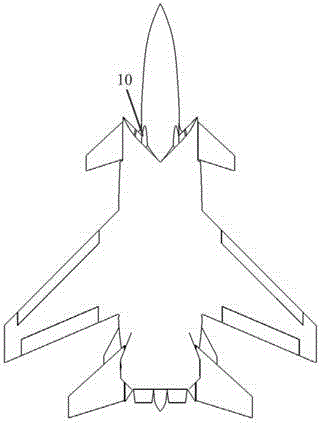

Pneumatic layout of dual flying wings of UAV (Unmanned Aerial Vehicle)

The invention relates to a pneumatic layout of dual flying wings of a UAV (Unmanned Aerial Vehicle). The pneumatic layout is characterized by comprising a pneumatic layout of a blended wing body flying wing, a layout of installing a turbofan engine above the rear section of the blended wing body flying wing and a pneumatic layout of installing a stabilator at two sides of a nacelle on the outer wall of the turbofan engine, wherein the blended wing body flying wing with a high lift-to-drag ratio is formed by a fuselage, wings, wingtip winglets and direction ailerons together; the stabilator which is used for providing a positive lifting force during flight trimming of the UAV is formed by horizontal tails and horizontal tail winglets, and the dual flying wings are formed by the blended wing body flying wing and the stabilator together. According to the pneumatic layout of the dual flying wings of the UAV, disclosed by the invention, the UAV has high lift-to-drag ratio, good operability and high stability, and the pneumatic layout has the advantage of good stealth performance.

Owner:NAVAL AERONAUTICAL & ASTRONAUTICAL UNIV PLA

Anti-splash single-hull planing boat

InactiveCN102923245AImprove lateral stabilityReduce rollingOutboard propulsion unitsVessel movement reduction by foilsAcute angleBilge

The invention discloses an anti-splash single-hull planing boat which comprises a boat body, a propelling device and a composite stabilizing wing, wherein the composite stabilizing wing is arranged at the bottom of a stem; the composite stabilizing wing comprises a vertical stabilizing wing and a horizontal stabilizing wing; downwardly inclined longitudinal anti-splash bodies are symmetrically arranged on two sides of the boat body from the front bilge part of a boat middle part to a stem bilge part; the widths of the longitudinal anti-splash bodies are gradually narrowed from the front part of the boat middle part to the stem; the head part of the boat body is gradually transitional from a shallow V-shaped cross section with an acute angle between the two side surfaces to the shallow V-shaped cross section with an obtuse angle between two side surfaces of the front part of the boat middle part; and the front part of the boat middle part is gradually transitional from a shallow V-shaped cross section with an obtuse angle between two side surfaces to a horizontal cross section, on which V-shaped edge strips extend downwards from two sides of the bottom of the stem, or an inverted shallow V-shaped cross section with an obtuse angle between two side surfaces. According to the invention, the splashing of lateral water flow of the sliding surface of the boat body can be effectively prevented, so that the rapidness, transverse stability, longitudinal stability, directional stability, seakeeping quality and so on are greatly improved, convenience for mounting propellers with larger diameters is achieved, and the propelling efficiency is increased.

Owner:JIANGSU UNIV OF SCI & TECH

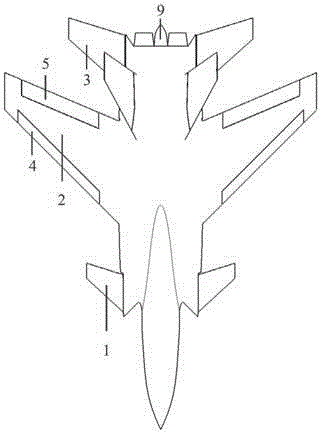

Aerodynamic configuration of three-surface aircraft

ActiveCN106043668AImprove the lift-to-drag ratioEasy to liftAircraft stabilisationHeat reducing structuresAviationJet aeroplane

