Conversion circuit from coplanar waveguides to substrate integrated non-radiative dielectric waveguide

A technology of coplanar waveguide and dielectric waveguide, which is applied to circuits, waveguide-type devices, electrical components, etc., can solve problems such as manufacturing and integration difficulties, and achieve the effects of suppressing leakage loss, simple manufacturing process, and reducing circuit volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

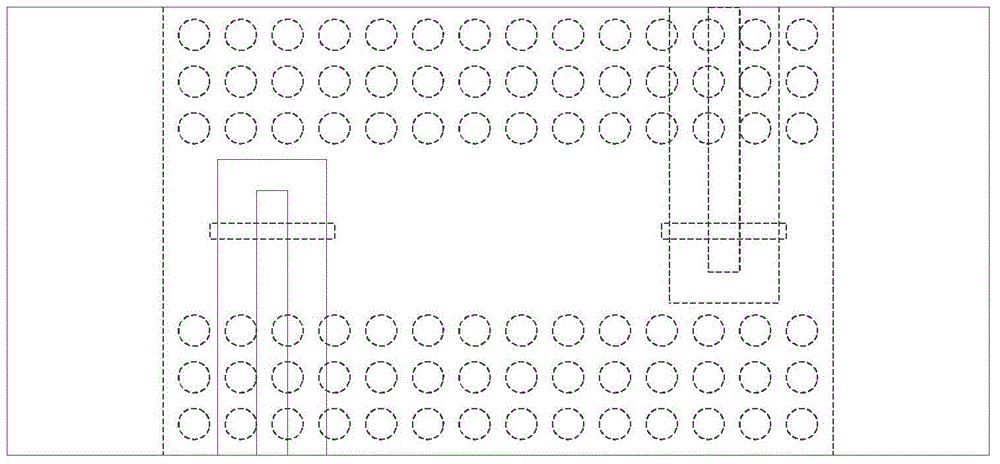

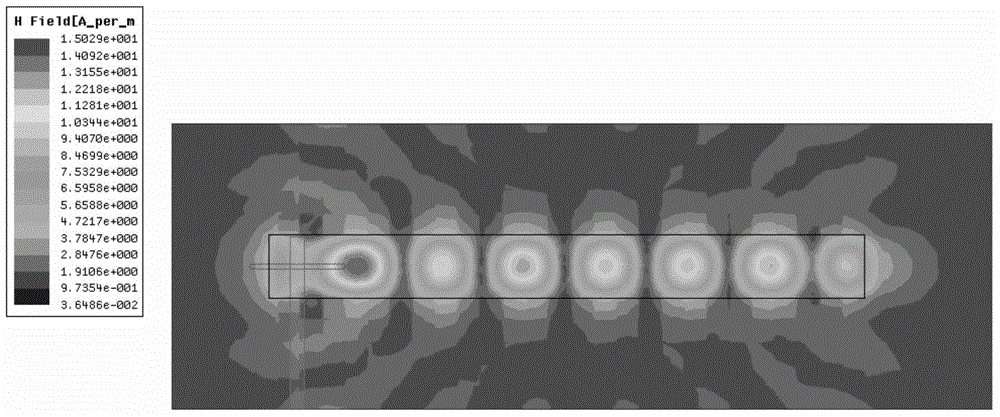

[0020] Such as figure 1 As shown, the overall structure of the present invention from top to bottom is: the first coplanar waveguide, the first dielectric substrate and the first ground plane, the printed circuit board, the second ground plane, the second dielectric substrate and the second coplanar waveguide . Such as figure 2 As shown, the printed circuit board is symmetrically provided with air holes on both sides of the folding line along the long side direction; A rectangular slot; on the second ground plate, a second rectangular slot perpendicular to the metal strip of the second coplanar waveguide is arranged on the fold line along the long side direction.

[0021] In terms of circuit function, the present invention has a three-layer circuit structure of a first coplanar waveguide, a substrate-integrated non-radiative dielectric waveguid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com