Scroll compressor

A scroll compressor and scroll technology, applied in the field of scroll compressors, can solve problems such as leakage, reduced compression capacity, and inability to exert oil sealing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

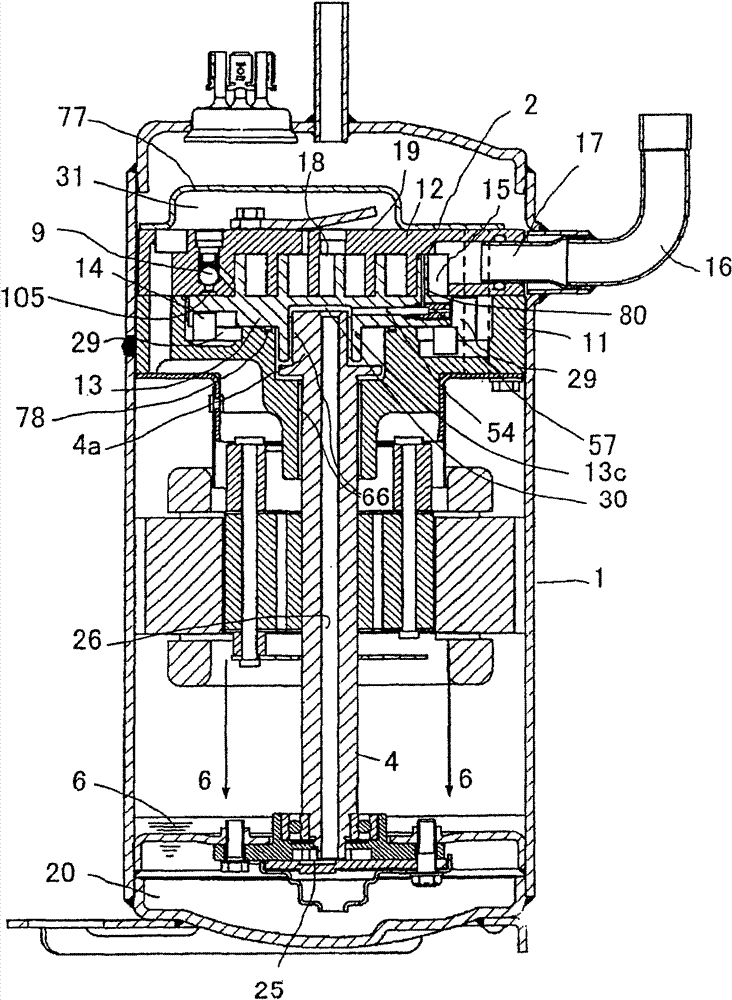

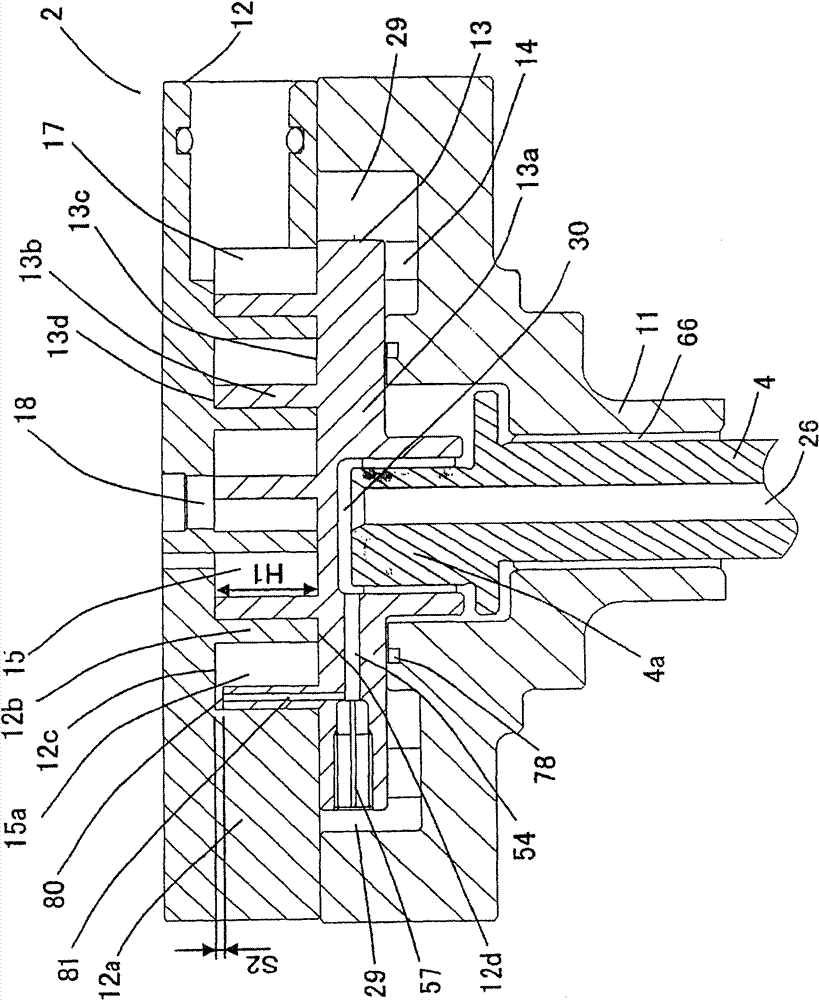

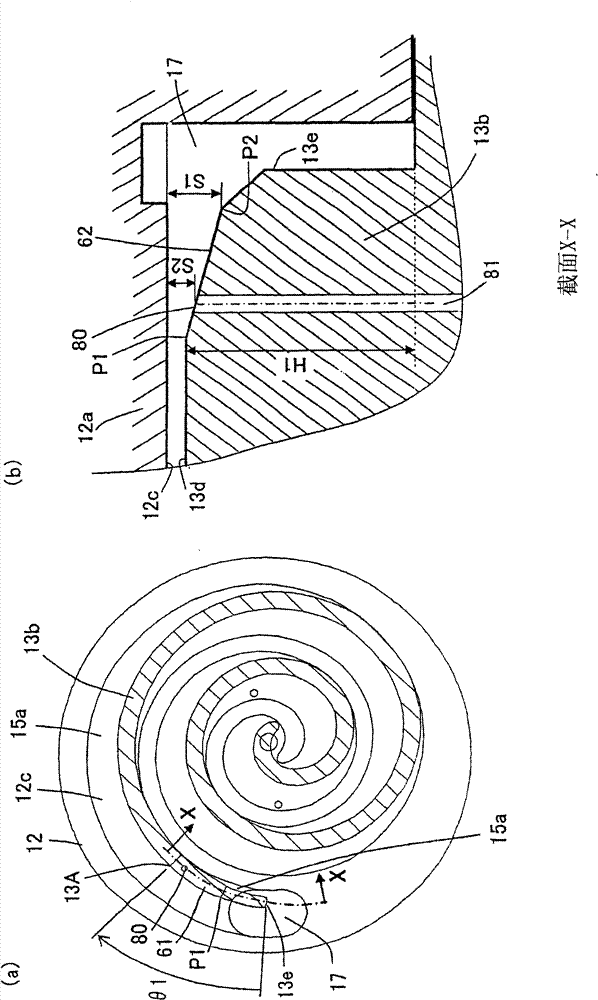

[0030] figure 1 It is a longitudinal sectional view of the scroll compressor in Embodiment 1 of the present invention. figure 2 It is a longitudinal sectional view of the compression mechanism part in this scroll compressor. image 3 (a) is a cross-sectional view of this compression mechanism portion, image 3 (b) for image 3 Cross-sectional view of part X-X in (a). and, in figure 2 In the sectional view of , the right half shows the cross section connecting the discharge port 18 and the suction chamber 17 , and the left half shows the cross section connecting the discharge port 18 and the oil supply hole 80 . The operation and action of the scroll compressors shown in these drawings will be described below.

[0031] Scroll compressor of the present invention such as figure 1 and figure 2 As shown, the main bearing part 11 of the crankshaft 4 is fixed in the airtight container 1 by welding or inserting after heating, and the orbiting scroll 13 engaged with the fix...

Embodiment 2

[0044] Figure 4 It is a longitudinal sectional view of the compression mechanism of the scroll compressor in Embodiment 2 of the present invention, Figure 5 (a) is a cross-sectional view of the compression mechanism of the scroll compressor in Embodiment 2 of the present invention, Figure 5 (b) for Figure 4 Cross-sectional view