Patents

Literature

89results about How to "Flexible preparation process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacturing method of high alloy seamless steel tube

InactiveCN101811149AImprove surface qualityImprove lubrication conditionsManufacturing cost reductionPunching

The invention discloses a manufacturing method of high alloy seamless steel tube, comprising the following technical steps: (1) producing a high alloy hollow shell with centrifugal casting technology; (2) heating the hollow shell and plugging the opening of the hollow shell when heating; (3) reaming and wall thinning for the hollow shell after being heated by using a perforating machine so as to form a blank; (4) tube rolling for the bland by using a pipe and tube mill so as to form a pierced billet; (5) sizing and reducing for the pierced billet by using a sizing and reducing machine so as to obtain the high alloy seamless steel tube. The blank with the manufacturing method uses centrifugal casting for the hollow shell and lubricant is added by using the characteristic of hollow shell, thereby avoiding the problems of high alloy material in the technologies of forging, rolling and punching such as low metal yield and high rejection rate due to difficult deformation, thereby greatly reducing the manufacturing cost.

Owner:XINXING DUCTILE IRON PIPES CO LTD

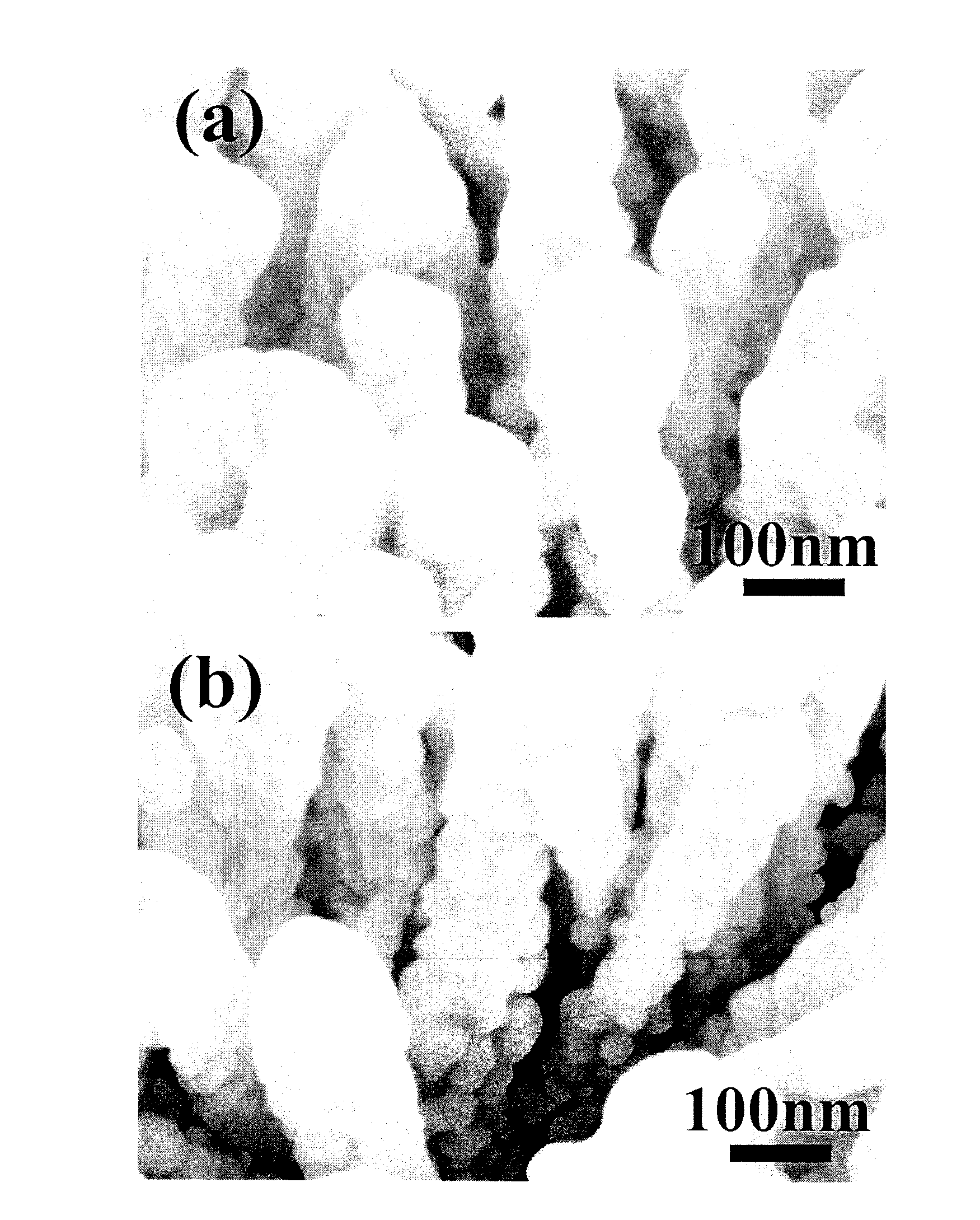

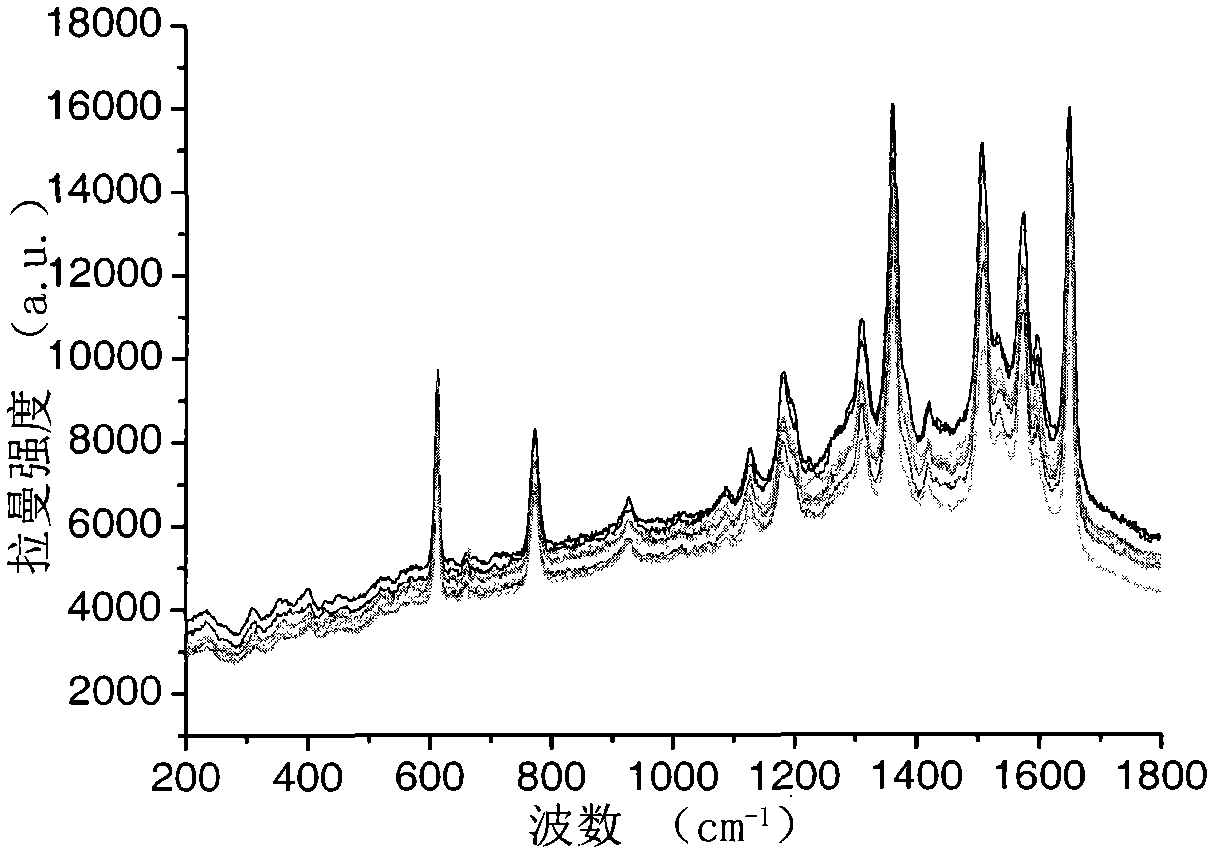

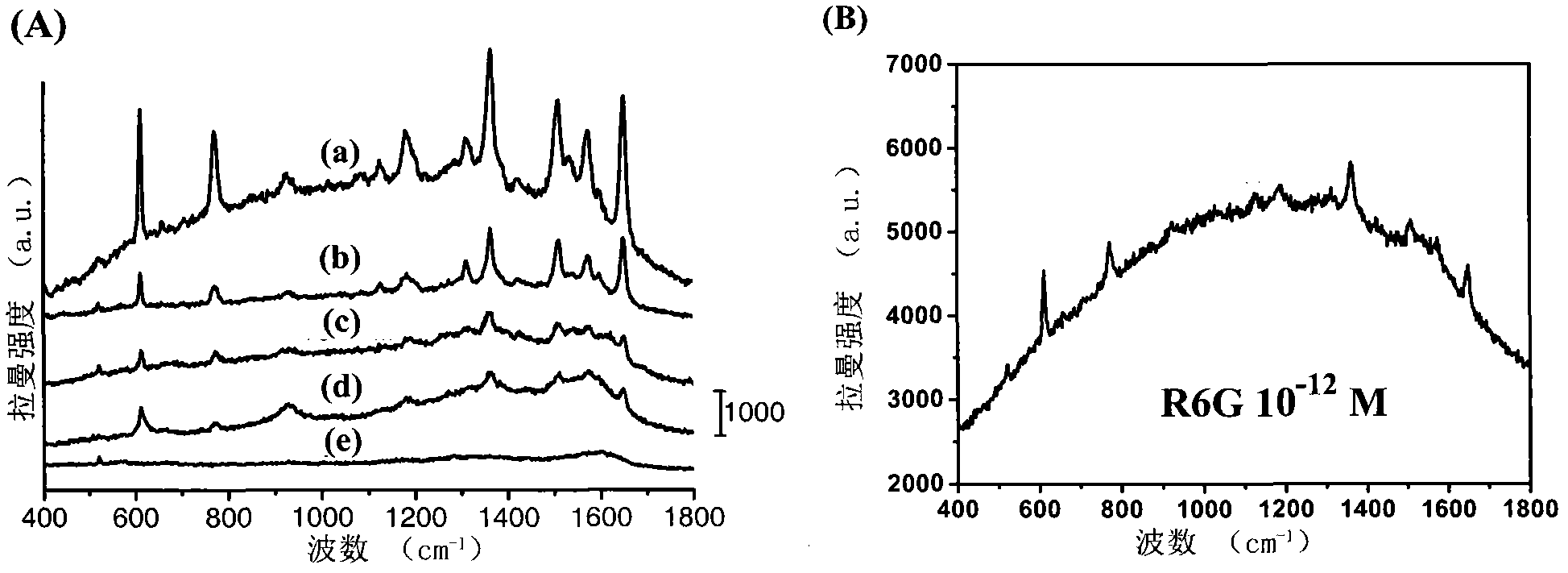

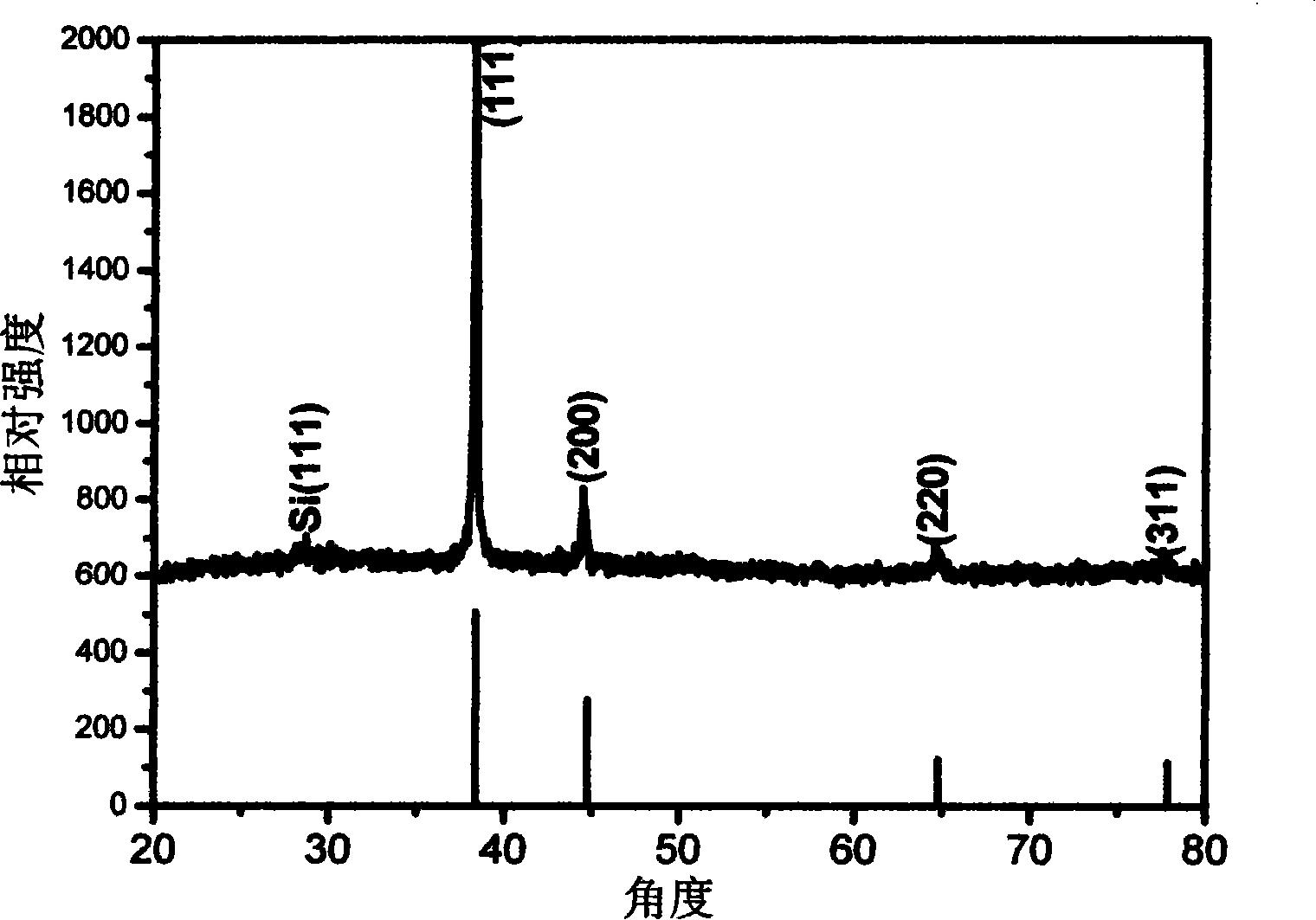

Silver nanoparticle-modified zinc oxide nanorod array and preparation method and application thereof

InactiveCN103030095AEliminate the disadvantages of oxidationLow costDecorative surface effectsRaman scatteringPolychlorinated biphenylZinc oxide nanorod sensor

The invention discloses a silver nanoparticle-modified zinc oxide nanorod array, a preparation method thereof and application thereof. An array consisting of zinc oxide nanorods is arranged on a substrate; the length of the zinc oxide nanorods is 1 to 1.4mu.m; the diameter of the rods is 50 to 60nm; the size of silver nanoparticles at the top ends of the rods is 100 to 120nm; the size of the silver nanoparticles on the surfaces of the rods is 25 to 35nm; the distance between the particles is less than or equal to 10nm; the distance between the silver nanoparticles at the top ends of the adjacent rods is 40 to 60nm; and the distance between the silver nanoparticles on the surfaces of the adjacent rods is 25 to 35nm. The method comprises the following steps of coating a zinc acetate ethanol solution on the substrate; after drying the substrate, cleaning, dispersing and thermally decomposing the substrate to obtain a substrate on which a zinc oxide seed layer is coated; performing electro-deposition on the substrate coated with the zinc oxide seed layer in a zinc nitrate ammonia complexation solution to obtain a substrate with the zinc oxide nanorod array; and performing silver ion sputtering on the substrate in an ion sputter to obtain the target product. The silver nanoparticle-modified zinc oxide nanorod array can serve as an active substrate of SERS (Surface Enhanced Raman Scattering) and is used for measuring rhodamine 6G or polychlorinated biphenyl 77.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

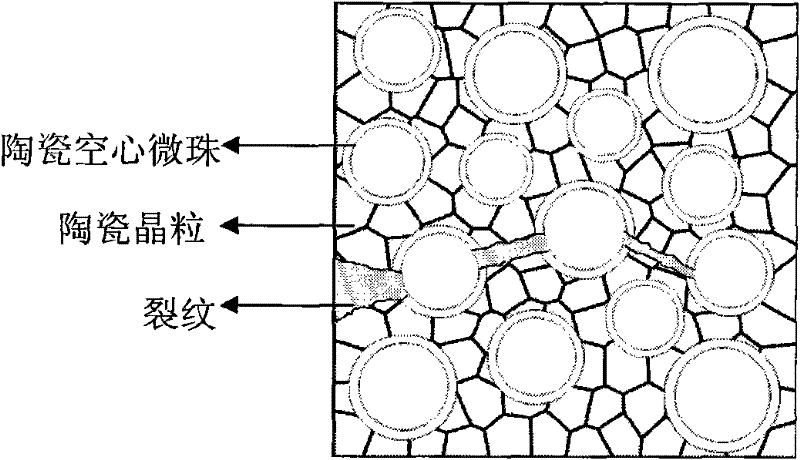

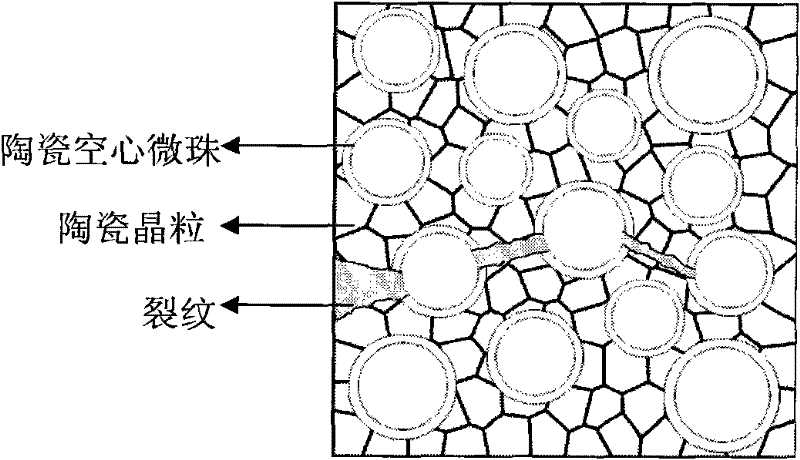

Ceramic with light weight, high strength and high toughness and preparation method thereof

The invention provides a ceramic with light weight, high strength and high toughness and a preparation method thereof. The method comprises the following steps: 1) presintering ceramic cenosphere powder to increase the strength of the ceramic cenosphere powder; 2) adding the presintered ceramic cenosphere powder in ceramic powder, adding the related additives; 3) selecting a moulding technology to mould the ceramic; 4) drying the obtained blank; and 5) sintering the dried blank. The invention provides the ceramic with light weight, high strength and high toughness and the preparation method thereof, wherein the ceramic cenosphere is a ceramic material toughened by the toughening body.

Owner:HEBEI YL BANGDA NEW MATERIALS LTD CO

Slurry compounding process of lithium ion battery slurry

The invention relates to a slurry compounding process of a lithium ion battery slurry. In mass percent, the process comprises the following steps of: (1) beating an adhesive, (2) configuring a conductive adhesive, and (3) configuring the slurry. The lithium ion battery slurry prepared by adopting the process has the characteristics of uniformity, stability, long standing time and the like, and at the same time the preparation process is simple, flexible and especially suitable for large-scale lithium ion battery slurry compounding applications.

