Nano composite ethylene-propylene rubber cable material and its preparation method

An ethylene-propylene rubber and nano-composite technology, which is applied in the direction of insulated cables, cables, circuits, etc., can solve the problems such as the inability to obtain aging-resistant cable outer insulation materials, the inability to meet the anti-oxidation performance of cable materials, and the decrease in flexibility. Flexibility, high flexibility, improved flame retardant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

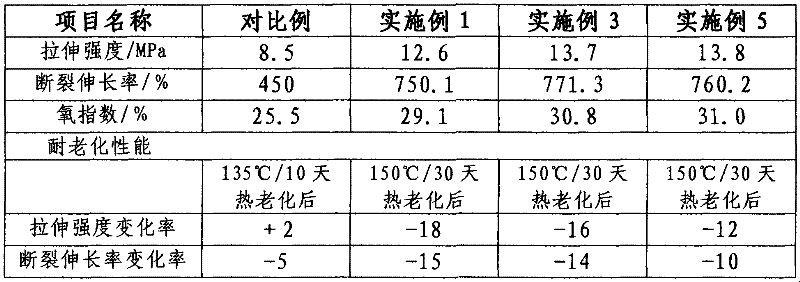

Examples

Embodiment 1

[0031] The concrete steps of preparation are:

[0032] Step 1, first according to the weight ratio between EPDM rubber, nano compound, organic modifier, inorganic metal hydroxide, antioxidant, vulcanization activator and peroxide is 100:1:10:50: The ratio of 10:10:10 was weighed respectively. Then add the corresponding amount of EPDM rubber, nano compound, organic modifier, inorganic metal hydroxide, anti-aging agent, vulcanization activator and peroxide into the open mill or internal mixer in sequence; wherein, The nano-composite is nano-montmorillonite and nano-calcium carbonate with a weight ratio of 1:0.5, wherein the nano-montmorillonite is a layered silicate with a layer spacing of 0.9nm and a cation exchange capacity of 60meq / 100g, and nano-carbonate The particle size of calcium is 100nm, the organic modifier is methacrylic acid, the inorganic metal hydroxide is aluminum hydroxide, and the anti-aging agent is 2,2,4-trimethyl-1,2- Dihydroquinoline polymer and 2-mercapt...

Embodiment 2

[0035] The concrete steps of preparation are:

[0036]Step 1, first according to the weight ratio between EPDM rubber, nano compound, organic modifier, inorganic metal hydroxide, antioxidant, vulcanization activator and peroxide is 100:6:8:85: 8:13:5.5 ratio, weigh them respectively. Then add the corresponding amount of EPDM rubber, nano compound, organic modifier, inorganic metal hydroxide, anti-aging agent, vulcanization activator and peroxide into the open mill or internal mixer in sequence; wherein, The nano-composite is nano-montmorillonite and nano-calcium carbonate with a weight ratio of 1:0.9, wherein the nano-montmorillonite is a layered silicate with a layer spacing of 1nm and a cation exchange capacity of 70meq / 100g, and nano-calcium carbonate The particle size is 78nm, the organic modifier is methacrylic acid, the inorganic metal hydroxide is aluminum hydroxide, and the anti-aging agent is 2,2,4-trimethyl-1,2-bis with a weight ratio of 3:1.5 Hydroquinoline polyme...

Embodiment 3

[0039] The concrete steps of preparation are:

[0040] Step 1, first according to the weight ratio between EPDM rubber, nano compound, organic modifier, inorganic metal hydroxide, antioxidant, vulcanization activator and peroxide is 100:10:5.5:125: 5.5:15:3 ratio, weigh them respectively. Then add the corresponding amount of EPDM rubber, nano compound, organic modifier, inorganic metal hydroxide, anti-aging agent, vulcanization activator and peroxide into the open mill or internal mixer in sequence; wherein, The nano-composite is nano-montmorillonite and nano-calcium carbonate with a weight ratio of 1:1.25, wherein the nano-montmorillonite is a layered silicate with a layer spacing of 1.1nm and a cation exchange capacity of 85meq / 100g, and nano-carbonate The particle size of calcium is 55nm, the organic modifier is methacrylic acid, the inorganic metal hydroxide is aluminum hydroxide, and the anti-aging agent is 2,2,4-trimethyl-1,2- Dihydroquinoline polymer and 2-mercaptoben...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com