Method for preparing high performance flexible negative electrode materials

A negative electrode material, high-performance technology, applied in the direction of negative electrode, active material electrode, battery electrode, etc., can solve the problems of application, electrolyte infiltration and impossibility, etc., and achieve simple equipment, excellent electrochemical performance, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

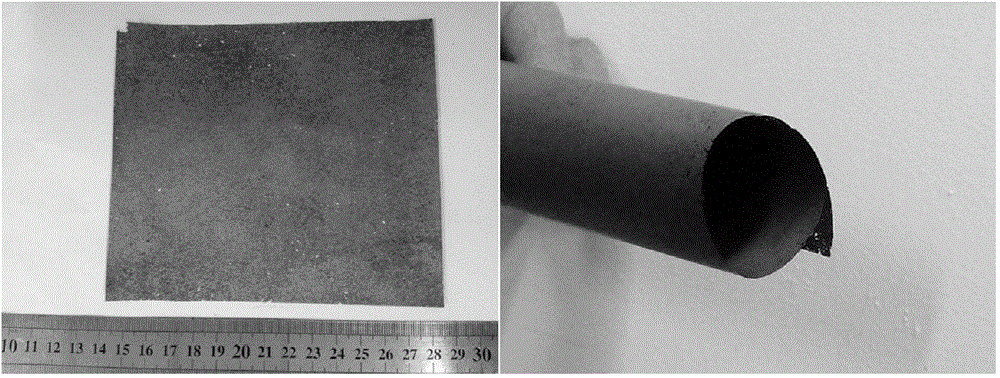

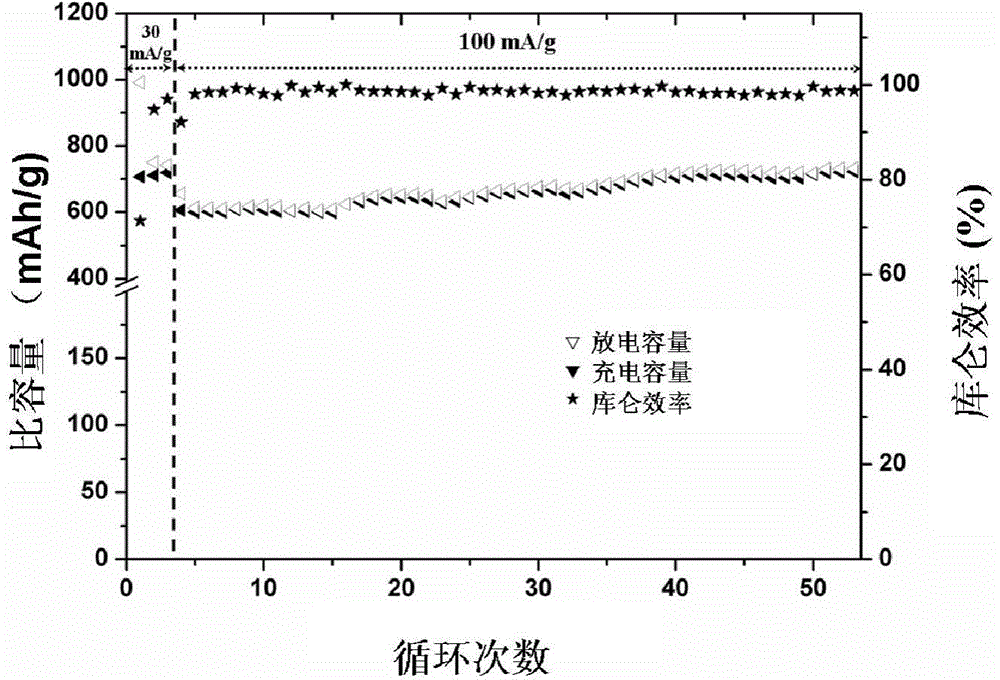

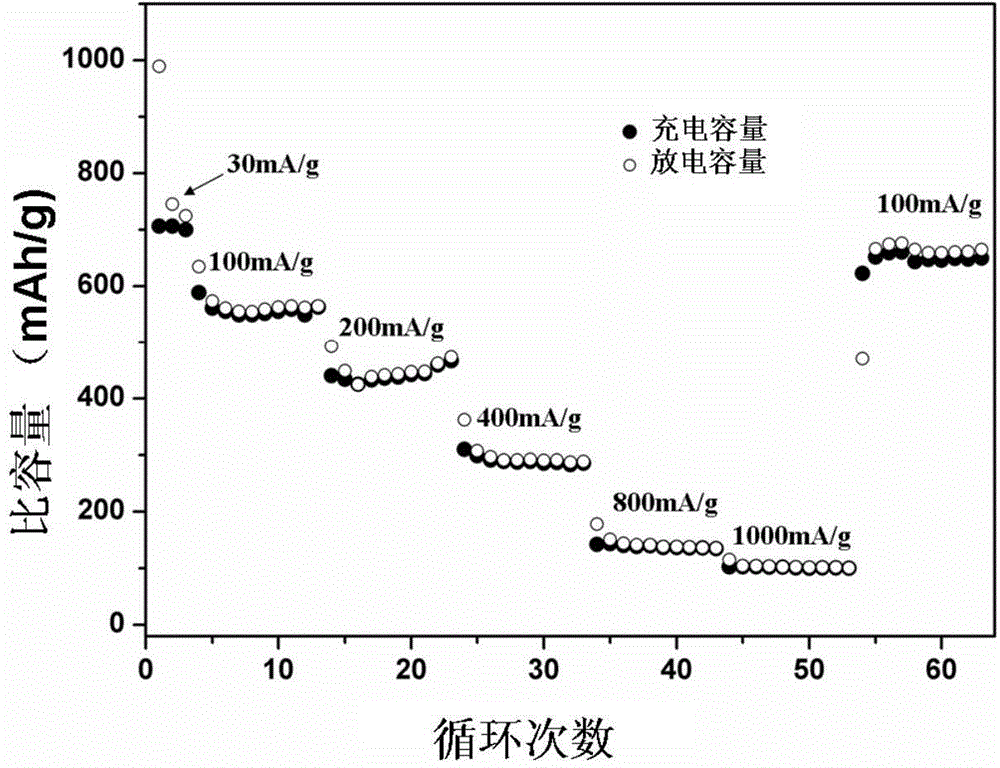

[0028] The expanded graphite with an expansion volume of 498 mL / g obtained by expanding natural graphite with a particle size of 50 mesh and a fixed carbon content of 98% is selected as a raw material. 0.1g expanded graphite, 0.2g Co(NO 3 ) 2 ·6H 2 O, 0.02g ammonium fluoride and 0.03g urea are uniformly dispersed in water. Afterwards, the mixed solution was transferred to a hydrothermal kettle for reaction at 130° C. for 6 h. The product was filtered and dried at 70°C to obtain expanded graphite loaded with metal oxide nanoparticles. Then it was placed in a tube furnace and heat-treated at 400 °C for 4 h in an inert atmosphere. Finally, the heat-treated powder is evenly spread, and a flexible negative electrode material with a thickness of about 80 μm is obtained by simple roll forming (see figure 1 , the left image is the flat state of the material, and the right image is the curled state of the material). At a current density of 100mA / g, the first coulombic efficiency ...

Embodiment 2