of part Y-Y of (a). exist Figure 4In the drawing, the right half shows the cross section connecting the discharge port 18 and the suction chamber 17 , and the left half shows the cross section connecting the discharge port 18 and the oil supply hole 80 .

[0045] exist Figure 4 and Figure 5 , the gap S3 in the thrust direction between the scroll tooth upper surface 13d of the orbiting scroll 13 and the scroll tooth groove bottom surface 12c of the fixed scroll 12 gradually increases from the inner ring side to the outer ring side along the circumferential direction. ; In the range from the point P3 on the inner ring side of the scroll tooth...

Embodiment 3

[0051] Image 6 It is a longitudinal sectional view of the orbiting scroll of the scroll compressor in Example 3 of the present invention. The diameter R of the oil supply hole is 20% or more of the wrap thickness t of the orbiting scroll 13 and is 70% or less of the thickness t.

[0052] By setting the diameter R of the oil supply hole 80 to be 20% or more of the thickness t of the wrap tooth of the orbiting scroll 13, it is possible to improve the oil pressure in the vicinity of the compression chamber 15a of the sealing process by sucking low-pressure gas from the suction chamber 17. An oil supply hole 80 passes through the sealing part of the scroll tooth upper surface 13d and the oil supply hole 80 in the thickness direction of the scroll tooth, and provides a uniform and appropriate amount of oil to the compression chamber 15 from the beginning of compression, improving the sealing performance and realizing a high-efficiency High reliability scroll compressor.

[0053]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com