Device and method for separating long chain hydrocarbon in chemical wastewater from methanol to olefin

A methanol-to-olefin and chemical wastewater technology, applied in the field of chemical engineering, can solve the problems of low separation efficiency and high energy consumption, and achieve the effects of improving separation efficiency, reducing back-mixing, and simplifying wastewater treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

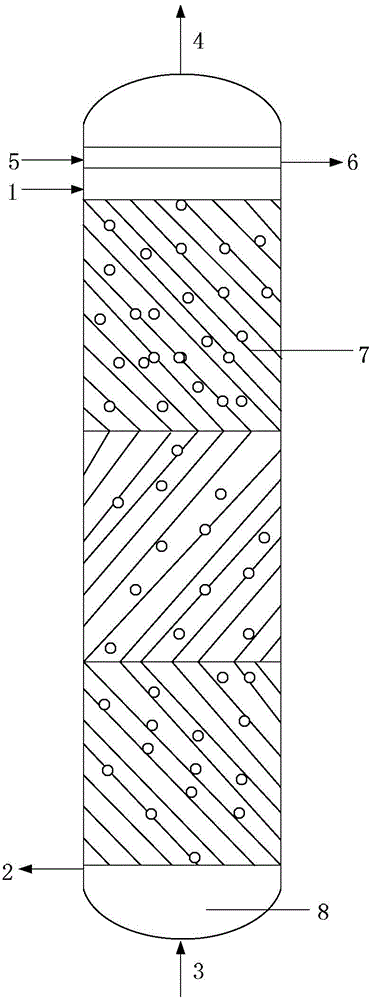

[0049] In the solvent air flotation tower of Example 1, the gas distributor is a sand core with an average aperture of 1mm and a diameter of 6cm, which is a gas distribution plate; it includes a group of hydrophobic coalescence plate components, and the hydrophobic coalescence plate is a polyethylene coalescence The boards are installed at an inclination angle of 30°, and the distance between the boards is 10cm.

[0050] Add 20L of methanol-to-olefins chemical wastewater from the wastewater inlet of the solvent air flotation tower, wherein the concentration of long-chain hydrocarbons in the methanol-to-olefins chemical wastewater is 0.0450wt%, and the volume ratio of wastewater to organic solvent is 400:1. Add 50ml of mixed hydrocarbons (mixed hydrocarbons generated in the process of methanol to olefins) from the solvent inlet above the wastewater phase, adjust the gas flow rate to 0.01cm / s, provide gas from the air cylinder, press it into the tower through the gas distributor,...

Embodiment 2

[0052] In the solvent air flotation tower of embodiment 2, the gas distributor is a sand core with an average aperture of 5 mm and a diameter of 6 cm, which is a gas distribution plate; it includes 5 groups of hydrophobic coalescent plate assemblies, and the hydrophobic coalescent plate is polypropylene polycarbonate The board is installed at an inclination angle of 60°, and the distance between the boards is 30cm.

[0053] Add 20L of methanol-to-olefins chemical wastewater from the wastewater inlet of the solvent air flotation tower, wherein the concentration of long-chain hydrocarbons in the methanol-to-olefins chemical wastewater is 0.0750wt%, and the volume ratio of wastewater to organic solvent is 10:1. Add 2L of a mixture of n-octane and n-hexane above the wastewater phase from the solvent inlet, adjust the gas flow rate to 0.5cm / s, press the pressure from the nitrogen cylinder into the tower through the gas distributor, and start the solvent air flotation operation. The...

Embodiment 3

[0055]In the solvent air flotation tower of embodiment 3, the gas distributor is a sand core with an average aperture of 2.5 mm and a diameter of 6 cm, which is a gas distribution plate; it includes 3 groups of hydrophobic coalescence plate components, and the hydrophobic coalescence plate is polystyrene The coalescing boards are installed at an inclination angle of 45°, and the distance between the boards is 20cm.

[0056] Add 20L of methanol-to-olefins chemical wastewater from the wastewater inlet of the solvent air flotation tower, wherein the concentration of long-chain hydrocarbons in the methanol-to-olefins chemical wastewater is 0.00444wt%, and the volume ratio of wastewater to organic solvent is 100:1. And add 10ml KOH electrolyte solution to the wastewater to reduce the stability of the droplets in the water, add 400ml n-heptanol as the solvent phase from the solvent inlet above the wastewater phase, adjust the gas flow rate to 0.1cm / s, and the pressure provided by the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com