The invention belongs to aircraft design in the technical field of aviation, relates to aerodynamic configuration of a three-surface aircraft, and solves the problem that the RCS of the three-surface aircraft with high aerodynamic performance is too large. The aerodynamic configuration comprises the aerodynamic configuration of an aircraft body, wings, canard wings, a horizontal tail and vertical tails and is characterized in that the wings, the canard wings and the horizontal tail form three surfaces for bearing aerodynamic force, the aircraft body has stealth performance, the full-flight-simulator double vertical tails incline outwardly, and double ventral fins incline outwardly. The aerodynamic configuration has the advantages that the aircraft using the aerodynamic configuration is high in lift-drag ratio, good in operability, good in stability and good in stealth performance.

Owner:NAVAL AVIATION UNIV

Firearm ammunition having improved flight and impact characteristics

InactiveUS20070089628A1Increased longitudinal stabilityAmmunition projectilesProjectilesLeading edgeTrailing edge

A novel bullet adapted to be discharged from a firearm at least includes: a leading edged portion; and a trailing edge portion coupled to the leading edge portion, the trailing edge portion comprising a base and spiral fins, the spiral fins adapted to channel the boundary layer during flight of the bullet, and increase longitudinal stability.

Owner:ELDER STEVEN MAX

Paddle wheel propulsion hovercraft

InactiveCN108515958AImprove driving efficiencyImprove maneuverabilityAmphibious vehiclesPropulsive elements of rotary typePropellerOperability

The invention discloses a paddle wheel propulsion hovercraft. The hovercraft comprises a hovercraft body, a power system, an air-cushion system and a propulsion system, wherein the air-cushion systemcomprises air-cushion fans and apron boards, the propulsion system comprises a pair of paddle wheel propellers, the paddle wheel propellers are symmetrically arranged on transverse two sides in the longitudinal middle of the bottom of the hover craft body, the paddle wheel propellers are arranged on the inner sides of the apron boards, the driving directions of the paddle wheel propellers are thesame as the driving direction of the hovercraft body, the lower edges of the paddle wheel propellers are lower than the lower edges of the apron boards, the paddle wheel propellers are arranged at thebottom of the hovercraft body through a lifting supporting frame, and the heights of the paddle wheel propellers are adjustable. Compared with a traditional full air-cushion hovercraft, the paddle wheel propulsion hovercraft is higher in propelling efficiency, smaller in noise and better in operability and stability.

