Method for producing non-woven cloud cotton fabric with spun-bonded method

A technology for non-woven fabrics and production methods, which is applied in the directions of non-woven fabrics, textiles and papermaking, and fabric elongation, can solve the problems of insufficient bulkiness, insufficient softness, complicated process of hot air guide layer, and high relative energy consumption, Achieve the effect of good vertical stability, good promotion and use value, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

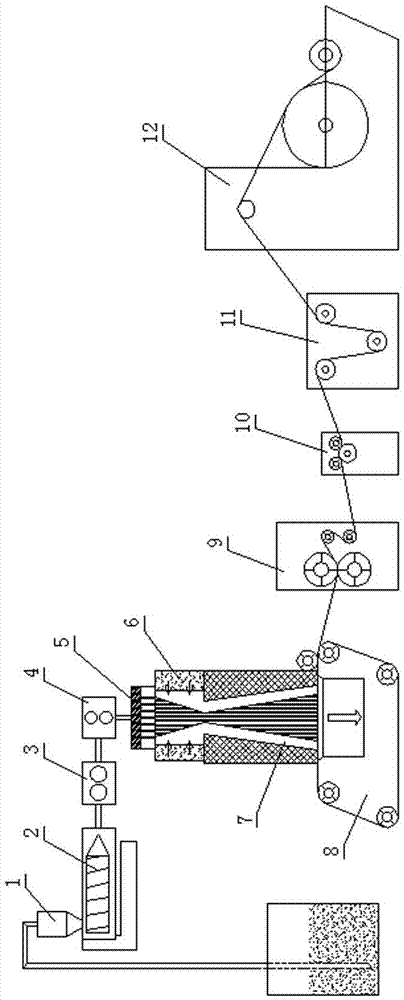

[0058] As shown in accompanying drawing, the production method of the cloud cotton nonwoven fabric of a kind of spunbond method of the present invention, the step of this method comprises:

[0059] (1) Mix and stir low melt index polypropylene raw materials, low melt index propylene polymer raw materials and erucic acid fatty acid amide masterbatch;

[0060] (2) Extrude and melt the mixed and stirred raw materials through the feeding system to the screw to obtain a hot melt;

[0061] (3) Filtrating, metering and distributing the hot melt at a certain temperature and pressure;

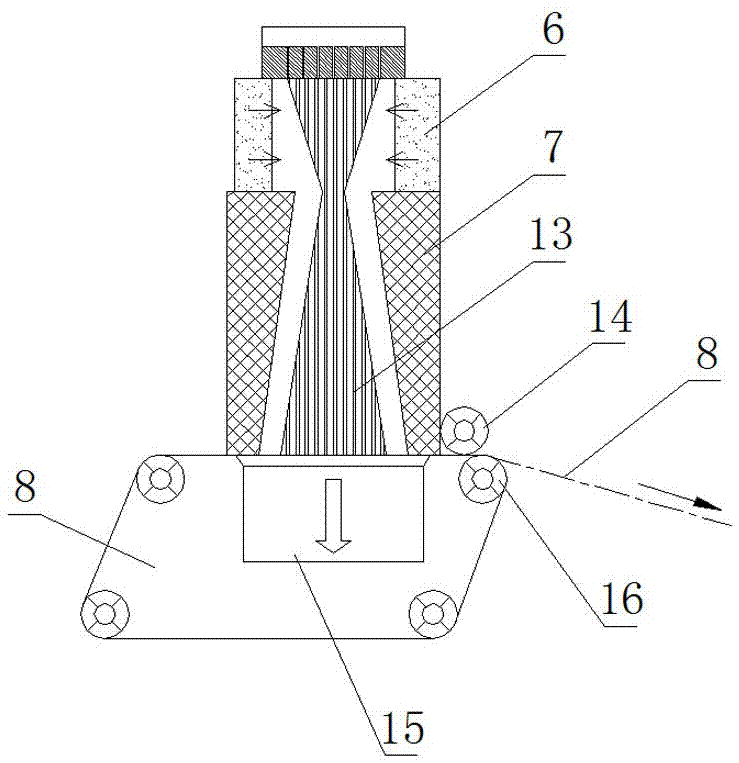

[0062] (4) Spinning the distributed and metered hot melt, and cooling the spun filaments with side cooling air to obtain primary growth filaments;

[0063] (5) stretching the primary filaments to obtain fibers;

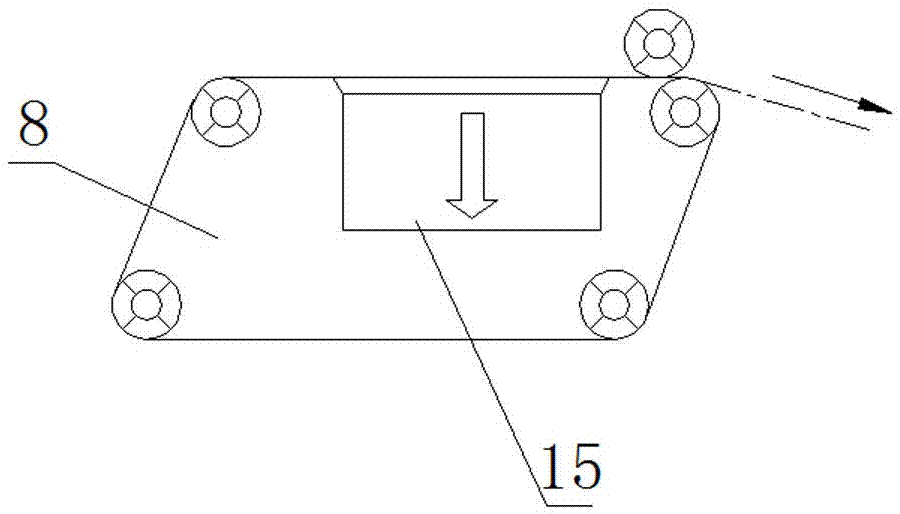

[0064] (6) Laying the fibers into a web to form a fiber web;

[0065] (7) After the fiber web is hot-rolled, a non-woven fabric is obtained;

[0066] (8) The non-woven fabric is stretched m...

Embodiment 2

[0076] The production method of the cloud cotton nonwoven fabric of the spunbonding method, the steps of the method include:

[0077] (1) First, the polypropylene raw material with a melt index of 35-38g / 10min, the propylene polymer raw material with a melt index of 48-52g / 10min, and the masterbatch of erucic acid fatty acid amide are mixed according to 74.5%:25.0%:0.5% The weight ratio is mixed;

[0078] (2) Add the above-mentioned mixed materials into the screw extruder through the feeding system for melting and extrusion to obtain a hot melt. The melting temperature of the screw is 180°C to 270°C;

[0079] (3) Filter the hot melt through a filtration system, measure and distribute it through a metering pump, the temperature is 230-250°C, and the pressure is 5-10MPa;

[0080] (4) Spray the filtered, metered and distributed hot melt through the spinneret from a hole diameter of 0.3-0.8mm, and cool it through the side-cooling air cooling system. The temperature of the side-co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com