Owner:JIANGSU LENENG BATTERY INC

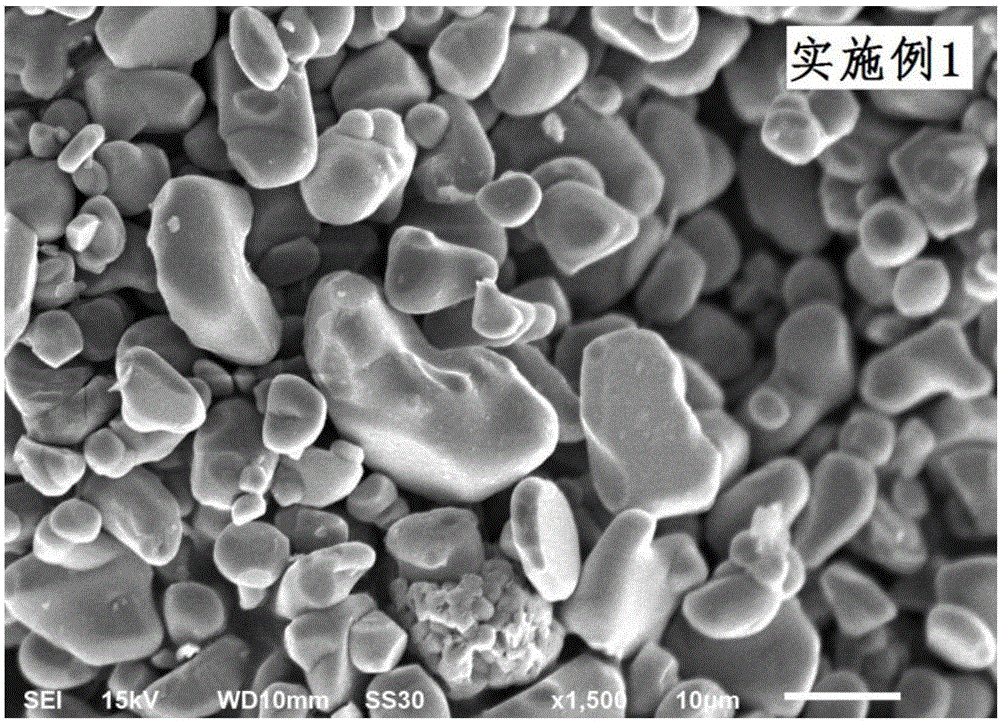

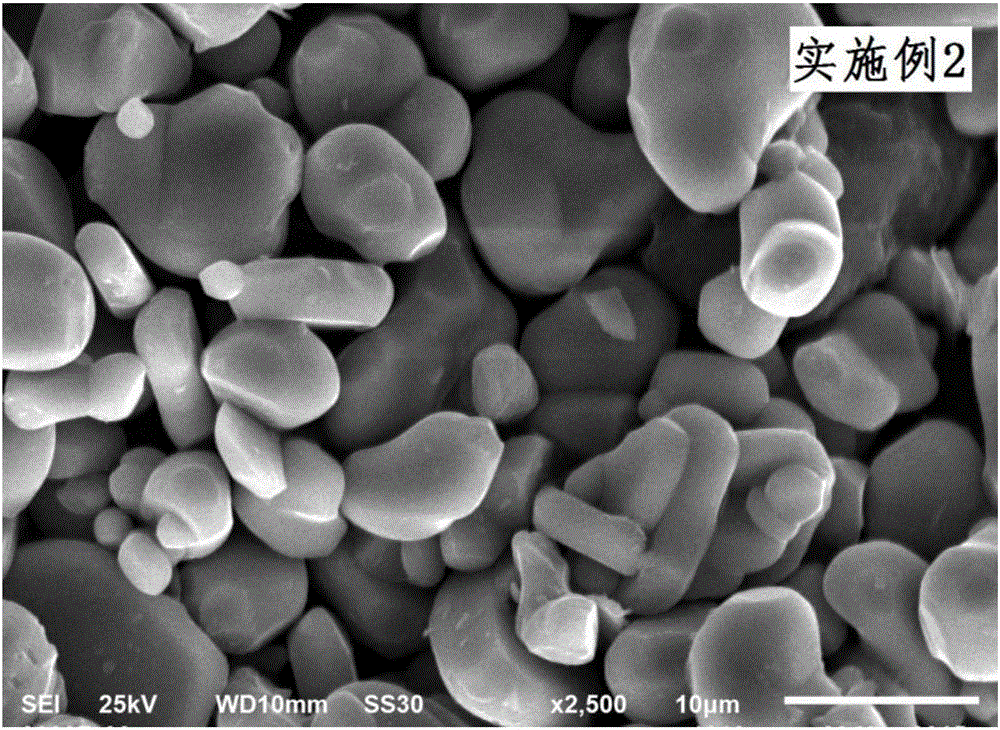

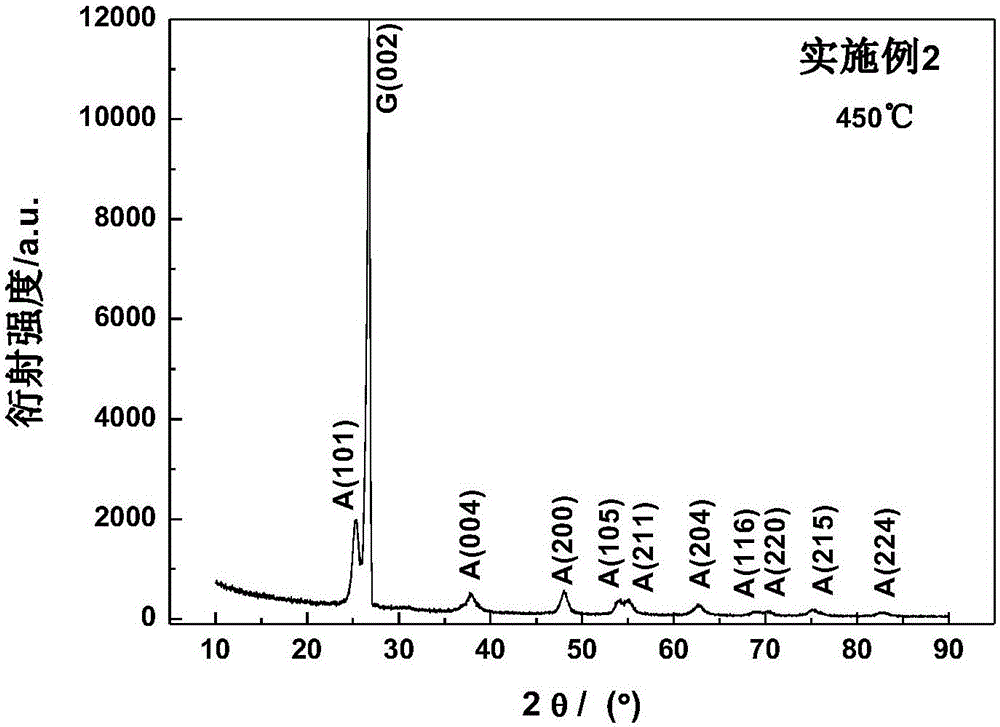

Method for preparing nanometer titania coated graphite cathode material

InactiveCN106711417AImprove mechanical propertiesGood physical and chemical stabilityCell electrodesSecondary cellsHigh rateDysprosium titanate

The invention discloses a method for preparing a nanometer titania coated graphite cathode material. The method comprises the steps that A, graphite is added into a mixed solution of glacial acetic acid, water and absolute ethyl alcohol at room temperature under the stirring condition, the materials are fully mixed, and a mixture is obtained; B, a titanate and absolute ethyl alcohol mixed solution is dropwise added into the mixture obtained in the step A within a certain time at room temperature under the stirring condition, standing is carried out for several hours, drying is carried out, and metatitanic acid gel coated powdered graphite is obtained; C, the metatitanic acid gel coated powdered graphite obtained in the step B is placed in a program temperature control furnace, the temperature is raised to 350 DEG C to 850 DEG C at a certain heating rate, the constant temperature is kept for several hours under the vacuum condition, the product is naturally cooled to room temperature, and the anatase and rutile type nanometer titania coated graphite material is obtained. The grain size of the nanometer titania coated graphite cathode material ranges from 1 micrometer to 35 micrometers, and high specific discharge capacity, good cycle performance and high high-rate charge and discharge performance are achieved.

Owner:HUBEI UEE ENERGY TECH CO LTD

Tungsten nitride based ternary nano composite super-hard film material and preparation method thereof

InactiveCN101624295ANo holesNo crackVacuum evaporation coatingSputtering coatingNitrogenTungsten nitride

The invention discloses a tungsten nitride based ternary nano composite super-hard film material and a preparation method thereof. The material is a nano composite super-hard film which is covered on a substrate and has a chemical formula of WxM1-xN, wherein in the nano composite super-hard film, W represents tungsten metal, M represents metal replacement, N represents nitrogen, and the value range of the x is 0.06 to 0.72; and the film consists of the tungsten metal, nitride solid solution phase of the M metal and tungsten metal phase or consists of tungsten nitride phase, tungsten metal phase and M metal phase, the grain size of the film is 4 to 30 nanometers, and the thickness of the film is 3 to 7mu m. The method comprises the following steps: firstly, placing a composite target consisting of the tungsten metal and the metal replacement and the substrate on a cathode and in a sample stage in a vacuum chamber of magnetron sputtering equipment respectively; after the vacuum degree of the vacuum chamber is less than or equal to 1*10<-3> pa and the temperature of the substrate reaches 350 and 450 DEG C, making the vacuum chamber in argon-nitrogen mixed atmosphere, sputtering the composite target for 60 to 120 minutes to obtain the tungsten nitride based ternary nano composite super-hard film material. The film material and the preparation method can be widely applied in the fields of mechanical manufacture, automobile and textile industry, geologic drilling, die industry and the like.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

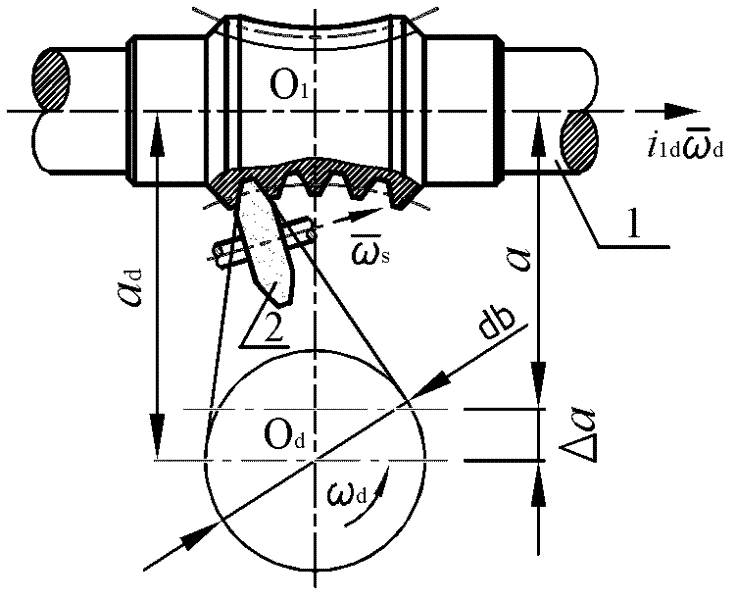

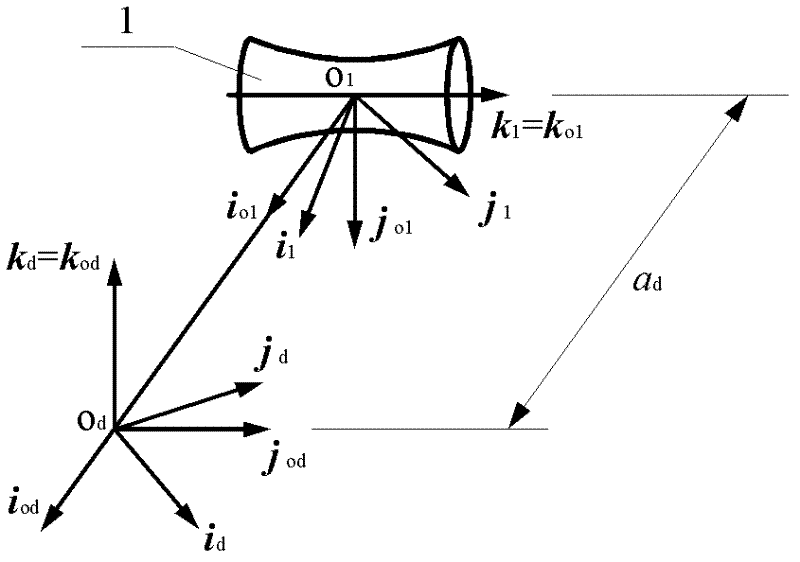

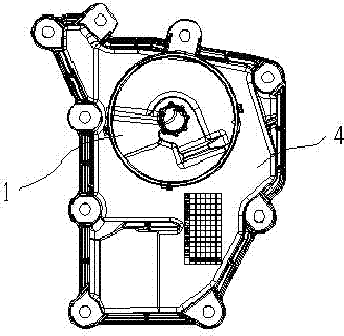

Modified double-toroid secondary enveloping toroid worm gear pair and manufacturing method thereof

InactiveCN102389996AEvenly distributedSparsely distributedToothed gearingsWorm wheelsGrinding wheelMechanical engineering

The invention relates to a modified double-toroid secondary enveloping toroid worm gear pair and a manufacturing method thereof. The technical scheme of the manufacturing method disclosed by the invention comprises the following steps of: grinding and spreading a toroid worm gear blank (1) by a double-toroid disc-shaped grinding wheel (2), wherein the process center distance is ad=a+delta a, and the process transmission ratio is i1d=i12+delta i; and adopting pure center distance profiling or adopting comprehensive profiling, determining profiling parameter ad and i1d by a trial method, calculating a worm gear engaging-out end reflecting line, and ensuring that the worm gear engaging-out end reflecting line can completely enter a first conjugate subarea of a worm wheel tooth surface. The cutting gear of a worm wheel is same as the relative standard transmission, only that a generative face of an applied toroid hob is consistent with a spiral surface of the modified worm gear. Accordingto the modified double-toroid secondary enveloping toroid worm gear pair disclosed by the invention, the worm wheel tooth surface does not exist a secondary contact area and can utilize the full length of a worm gear, a worm gear engaging-in end of the worm gear can keep the certain double-line contact length, and the manufacturing process is simpler and more flexible; and the modified double-toroid secondary enveloping toroid worm gear pair can also naturally inherit the advantages of standard double-toroid sedondary enveloping transmission.

Owner:WUHAN UNIV OF SCI & TECH

High-viscosity lithium ion battery slurry blending technology

InactiveCN107086292ACheap manufacturingSimple processCell electrodesTransportation and packagingAdhesiveEngineering

A high-viscosity lithium ion battery slurry blending technology is used for stirring of positive and negative slurries for a lithium ion battery and comprises the following steps: admixing an adhesive, a conductive agent, a thickening agent and an active substance into a stirring barrel, dry-blending, adding a solvent, wetting and kneading and dispersing, and finally filtering by the use of a filter screen so as to obtain slurry. Through dry-blending and kneading stirring process and by application of high-speed shearing force and mechanochemical force, the conductive agent covers around the granular active substance, and the adhesive is uniformly distributed in the active substance so as to obtain the uniformly-dispersed and stable slurry placed for a long time. By the technology, stirring time is shortened, production efficiency is raised, and cost is reduced. The preparation technology is simple and flexible, is suitable for large-scale slurry blending for lithium ion batteries, especially applicable to materials with small particle size and large specific surface area, and is a high-viscosity slurry mixing technology with a high-solid-content formula.

Owner:湖北猛狮新能源科技有限公司

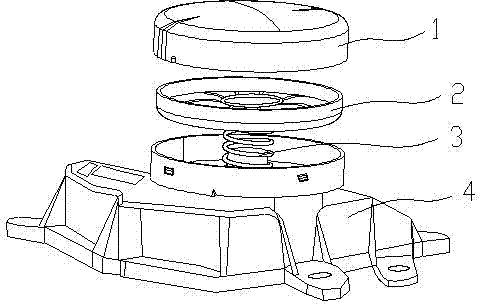

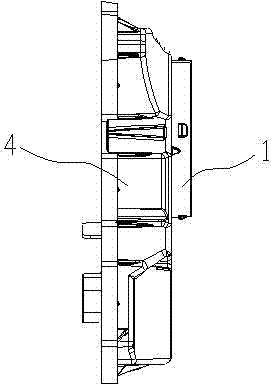

Plastic oil and gas separator with labyrinth type and screw type combined

ActiveCN103939177ALow densityHas the effect of double separationMachines/enginesCrankcase ventillationEconomic benefitsAir separation

The invention relates to a plastic oil and gas separator with the labyrinth type and the screw type combined in order to solve the problems that oil and gas separation efficiency can not be optimized, and the mixture of engine oil and gas can not be completely separated. The plastic oil and gas separator with the labyrinth type and the screw type combined comprises a shell and a clamping cover arranged on the end face of the shell and is characterized in that the shell is of a flat box type structure formed through one-time injection molding, and an oil and gas mixture inlet, an oil return cavity and an air separation cavity are all provided with smooth surfaces; the oil and gas mixture firstly passes through a labyrinth type channel and then passes through a fine separator assembly; the fine separator assembly is provided with a plurality of oil and gas separation holes with screw-type channels; the position where the clamping cover is matched with the shell is provided with an oil and gas separation diaphragm. The plastic oil and gas separator with the labyrinth type and the screw type combined is scientific and reasonable in structure and has good economic benefits and the environmental-friendly working effect, and separated matter can be recycled.

Owner:SHENTONG TECH GRP CO LTD

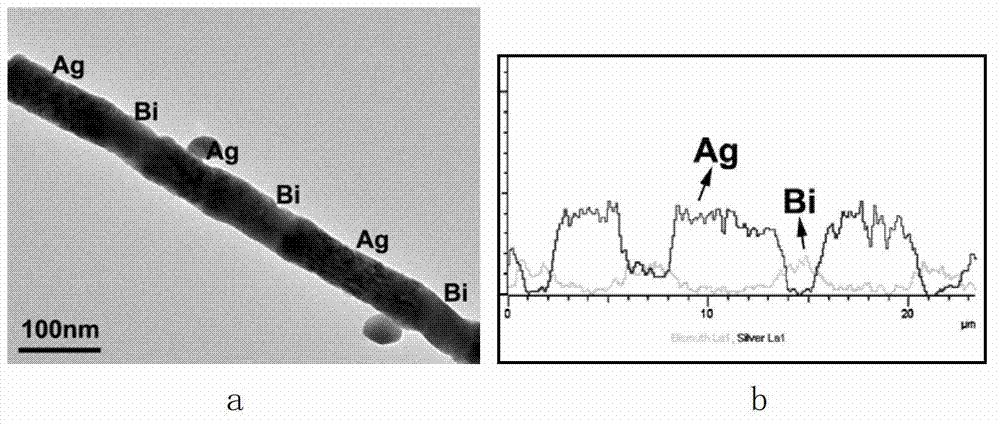

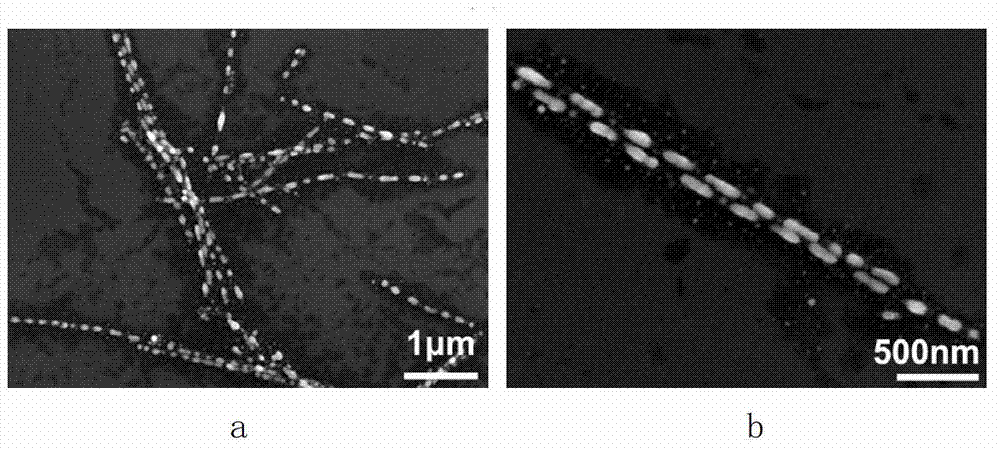

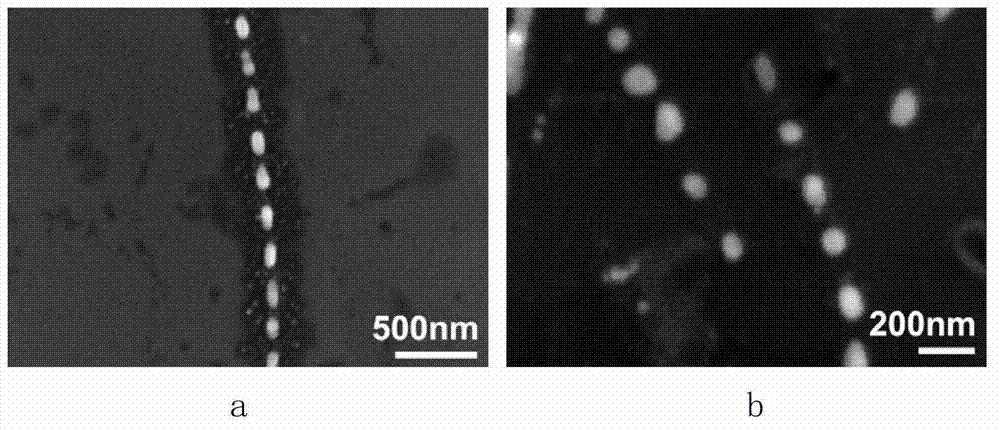

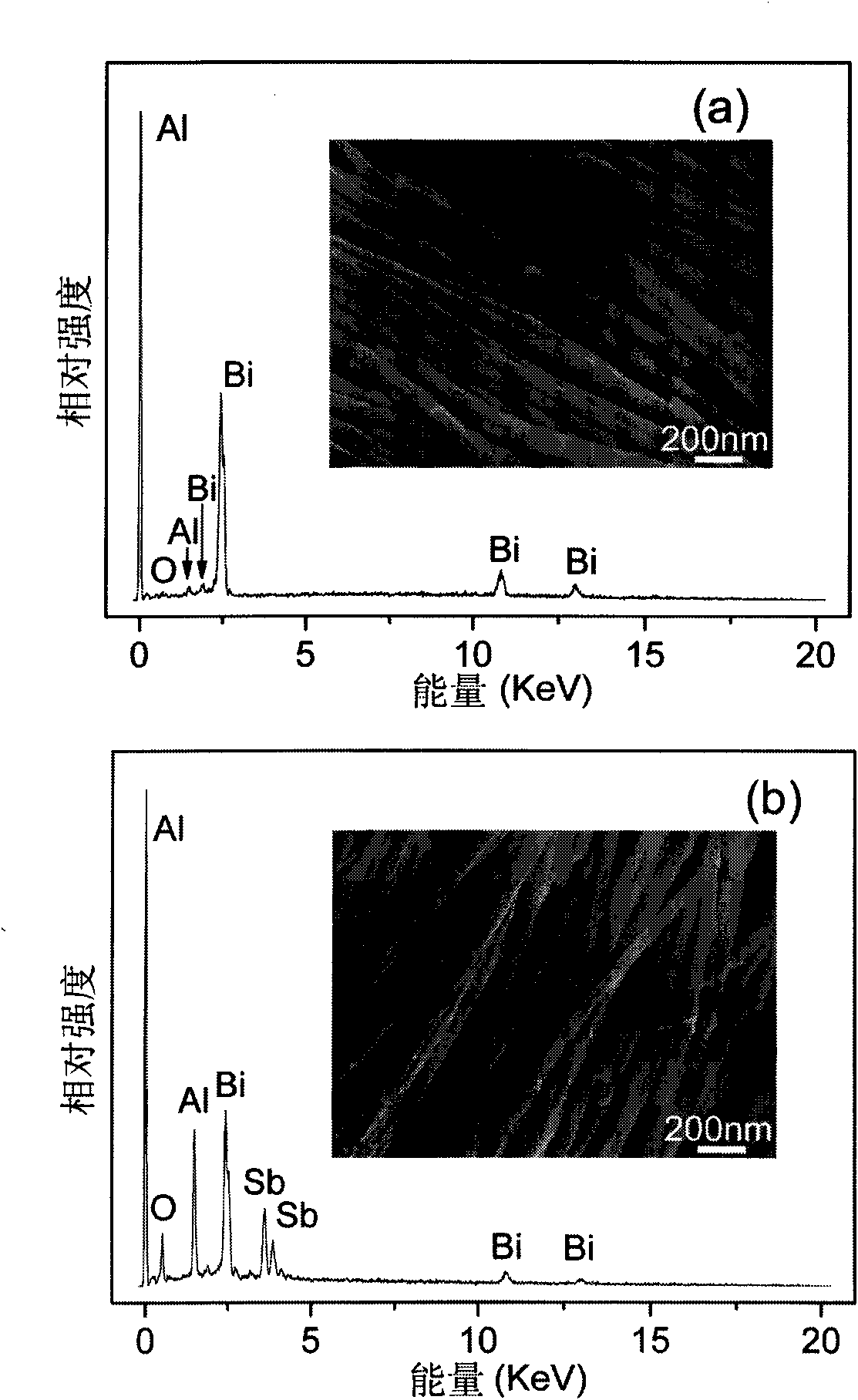

Preparation method for silver nanoparticle chain

ActiveCN103111621APreparation method scienceEfficient manufacturing methodNanotechnologyElectrolytic agentMetallic materials

