Steam-water system arrangement structure of deep peak regulation double-hearth power station pulverized coal boiler

A technology of pulverized coal boiler and steam-water system, which is applied in steam separation device, burner for burning powder fuel, steam superheating, etc. It can solve the problem that it is difficult to achieve the goal of deep peak regulation, and achieve the effect of simplifying the steam-water system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

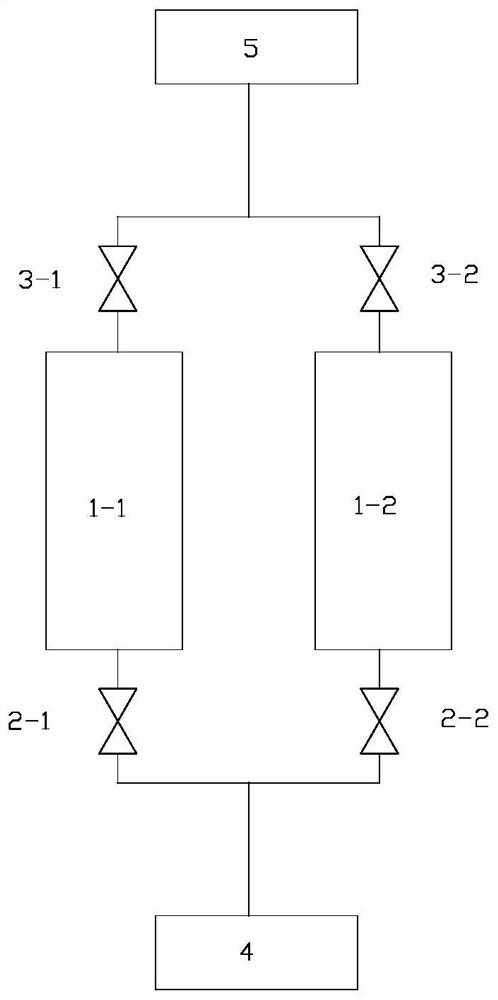

[0021] see figure 1 , the steam-water system layout structure of a pulverized-coal boiler of a deep peak-shaving double-furnace power station provided by the present invention, its specific layout form is: the first furnace water-cooled wall 1 and the second furnace water-cooled wall 2 in the double furnace are arranged independently, and The furnace structure is coupled; the economizer 4 upstream of the inlet header of the first furnace water wall 1 and the second furnace water wall 2 adopts a combined arrangement, and the two sets of water wall evaporation systems share a set of economizers; the first furnace water wall 1 and the superheater 5 downstream of the outlet header of the second furnace water-cooled wall 2 adopt a combined arrangement, and the two sets of water-cooled wall evaporation systems share a set of superheaters.

[0022] When the boiler ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com