compressor

A compressor and compression mechanism technology, applied in the field of compressors, can solve the problems of reduced sealing of the compression mechanism, increased leakage loss, insufficient oil supply, etc., to achieve the effect of suppressing leakage loss and sufficient oil supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

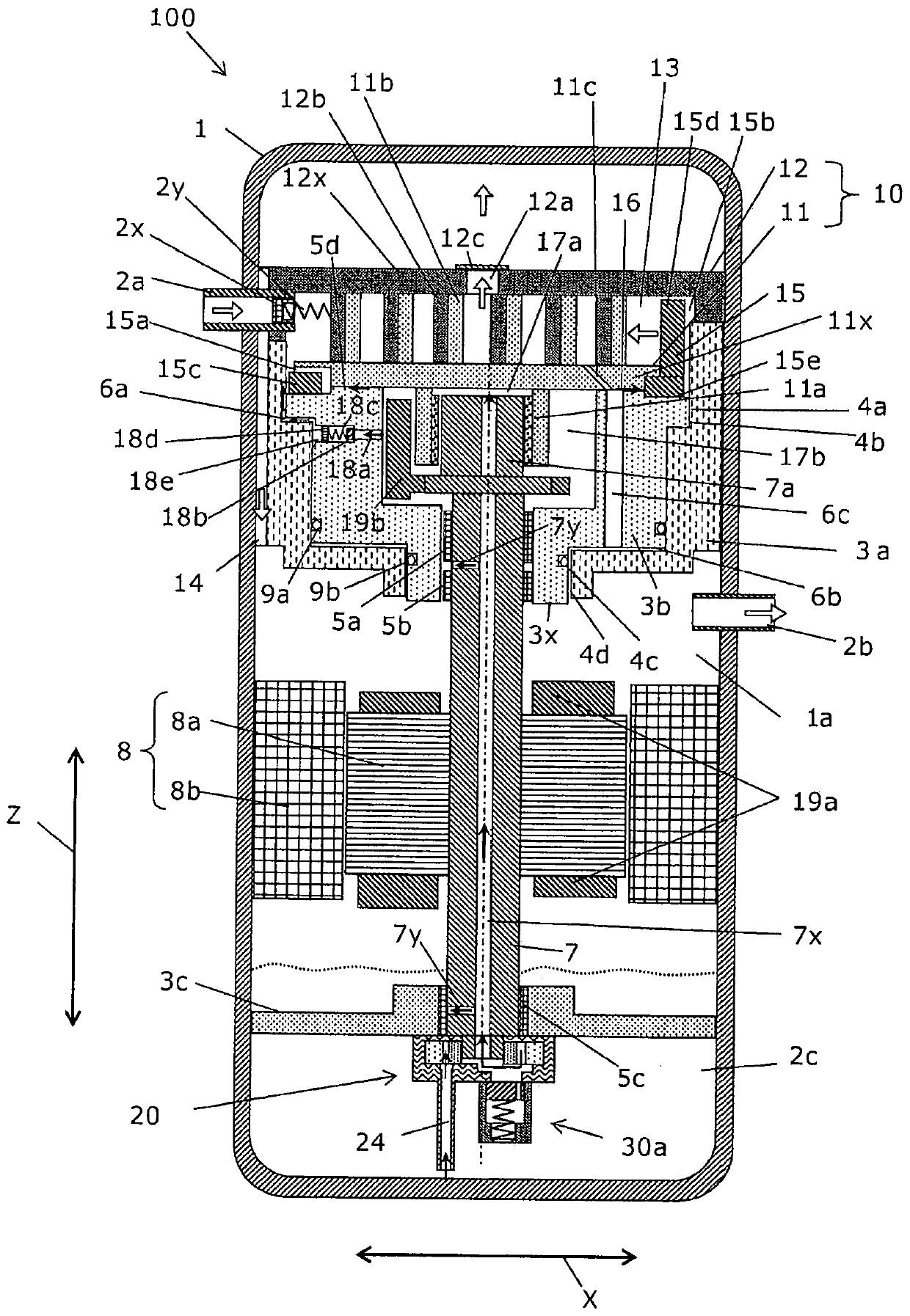

[0033] figure 1 It is a schematic longitudinal sectional view showing the compressor according to Embodiment 1 of the present invention. Below, refer to figure 1 The configuration of the compressor 100 will be described. figure 1 The compressor 100 is a so-called vertical scroll compressor, and compresses and discharges a working gas such as refrigerant, for example. The compressor 100 includes an airtight container 1, a compression mechanism unit 10, a motor 8, a drive shaft 7, an oil storage space 2c, an oil supply pump 20, and a differential pressure oil supply mechanism 30a.

