Catalytic distillation assembly and catalytic distillation method using the same

A catalytic distillation and component technology, which is applied in chemical instruments and methods, fractionation, chemical/physical processes, etc., can solve the problems of catalyst difficulties, small bed porosity, and reduced catalyst particle strength, etc. The effect of high reaction efficiency and good mass transfer characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

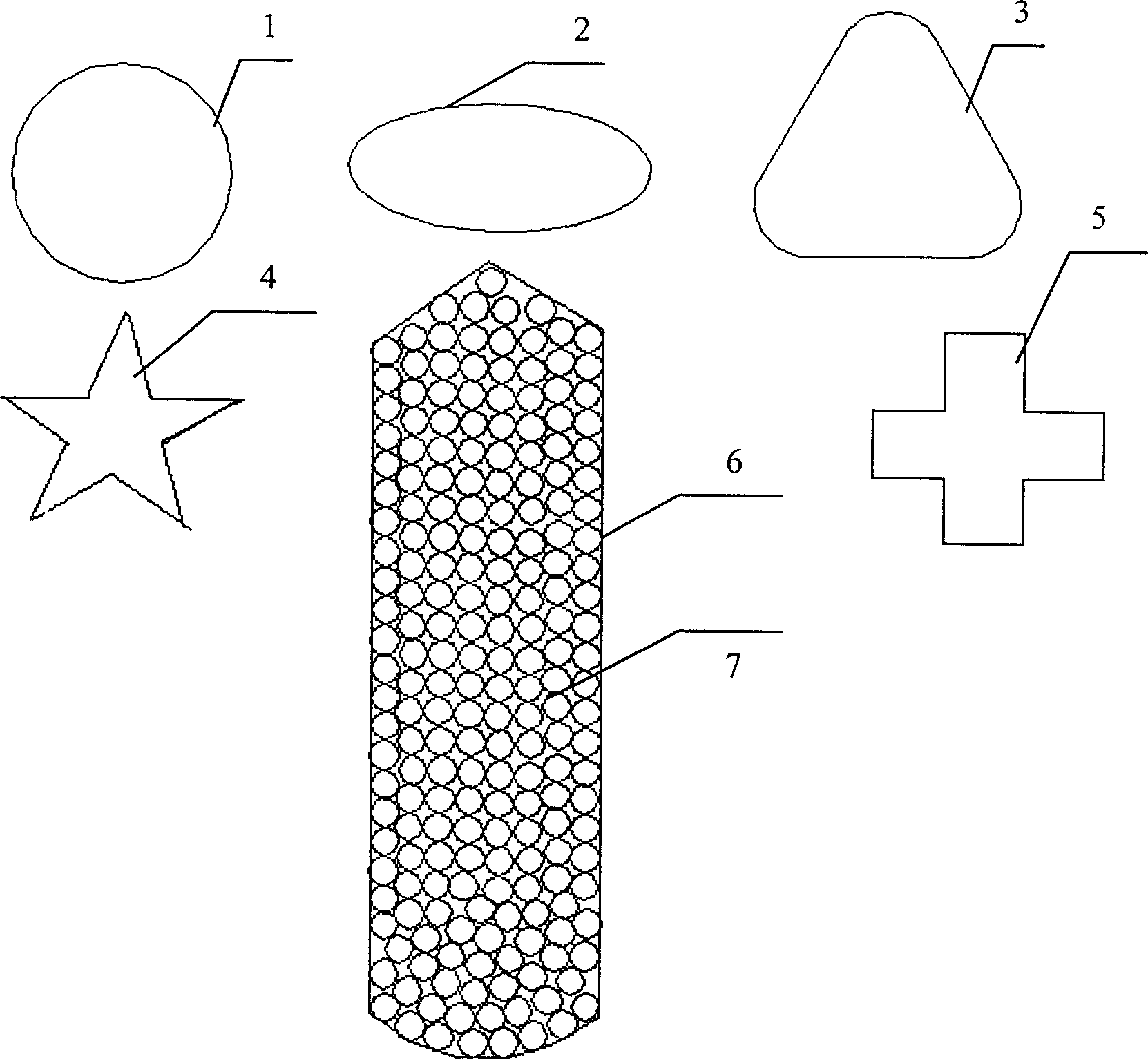

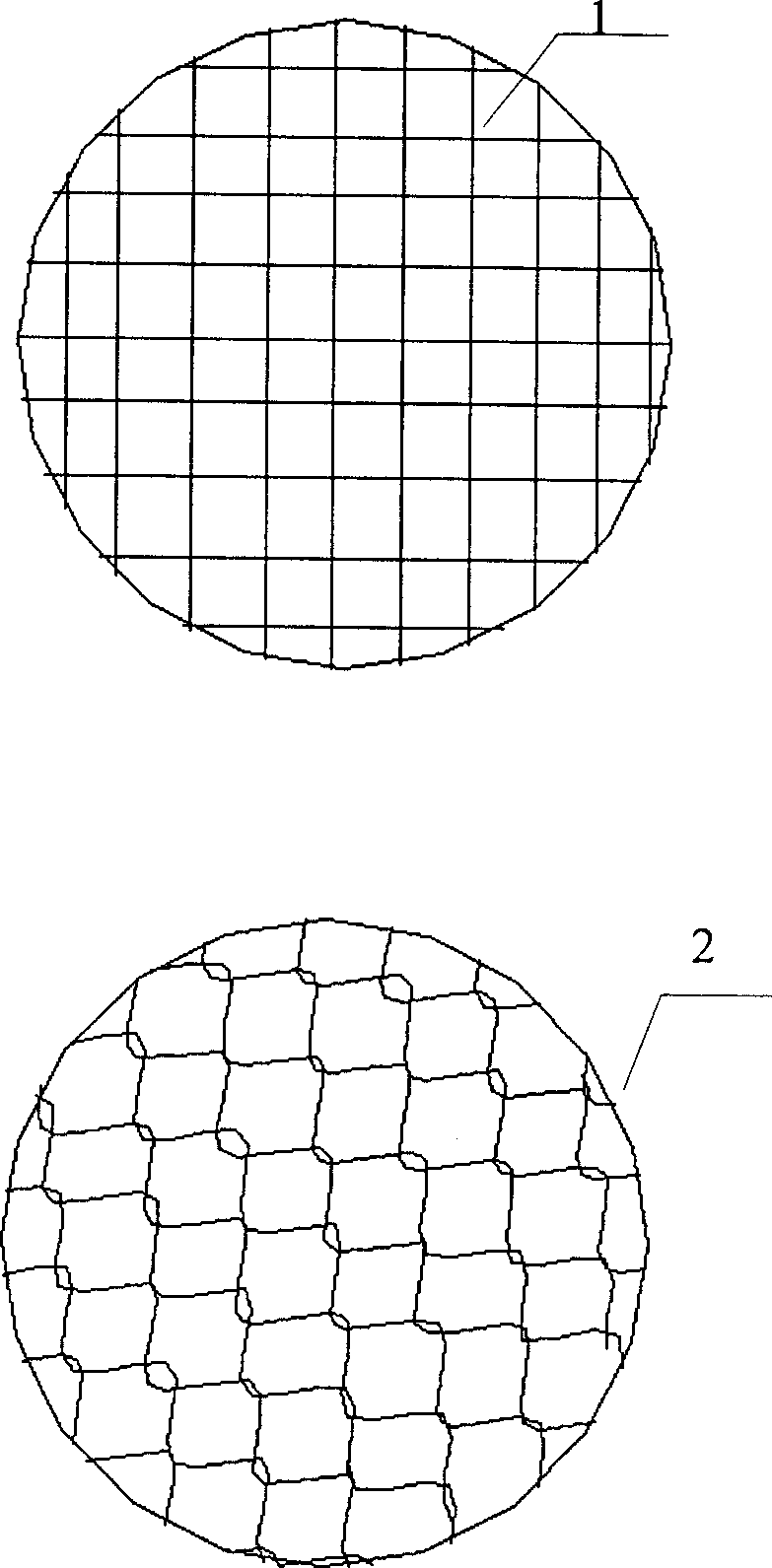

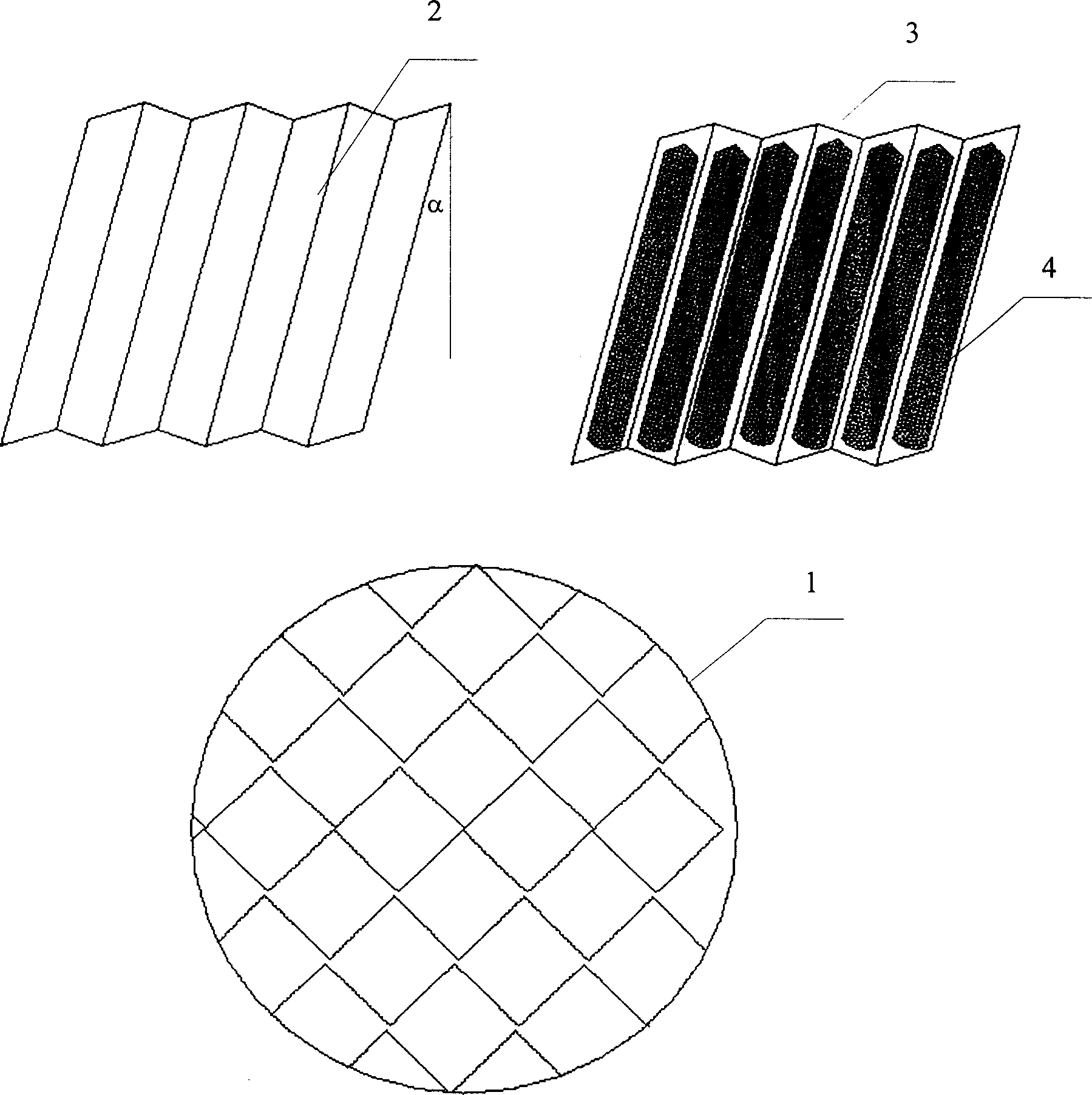

[0040] The catalytic distillation assembly of the present invention is used for C 3 The experimental small-scale device for catalytic distillation of MAPD (propargyl-propadiene), the diameter of the small-scale device is 100mm, and the height is 6000mm. The catalytic distillation assembly