Owner:SHANGHAI LIZARD BOAD TECH CO LTD

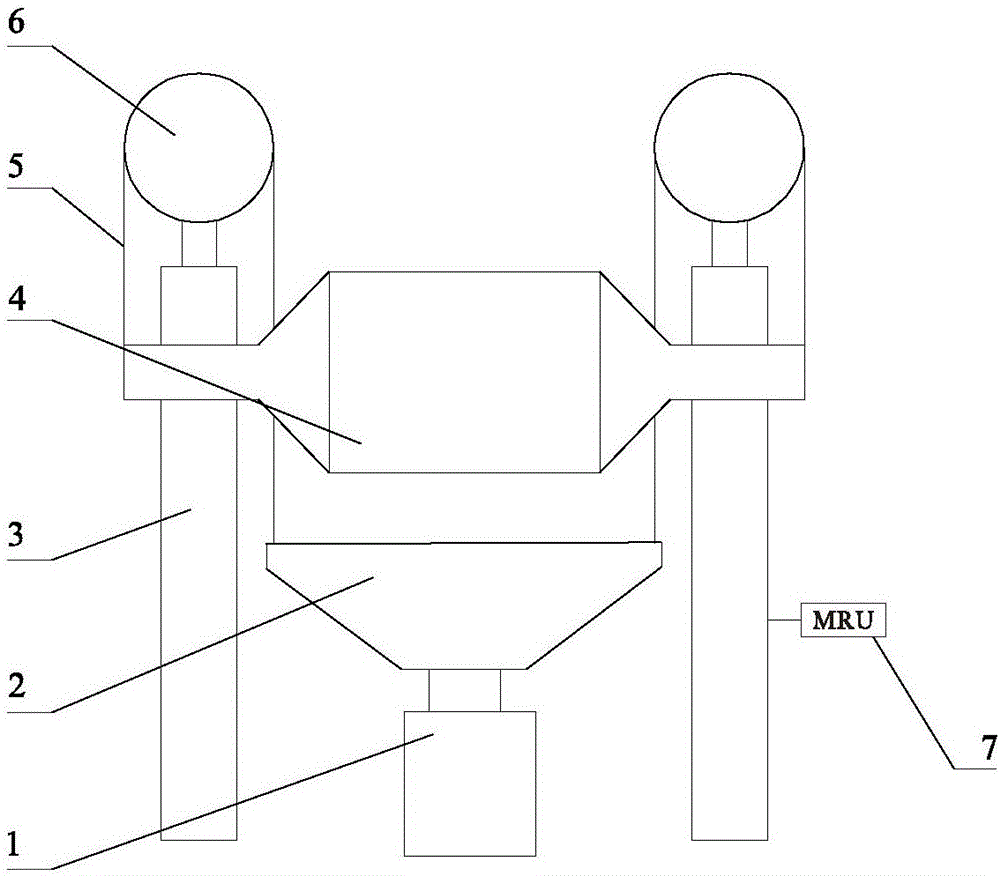

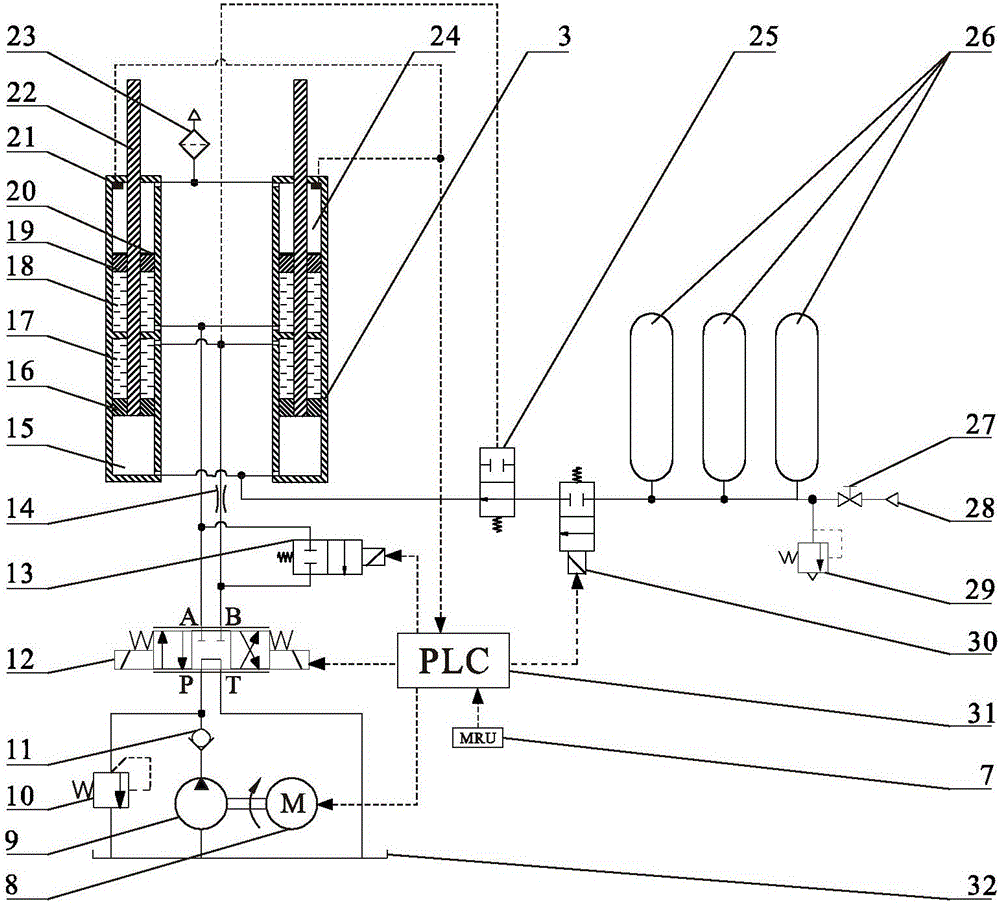

Heave compensation device of hook block assembly for marine floating drilling

ActiveCN106321534AOvercome frictionOvercome system inertiaDrilling rodsServomotorsLoop controlHydraulic pump