The invention discloses a preparation method for a silver nanoparticle chain. At first, an aluminum sheet is processed through an anodic oxidation method so that a through-hole alumina template is obtained; a gold film is plated on one side of the through-hole alumina template in an evaporated mode and then the through-hole alumina template is used as a negative pole and placed in silver electrolyte and bismuth electrolyte respectively for multiple times of alternative electrolytic depositions, so that the alumina template is obtained, wherein the through holes of the through-hole alumina template are placed with the silver cylinders and the bismuth cylinders, the silver cylinders and the bismuth cylinders are connected alternatively and one side of the alumina template is plated with the gold film; then the alumina template is soaked in aqueous alkali, so that a nanowire array which is formed by the alternative connection of the silver cylinders and the bismuth cylinders is obtained; and then the nanowire array is placed in ethylalcohol for ultrasonic dispersion, so that a nanowire which is formed by the alternative connection of the silver cylinders and the bismuth cylinders is obtained; and the nanowire which is formed by the alternative connection of the silver cylinders and the bismuth cylinders is placed in an environment with a vacuum degree<=10 Pa to 3 Pa and a temperature 450 DEG C to 500 DEG C to be annealed for 2 hours to 6 hours, so that a target product is obtained. The preparation method for the silver nanoparticle chain has the advantages of being simple in process, low in cost, high in practical value, and capable of being widely used in the preparation of one-dimensional nanoparticle chains of various metal materials.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

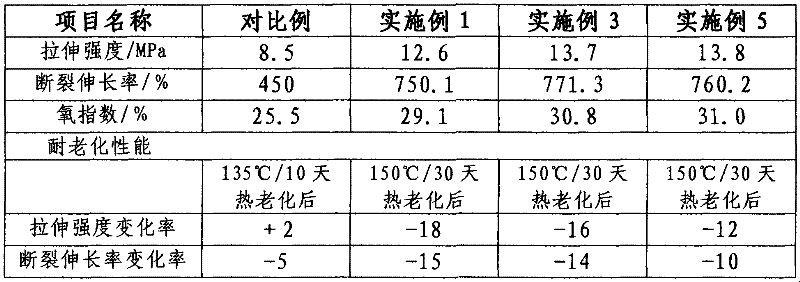

Nano composite ethylene-propylene rubber cable material and its preparation method

ActiveCN102344610AGood dispersionImproved and stabilized flame retardancyPlastic/resin/waxes insulatorsInsulated cablesActive agentMining industry

The invention discloses a nano composite ethylene-propylene rubber cable material and its preparation method. The material is composed of ethylene-propylene-diene rubber, a nano compound, an organic modifier, inorganic metal hydroxide, an aging resister, a curing active agent and a peroxide according to 100:1-20:0.5-10:50-200:0.5-10:10-20:0.1-10, wherein, the nano compound is nano montmorillonite and nano calcium carbonate according to the weight ratio of 1:0.5-2, the organic modifier is a silane coupling agent or a titanic acid coupling agent or methacrylic acid or acrylic acid, the curing active agent is zinc oxide and stearic acid, the peroxide is dicumyl peroxide. The preparation method comprises the following steps: proportioning the raw materials according to the weight, successively adding the raw materials with the corresponding weight into an open mill or an internal mixer for mixing, placing on a plate vulcanizing machine for vulcanizing, producing the products with zero-halogen flame-retardant, age resistance and excellent mechanical property. The products is suitable for the occasions with requirement of zero-halogen flame-retardant, age resistance and frequent movement in the nuclear power plants, warships, mining industry and the like.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Nanofiber membrane with heavy metal adsorbing function and preparation method of nanofiber membrane

InactiveCN104587981ASimple processLow costOther chemical processesWater contaminantsSorbentNanofiber

The invention relates to a nanofiber membrane with a heavy metal adsorbing function and a preparation method of the nanofiber membrane. The nanofiber membrane comprises a matrix and macromolecules self-assembled on the surface of the matrix. The preparation method comprises the following step: self-assembling the macromolecules carrying amino groups on a thermoplastic nanofiber membrane by virtue of a chemical oxidative polymerization method to obtain the nanofiber membrane. The nanofiber membrane is simple in preparation process and low in cost, and is capable of efficiently adsorbing heavy metal ions; the defect that a conventional heavy metal ion adsorbing agent requires to be separated for the second time is avoided; the effective removal of hexavalent chromium ions is realized by using a principle of first adsorption and then reduction; meanwhile, the macromolecules have a strong hydrogen bond function among hydrophilic nanofiber membranes, cannot drop from the membranes, and can be recycled.

Owner:DONGHUA UNIV

Liquid-containing film structure

InactiveCN101490602AImprove mechanical propertiesImproves Structural IntegrityLiquid crystal compositionsBiocideLiquid-crystal displayDisplay device

Owner:SIPIX IMAGING INC

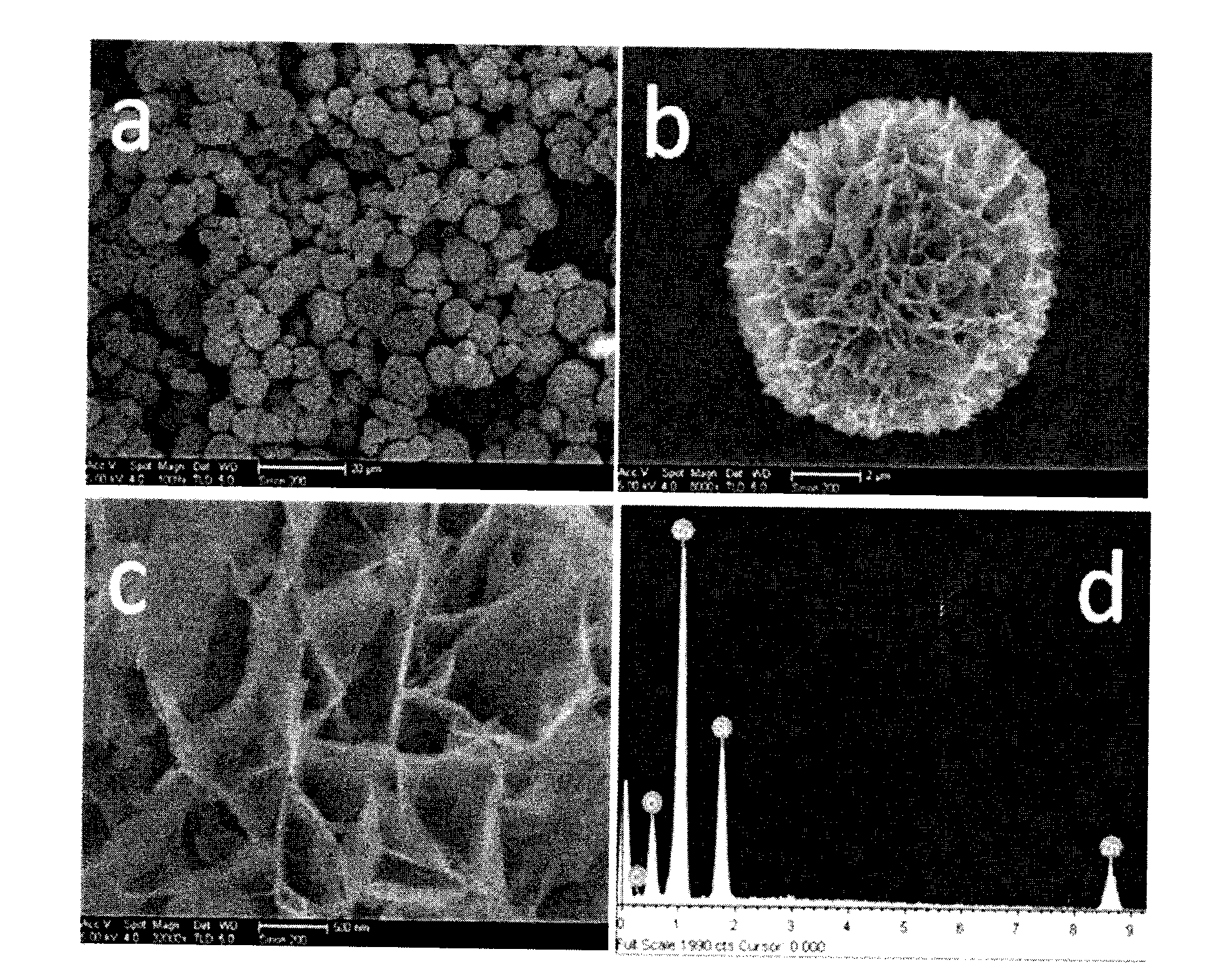

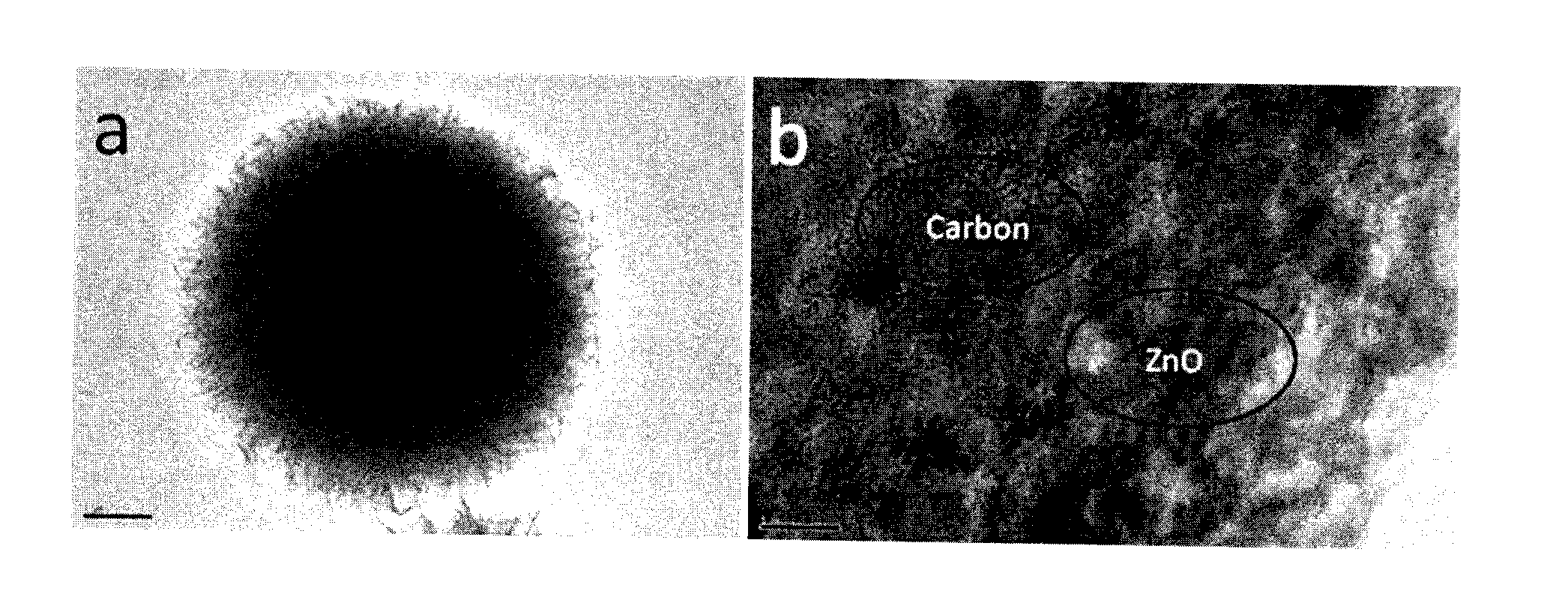

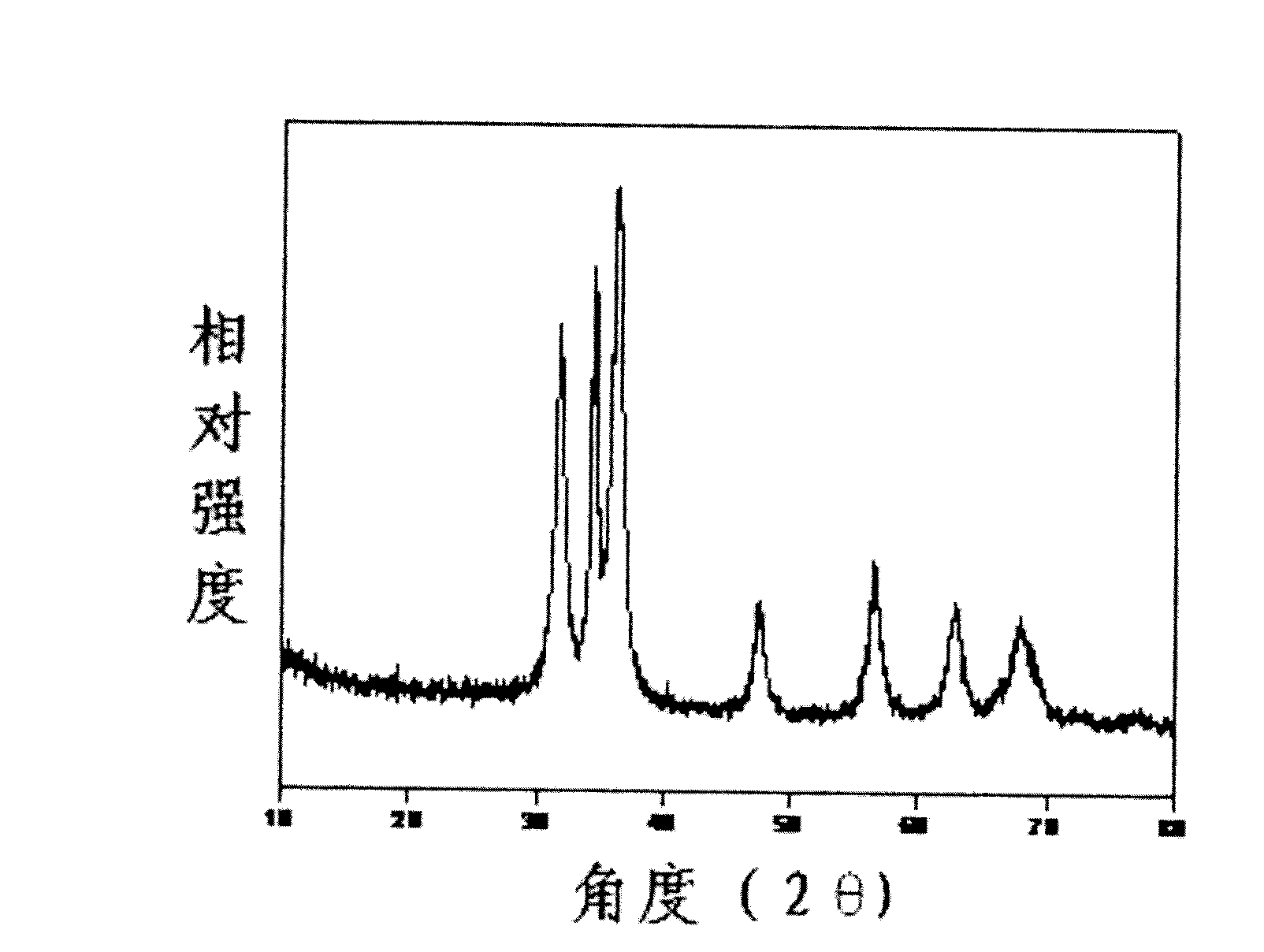

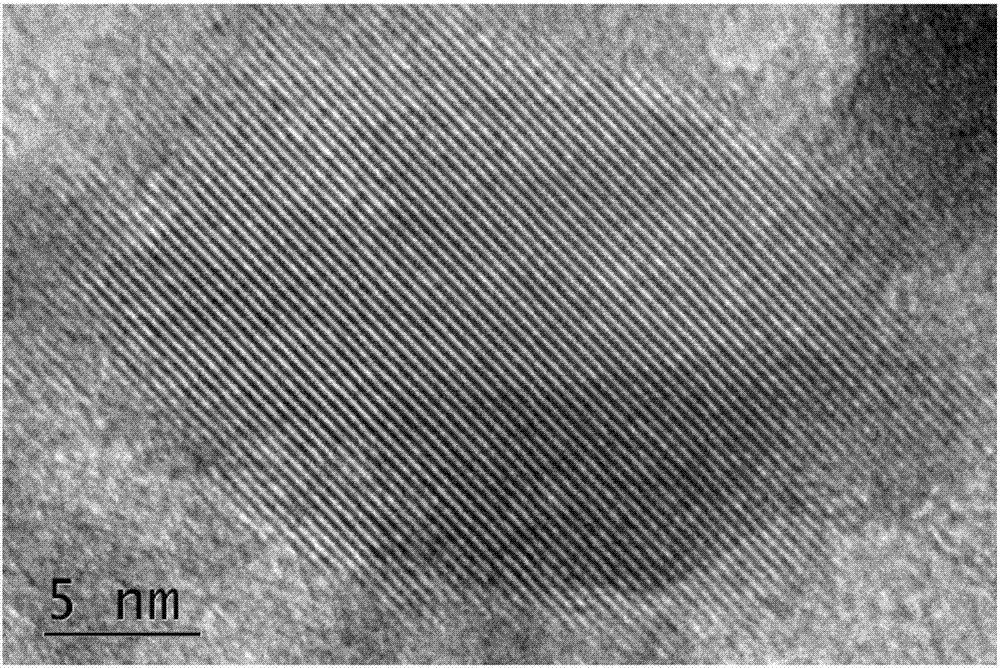

Micro-nano structure zinc oxide-carbon composite pellet and preparation method thereof

InactiveCN103145113ALarge specific surface areaTightly boundMaterial nanotechnologyZinc oxides/hydroxidesCarbon compositesMicro nano

The invention discloses a micro-nano structure zinc oxide-carbon composite pellet and a preparation method thereof. The micro-nano structure zinc oxide-carbon composite pellet is obtained by hybridization compounding of zinc oxide and carbon to obtain a solid pellet having the diameter of 6-12 micrometers, wherein vertical nanosheets having the length of 700-900 nanometers, the height of 700-900 nanometers and the thickness of 15 to 25 nanometers are formed on surfaces of the solid pellet and are connected with each other into a nest; a mole ratio of zinc oxide to carbon is (60-70%): (30-40%); zinc oxide has a hexagonal structure; and carbon comprises amorphous carbon and graphitized carbon and a weight ratio of the amorphous carbon to the graphitized carbon is (85-95%): (5-15%). The preparation method comprises the following steps of dissolving zinc acetate dihydrate, urea, sodium citrate dihydrate and glucose in water to obtain a mixed solution, carrying out hydrothermal treatment on the mixed solution to obtain a reaction solution, orderly carrying out solid-liquid separation, washing and drying to obtain an intermediate product, putting the intermediate product in an inert gas atmosphere, and carrying out annealing to obtain the micro-nano structure zinc oxide-carbon composite pellet. The micro-nano structure zinc oxide-carbon composite pellet can be widely used for fields of catalysis, adsorption and photoelectricity.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI +1

