Method for preparing nanometer titania coated graphite cathode material

A nano-titanium dioxide and graphite negative electrode technology, which is applied in the field of catalyst additives and lithium-ion battery negative electrode materials, can solve the problems of carbon nanotube negative electrode lack of voltage platform, low initial charge and discharge efficiency, carbon nanotube potential hysteresis, etc., and achieve high mechanical properties , good processing performance, and the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

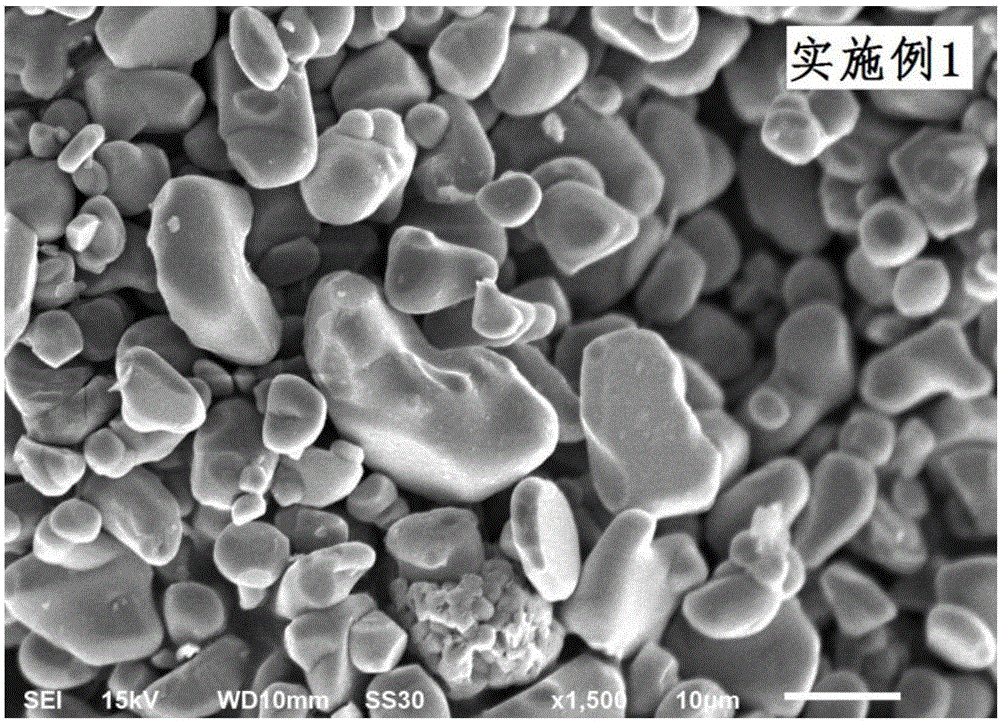

Embodiment 1

[0043] A preparation method of nano titanium dioxide coated graphite negative electrode material, the steps are:

[0044] Step 1: Add 60g of graphite to a mixed solution of 120mL of glacial acetic acid, 50mL of water and 100mL of absolute ethanol at room temperature with stirring, and mix thoroughly to obtain a mixture of graphite, glacial acetic acid, distilled water and absolute ethanol;

[0045] In the second step, at room temperature and under stirring conditions, within 30 minutes, mix 400 mL of butyl titanate 100 mL, n-propyl titanate 100 mL, isopropyl titanate 100 mL, and tetraethyl titanate 100 mL, and 100 mL Add the mixture of absolute ethanol dropwise to the mixture of graphite, glacial acetic acid, distilled water and absolute ethanol obtained in the first step, let stand for 0.5 hours, and dry at 120°C for 4 hours to obtain off-white or gray titanate gel packs Graphite powder;

[0046] The third step is to place the titanate gel-coated graphite powder obtained in ...