The invention discloses a heave compensation device of a hook block assembly for marine floating drilling. Double piston type hydraulic cylinders are taken as compensation hydraulic cylinders, and high pressure cylinders are connected to high pressure air cavities of the double piston type hydraulic cylinders, so that a passive compensation force is provided to piston rods; meanwhile, hydraulic oil output by a high pressure pump is introduced to upper and lower high pressure oil cavities of the double piston type hydraulic cylinders through a proportional direction valve, so that an active compensation force, the magnitude and direction of which can be controlled, is provided to the piston rods, and the passive and active compensation forces drive a drill jointly to load to realize a heave compensation function. A PLC drives the piston rods to realize the heave compensation function through displacement closed-loop control according to a platform heave movement signal detected by a movement reference unit and a compensation hydraulic cylinder piston rod movement signal detected by a laser range finder. According to the device disclosed by the invention, the compensation control precision can be improved, the system energy consumption and manufacturing cost can be reduced and the service life of the compensation hydraulic cylinder can be prolonged.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

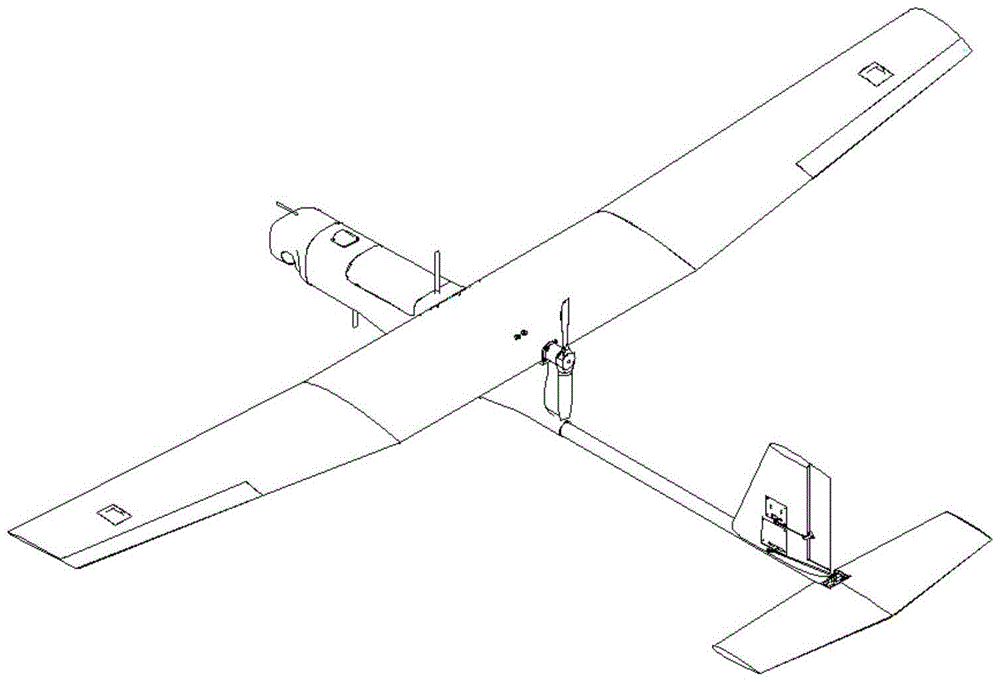

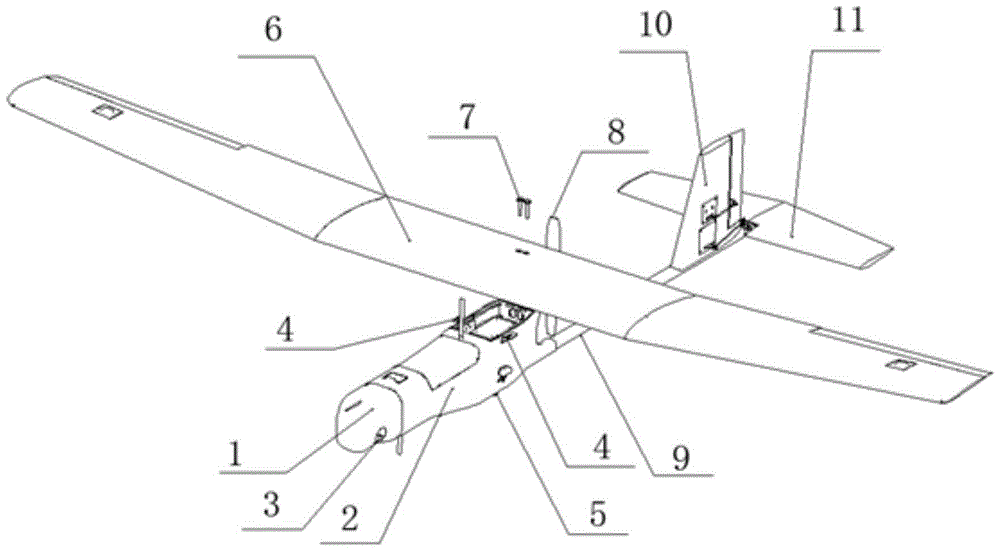

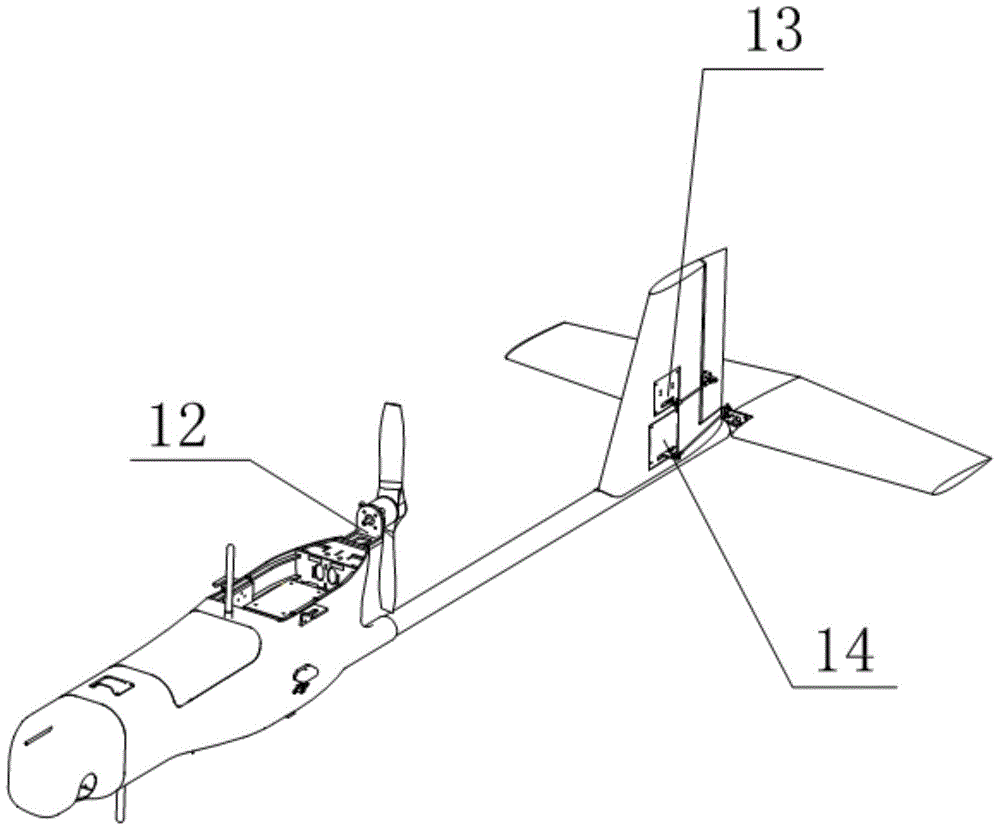

General layout of unmanned aerial vehicle capable of taking off with catapult assisted and being recovered by bumping net

