A filling device in the sorting section of a flotation column

A filling device and flotation column technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

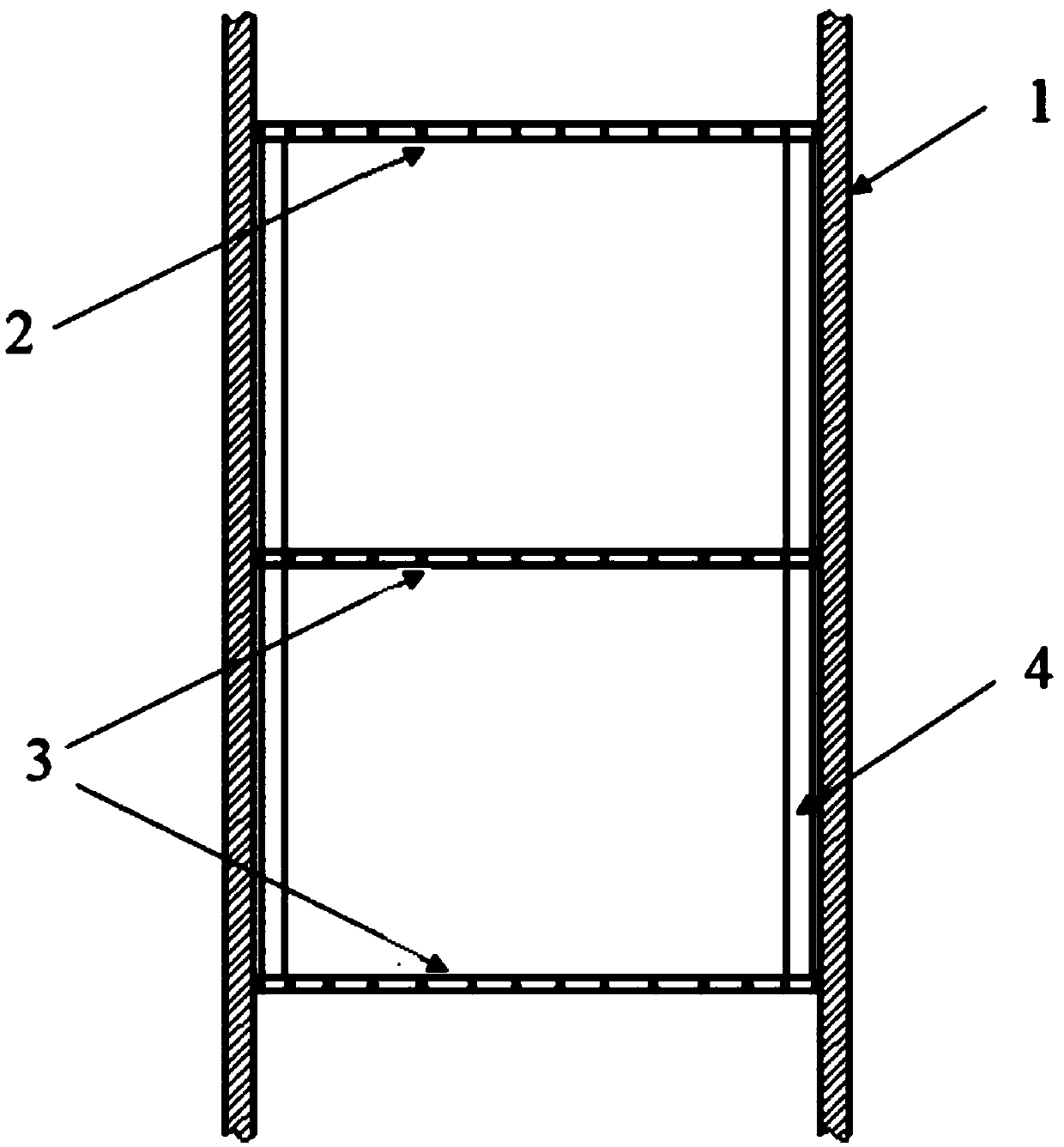

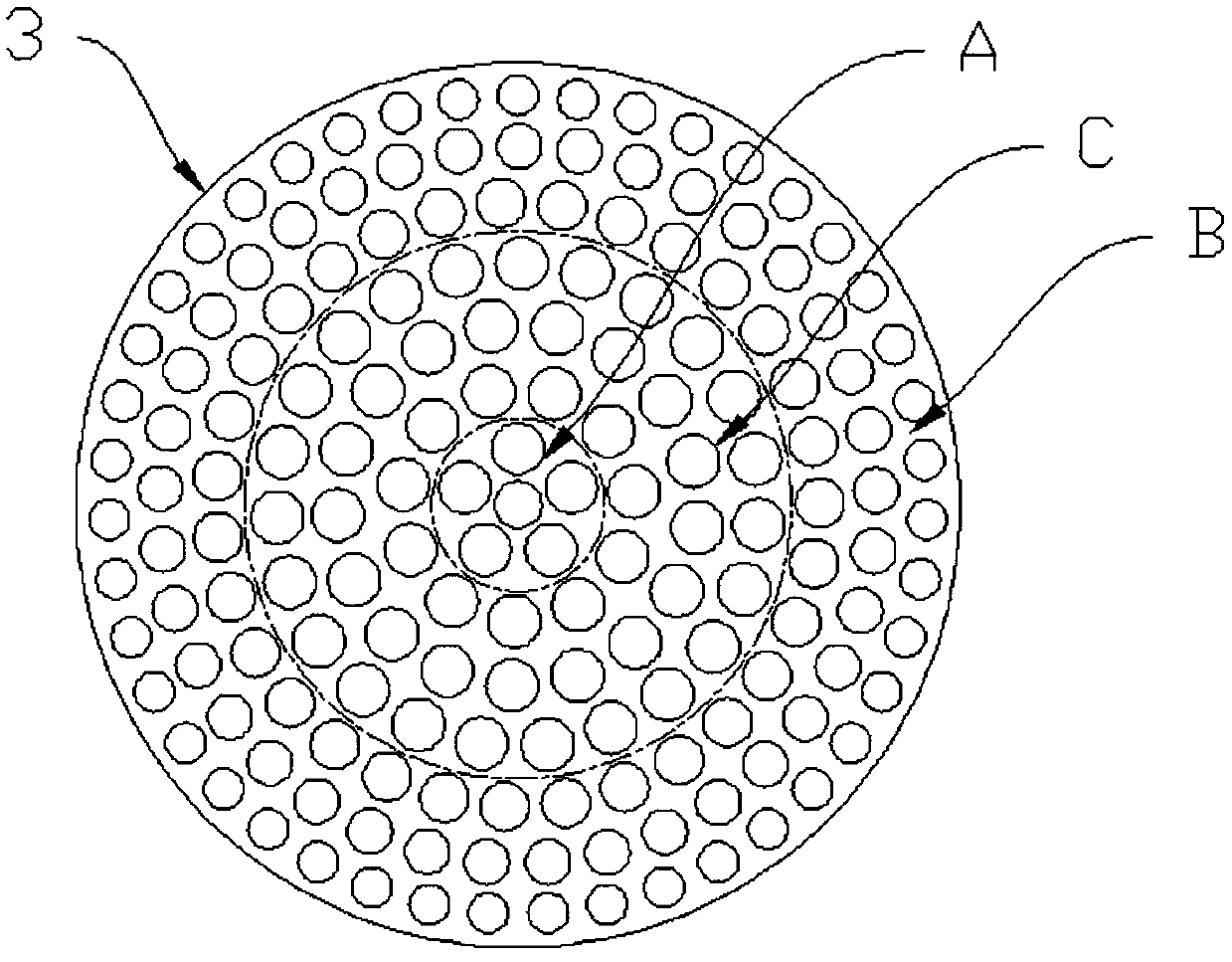

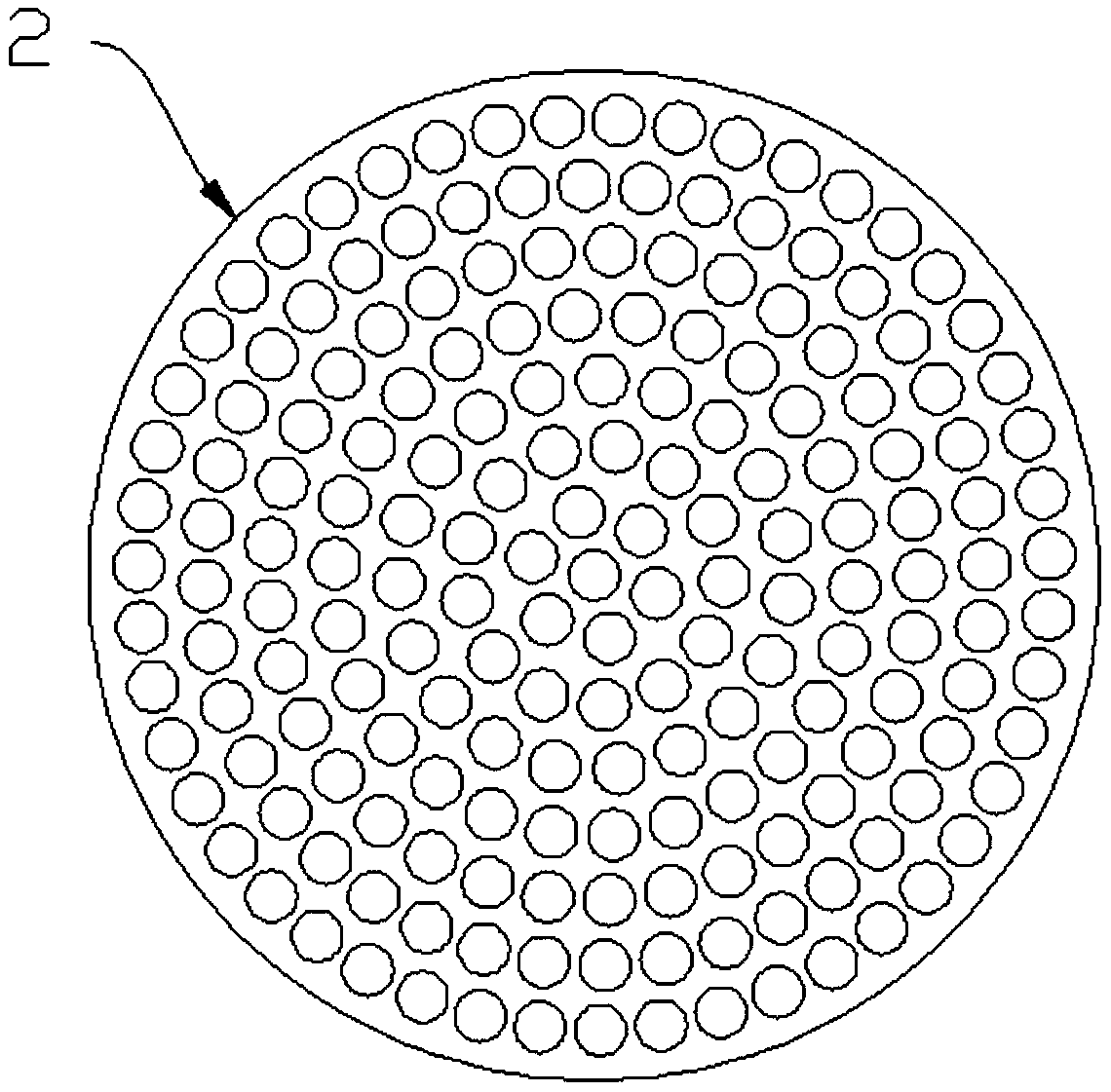

[0023] Such as Figures 1 to 3 As shown, a filling device in the sorting section of a flotation column includes a sieve layer arranged in the flotation column 1 that matches the size of the flotation column, and the sieve layer includes a layer arranged on the upper part of the flotation column Uniform sieve plates 2 and one to three layers of non-uniform sieve plates 3 arranged at the lower part of the flotation column are supported by diversion tubes 4 between adjacent two layers of sieve plates; the non-uniform sieve plates 3 are arranged in different radial directions The diameter of the circular hole, wherein the diameter of the circular hole in the central area A and the edge area B of the sieve plate is smaller than that of the area C between them, the diameter of the circular hole from the A area to the C area gradually becomes larger, and the C area to the B area ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com