[0034] The airtight container 1 is formed in a cylindrical shape, for example, and has pressure resistance. A suction pipe 2 a for taking working gas into the airtight container 1 is connected to one side of the airtight container 1 , and a discharge pipe 2 b for discharging compressed working gas from the airtight container 1 to the outside is connected to the other side. Arrows in the piping sh...

Embodiment approach 2

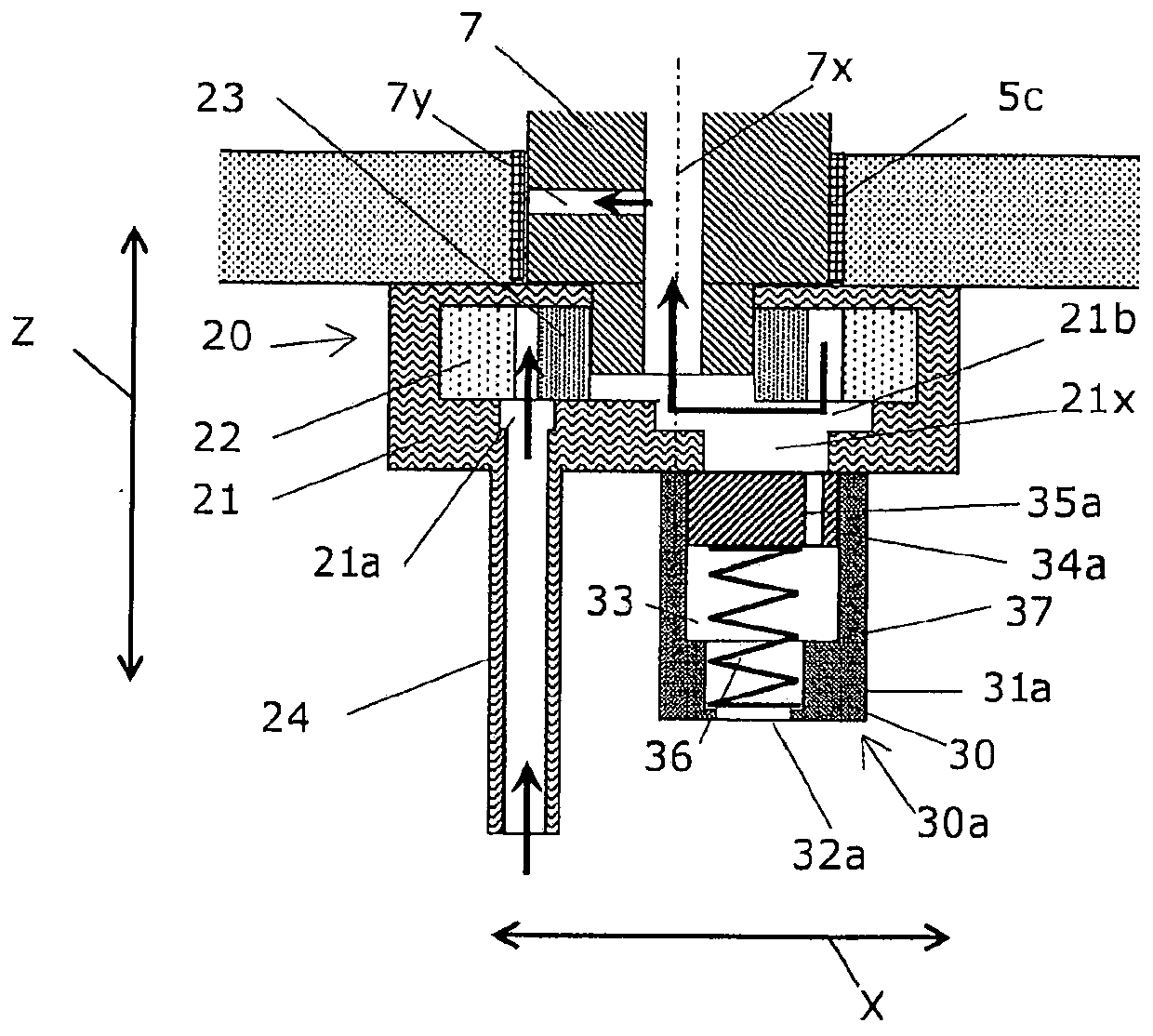

[0074] Figure 7 It is a schematic longitudinal sectional view showing a compressor according to Embodiment 2 of the present invention. Next, compressor 200 according to Embodiment 2 of the present invention will be described. The compressor 200 according to Embodiment 2 of the present invention differs from the compressor 100 according to Embodiment 1 of the present invention only in the structure of the differential pressure oil supply mechanism 30a.

