Millimeter level mesoporous ozone oxidation catalyst and preparation and application method thereof

A technology of ozone oxidation and catalyst, which is applied in the field of water treatment, can solve the problems of low catalytic efficiency and poor fluid mechanical properties, and achieve the effects of high degradation efficiency, improved mineralization degree, and good catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

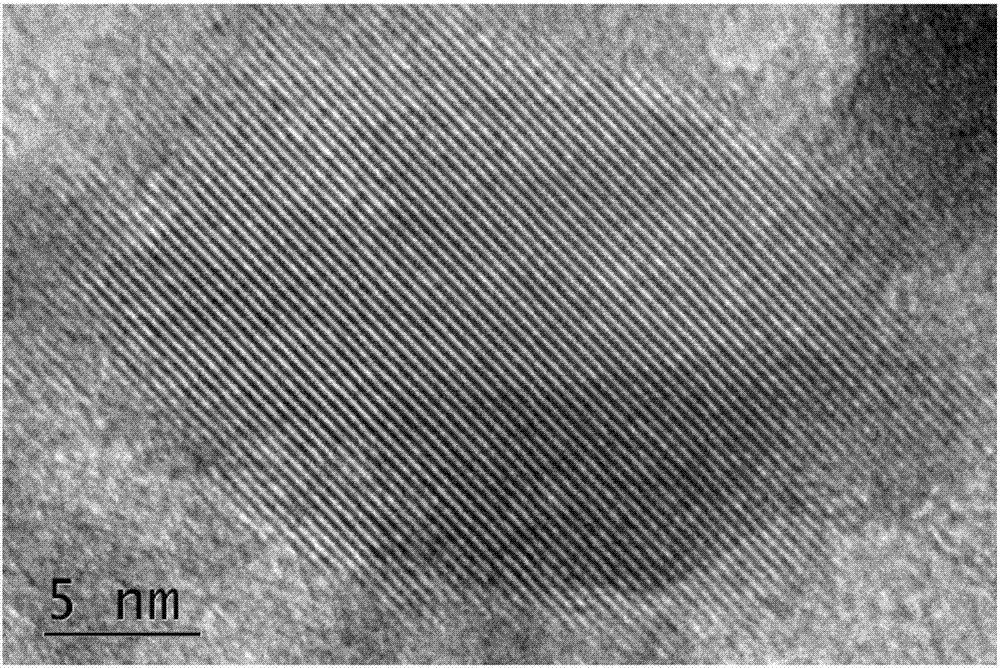

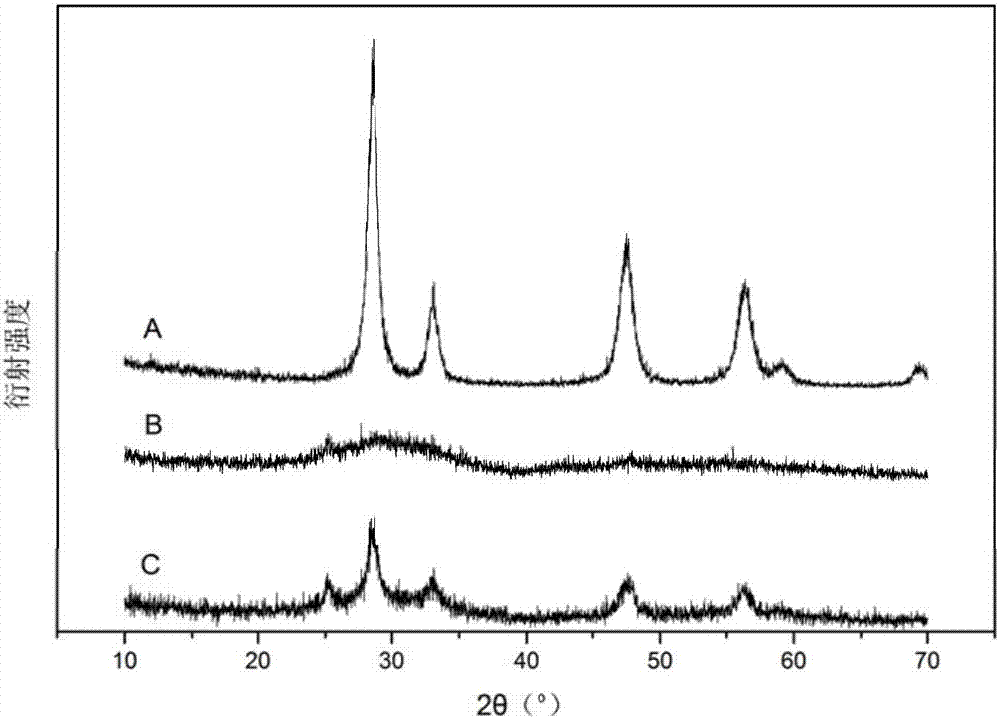

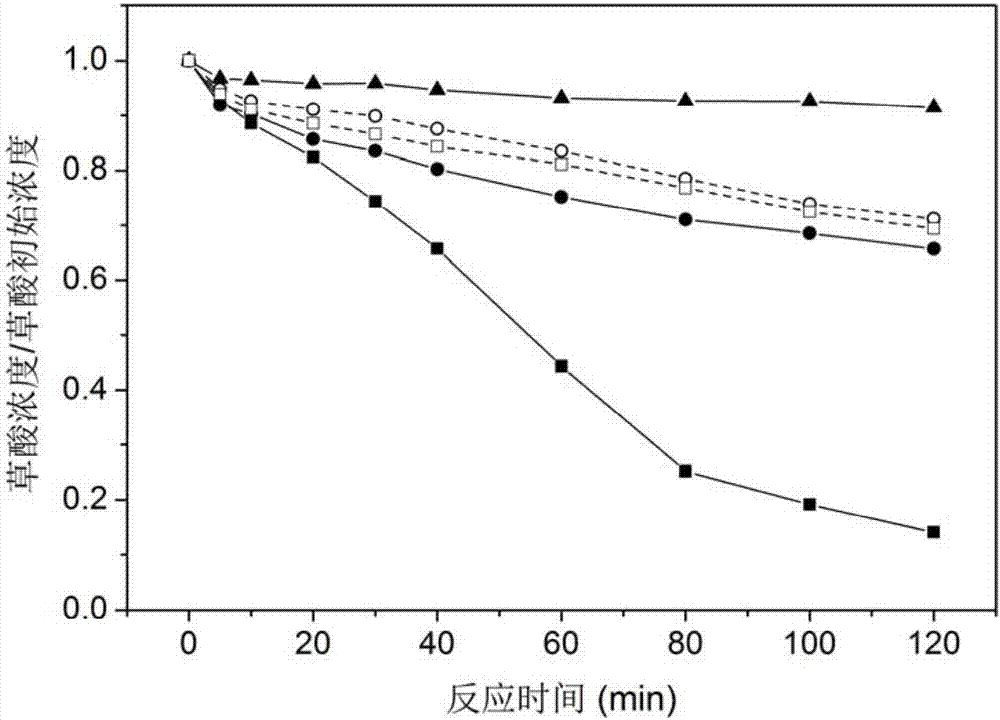

[0049] Preparation and Characterization of Millimeter Mesoporous Ozone Oxidation Catalysts

[0050] (1) Preparation of calcium alginate gel template spheres: at room temperature, use a syringe with a needle inner diameter of 0.41 mm to inject 0.27 mol / L CaCl 2 Add sodium alginate aqueous solution with a mass fraction of 1.0% to the aqueous solution dropwise, use a syringe pump to control the injection flow at 4.5mL / h, form gel balls and continue stirring for 24 hours, and wash with water to obtain calcium alginate gel template balls;

[0051] (2) Preparation of titanium-zirconium composite oxide spheres: After washing the calcium alginate gel template spheres prepared in step (1) with absolute ethanol, they were soaked in the titanium-zirconium alkoxide mixed solution for 24 hours, and then transferred to Soak in isopropanol aqueous solution for 12 hours, take it out, dry at room temperature for 48 hours, dry at 60°C for 6 hours, then calcinate at 500°C for 5 hours, cool to ro...

Embodiment 2

[0059] Preparation and Characterization of Millimeter Mesoporous Ozone Oxidation Catalysts