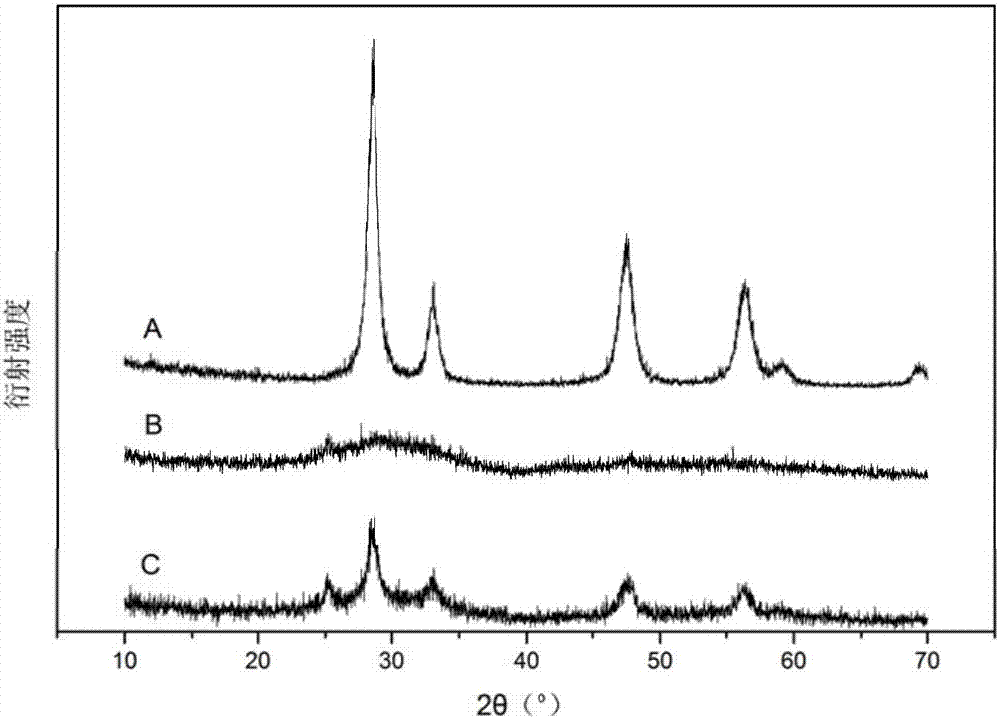

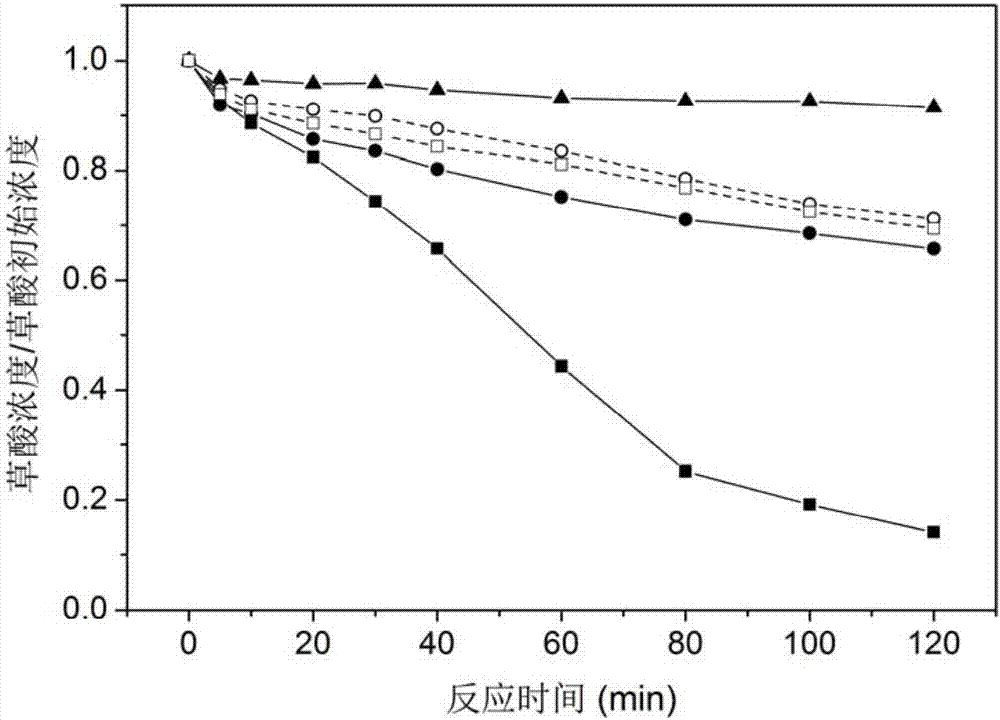

Millimeter level mesoporous ozone oxidation catalyst and preparation and application method thereof

ActiveCN106944027AHigh catalytic activityGood long-lasting activitySpecific water treatment objectivesWater contaminantsMicrosphereTitanium zirconium

The invention discloses a millimeter level mesoporous ozone oxidation catalyst and preparation and an application method thereof, belongs to the technical field of water processing, and aims to solve the problems that the hydrodynamic performance of a conventional ozone oxidation catalyst is bad, the catalytic efficiency is low, and the stability is insufficient. The millimeter level mesoporous ozone oxidation catalyst comprises cerium, titanium, zirconium, and oxygen, is a millimeter level mesoporous spherical particle, has a unique crystal structure, at the same time, has the advantages of durable and stable catalytic activity, excellent hydrodynamic characteristics and pore structure, high compression strength, acid / alkali resistance, ligand stability, oxidation resistance, and thermal stability, and can prominently improve the mineralization degree of ozone oxidation. The valence composition of active components is not changed after repeated use. The preparation method comprises the following steps: preparing millimeter level mesoporous titanium-zirconium composite microspheres by a calcium alginate template method, and then combining cerium and the titanium-zirconium compound by an impregnation method. The provided catalyst can be applied to fixed bed reactor / fluidized bed reactor wastewater treatment, and can be thermally regenerated when pollutants are accumulated on the catalyst.

Owner:NANJING UNIV

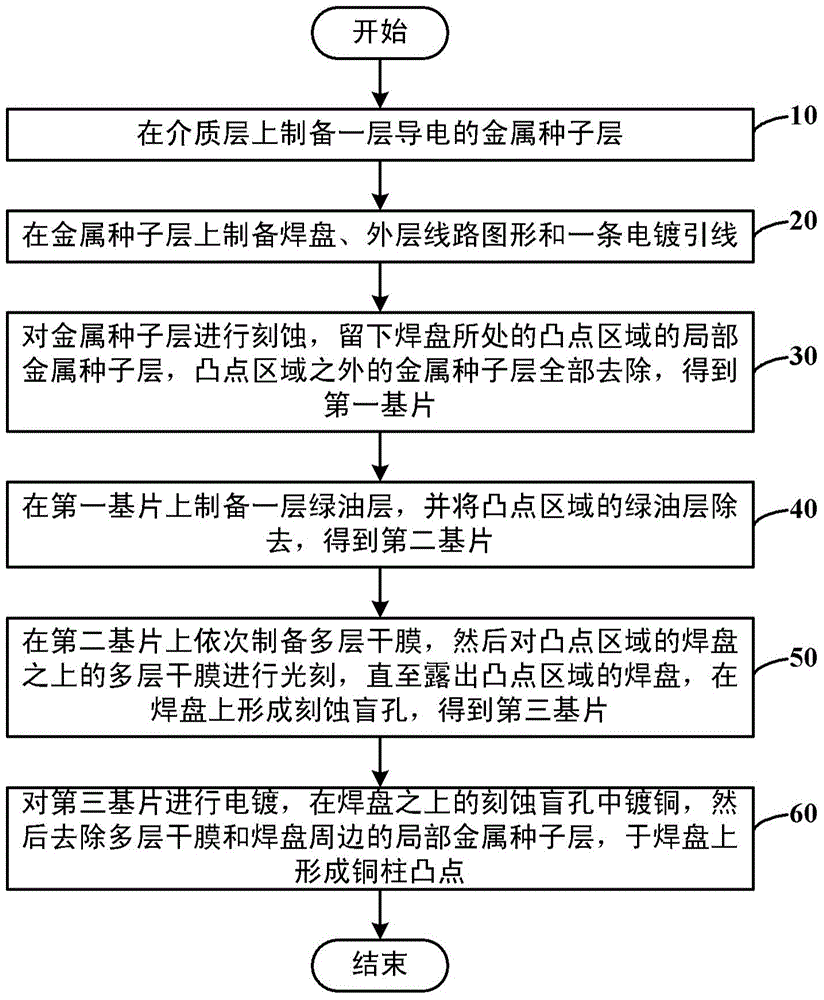

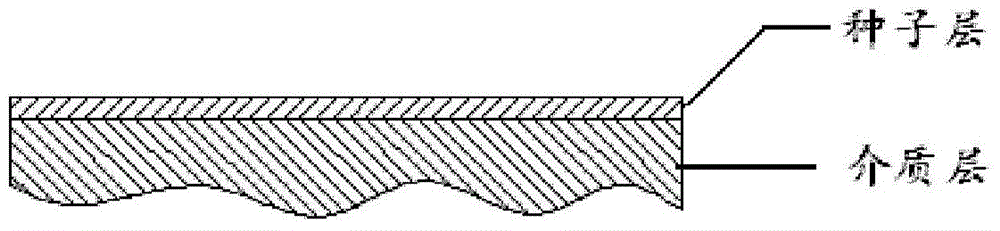

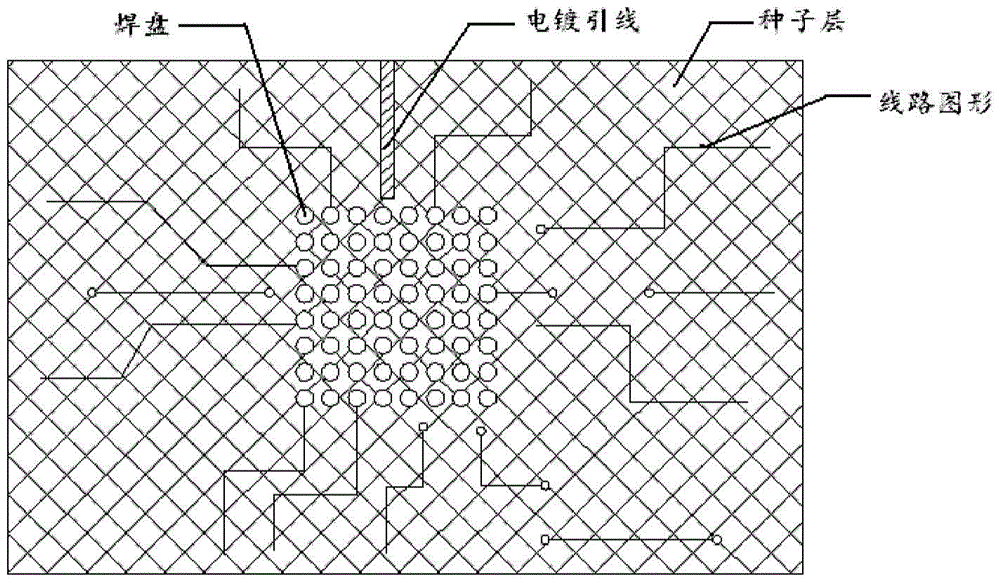

Method for preparing copper cylinder salient points

ActiveCN103985647AGood process compatibilityFlexible preparation processSolid-state devicesSemiconductor/solid-state device manufacturingCopper platingOptoelectronics

The invention discloses a method for preparing copper cylinder salient points. With the adoption of the local metal seed layer technology and the multilayer sensitive dry film technology, the method includes the steps that a conductive metal seed layer is prepared on a dielectric layer; a bonding pad, an outer-layer circuit pattern and an electroplating lead are prepared on the metal seed layer; the metal seed layer is etched, a local metal seed layer of a salient point region where the bonding pad is located is reserved, the portions, except for the salient point region, of the metal seed layer are all removed, and therefore a first substrate is obtained; a green oil layer is prepared on the first substrate, the portion, in the salient point region, of the green oil layer is removed, and therefore a second substrate is obtained; multiple layers of dry films are sequentially prepared on the second substrate, photoetching is then conducted on the dry films on the bonding pad of the salient point region until the bonding pad of the salient point region is exposed, etching blind holes are formed in the bonding pad, and therefore a third substrate is obtained; the third substrate is electroplated, the etching blind holes in the bonding pad are plated with copper, the portions, around the dry films and the bonding pad, of the local metal seed layer are then removed, and therefore copper cylinder salient points are generated on the bonding pad.