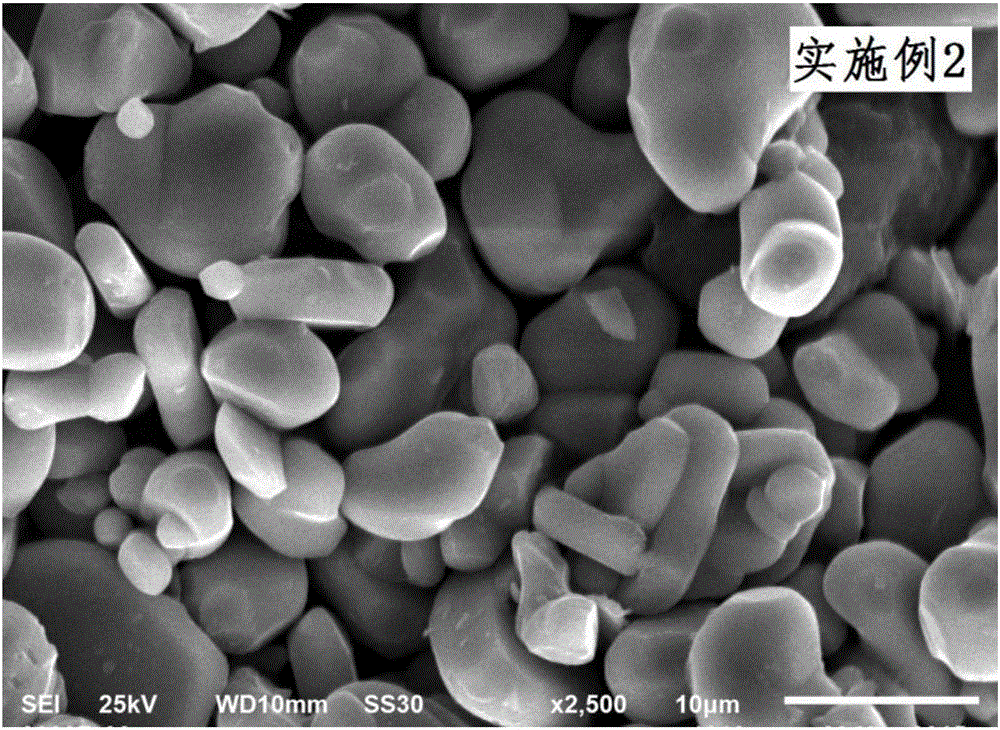

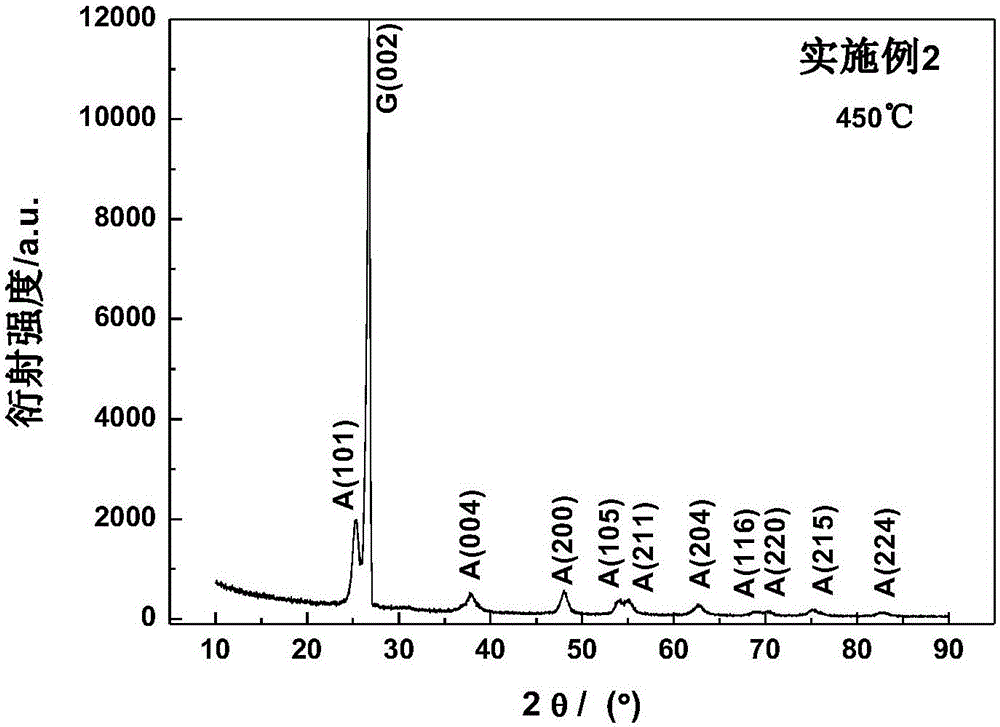

Embodiment 2

[0049] A preparation method of nano titanium dioxide coated graphite negative electrode material, the steps are:

[0050] The first step, at room temperature, under agitation condition, the graphite of 85g is added in the mixed solution of 100mL glacial acetic acid and 40mL water and 200mL dehydrated alcohol, fully mix, obtain graphite and glacial acetic acid, twice distilled water and dehydrated alcohol mixture;

[0051] Step 2: Add 120 mL of butyl titanate, 120 mL of n-propyl titanate, and 120 mL of tetraethyl titanate to a mixture of 360 mL and 200 mL of anhydrous ethanol dropwise within 60 minutes. Put the graphite obtained in the first step into the mixture of glacial acetic acid, twice distilled water and absolute ethanol, let it stand for 1 hour, and dry it at 130°C for 6 hours to obtain off-white or gray titanate gel-coated graphite powder;

[0052] The third step is to place the titanate gel-coated graphite powder obtained in the second step in a temperature-programm...

Embodiment 3

[0055] A preparation method of nano titanium dioxide coated graphite negative electrode material, the steps are:

[0056] Step 1: Add 105g of graphite to a mixed solution of 80mL of glacial acetic acid, 30mL of water and 300mL of absolute ethanol at room temperature with stirring, and mix thoroughly to obtain a mixture of graphite, glacial acetic acid, pure water and absolute ethanol ;

[0057] Step 2: Add 160 mL of butyl titanate, 160 mL of n-propyl titanate, and 300 mL of absolute ethanol to the graphite obtained in the first step within 90 minutes under stirring. In a mixture of glacial acetic acid, pure water and absolute ethanol, let stand for 2 hours, and dry at 140°C for 8 hours to obtain gray or gray black titanate gel-coated graphite powder;

[0058] The third step is to place the titanate gel-coated graphite powder obtained in the second step in a temperature-programmed furnace, raise the temperature to 550°C at a rate of 2°C per minute, and keep the temperature con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com