Thin-wall oil tank of unmanned helicopter

An unmanned helicopter and fuel tank technology, which is applied to the fuel tank and weight reduction of the power unit, can solve the problems of increasing the weight of the fuselage, shortening the working time of the aircraft, and small fuel tank capacity, so as to increase the aircraft load and reduce its own weight. , The effect of increasing the oil load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiment of the present invention is described below by example:

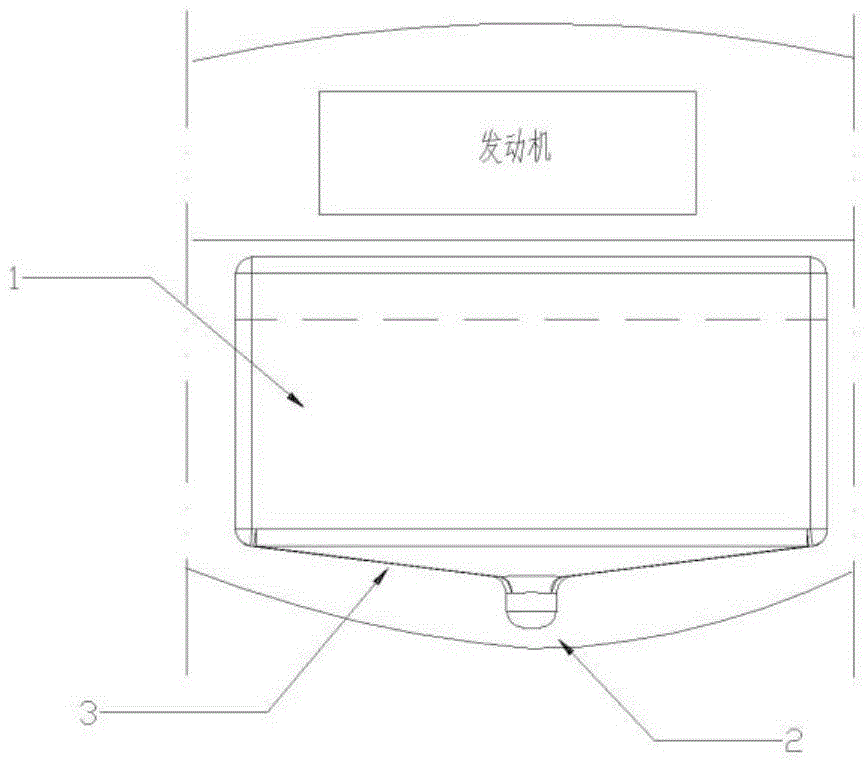

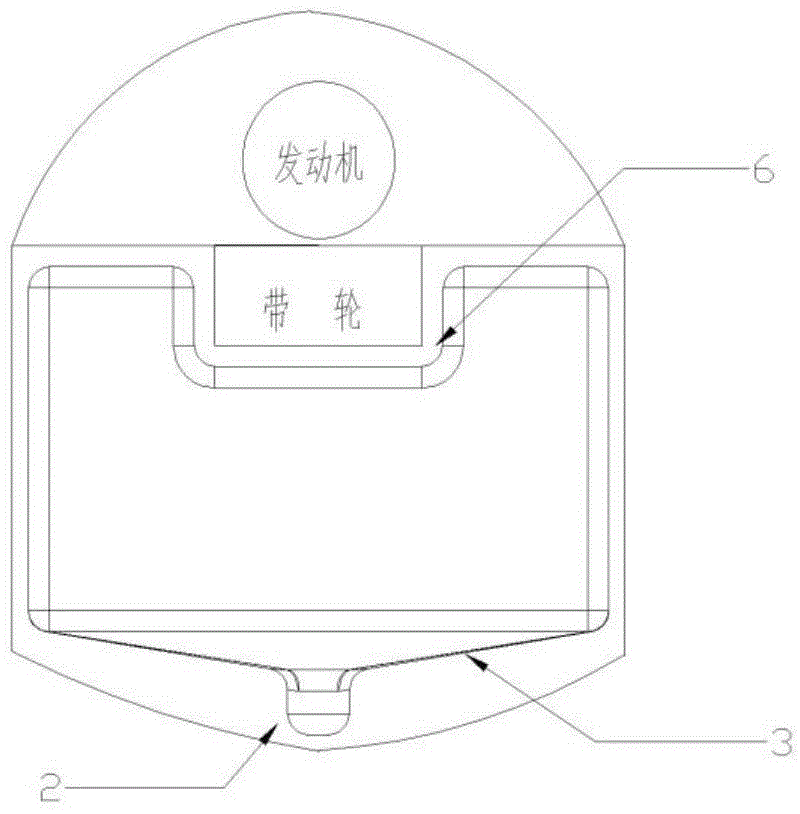

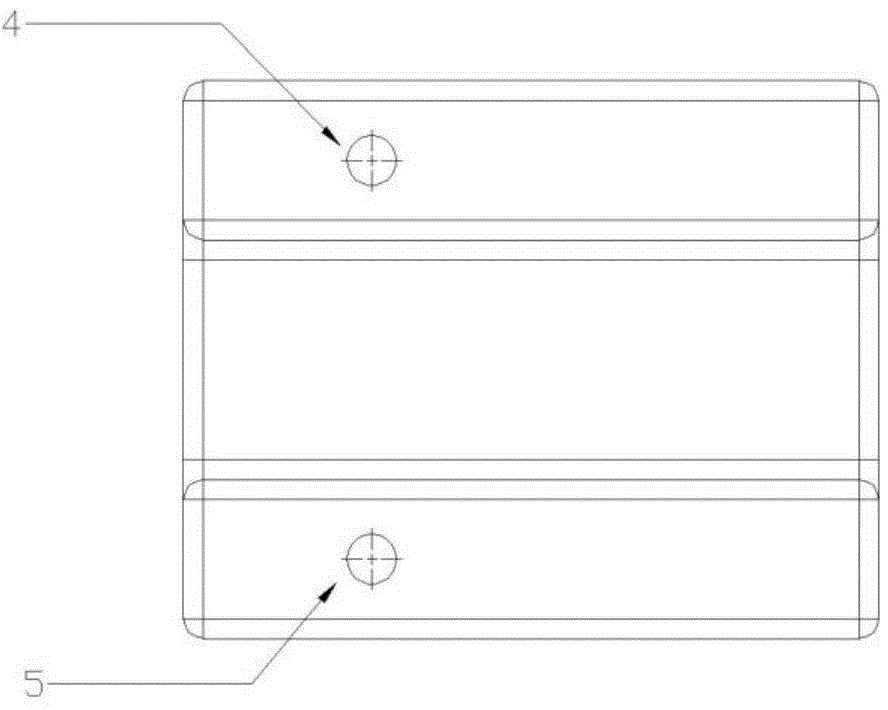

[0025] See figure 1 — Figure 5 , a kind of unmanned helicopter thin-walled fuel tank of the present invention, it is a kind of cubic special-shaped structure, and this structure is formed by connecting and combining upper and lower two parts; Its upper part is the cube structure with groove, and its lower part is made of 4 The triangular plates are spliced into a slope structure and an oil vortex is arranged at the bottom. The interior of the fuel tank is composed of a sponge, a weight and an oil inlet pipe. Because there will be a small amount of residue at the bottom when the fuel tank is filled with oil, after adding the sponge, it can ensure sufficient oil absorption, and at the same time, the oil can directly filter out the residue through the sponge and enter the oil pipe. The design of the heavy hammer is to ensure that the fuel intake is always at the bottom due to gravity, and the slope ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com