Owner:NAT CENT FOR ADVANCED PACKAGING

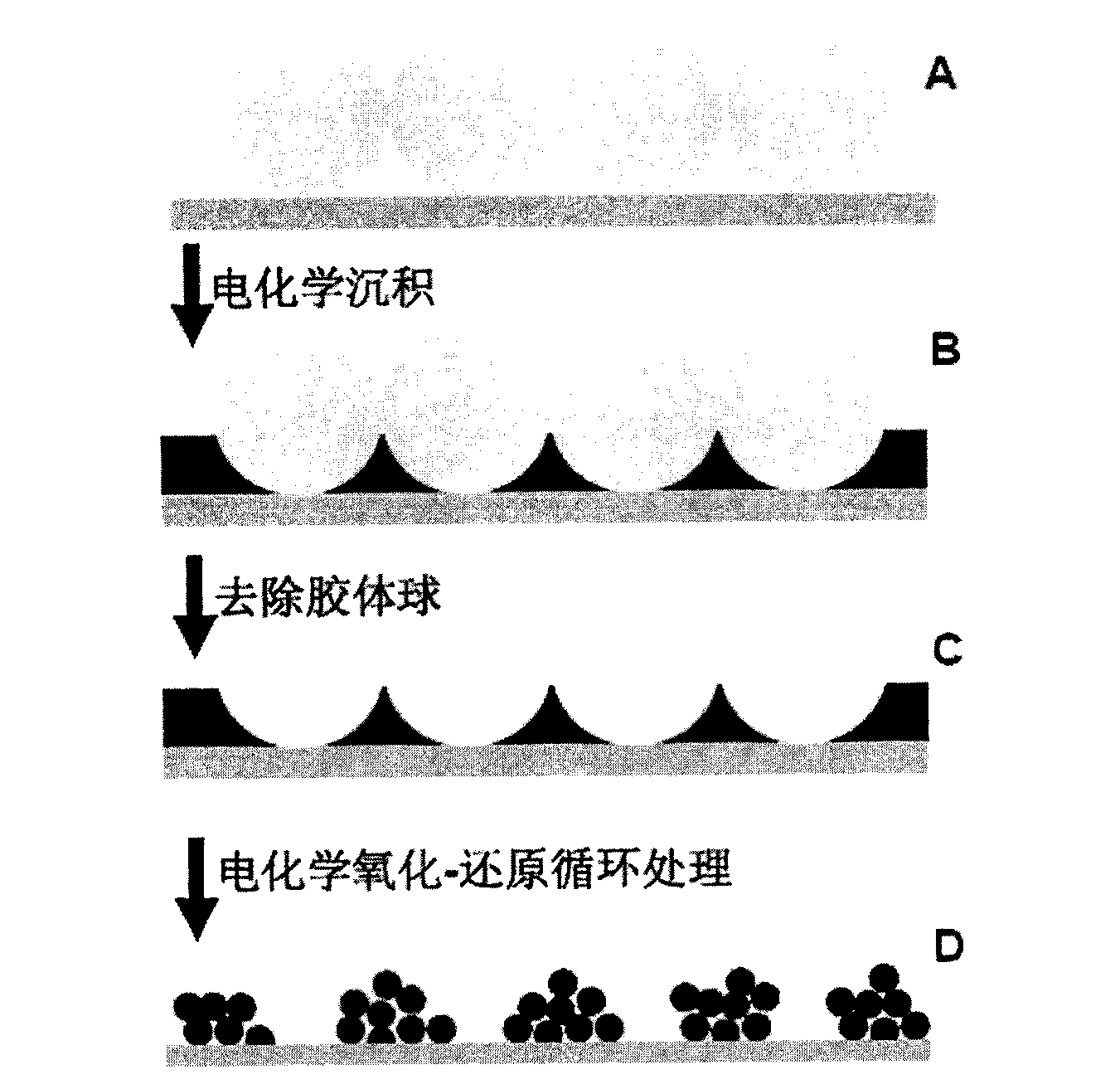

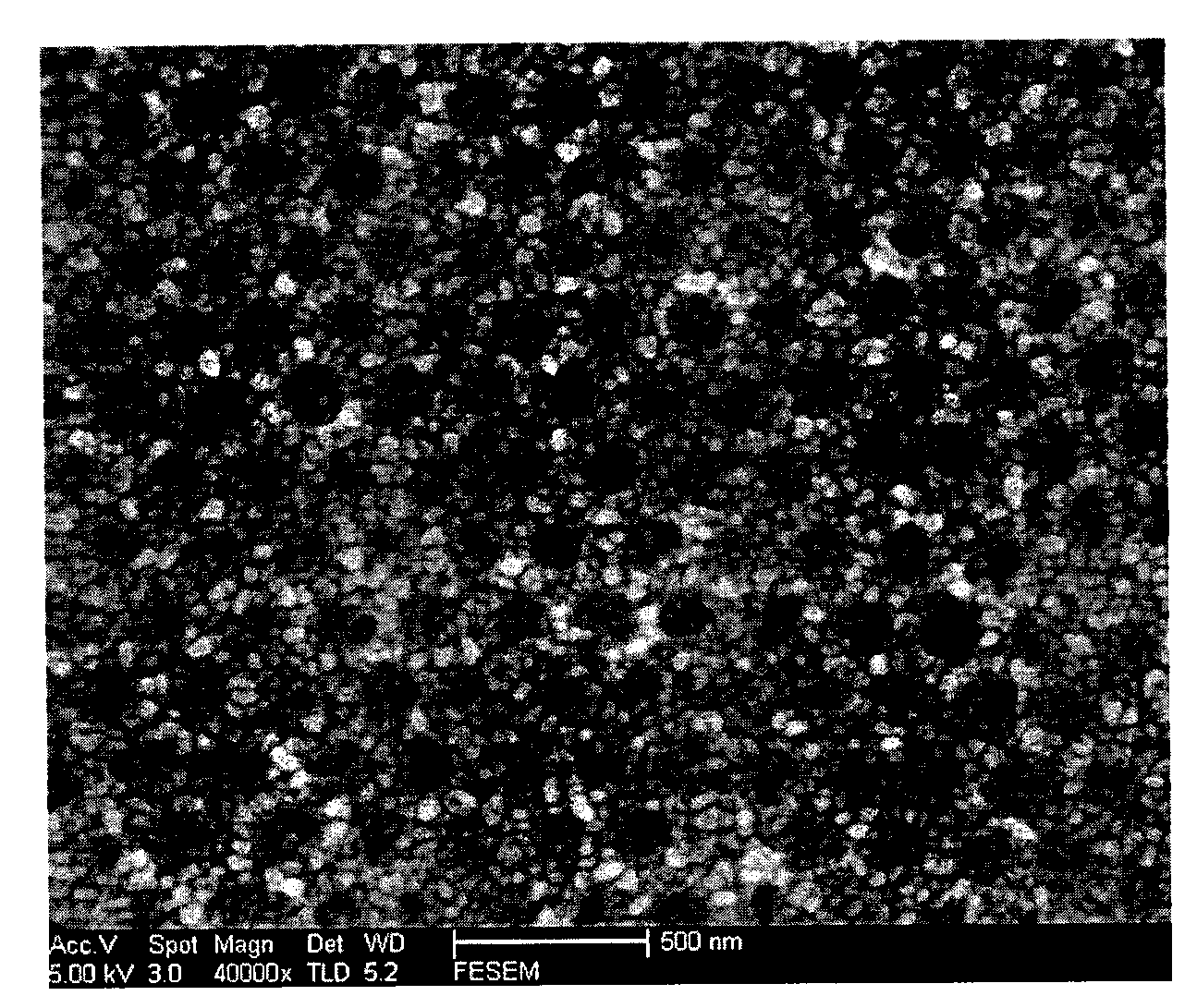

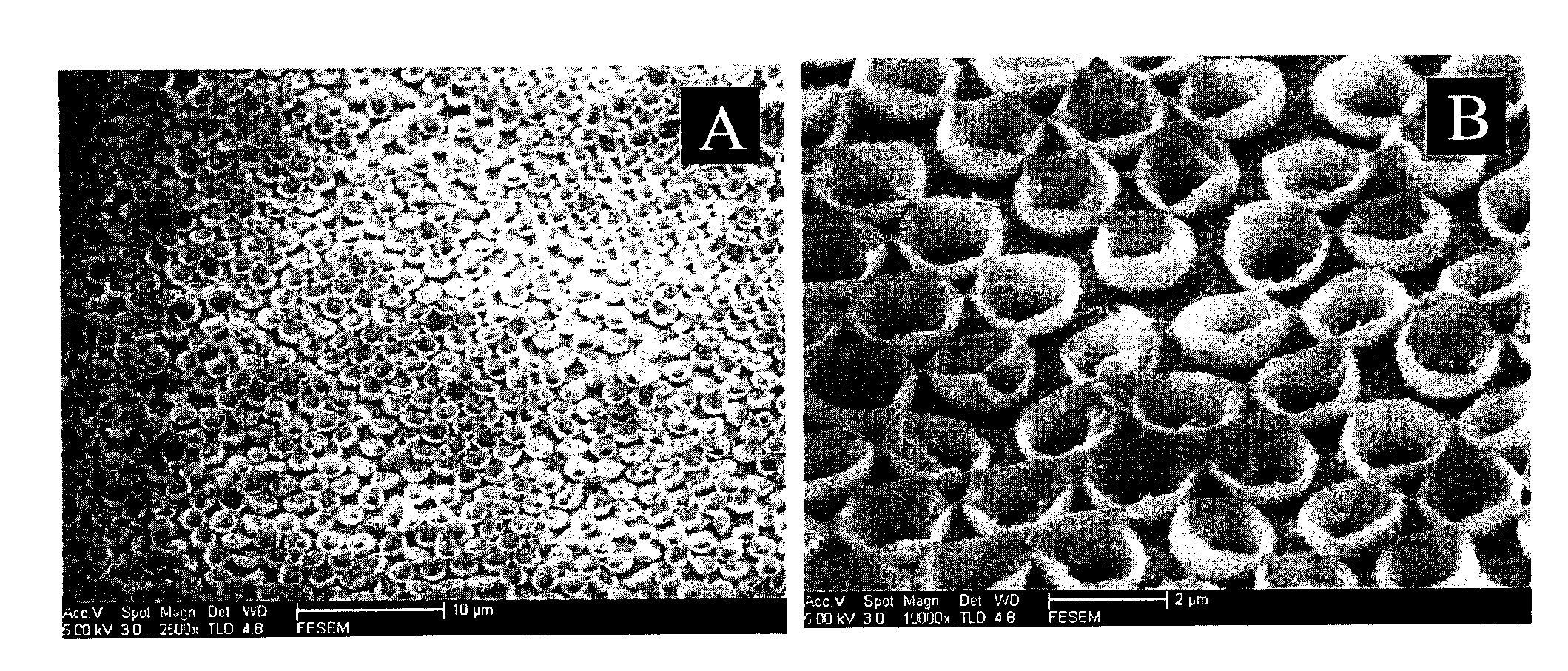

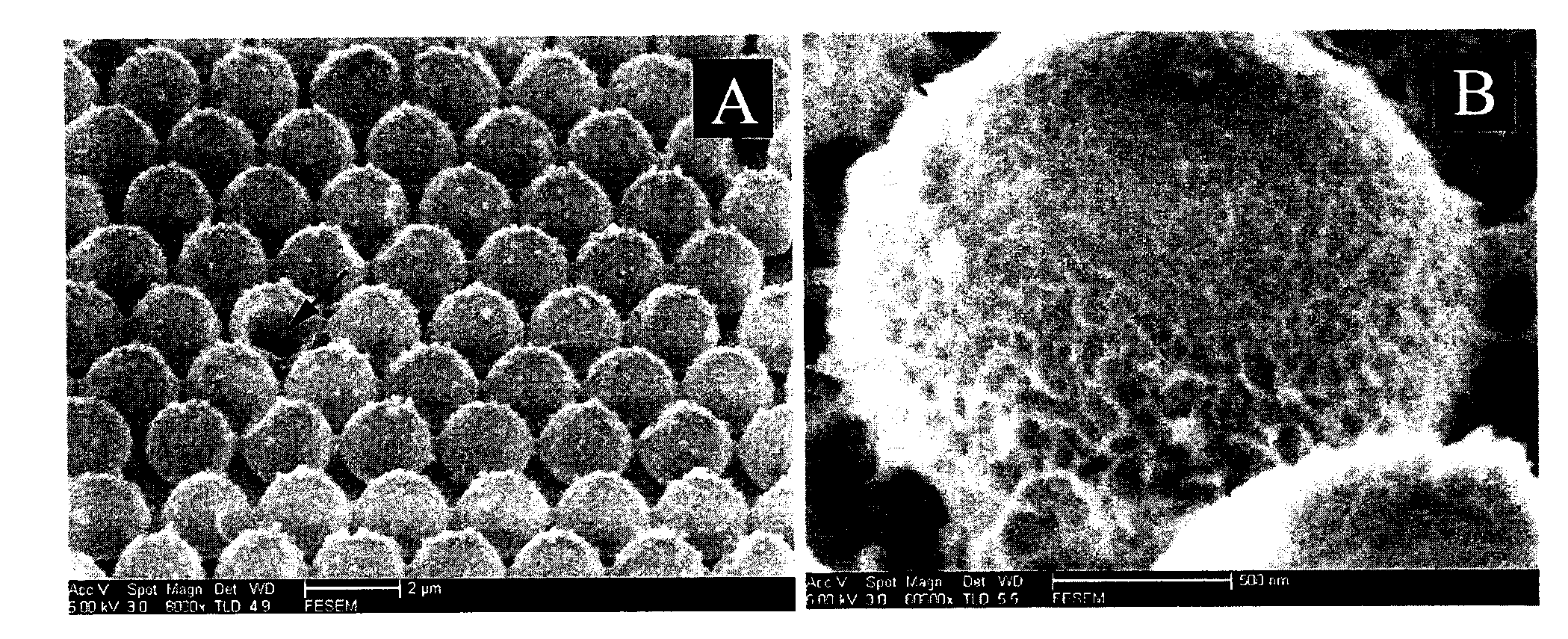

Ordered hole array with gold-nanoparticle-based micro-nanometer composite structure and preparation method for ordered hole array

InactiveCN102877094AWith micro-nano structureImprove stabilityElectroforming processesGold particlesPolystyrene

The invention discloses an ordered hole array with a gold-nanoparticle-based micro-nanometer composite structure and a preparation method for the ordered hole array. According to the array, gold particles which form a wall of the ordered hole array are accumulated on a conducting substrate, the spacing of ordered holes is 0.1 to 30mu m, the particle size of each gold particle is 10 to 100nm, and 1 to 300 layers of gold particles are accumulated. The method comprises the following steps of: putting a single-layer colloidal crystal template on the conducting substrate; putting the conducting substrate into a gold electrolyte and electrodepositing to obtain a complex array; dissolving polystyrene colloidal spheres in the complex array to obtain a gold body array; and putting the gold body array into a potassium chloride solution for electrochemical oxidation-reduction circulation treatment, wherein the process of the electrochemical oxidation-reduction circulation treatment is that: the voltage begins from -0.3V, linearly rises to 1.2V at the rate of 1V / s, remains for 1.2s, and linearly drops to -0.3V at the rate of 0.5V / s, and the operation is circulated for 5 to 35 times to obtain a target product. The target product can be widely used for catalysis, electrochemistry and surface-enhanced Raman scattering active substrates.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

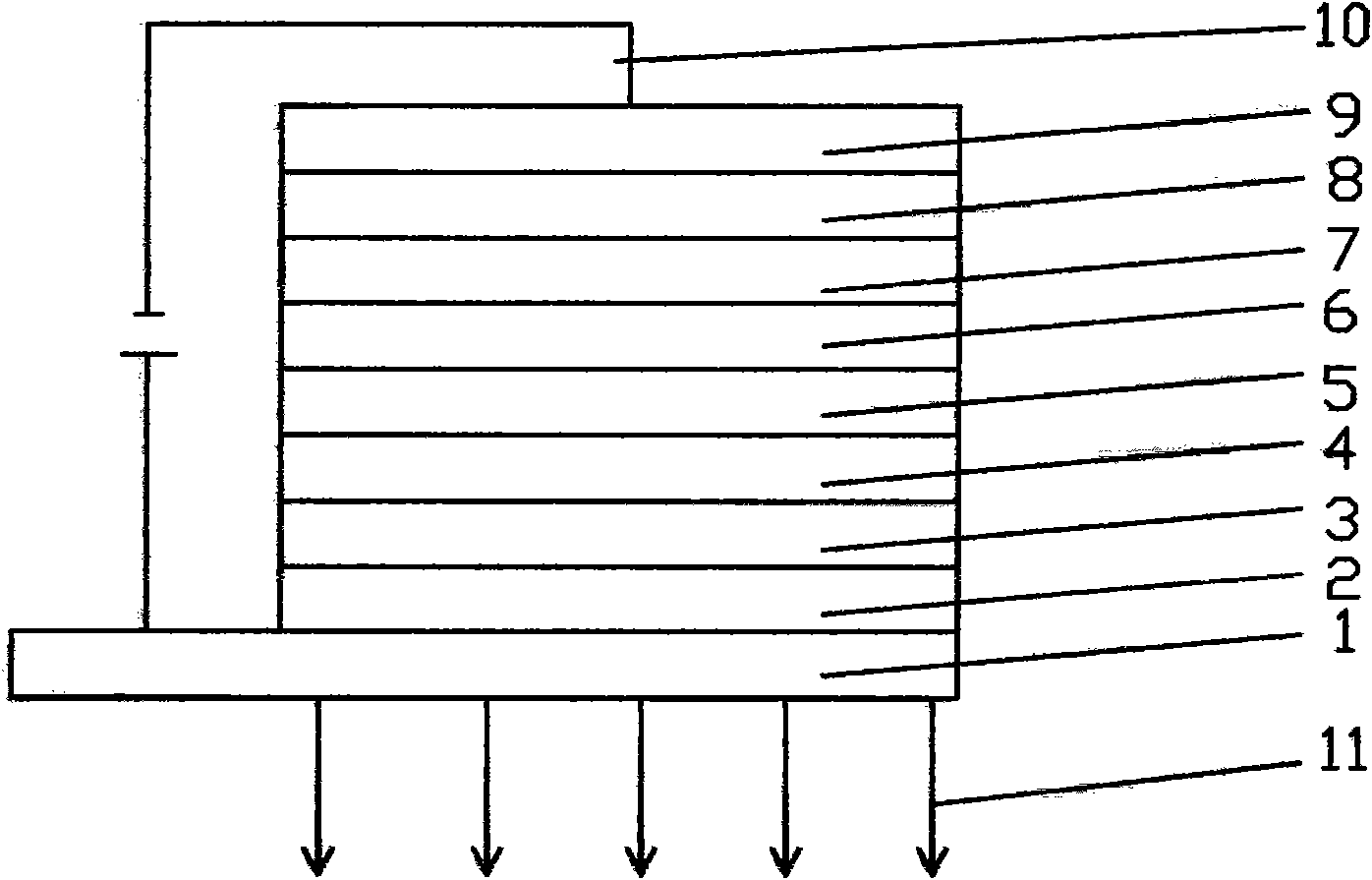

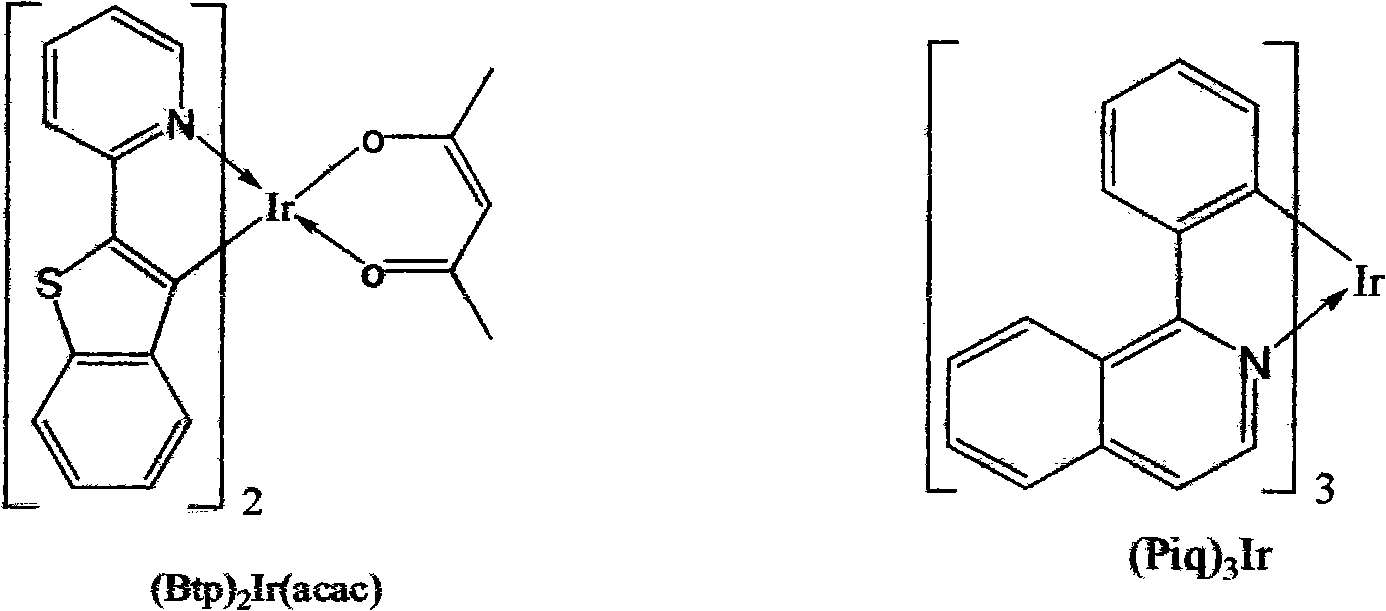

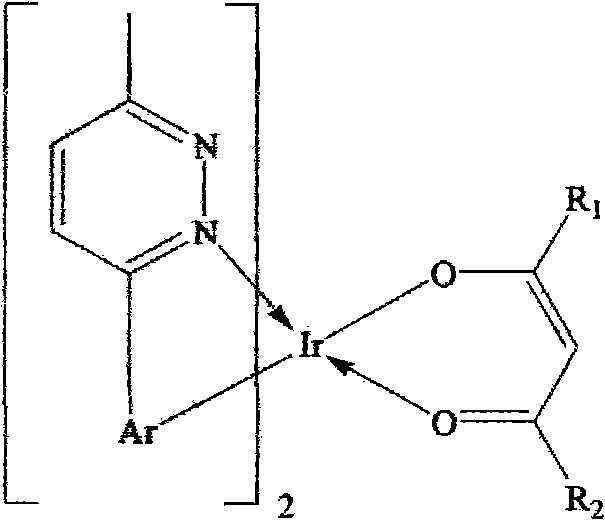

Novel efficient metallic iridium coordination compound red organic electrophosphorescent material and organic electroluminescent device thereof

InactiveCN101935523AImprove overall lifespanImprove efficiencyGroup 8/9/10/18 element organic compoundsSolid-state devicesIridiumDopant

The invention discloses a novel efficient metallic iridium coordination compound red organic electrophosphorescent material and an organic electroluminescent device thereof. The organic electroluminescent device is in a lamellar doping type structure, wherein a luminescent layer adopts Zn(BTZ)2 as a phosphorescent main material and a series Ir (III) coordination compound as a doping agent. The metallic iridium coordination compound red organic electrophosphorescent material taking pyridazine united aromatic hydrocarbon as a basic skeleton structure can realize saturated red phosphorescence emission of 610-620 nanometers with colour purity (0.65, 0.35) by combining with the structure optimization of the organic electroluminescent device taking the metallic iridium coordination compound red organic electrophosphorescent material as the doping agent and has maximum current efficiency of 12 cd / A and service life of 20000 hours; and compared with the traditional red light material, the metallic iridium coordination compound red organic electrophosphorescent material has the advantages of higher efficiency, more saturated colour purity and obvious red phosphorescent emission of the service life of the excellent device. The invention has flexible manufacture process and provides excellent materials for full color display and illumination application.

Owner:XIAN RUILIAN NEW MATERIAL CO LTD

Suspension liquid-state iron-containing composite reagent as well as preparation method thereof and method for efficiently removing selenate in water

ActiveCN106365244AEfficient removalImprove cleaning efficiencyWater contaminantsWater/sewage treatment by flocculation/precipitationHigh concentrationSulfate radicals

The invention discloses a suspension liquid-state iron-containing composite reagent as well as a preparation method thereof and a method for efficiently removing selenate in water and belongs to the technical field of water treatment. The method for efficiently removing selenate in water comprises the following three steps: step one, preparing the suspension liquid-state iron-containing composite reagent from zero-valence iron powder, water, hydrogen peroxide and hydrochloric acid; step two, removing selenate by using the suspension liquid-state iron-containing composite reagent, and integrally adding the prepared suspension liquid-state iron-containing composite reagent containing a solid phase, a colloidal phase and a liquid phase into selenate-containing water to be treated; and step three, carrying out solid-liquid separation. The suspension liquid-state iron-containing composite reagent has the advantages that the iron-containing composite reagent is simple to prepare and low in cost of raw materials, the iron-containing composite reagent contains a plurality of reduction active components, the removal of selenic acid through a reduction method is facilitated, and the iron-containing composite reagent is rich in colloidal phase and high in efficiency of transferring mass with solution, has both adsorption and flocculation effects, is capable of efficiently removing selenate, can still efficiently operate in the co-presence of anions such as high-concentration sulfate radicals and the like, is especially applicable to high-salt selenium-containing wastewater, is environmental-friendly, and is free of secondary pollution.

