Zein composite particle, delivery system, preparation method and application

A technology of zein and composite particles, which is applied to pharmaceutical formulations, cosmetic preparations, cosmetic preparations, etc., can solve the problems of small oil load, inability to realize redispersion of composite particles, poor stability, etc., and achieve high load Effects of oil quantity, excellent pH stability, excellent dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Preparation of zein solution: Dissolve NaOH in deionized water to prepare 100ml of strong alkaline solution with pH=13, add 0.5g zein (cas:9010-66-6, sigma), and sonicate for 10s A strong alkaline solution of zein was obtained. Solution A is obtained. 0.25g NaIO4 oxidized cellulose was dissolved in 100ml deionized water to obtain dispersion B.

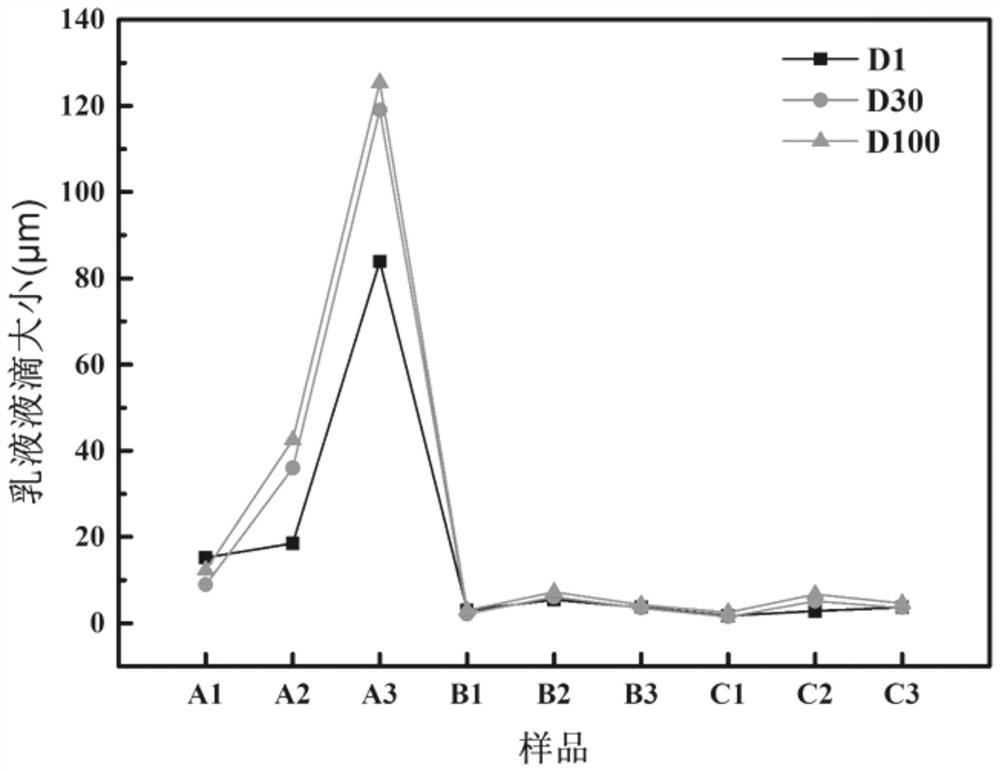

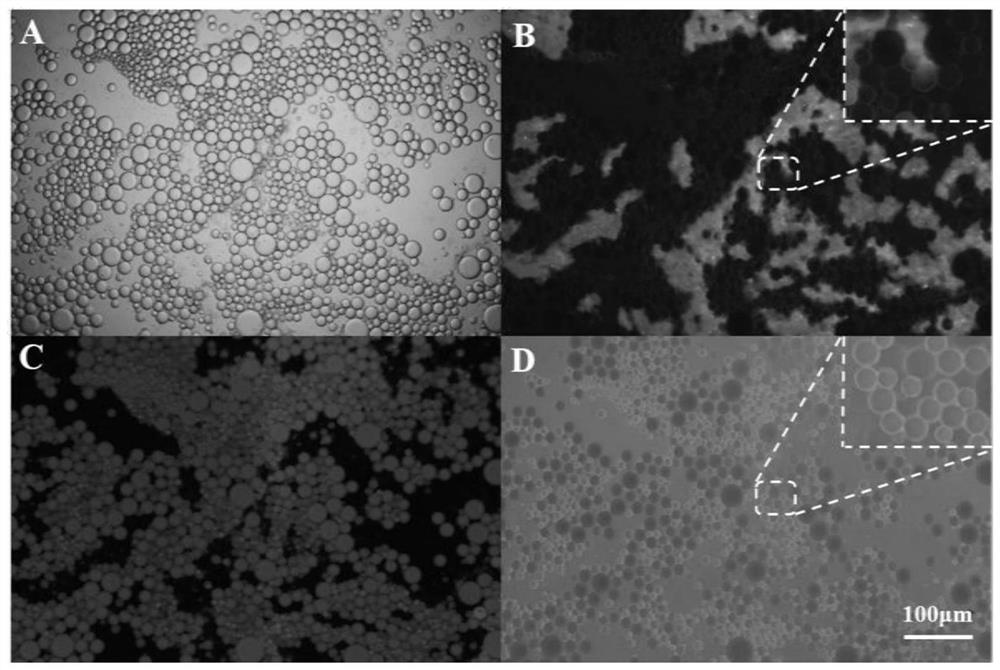

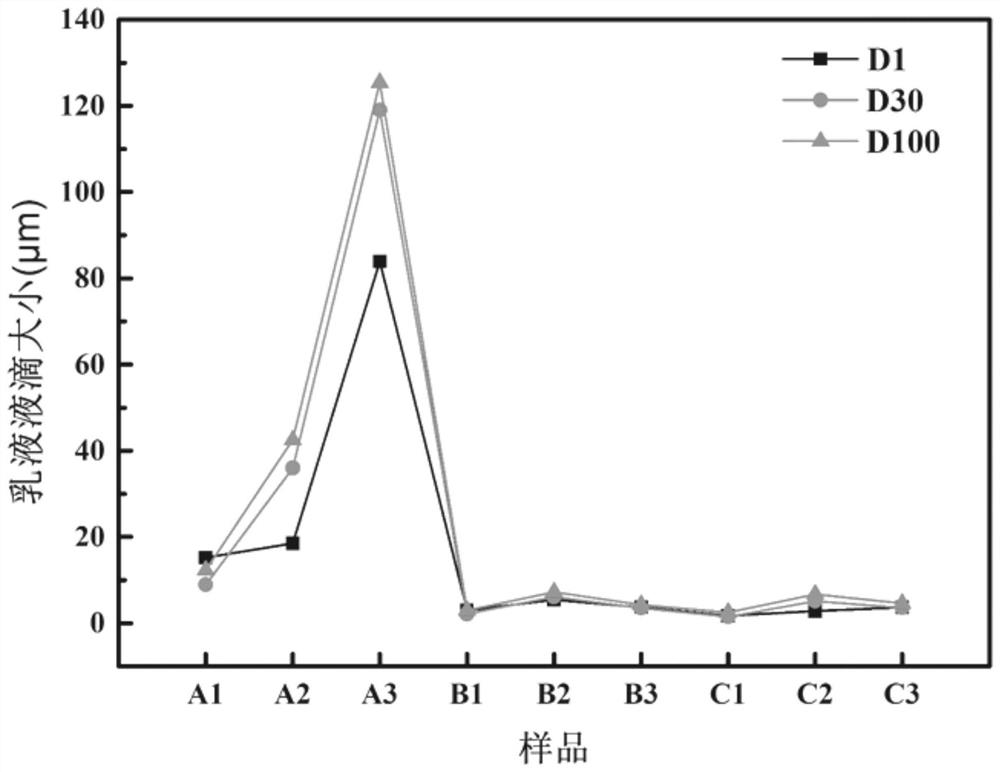

[0042] (2) Synthesis of composite particles: uniformly mix solution A and dispersion B, sonicate for 20s, then adjust pH=13, react at 80°C for 4 hours, adjust pH=7 to obtain zein / cellulose composite particles Dispersion; centrifuged, washed, freeze-dried Composite particle 1 , The measured particle diameters of the particles at pH=5, 7, and 9 are listed in Table 1.

[0043] (3) Preparation of Pickering emulsion: the Composite particle 1 . Water and corn oil are prepared by homogenizing at 8000r / min for 1min with a weight ratio of 0.02:4:6, 0.25:5:5, 0.03:6:4 Emulsion system 1 .

Embodiment 2

[0045] (1) Preparation of zein solution: Dissolve NaOH in deionized water to prepare 100 ml of strong alkaline solution with pH=13, add 0.50 g of zein (cas:9010-66-6, sigma), and sonicate for 10 s A strong alkaline solution of zein was obtained. Solution A is obtained. 0.50gNaIO 4 Oxidized cellulose was dissolved in 100 ml of deionized water to obtain dispersion B.