InactiveCN105667790AConducive to collision net recoveryAvoid damageAircraftsUncrewed vehiclePropeller

The invention discloses the general layout of an unmanned aerial vehicle capable of taking off with catapult assisted and being recovered by bumping a net. The unmanned aerial vehicle comprises a vehicle head, a vehicle body, a wing, a propeller, a tail pipe, a horizontal tail and a vertical tail. The abdomen of the vehicle body is a plane, the wing is mounted on the upper portion of the vehicle body, and the tail pipe and the propeller are mounted at the tail of the vehicle body. The propeller is mounted at the upper end of the tail of the vehicle body, the tail pipe is mounted at the lower end of the tail of the vehicle body, and the bottom of the tail pipe is flush with the abdomen plane of the vehicle body. A paddle closest to the tail pipe is kept a distance from the tail pipe when the paddles of the propeller are located in the vertical direction. A catapult hanging point for catapult-assisted taking off of the unmanned aerial vehicle is arranged on the abdomen of the vehicle body. The vehicle body and the wing are directly connected in a detachable mode, the vehicle body and the tail pipe are directly connected in a detachable mode, and the tail pipe and the horizontal tail are directly connected in a detachable mode. The unmanned aerial vehicle has the characteristics of being capable of being conveniently recovered by bumping the net, convenient to assemble and disassemble, high in pneumatic efficiency and the like.