Owner:NANJING UNIV

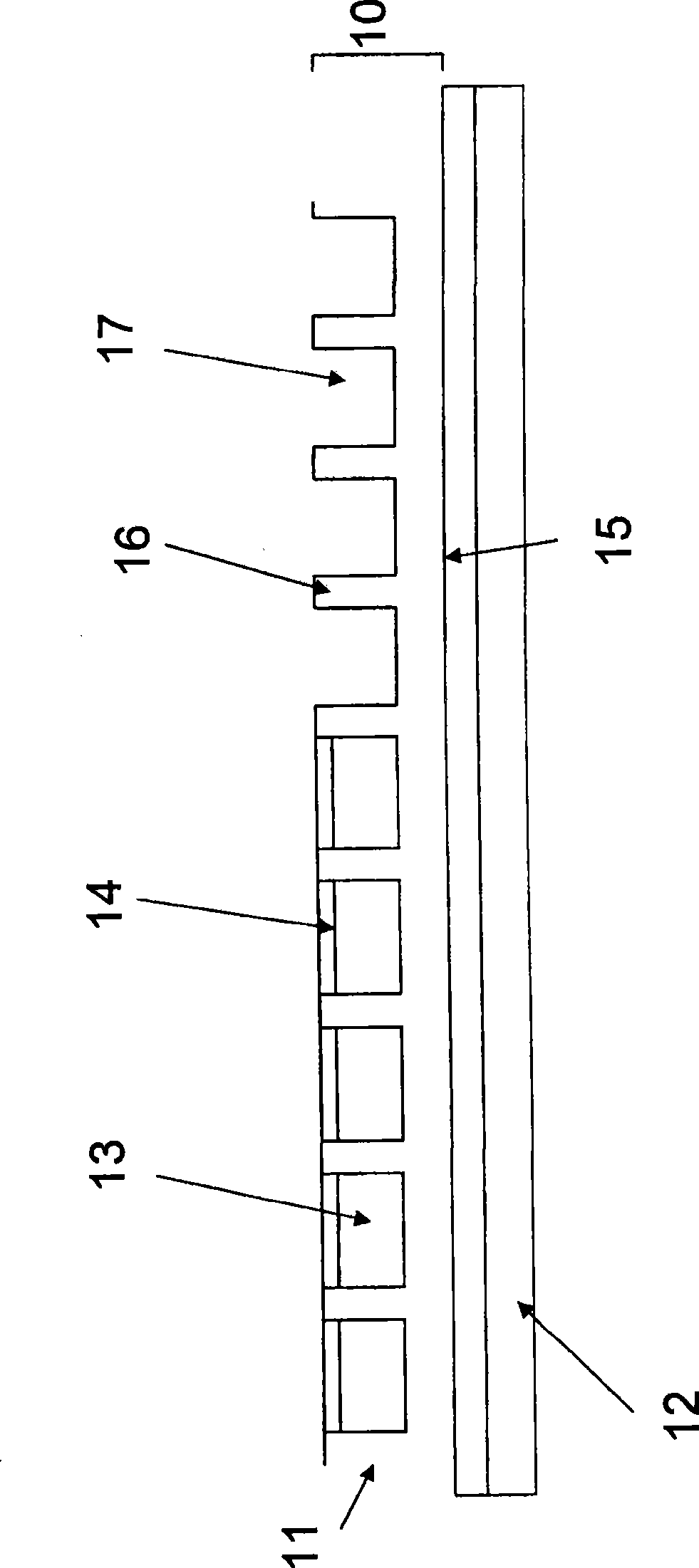

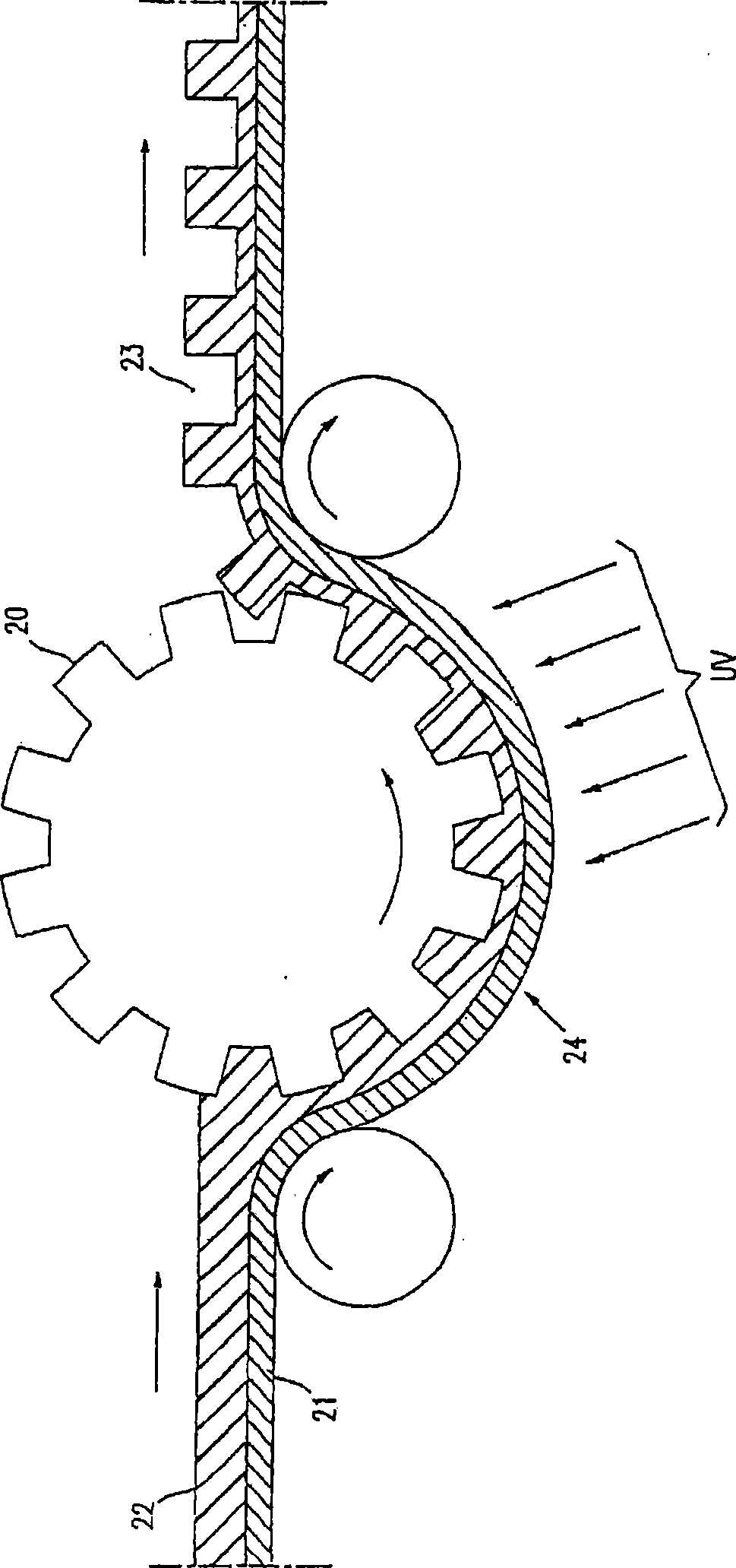

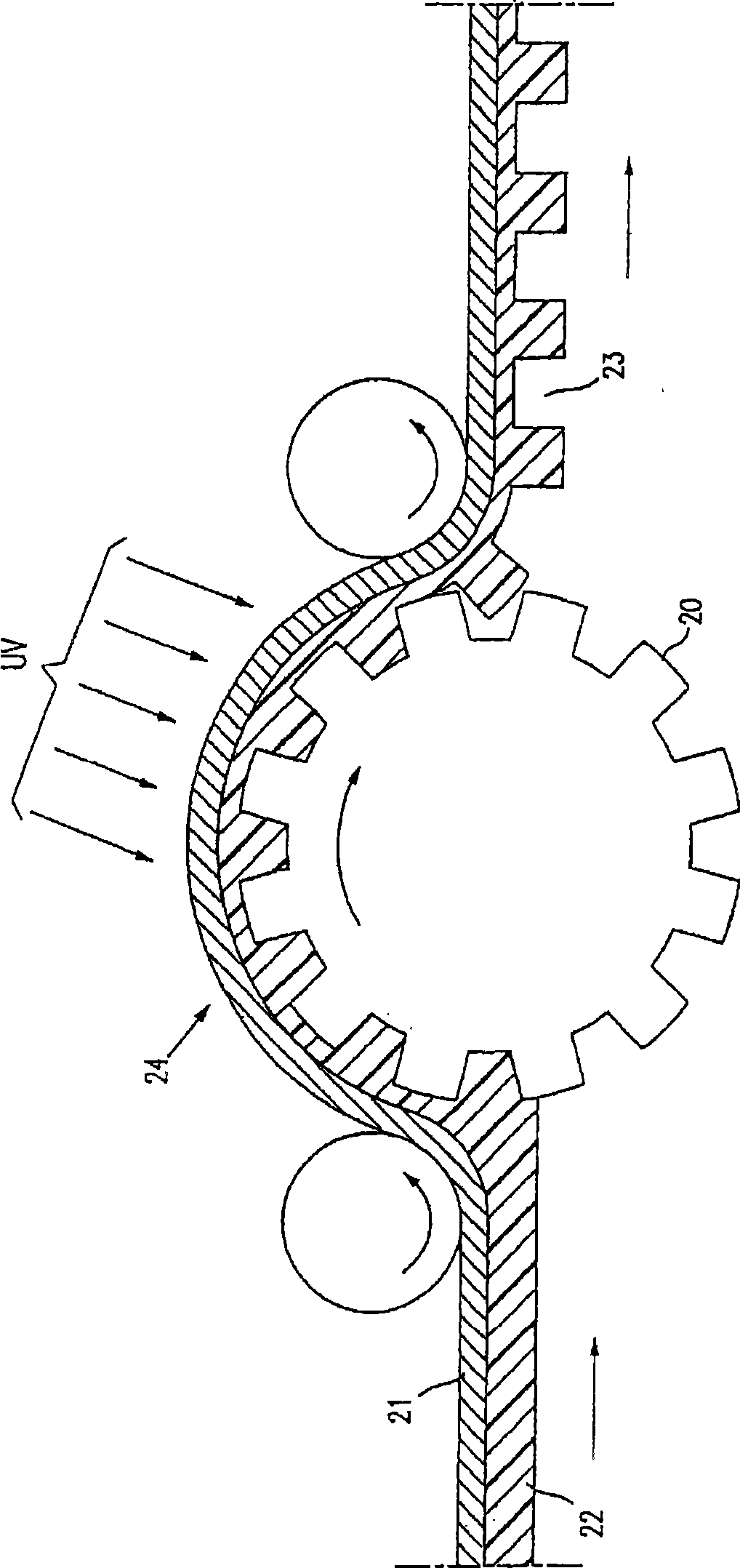

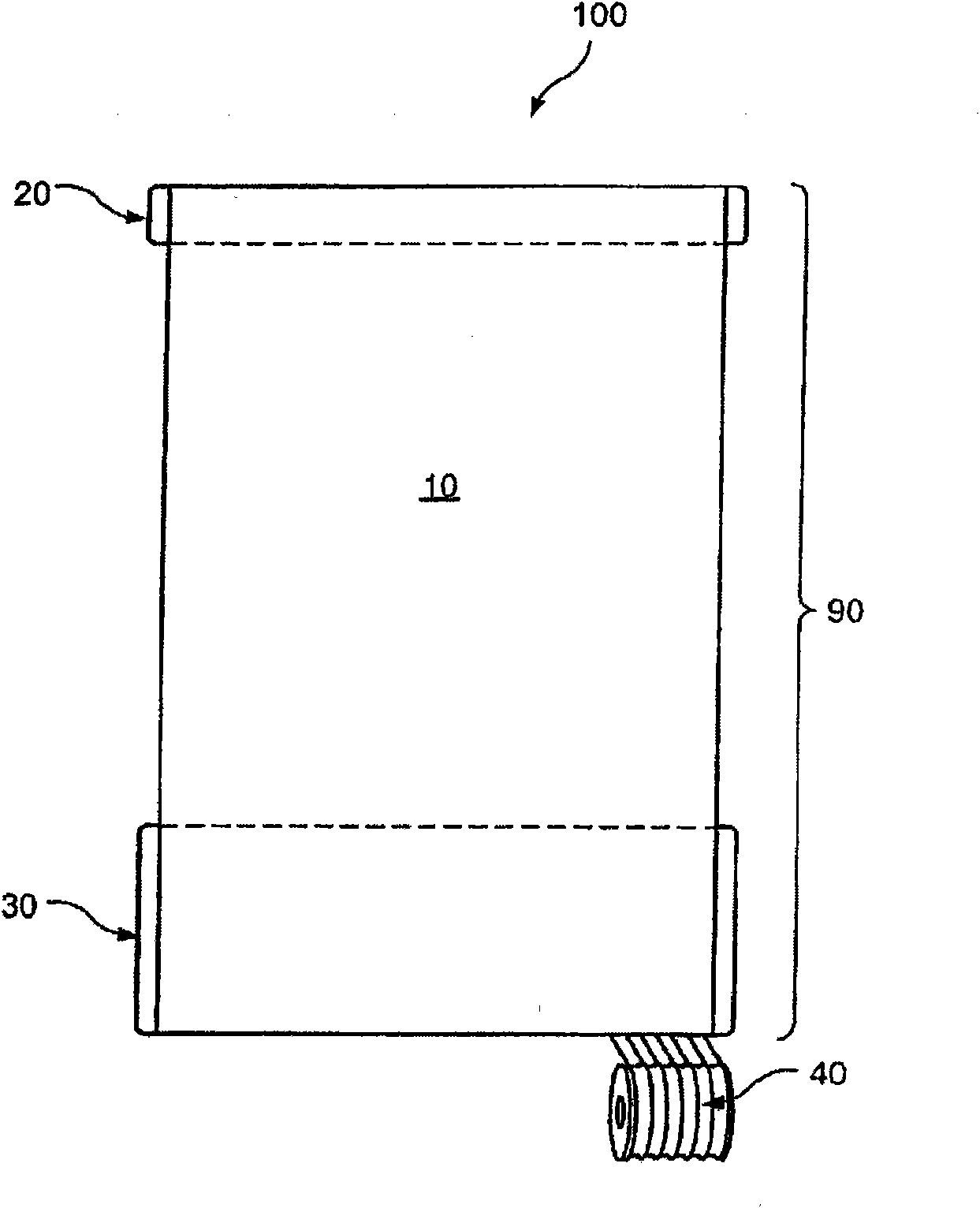

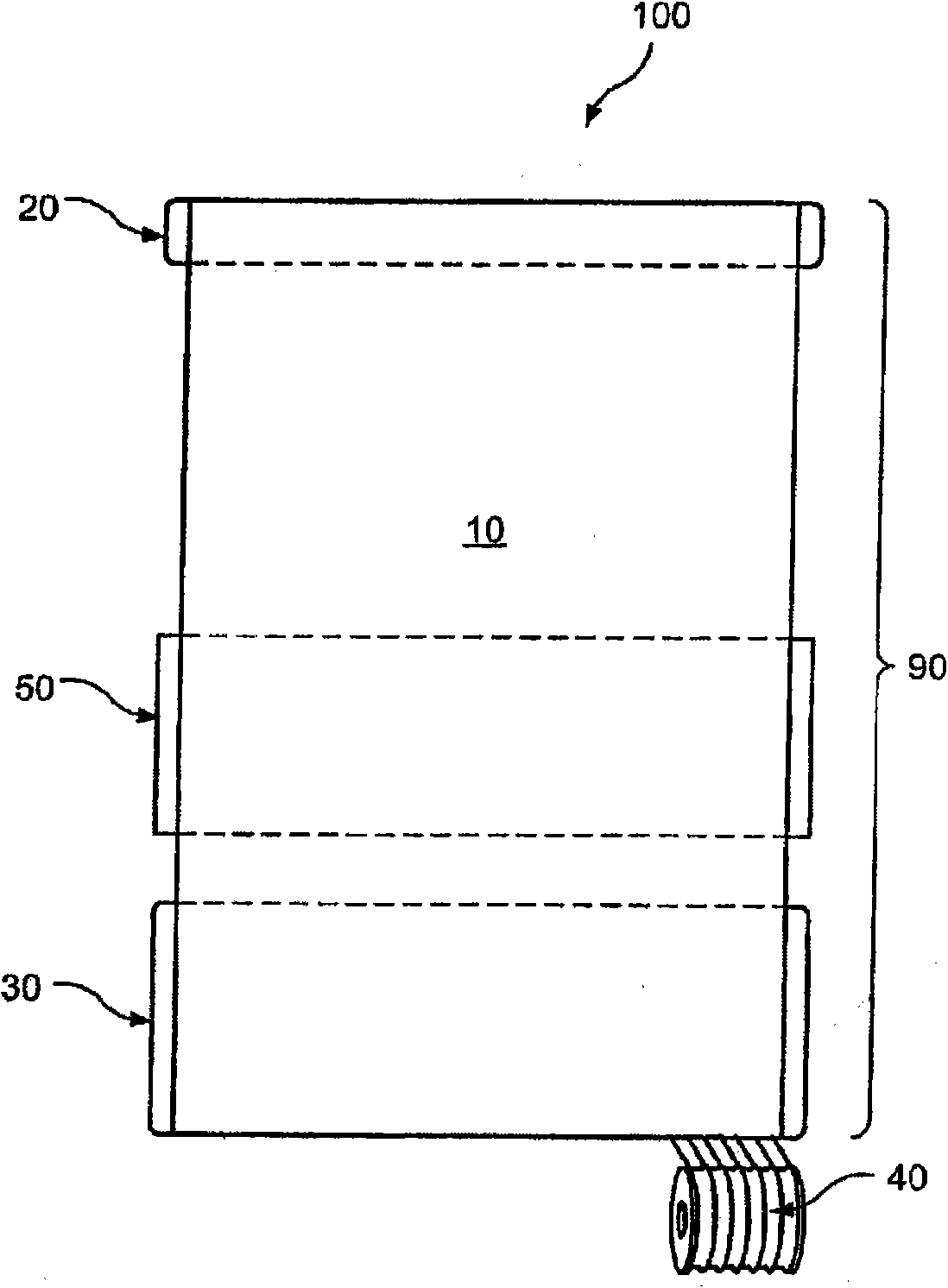

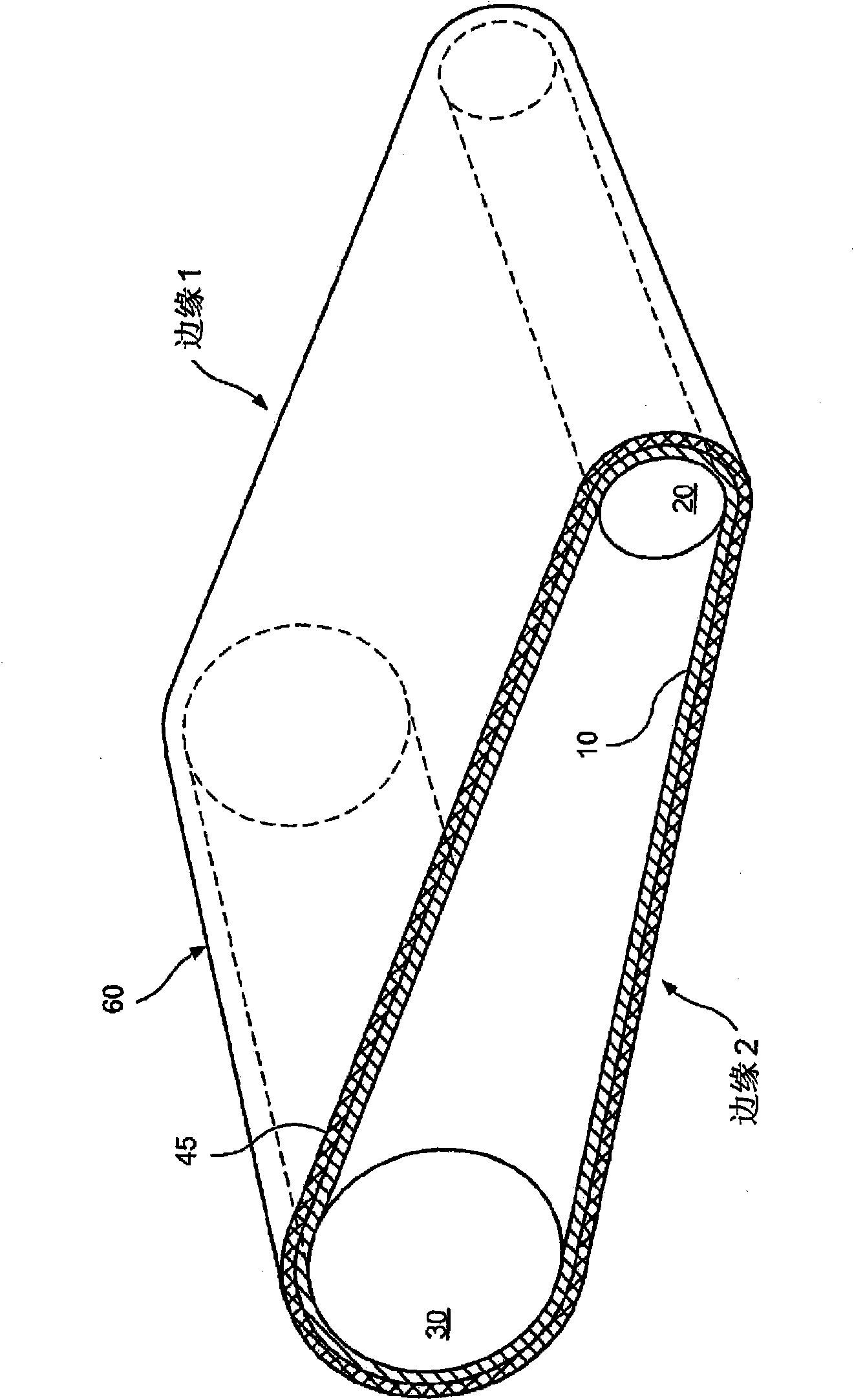

Multilayer fabric and manufacturing method thereof

ActiveCN101784723AImprove productivityFlexible preparation processLayered productsFibre treatmentFiberMechanical engineering

The invention is directed to a method and machine for manufacturing an industrial fabric using a ''folding'' technique. The invention relates to a laminated fabric that is produced using this technique. The method comprises the steps of forming a base support structure having a width which is larger than a width of the final fabric, attaching at least one layer of staple fiber batt material to one or both sides of the base support structure, folding the base support structure onto itself in a widthwise manner one or more times to form a multi-layered structure, and bonding the layers of the multilayered structure together to form a laminated fabric structure.

