Airship pneumathode with alterable bulk

An airbag and variable technology, applied in the field of airships, can solve problems such as difficult disassembly and transportation, difficulty in high-altitude flight, high energy consumption of airbag shape and stiffness, etc., to achieve good longitudinal stability, simplify the structure of the airbag, and facilitate transportation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

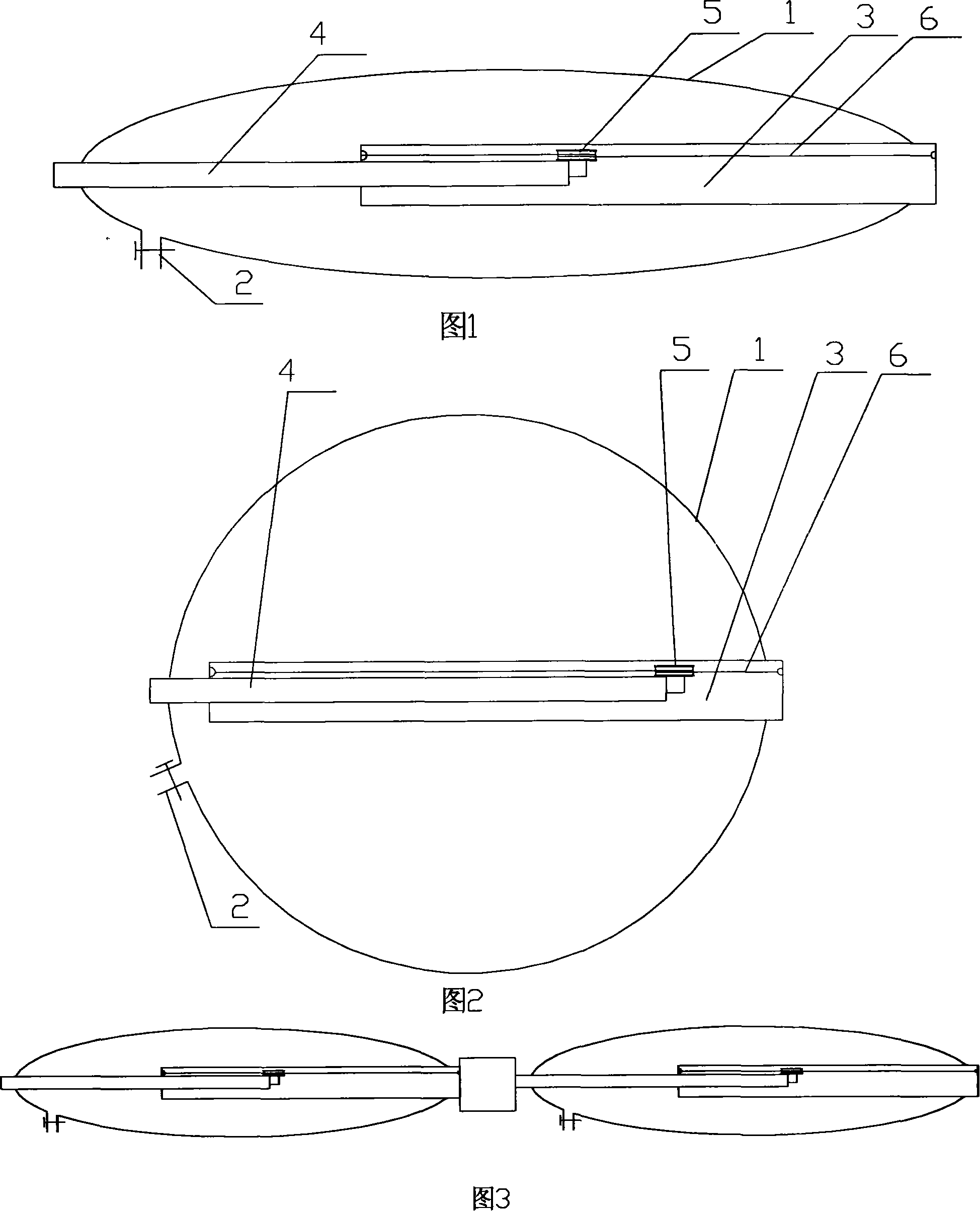

Embodiment Construction

[0006] The airbag is made of airtight airbag cloth into a strip-shaped airtight airbag. The inflation nozzle is a commonly used airbag inflation valve, which is installed on the skin of the airbag. The material of the slide plate and the bottom plate can be light weight metal (such as aluminum alloy, magnesium alloy, titanium alloy, etc.) and composite materials (such as carbon fiber, plastic, etc.) made. The slide plate is installed on the bottom plate through the chute, and one end of the bottom plate and one end of the slide plate are glued to the airbag skin respectively. fixed on the other end of the bottom plate. The airship power propulsion device is installed on the bottom plate, and the airship flight system, including the flight control system, mission system, power supply system, etc., is installed on the airbag expansion device to form the airship. Lifting gas (gas lighter than air, such as hydrogen, helium, etc.) is filled in the airbag. The electric winch is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com