[0030] The expanded graphite with an expansion volume of 435 mL / g obtained by expanding natural graphite with an average particle size of 100 mesh and a fixed carbon content of 95% is selected as a raw material. 0.1g expanded graphite, 0.23g Fe(NO 3 ) 2 ·6H 2 O, 0.015g ammonium fluoride and 0.035g urea are uniformly dispersed in water. Afterwards, the mixture was transferred to a hydrothermal kettle for reaction at 120° C. for 4 hours. The product was filtered and dried at 80°C to obtain expanded graphite loaded with metal oxide nanoparticles. Then it was placed in a tube furnace and heat-treated at 800 °C for 2 h in an inert atmosphere. Finally, the heat-treated powder is evenly spread, and a flexible negative electrode material with a thickness of about 60 μm can be prepared by simple roll forming. At a current density of 100mA / g, the first coulombic efficiency reaches 71%, and the reversible capacity after 50 cycles reaches 632mAh / g.

Embodiment 3

[0032] The expanded graphite with an expansion volume of 350 mL / g obtained by expanding natural graphite with an average particle size of 160 mesh and a fixed carbon content of 95% is selected as a raw material. 0.1g expanded graphite, 0.13g SnCl 4 , 0.01g ammonium fluoride and 0.025g urea are uniformly dispersed in water. Afterwards, the mixed solution was transferred to a hydrothermal kettle for reaction at 110° C. for 6 h. The product was filtered and dried at 75°C to obtain expanded graphite loaded with metal oxide nanoparticles. Then it was placed in a tube furnace and heat-treated at 600 °C for 3 h in an inert atmosphere. Finally, the heat-treated powder is evenly spread, and a flexible negative electrode material with a thickness of about 150 μm can be prepared by simple roll forming. At a current density of 100mA / g, the first coulombic efficiency reaches 68%, and the reversible capacity after 50 cycles reaches 547mAh / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com