Owner:ALBANY INT CORP

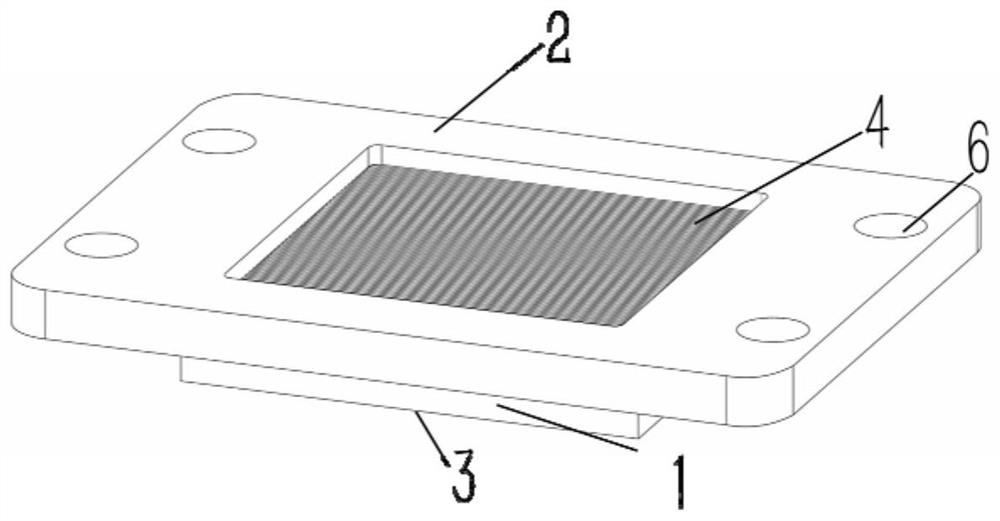

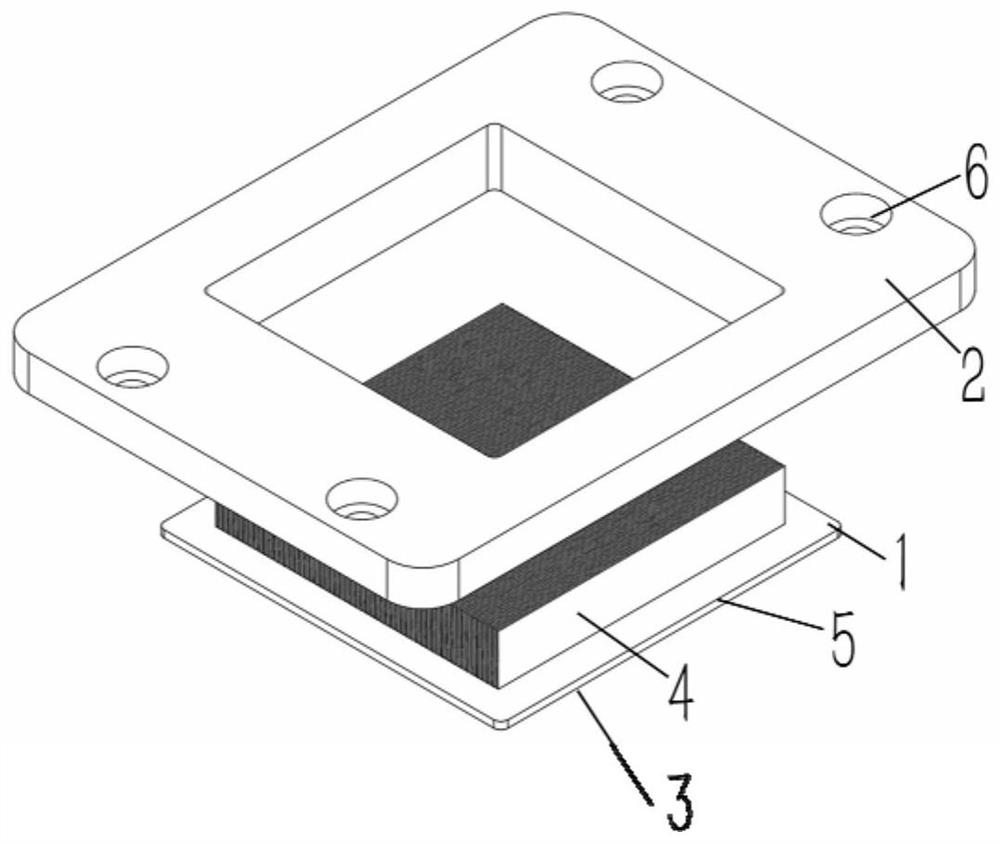

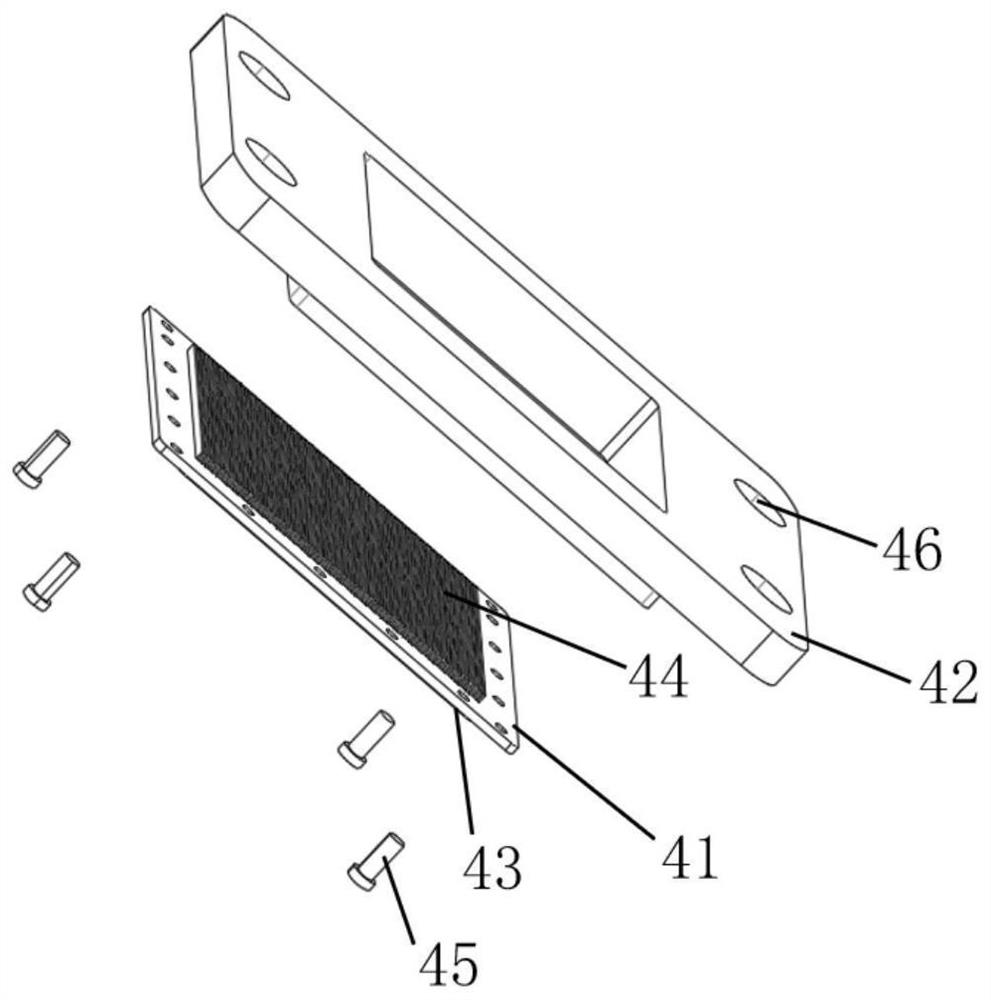

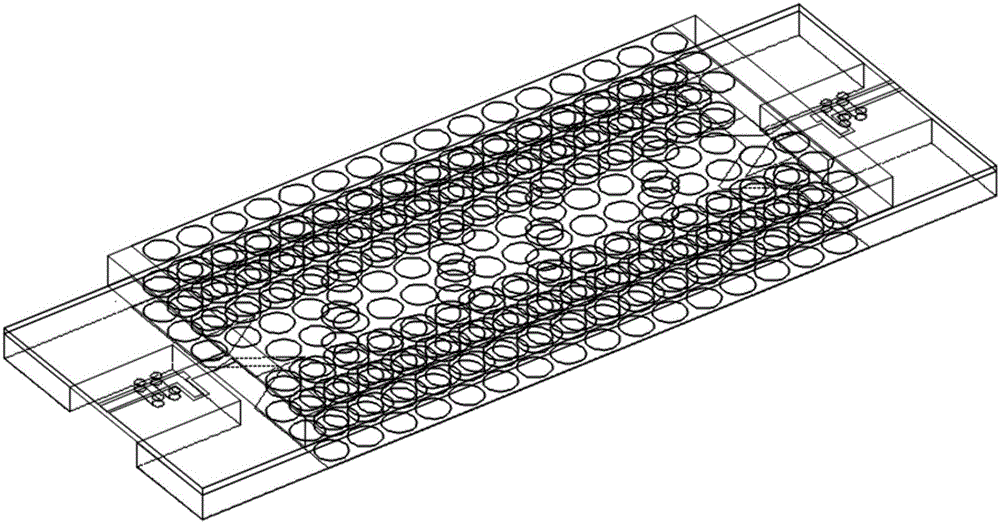

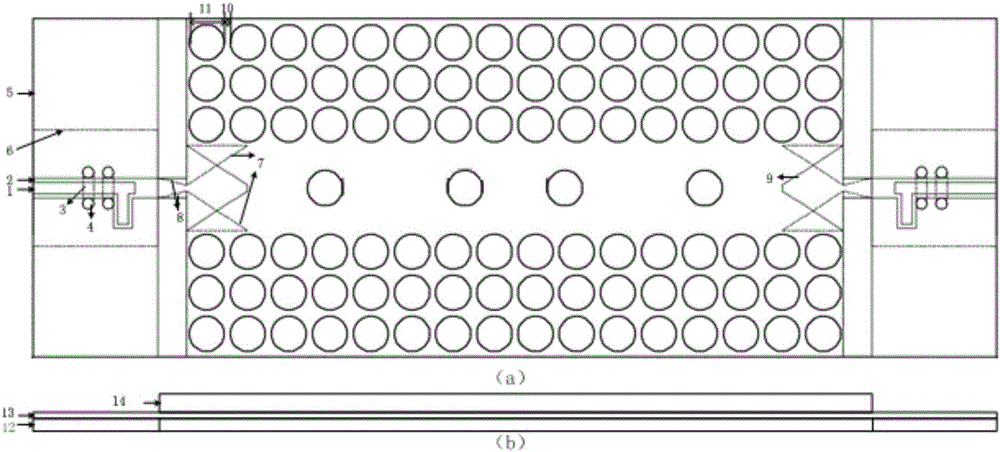

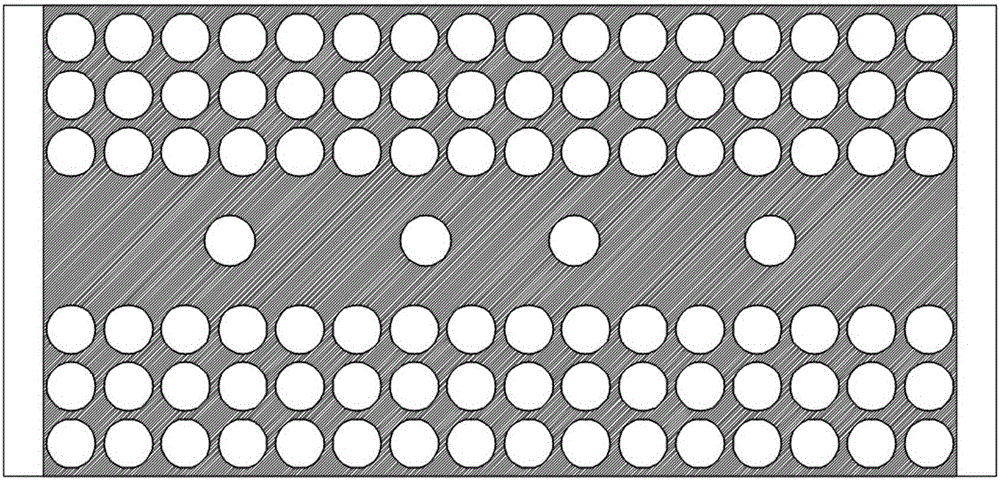

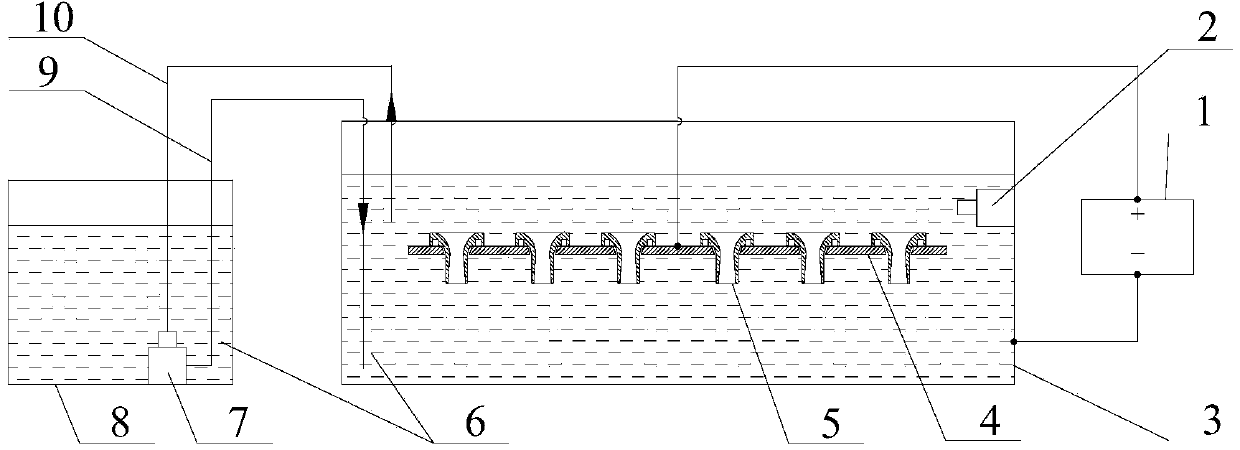

Immersion cooling heat dissipation structure, radiator, heat dissipation system and manufacturing method of immersion cooling heat dissipation structure

PendingCN112071817AAvoid the defect of high contact thermal resistanceIncrease the heat exchange areaSemiconductor/solid-state device detailsSolid-state devicesManufacturing technologyThermodynamics

The invention discloses an immersion cooling heat dissipation structure, a radiator, a heat dissipation system and a manufacturing method of the immersion cooling heat dissipation structure. The immersion cooling heat dissipation structure comprises a boiling heat exchange unit, and the boiling heat exchange unit comprises a first surface and a second surface which are arranged back to back; a microstructure composed of a plurality of opposite convex parts and / or a plurality of opposite concave parts is distributed on the first surface, and the first surface is at least used for making contactwith an electrically insulating immersion cooling medium; the second surface is a smooth face and used for being attached to a heating element, or the second surface and the heating element are integrally arranged. The immersion cooling heat dissipation structure provided by the invention has the advantages of higher heat exchange area, more nucleation sites, stronger capillary fluid infusion capability, excellent boiling heat exchange performance, high heat transfer coefficient and critical heat flux density, low superheat degree of a nucleation boiling starting point and great advantages ina small-space high-heat-flux heat dissipation application scene; meanwhile, the manufacturing process is relatively flexible and controllable, the cost is low, industrial large-scale application canbe achieved, and the market competitiveness is high.

Owner:SUGON DATAENERGYBEIJING CO LTD

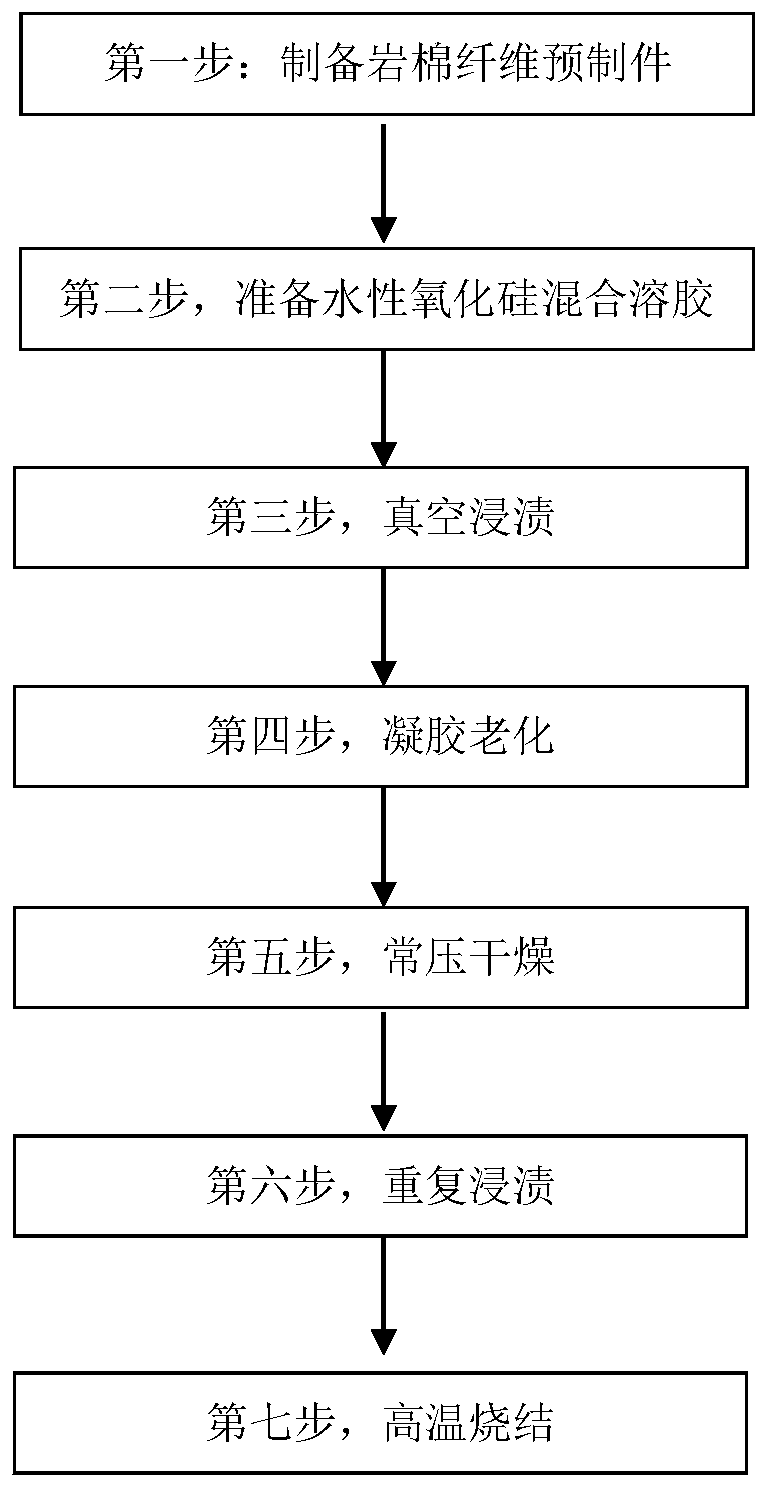

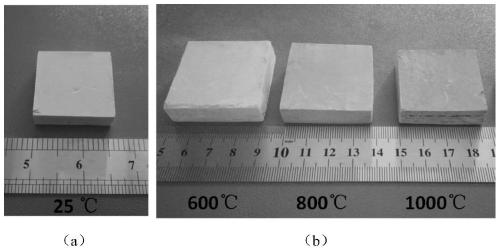

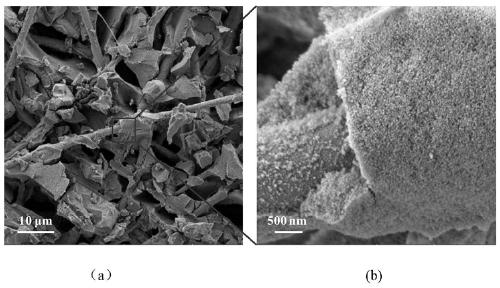

Rock wool fiber-reinforced silicon oxide-based high-strength thermal-insulation composite material and preparation method thereof

The invention discloses a rock wool fiber-reinforced silicon oxide-based high-strength thermal-insulation composite material and a preparation method thereof. The objective of the invention is to enable the composite material to be high in strength and low in thermal conductivity. The material is composed of a silicon oxide matrix and a rock wool fiber prefabricated part, wherein pores of rock wool fibers are filled with the silicon oxide matrix, and the rock wool fibers are bonded into a whole; the rock wool fiber prefabricated part is formed by laying the rock wool fibers; and the silicon oxide matrix is formed by stacking small silicon oxide particles, and the small silicon oxide particles are obtained by carrying out gel aging, normal-pressure drying, repeated dipping and high-temperature sintering on water-based silica sol. The preparation method comprises the following steps: impregnating water-based silica sol with the rock wool fiber prefabricated part under vacuum to form a fiber prefabricated part / sol mixture, carrying out heating for a period of time to obtain a wet gel composite material, drying the wet gel composite material at normal pressure, carrying out repeated impregnation 2-6 times, and finally conducting sintering at high temperature to obtain the composite material. The material is high in mechanical property, low in heat conductivity and low in density; and the preparation method is low in cost, high in safety and simple and flexible in preparation process.

Owner:NAT UNIV OF DEFENSE TECH

Cobaltosic oxide micro-nano composite structure array and manufacturing method thereof

InactiveCN102874742AReduce coupling effectDifferent magnetic propertiesDecorative surface effectsCoupling light guidesElectrochemical responseMicro nano

The invention discloses a cobaltosic oxide micro-nano composite structure array and a manufacturing method thereof. A cobaltosic oxide bowl array or a cobaltosic oxide hollow sphere array which is loosely arrayed is arranged on a conductive substrate of the composite array, the surfaces of the conductive substrates among bowls or hollow spheres forming the bowl array or the hollow sphere array are coated with meshy cobaltosic oxide sheets; the diameter of the bowl opening of each cobaltosic oxide bowl is 1 to 30 mu m, the thickness of the wall of each cobaltosic oxide bowl is 10 to 100 nm, and the cobaltosic oxide bowls consist of the meshy cobaltosic oxide sheets; and the inner diameter of each cobaltosic oxide hollow sphere is 1 to 30 mu m, the thickness of a shell of each cobaltosic oxide hollow sphere is 20 to 300nm, the cobaltosic oxide hollow spheres consist of the meshy cobaltosic oxide sheets, and the thickness of each meshy cobaltosic oxide sheet is 5 to 20nm. The method comprises the following steps of: putting the conductive substrate on which a single-layer colloid crystal template is arranged into a plasma etching machine for etching for at least 10 minutes; putting the etched conductive substrate in a cobalt electrolyte; performing electro deposition at the current density of 2 to 50 mu A / cm<2> for 10 to 50min or 55min to 4h; and putting a product into a solvent to remove the template to obtain the target product. The composite array can be applied to magnetic devices and electrochemical reaction cavity carriers.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

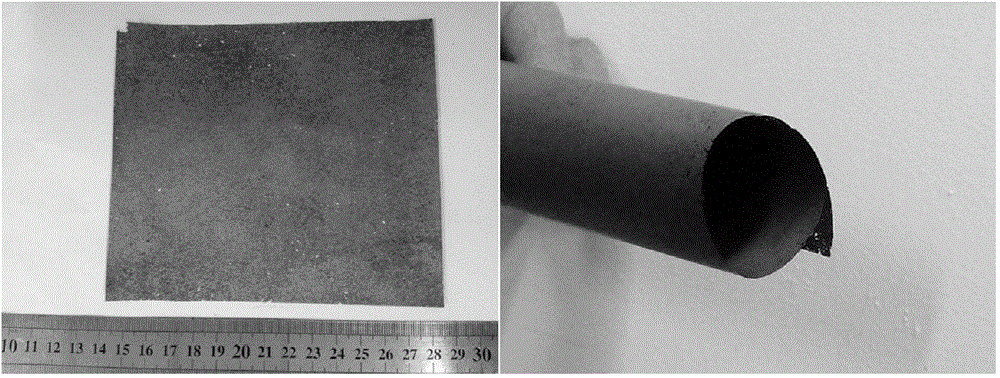

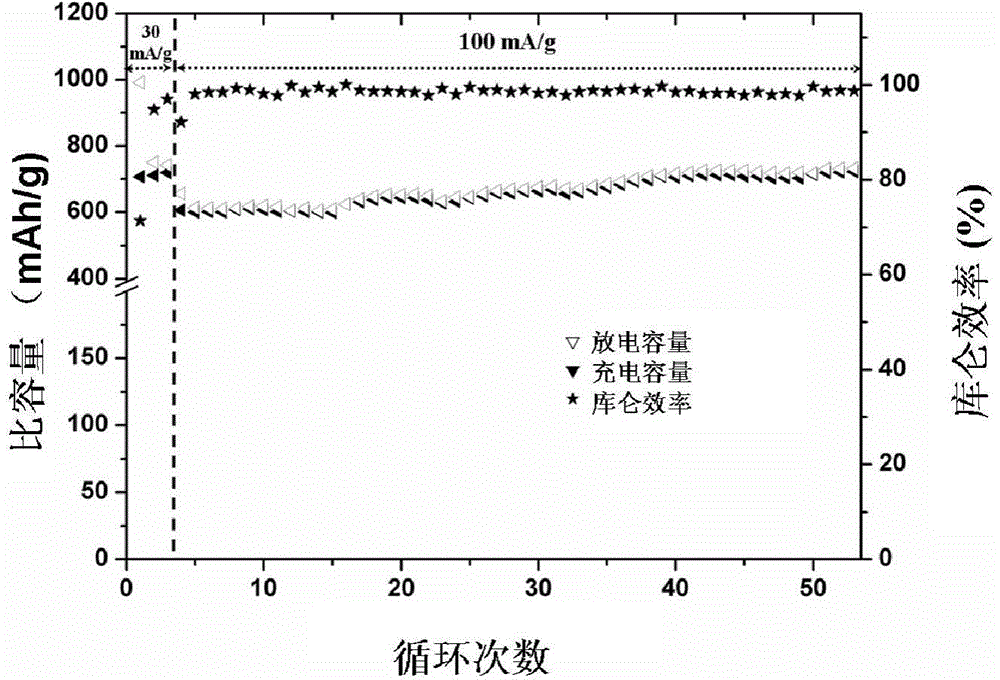

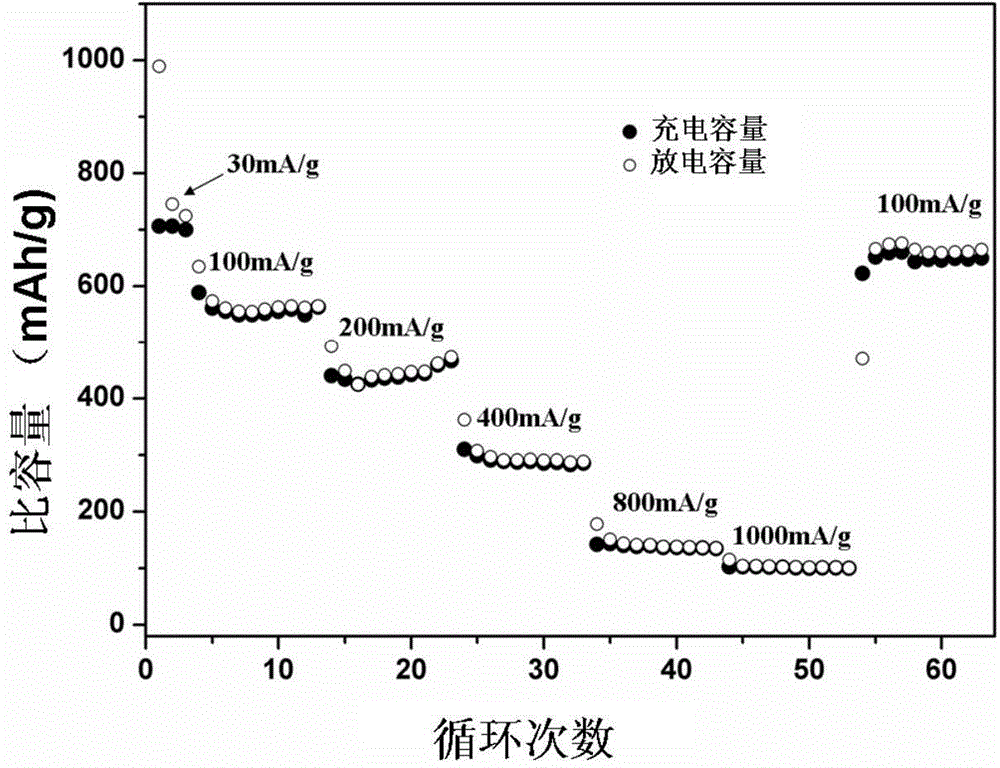

Method for preparing high performance flexible negative electrode materials

InactiveCN104916832AReduce manufacturing costSimple preparation processNegative electrodesLithiumGraphite

The invention discloses a method for preparing high performance flexible negative electrode materials, wherein high performance flexible negative electrode materials which are 40-300MuM in thickness are prepared by simply rolling and forming expanded graphite supported with moderate high storage lithium capacity metal oxide particles. The method for preparing the high performance flexible negative electrode materials is simple and rapid in operation, excellent in stability, low in energy consumption, wide source of raw materials, low in cost and easy to produce in large scale. Prepared flexible negative electrodes do not need to add binders, conductive agents and metal current collectors, and has the advantages of high initial coulomb efficiency and reversible capacity, excellent cycling stability and rate capability and the like.

