Method for block-by-block casting of concrete continuous beam bridge by using military truss shift mould

A technology of shifting formwork and truss is applied in the field of concrete continuous girder bridges cast in blocks by using military truss shifting diecasting. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

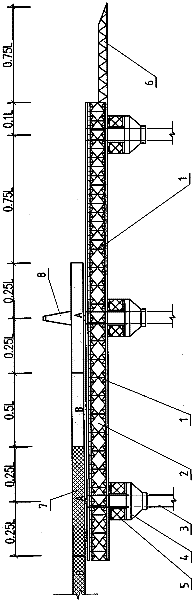

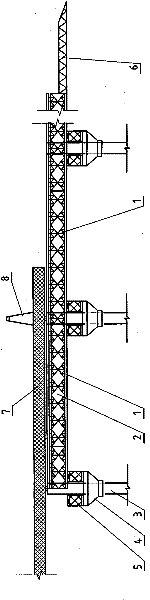

[0025] Embodiment 1: The method of using the two-hole longitudinal steel truss to move the mold and divide the hole into the concrete continuous beam bridge is as follows: Picture 1-1 with 1-2 Shown:

[0026] a. Conditions of use: In order to save the amount of steel trusses used when the construction period is not controlled, the total length of the longitudinal steel trusses 1 is 2.5L, and the process of pouring single-span box girders in A and B sections is implemented. Only one span is poured, and in order to meet the requirement of longitudinal movement and anti-overturning stability of the longitudinal steel truss 1, a guide beam 6 shall be erected on the horizontal steel truss 5 at the front end of the mold shifting.

[0027] b. Applicable span: when L≤25m, Bailey longitudinal steel truss 1 is used for the construction of moving formwork and blocks, each piece is 1.5m high, 3m long, 0.23m wide, and weighs 270kg; chord 2 [10, which can be pinned manually Knot installat...

Embodiment 2

[0039] Example 2 as image 3 Shown: a method of moving concrete continuous girder bridges by using temporary piers in the middle of the span. The diameter is half of the span L of the continuous concrete beam of the whole hole, the self-weight bending moment of the continuous concrete beam can be reduced by four times, and the construction can be carried out according to the scheme of L<25m mentioned in the previous paragraph; Pier 9 adopts vertical steel pipe columns with expanded foundation, and a pair of hydraulic jacks are installed on the top of steel pipe temporary pier 9. When the concrete continuous beam has a large deflection during the construction of moving the formwork and block pouring, vertical jacks can be used to adjust it; After the hole reinforced concrete continuous beam pouring construction is completed, the steel pipe temporary pier 9 is tied up with a wire rope and dragged to a new position for reinstallation.

Embodiment 3

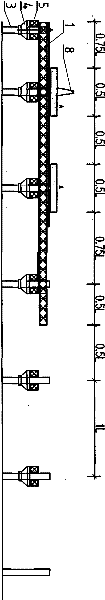

[0040] Example 3 as diagram 2-1 , 2-2 , 2-3, 2-4 and 2-5 show: a method (abbreviated as CMSS) for simultaneously pouring two-span concrete continuous girder bridges by using three-hole longitudinal steel truss moving mold blocks, when 25m

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com