[0075] Figure 8 It is a schematic diagram showing the behavior of the differential pressure oil supply mechanism when the rotational speed of the compressor according to Embodiment 2 of the present invention is lower than the first rotational speed threshold value N1. Figure 9 It is a sectional view showing the behavior of the differential pressure oil supply mechanism when the rotational speed of the compressor according to Embodiment 2 of the present invention is equal to or greater than the first rotational speed thresh...

Embodiment approach 3

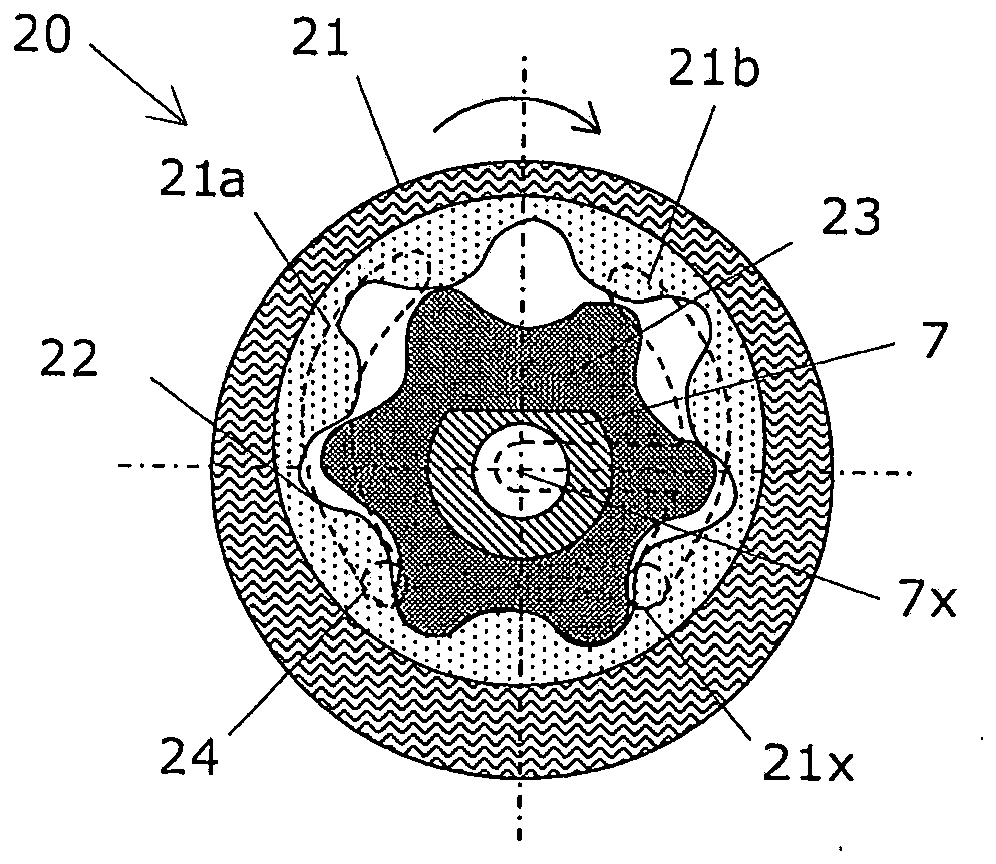

[0090] Figure 12 It is a cross-sectional view of a pressure differential oil supply mechanism of a compressor according to Embodiment 3 of the present invention.

[0091] Next, compressor 300 according to Embodiment 3 of the present invention will be described. The compressor 300 according to Embodiment 3 of the present invention differs from the compressor 200 according to Embodiment 2 of the present invention only in the shape of the casing 31b, which is the case where the shape of the valve body 34b is cylindrical. First, refer to Figure 12 , the structure of the differential pressure oil supply mechanism 230a of the compressor 300 according to Embodiment 3 of the present invention will be described. In addition, pairs with Figure 1 to Figure 11 Parts having the same configuration as the compressors are denoted by the same reference numerals, and description thereof will be omitted.

[0092] A differential pressure oil supply mechanism 230a is provided below the oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com