Owner:SHANXI UNIV

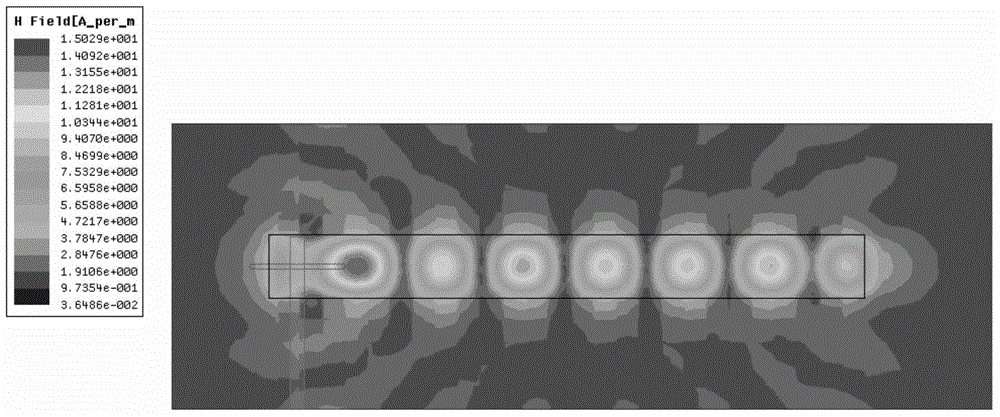

Bandpass filter based on substrate integrated non-radiative dielectric waveguide

ActiveCN105846018AThe production process is simpleSuppression of leakage lossWaveguide type devicesPhysicsWave band

The invention discloses a bandpass filter based on a substrate integrated non-radiative dielectric waveguide. The bandpass filter is implemented through adopting a slot coupling theory on a central dielectric strip of the substrate integrated non-radiative dielectric waveguide on the basis of three layers of circuits consisting of the three-layer substrate integrated non-radiative dielectric waveguide and transition circuits from coplanar waveguides to a slot line. Since surface current at the central dielectric strip is strong, size and position of through holes are reasonably designed, and the bandpass filter with passband being 0.8GHz and good frequency selectivity can be implemented. The bandpass filter based on the substrate integrated non-radiative dielectric waveguide can be implemented smoothly, the integration of a hybrid multi-layer circuit based on microwaves and millimeter waves is realized, the design of millimeter wave band circuits and millimeter wave band devices is facilitated, the manufacturing process is simple, and the cost is low.

Owner:NANJING UNIV OF POSTS & TELECOMM

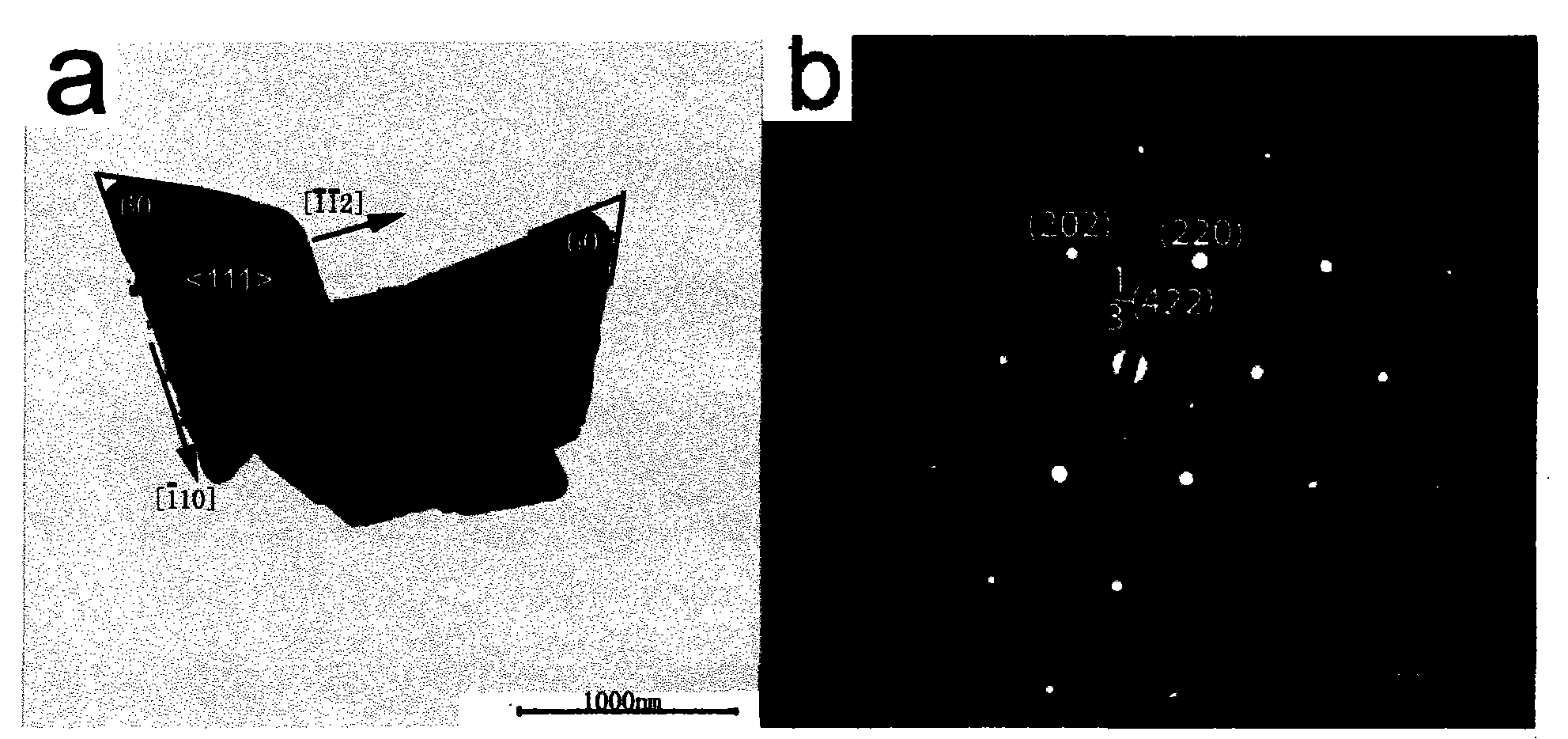

Two-dimensional noble metal nanometer material and preparation method thereof

InactiveCN101565840BNo pollution in the processSimple processJewelleryPlatinumVolumetric Mass Density

The invention discloses a two-dimensional noble metal nanometer material and a preparation method thereof. The material comprises a substrate and a noble metal on the substrate; particularly, a gold film is covered on the substrate, vertical noble metal nanometer sheets are arranged on the substrate covered by the gold film and have the height of 0.5 microns to 1.5 microns, the width of 0.5 microns to 2.5 microns and the thickness of 15 nm to 25 nm, and the noble metal is metal gold, metal silver or metal platinum. The method comprises an electrodeposition method which comprises the followingsteps: firstly, depositing the gold film on the surface of the substrate; putting the substrate as a cathode into an electrolyte to electrolytically deposit for 3 hours to 7 hours under a current of 1to 50 microampere / cm<2>, wherein the electrolyte is prepared by an acid solution of the noble metal and polythene pyrrolidone according to the density of 1g / L:3 to 7g / L; and then, washing and dryingto prepare the two-dimensional noble metal nanometer material. The product can be widely applied to the fields of biomedicine, diagnosis, and the like. The preparation method needs raw materials having fewer types and low cost and being easy to get, has simple technological process and no environmental pollution and is easy to realize the industrialized production.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Conversion circuit from coplanar waveguides to substrate integrated non-radiative dielectric waveguide

InactiveCN104835996ASuppression of leakage lossReduce volumeWaveguide type devicesDielectricElectromagnetic field coupling

The invention discloses a conversion circuit from coplanar waveguides to a substrate integrated non-radiative dielectric waveguide. The conversion circuit is a dual conversion three-layer circuit structure formed by clamping a layer of substrate integrated non-radiative dielectric waveguide between two layers of coplanar waveguides. By opening a rectangular slot in a grounding plate, an electromagnetic field transmitted in the coplanar waveguide at the top is coupled into the substrate integrated non-radiative dielectric waveguide in the middle, and is then coupled from the substrate integrated non-radiative dielectric waveguide into the coplanar waveguide at the bottom. The substrate integrated non-radiative dielectric waveguide is achieved by designing a series of air through holes in a printed circuit board. According to the invention, the conversion circuit can successfully achieve the transition from a planar structure to a non-planar structure, and facilitate the design and integration of a millimeter-wave frequency band circuit; and is simple in production process and low in cost.

Owner:NANJING UNIV OF POSTS & TELECOMM

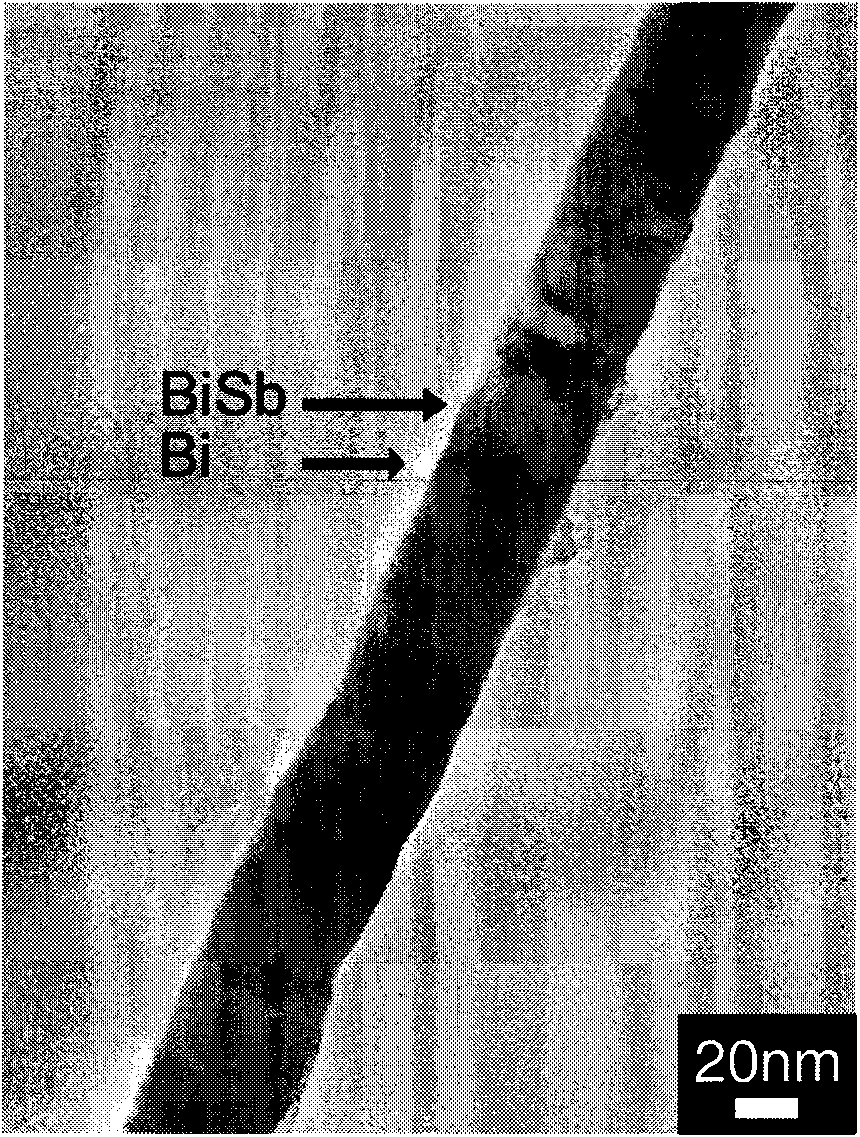

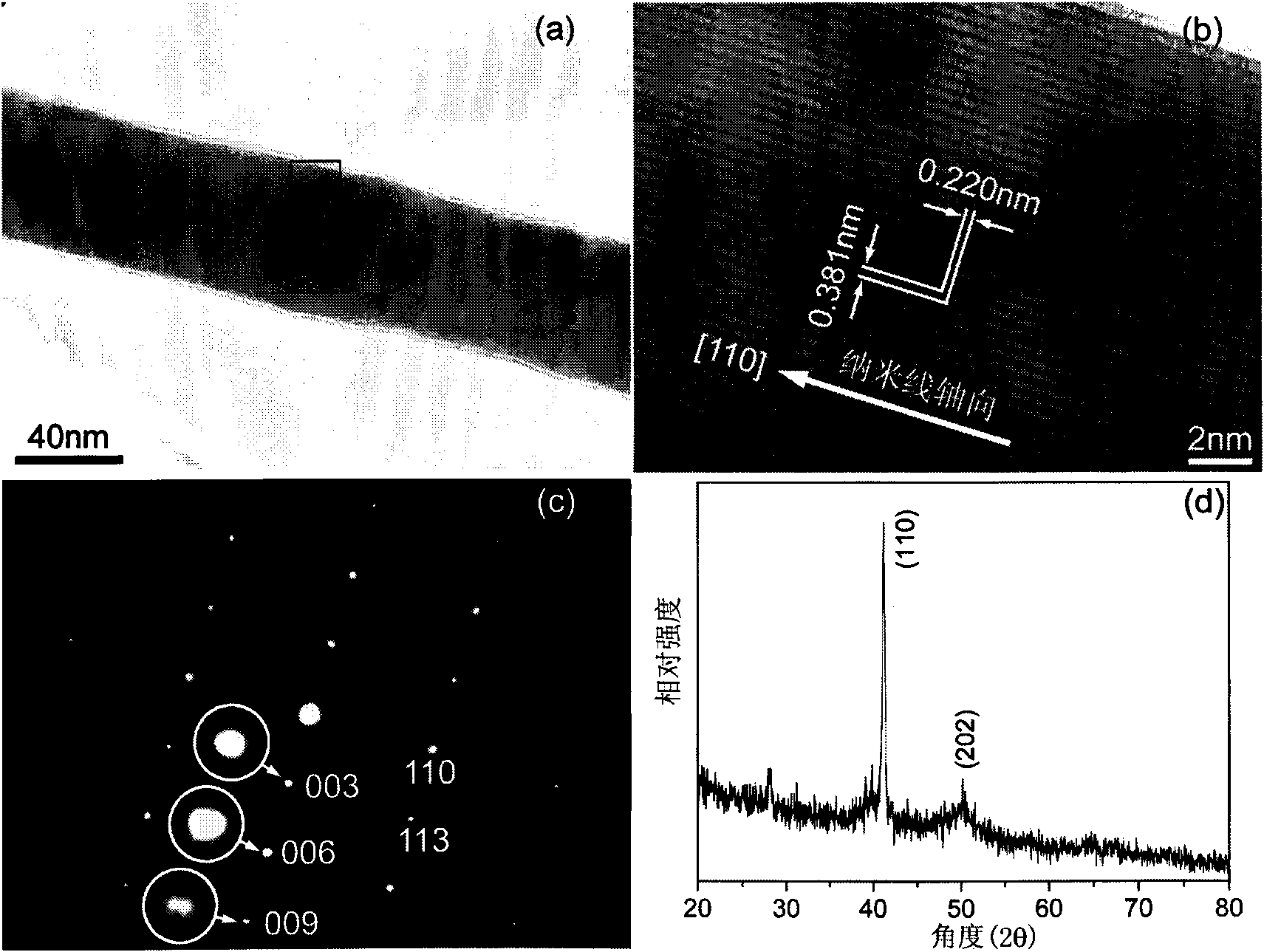

Bismuth/bismuth-antimony extensional superlattice nanowire and preparation method thereof

InactiveCN101857971AClear interfaceSimple manufacturing methodPolycrystalline material growthSingle crystal growth detailsNanowireGlycerol

The invention discloses a bismuth / bismuth-antimony extensional superlattice nanowire and a preparation method thereof. The nanowire is a bismuth / bismuth-antimony superlattice nanowire with the diameter of 30-120 nanometers, which is formed by extensionally connecting a bismuth nanowire and a bismuth-antimony nanowire, wherein the lengths of each segment of the bismuth nanowire and the bismuth-antimony nanowire are respectively 3-99 nanometers and 3-99 nanometers; and the bismuth-antimony nanowire contains 80-50 percent of bismuth and 20-50 percent of stibium. The preparation method comprises the following steps of: firstly, preparing an electrodeposition solution by using bismuth chloride, antimony chloride, hydrochloric acid, tartaric acid, citric acid, sodium chloride and glycerol; thenplacing a gold film plated porous alumina template as a cathode into the electrodeposition solution for electrodeposition under two pulse voltages alternately connected in series; and finally, placing the porous alumina template electrodeposited with the bismuth / bismuth-antimony extensional superlattice nanowire into an alkali solution to corrode the alumina template so as to prepare the bismuth / bismuth-antimony extensional superlattice nanowire. The bismuth / bismuth-antimony extensional superlattice nanowire can be widely used in the fields of thermo-electric generation, thermoelectric refrigeration, and the like; in addition, the method is easy to implement and suitable for large-scale industrialized production.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

High-heat dissipation solar cell back panel and module and fabrication method of back panel

ActiveCN107026214AImprove long-term reliabilityLower working temperatureMaterial nanotechnologyPhotovoltaic energy generationCarbon nanotubeWorking temperature

The invention relates to a high-heat dissipation solar cell back panel and module and a fabrication method of the back panel. The high-heat dissipation solar cell back panel comprises a high-heat dissipation air surface outer layer, a substrate layer and an inner layer having favorable adhesive force with a package material which are sequentially arranged, wherein the high-heat dissipation air surface outer layer and the inner layer having favorable adhesive force with the package material are both functional fluorine-containing coating layers containing carbon nanotubes and / or graphene. The high-heat dissipation solar cell back panel has the beneficial effects that layers of the whole back panel are tightly combined by chemical bonds, hydrogen bonds and Vander Waals forces, and the whole back panel is a typical non-layered and integrated structure; double surfaces of the back panel contain fluorine, and the long-term reliability of the module is improved; the heat conduction coefficient and the thermal radiation efficiency of the back panel can be controlled according to the contents of the carbon nanotubes and the graphene; and heat generated by the cell module is timely dissipated, the working temperature of the module can be expected to be effectively reduced to be 2-6 DEG C, the output power of a photovoltaic module is improved by 1-2%, the lifetime of the cell is prolonged, and the power generation cost of the module is reduced.

Owner:江苏中来新材科技有限公司

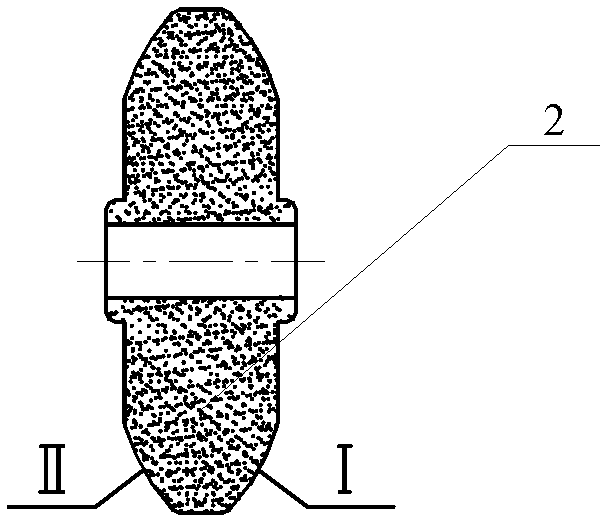

Ceramic rotor spinning false twisting disc and ceramic processing method for inner surface of false twisting disc

InactiveCN104005125ANo impuritiesDense surfaceAnodisationContinuous wound-up machinesOxide ceramicChemical composition

The invention discloses a ceramic rotor spinning false twisting disc and a ceramic processing method for the inner surface of the false twisting disc and belongs to the field of spinning machinery equipment. The ceramic rotor spinning false twisting disc and the ceramic processing method for the inner surface of the false twisting disc are aimed to solve the problems of non-uniform surface coating distribution, poor quality and short service life of a traditional chrome plated false twisting disc and problems of high production cost and complex technique of a powder sintering ceramic false twisting disc. The inner surface of the ceramic rotor spinning false twisting disc is plated with a layer of ceramic film. The ceramic processing method for the inner surface of the false twisting disc includes that preparing an oxide ceramic layer at the surface of the false twisting disc, wherein the chemical ingredient of the generated ceramic layer is oxide which is same with the chemical ingredient of the false twisting disc produced through a ceramic powder pressing sintering technique; remelting and refining the ceramic layer, wherein the refined surface is uniform and wearable, and the service time of the false twisting disc on equipment is prolonged. The ceramic rotor spinning false twisting disc is suitable for spinning various materials.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com