Special oil lubrication solid bearing seat for ventilating machine

A fan and bearing seat technology, which is applied to the components of the pumping device for elastic fluid, mechanical equipment, machine/engine, etc., can solve the problem of affecting the output rate of industrial products, being easily corroded, and affecting the service life of the fan. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

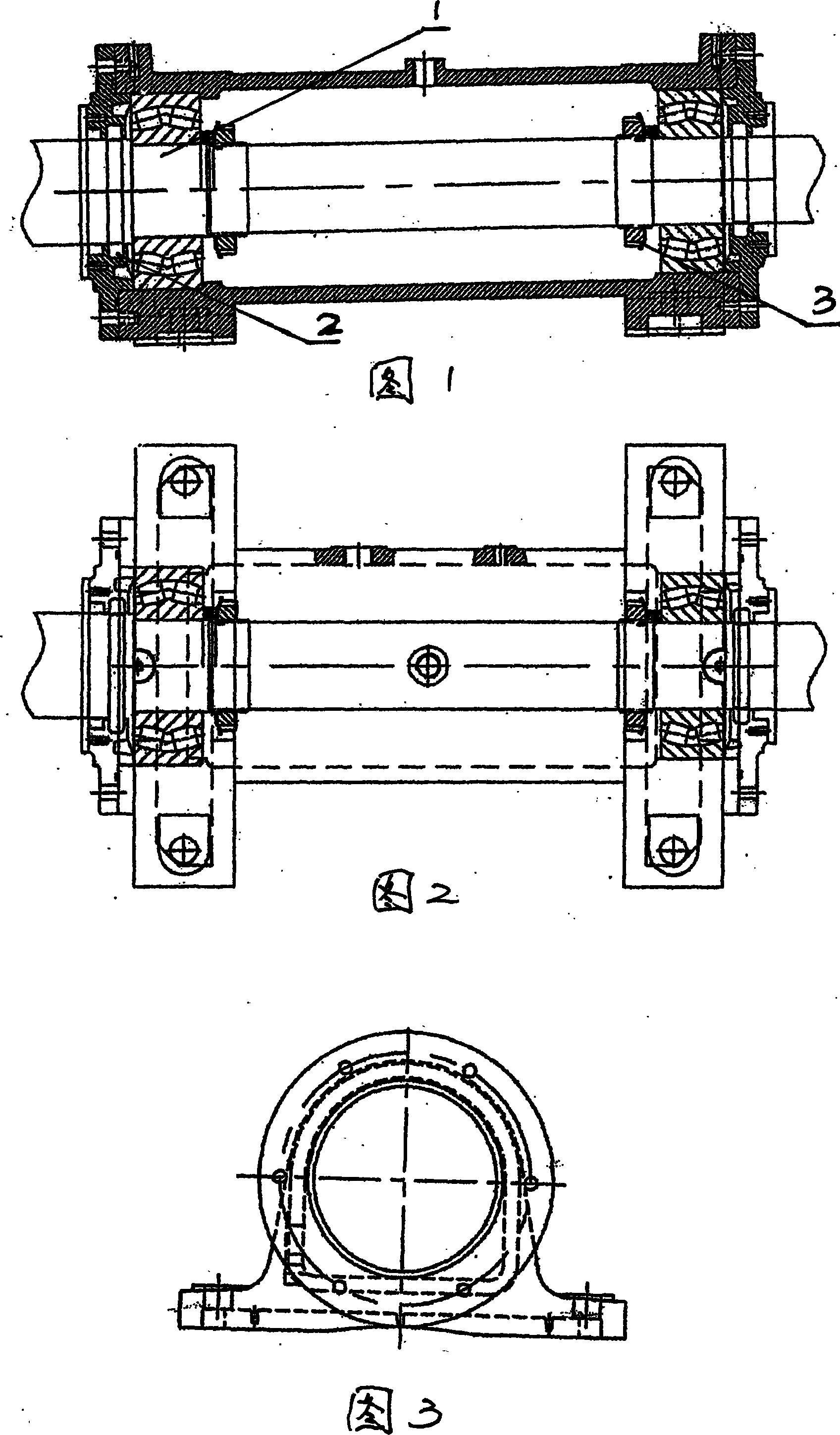

[0011] Describe in detail below in conjunction with accompanying drawing:

[0012] In the fan structure, there are two bearings (3) on the fan rotor (1), and there is a labyrinth oil passage (2) in front of the bearings to supply oil to ensure the normal operation of the bearings and oil seals, so that the rotor and bearings can A relatively good closed environment is formed to ensure that the bearings and internal units are not corroded.

[0013] In specific implementation, the oil circuit can also adopt a multi-curve reciprocating structure to ensure oil recovery and circulation.

[0014] In addition, the two bearings can be designed into a structure with little difference in size to increase the strength of the mechanical load and avoid damage to the life of the fan due to the bottleneck principle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com