Pod type electric jet propeller

A pod-type, propulsion technology, applied in ship propulsion, propulsion components, propulsion transmission devices, etc., to achieve the effect of improving propulsion efficiency, eliminating inflow bubbles, and improving propulsion efficiency and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

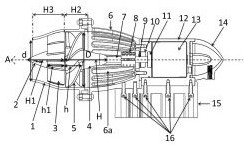

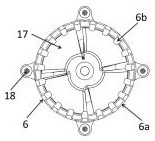

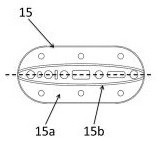

[0019] figure 1 , figure 2 and image 3 The pod-type electric jet thruster shown includes: a pump body compression chamber (1), the inner wall of which has a curved surface composed of multiple curves, and the inner chamber has a rectifier (3) and a conical hub (2); a hydraulic The generating device is designed as an impeller (5) equipped with a conical hub (4), and is installed on the shaft (7), linked with the motor shaft (9) through a coupling (8); a motor (13 ); a motor sealing cabin (12), with a seal (11) and a water-lubricated bearing (10) at the shaft end, which is integrally installed on the conical inlet fluid (6); a conical drainage cover (14), It is installed at the tail end of the motor sealing compartment to pre-correct the direction of water inflow; a boom (15) is installed on the motor sealing compartment (12) and the conical inlet fluid (6) through bolts (16), French Lan Panru image 3 (15a) Mounted with the bottom of the ship.

[0020] The conical inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com