Owner:NAT UNIV OF DEFENSE TECH

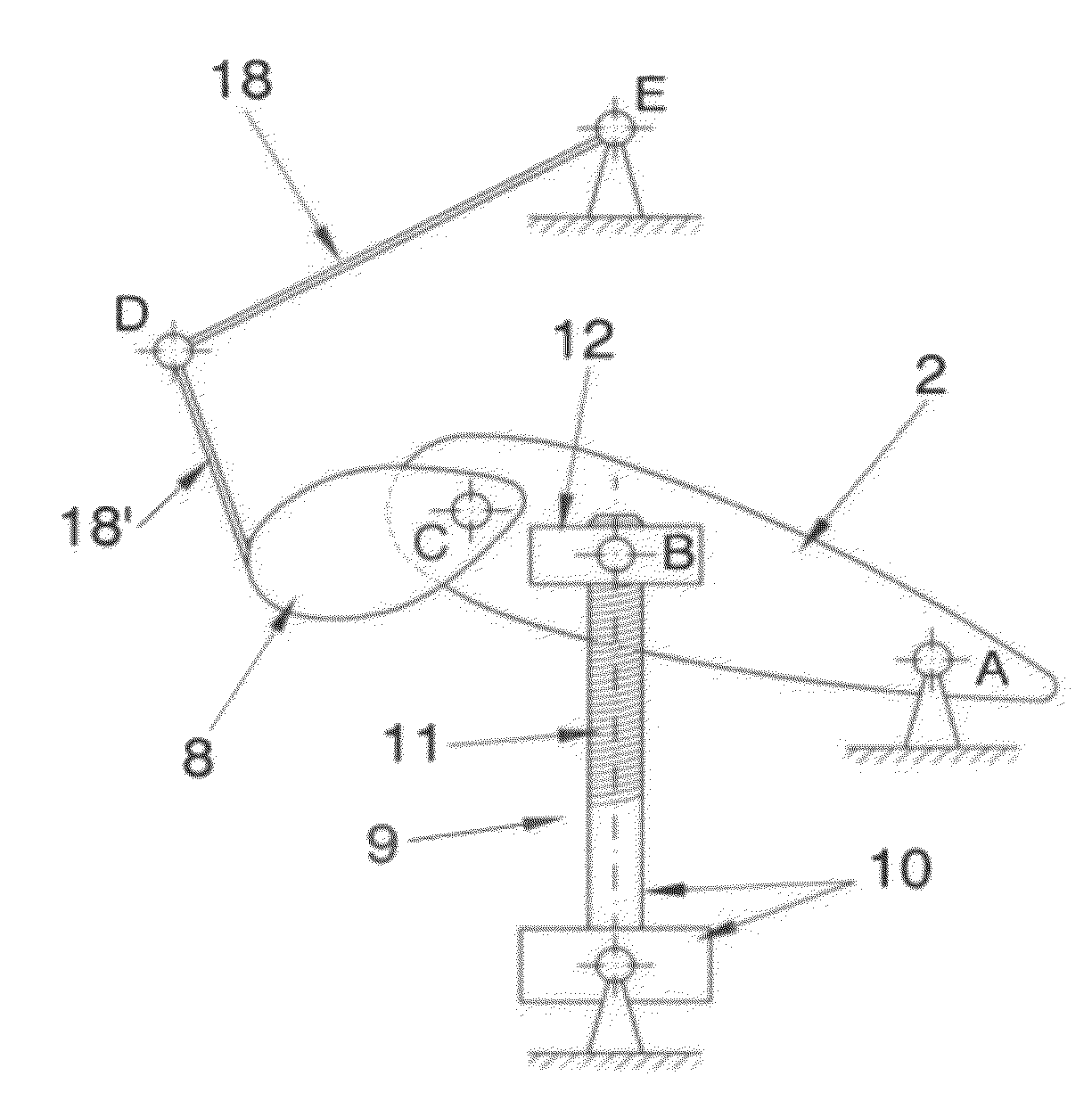

System for increasing controllability for an aircraft

ActiveUS20120138738A1Reducing weight and aerodynamic dragReduce design sizeAircraft stabilisationWithout power ampliicationAirplaneEngineering

The system includes deflection transmission means (16) to provide a deflection position of the high-lift device (8) for each setting angle position of an adjustable HTP (2). Preferably, the deflection transmission means (18,20,23) comprise essentially of a mechanical linkage connected between the high-lift device (8) and the aircraft (1).

Owner:AIRBUS OPERATIONS SL

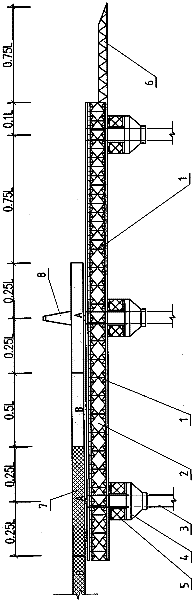

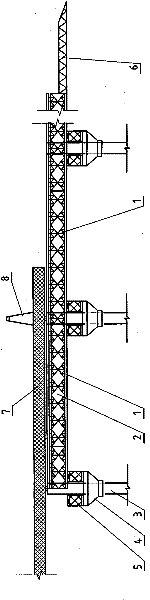

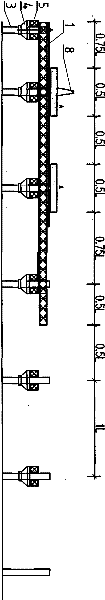

Method for block-by-block casting of concrete continuous beam bridge by using military truss shift mould

InactiveCN102206934ALight weightEasy to assemble and disassembleBridge erection/assemblyBridge materialsContinuous beamPre stress

