Cobaltosic oxide micro-nano composite structure array and manufacturing method thereof

A technology of tricobalt tetroxide and tricobalt tetroxide bowl, which is applied in the field of cobalt trioxide micro-nano composite structure array and its preparation, can solve the problems of not being able to produce the final product, unfavorable application, etc., and achieve high production efficiency, reduce coupling effect, and use less materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The concrete steps of preparation are:

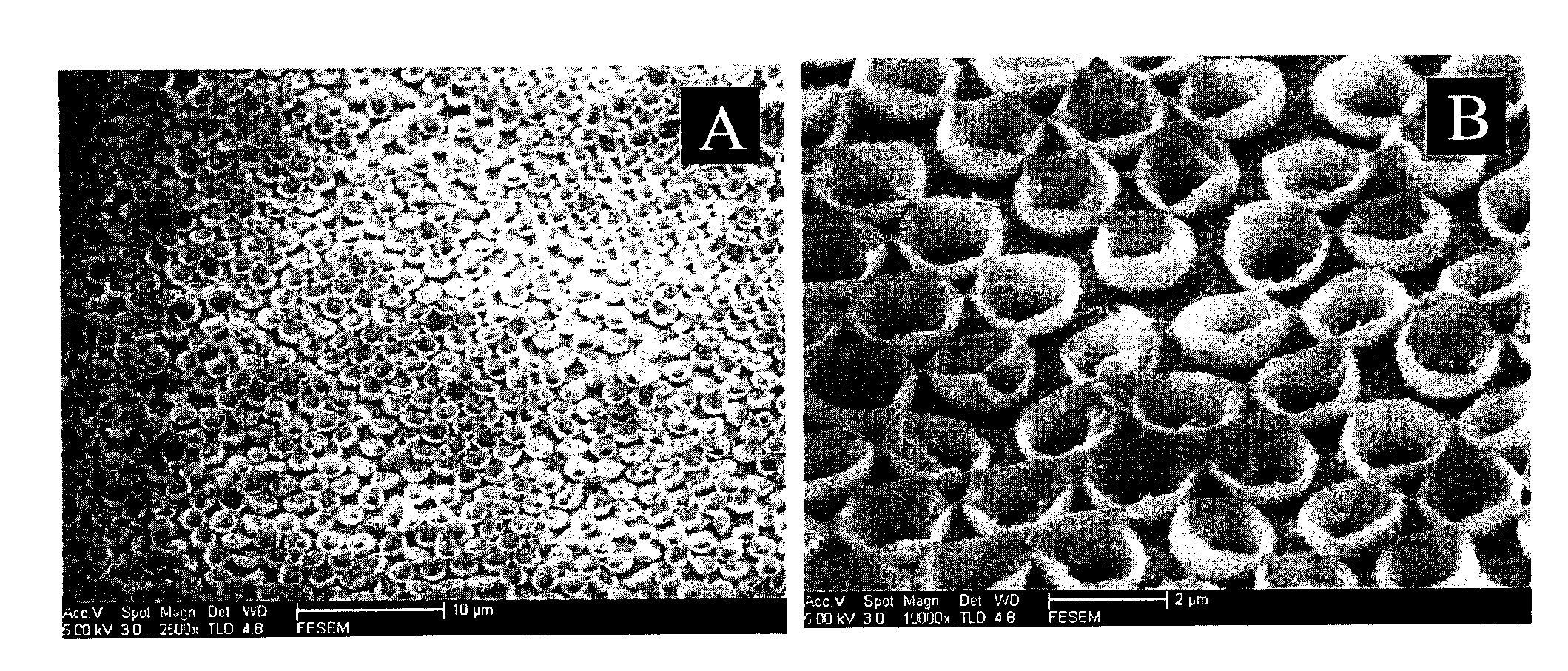

[0027] Step 1, first place a single-layer colloidal crystal template composed of polystyrene colloidal spheres with a diameter of 2 μm on a conductive substrate; wherein the conductive substrate is conductive glass. Then place the conductive substrate with a single-layer colloidal crystal template on it in a plasma etching machine and use plasma to etch it; wherein, the plasma is argon plasma, and the etching power is 200W, and the etching power is 200W. The time is 10 minutes, and a conductive substrate with a loose single-layer colloidal crystal template placed thereon is obtained.

[0028] Step 2, first place the conductive substrate with a loose single-layer colloidal crystal template on it in the cobalt electrolyte, use it as the working electrode, and conduct the substrate at a current density of 2 μA / cm 2 Next, the three-electrode method was used for electrodeposition for 50 minutes (or 4 hours); wherein, the counter elec...