[0046] (2) Synthesis of composite particles: uniformly mix solution A and dispersion B, sonicate for 20s, then adjust pH=13, react at 80°C for 4 hours, adjust pH=7 to obtain zein / cellulose composite particles Dispersion; centrifuged, washed, freeze-dried Composite particles 2 , The measured particle diameters of the particles at pH=5, 7, and 9 are listed in Table 1.

[0047] (3) Preparation of Pickering emulsion: the Composite particles 2. The weight ratio of water and corn oil is 0.02:4:6, 0.25:5:5, 0.03:6:4 and prepared by homogenizing at 8000r / min for 1min Emulsion system 2 .

Embodiment 3

[0049] (1) Preparation of zein solution: Dissolve NaOH in deionized water to prepare 100 ml of strong alkaline solution with pH=13, add 0.50 g of zein (cas:9010-66-6, sigma), and sonicate for 10 s A strong alkaline solution of zein was obtained. Solution A is obtained. 1.00g NaIO4 oxidized cellulose was dissolved in 100ml deionized water to obtain dispersion B.

[0050] (2) Synthesis of composite particles: uniformly mix solution A and dispersion B, sonicate for 20s, then adjust pH=13, react at 80°C for 4 hours, adjust pH=7 to obtain zein / cellulose composite particles Dispersion; centrifuged, washed, freeze-dried Composite particles 3 , The measured particle diameters of the particles at pH=5, 7, and 9 are listed in Table 1.

[0051] (3) Preparation of Pickering emulsion: the Composite particles 3 . Water and corn oil are prepared by homogenizing at 8000r / min for 1min with a weight ratio of 0.02:4:6, 0.25:5:5, 0.03:6:4 Emulsion system 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com