of the present invention is made into a diameter of 100mm and a high 50mm integral member. The catalyst used in the catalytic distillation assembly adopts a spherical catalyst with a diameter of φ3mm produced by Beijing Research Institute of Chemical Industry, and the flat wire mesh cylindrical container of the catalyst is 12mm in diameter. , the length is the same as the space length of the structured packing used to accommodate the wire mesh container. The structured packing is made of stainless steel corrugated plate packing with patterns pressed on the surface, the wave pitch is 40mm, the wave peak is 20mm, and the diameter is 100mm. The wire mesh container filled with the catalyst is ins...

Embodiment 2

[0045] The catalytic distillation assembly of the present invention is used for C 3 The industrial side line experimental device for catalytic distillation of MAPD (propargyl propadiene), the industrial measuring line device has a diameter of 300mm and a height of 23000mm. The catalytic distillation assembly of the present invention is made into a diameter of 300mm and a high 100mm integral member. The catalyst used in the crude piece of catalytic distillation adopts the spherical catalyst with a diameter of φ3mm produced by Beijing Research Institute of Chemical Industry, and the wire mesh container of the catalyst is a plane with a diameter of 15mm. Wire mesh cylindrical, the length is the same as the space length of the structured packing used to accommodate the wire mesh container. The structured packing is made of stainless steel corrugated plate packing with patterns pressed on the surface, the wave pitch is 44mm, the wave peak is 22mm, and the diameter is 300mm. The she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com