Embodiment 2

[0030] The concrete steps of preparation are:

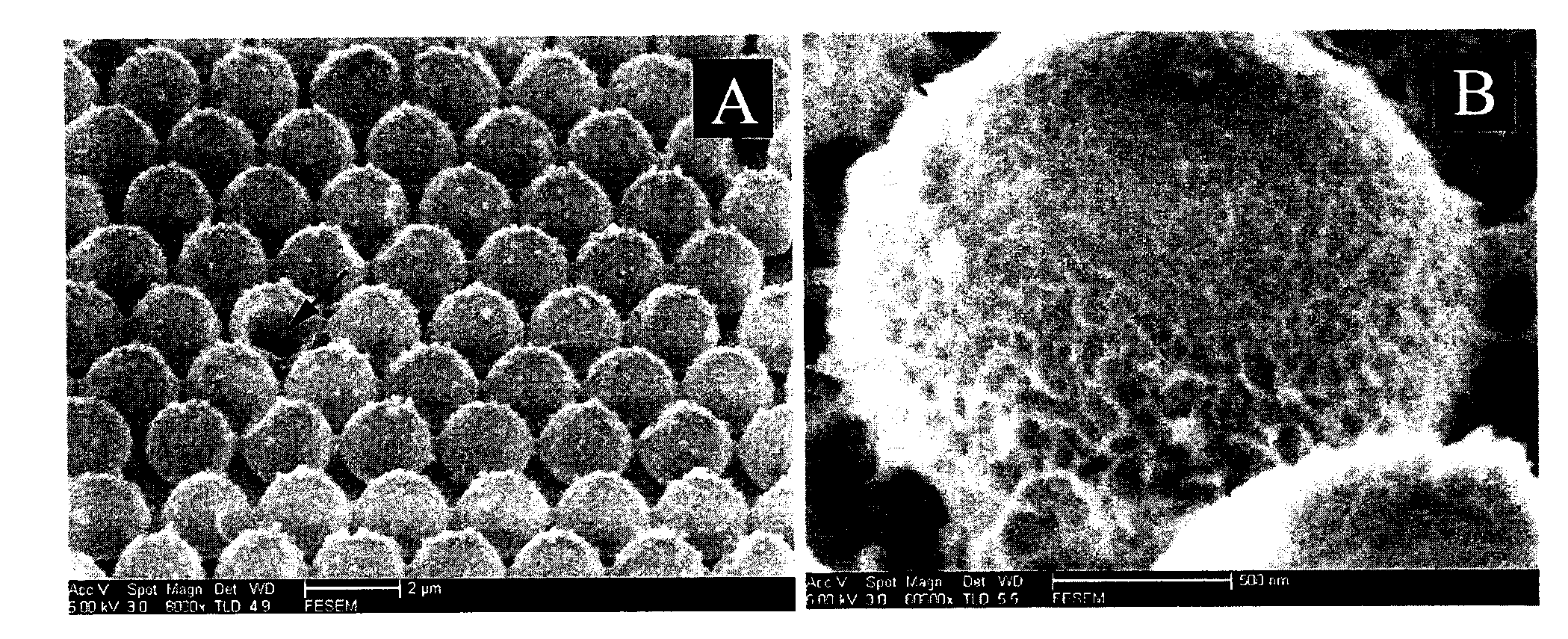

[0031] Step 1, first place a single-layer colloidal crystal template composed of polystyrene colloidal spheres with a diameter of 2 μm on a conductive substrate; wherein the conductive substrate is conductive glass. Then place the conductive substrate with a single-layer colloidal crystal template on it in a plasma etching machine and use plasma to etch it; wherein, the plasma is argon plasma, and the etching power is 200W, and the etching power is 200W. The time is 28 minutes, and a conductive substrate with a loose single-layer colloidal crystal template placed thereon is obtained.

[0032] Step 2, first place the conductive substrate with a loose single-layer colloidal crystal template on it in the cobalt electrolyte, use it as the working electrode, and set the current density at 13 μA / cm 2The three-electrode method is used for electrodeposition for 40 minutes (or 3.3 hours); wherein, the counter electrode during electrodepo...

Embodiment 3

[0034] The concrete steps of preparation are:

[0035] Step 1, first place a single-layer colloidal crystal template composed of polystyrene colloidal spheres with a diameter of 2 μm on a conductive substrate; wherein the conductive substrate is conductive glass. Then place the conductive substrate with a single-layer colloidal crystal template on it in a plasma etching machine and use plasma to etch it; wherein, the plasma is argon plasma, and the etching power is 200W, and the etching power is 200W. The time is 35 minutes, and a conductive substrate with a loose single-layer colloidal crystal template placed thereon is obtained.

[0036] Step 2, first place the conductive substrate with a loose single-layer colloidal crystal template on it in the cobalt electrolyte, use it as the working electrode, and conduct the substrate at a current density of 25 μA / cm 2 Next, the three-electrode method was used for electrodeposition for 30 minutes (or 2.5 hours); wherein, the counter e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com