The invention relates to a method for block-by-block casting of a concrete continuous beam bridge by using a military truss shift mould. The method is characterized by comprising the following steps of: firstly, dividing a full-span concrete continuous beam with span of L into two segmented box girders, casting the segmented box girder A located on a bridge pier and tensioning the prestress on the upper edge of the segmented box girder A; secondly, transferring withdrawn templates to the segmented box girder B located at the middle span and pouring after the segmented box girder A is cast completely, tensioning the linkage prestress of the segmented box girder A and the segmented box girder B and the prestress on the lower edge of the segmented box girder B after the strength is achieved, finally, transferring the withdrawn templates to the segmented box girder A of the next span to cast. The cross section of the concrete continuous beam can be of a single-box single-chamber type, a single-box two-chamber type, a single-box three-chamber type, a single-box four-chamber type, a single-box fifth-chamber type or a single-box six-chamber type; the bridge pier adopts a non-cover beam column structure comprising a single-column bridge pier, a dual-column bridge pier or a three-column bridge pier. Due to the adoption of the method for block-by-block casting of the concrete continuous beam bridge by using the military truss shift mould, only one set of military truss beam construction equipment with light weight, convenience in mounting / dismounting and good universality is used in construction, high construction speed and a short construction period are realized, and the majority of the members can be used repeatedly, so that good quality, cost reduction and investment saving are realized.

Owner:COMM DESIGN INST CO LTD OF JIANGXI PROV

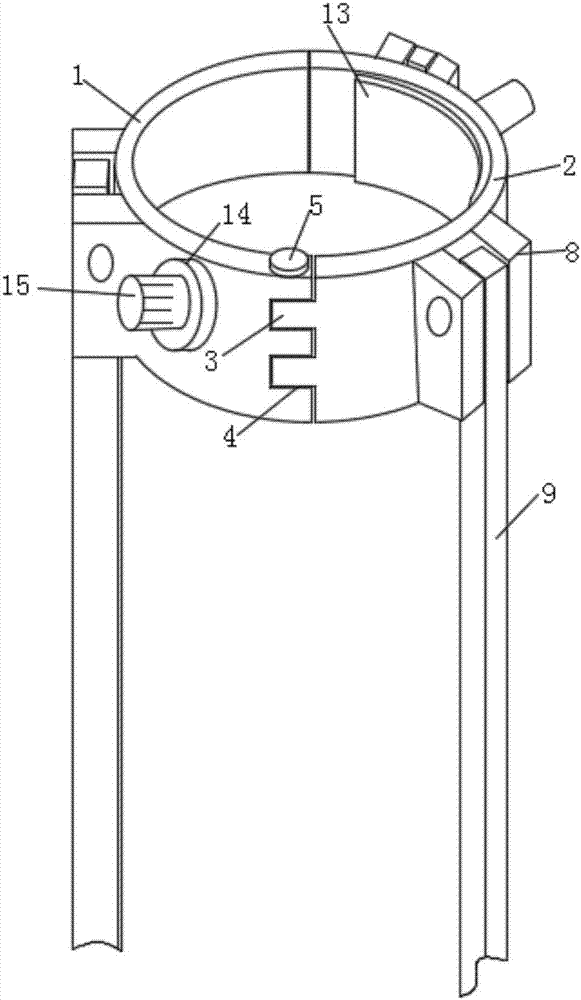

Easy-to-adjust stable support device for garden trees

The invention discloses an easy-to-adjust stable support device for garden trees. The easy-to-adjust stable support device comprises a retainer ring which is formed by a left half retainer ring body and a right half retainer ring body, the tail end of the left half retainer ring body is fixedly connected with the right half retainer ring body through a bolt, a support rod is movably hinged in limit plates, a flat pedal is horizontally and fixedly mounted on the outer surface of the lower end of each support rod, multiple sets of pointed rods are fixedly arranged on the lower surface of each flat pedal, an insert plate is fixedly connected to the lower end of each support rod, and a curved clamp plate is arranged on the inner surface of each of the left half retainer ring body and the right half retainer ring body. By the arrangement, the support device is reused, the problem that the support rods move horizontally in stormy weather can be solved through adhesion of the flat pedals to the ground and insertion of the pointed rods to the ground, stability in support is improved, most of trees within 25 centimeters in diameter can be fixed stably, and damage to the skin of trees can be prevented.

Owner:雷丽萌

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com