Gas-liquid combined hydraulic impacter

A hydraulic impactor, gas-liquid combination technology, applied in the directions of portable impact tools, striking tools, fluid pressure actuating devices, etc., can solve the problems of large back pressure resistance in the front cavity, vibration and noise, affecting the working life of valves and pistons, etc. , to achieve the effect of high energy utilization rate, long working life, and sufficient fuel supply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] A specific implementation of a gas-hydraulic combined hydraulic impactor will be described in detail below with reference to the accompanying drawings.

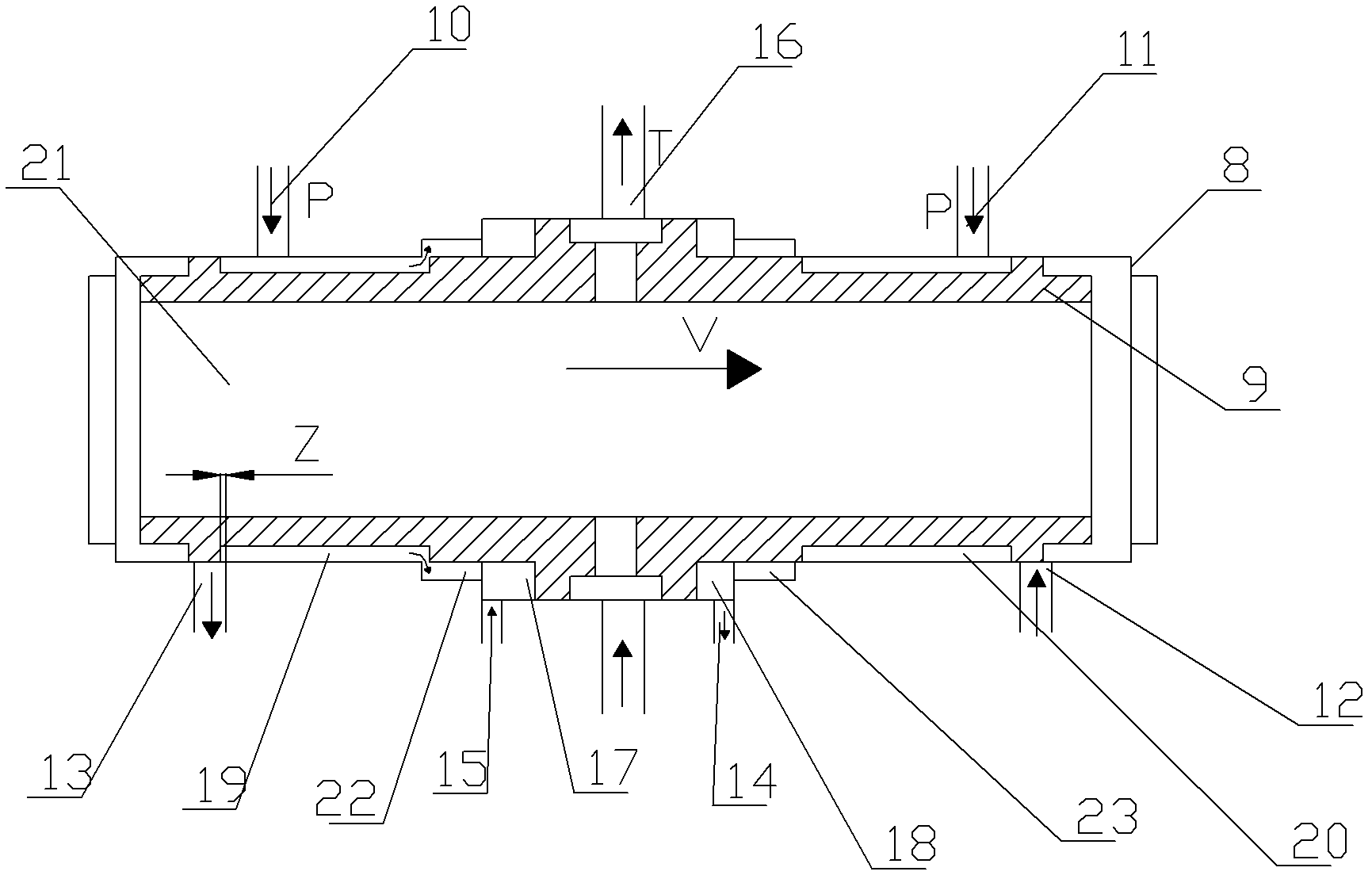

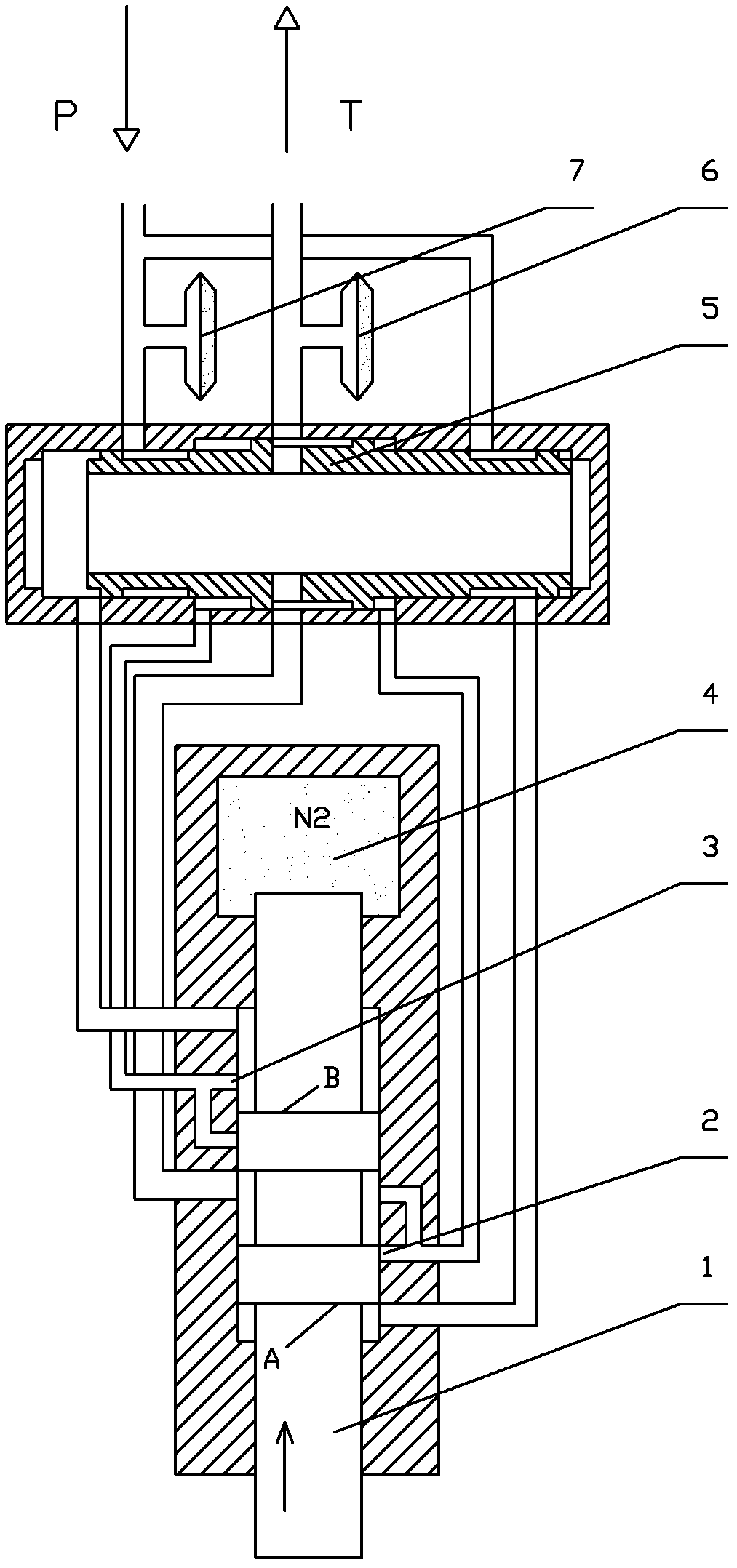

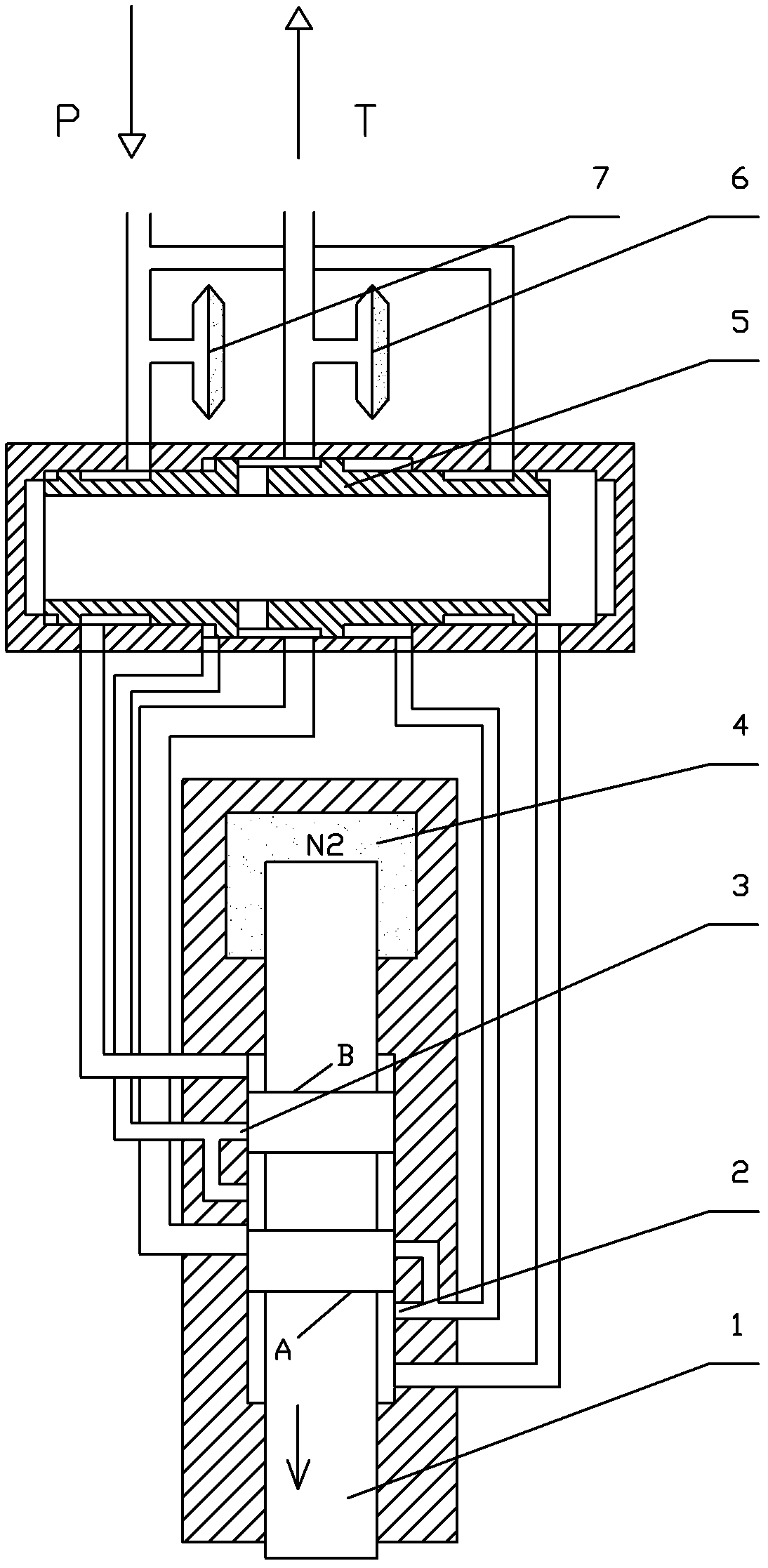

[0016] A gas-hydraulic combined hydraulic impactor, including a double-sided oil inlet and discharge impactor, the double-sided oil inlet and discharge impactor includes a piston 1, a hydraulic control reversing valve and an oil circuit, and the double-sided oil inlet and discharge impactor The tail end of the piston 1 is provided with a nitrogen chamber 4, the connection between the nitrogen chamber 4 and the piston 1 is sealed and the tail end of the piston 1 is arranged in the nitrogen chamber 4 during the return stroke and stroke. Inside, the hydraulic control reversing valve includes a valve body 8 and a valve core 9, the valve core 9 is installed in the valve body 8, and the valve body 8 includes two high-pressure oil inlets (10, 11), one Piston-cylinder front chamber connection port 12, a piston-cylinder rear ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com