[0060](1) Preparation of calcium alginate gel template spheres: at room temperature, use a syringe with a needle inner diameter of 0.25 mm to inject 0.27 mol / L CaCl 2 Add sodium alginate aqueous solution with a mass fraction of 1.0% to the aqueous solution dropwise, use a syringe pump to control the injection flow at 4.5mL / h, form gel balls and continue stirring for 12 hours, and wash with water to obtain calcium alginate gel template balls;

[0061] (2) Preparation of titanium-zirconium composite oxide spheres: After washing the calcium alginate gel template spheres prepared in step (1) with absolute ethanol, they were soaked in the titanium-zirconium alkoxide mixed solution for 12 hours, and then transferred to Soak in isopropanol aqueous solution for 24 hours, take it out and dry at room temperature for 24 hours, dry at 65°C for 4 hours, then calcinate at 350°C for 8 hours, cool to ...

Embodiment 3

[0066] Preparation and Characterization of Millimeter Mesoporous Ozone Oxidation Catalysts

[0067] (1) Preparation of calcium alginate gel template spheres: at room temperature, use a syringe with a needle inner diameter of 0.69 mm to inject 0.27 mol / L CaCl 2 Add sodium alginate aqueous solution with a mass fraction of 1.0% to the aqueous solution dropwise, use a syringe pump to control the injection flow at 4.5mL / h, form gel balls and continue stirring for 18 hours, and wash with water to obtain calcium alginate gel template balls;

[0068] (2) Preparation of titanium-zirconium composite oxide spheres: After washing the calcium alginate gel template spheres prepared in step (1) with absolute ethanol, they were soaked in the titanium-zirconium alkoxide mixed solution for 18 hours, and then transferred to Soak in isopropanol aqueous solution for 18 hours, take it out, dry at room temperature for 72 hours, dry at 55°C for 8 hours, then calcinate at 600°C for 3 hours, cool to ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com