Piston for internal combustion engine

An internal combustion engine and piston technology, which is applied in the field of pistons for internal combustion engines, can solve problems such as fracture, hindering the high rotation or compactness of the engine, and increasing the weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

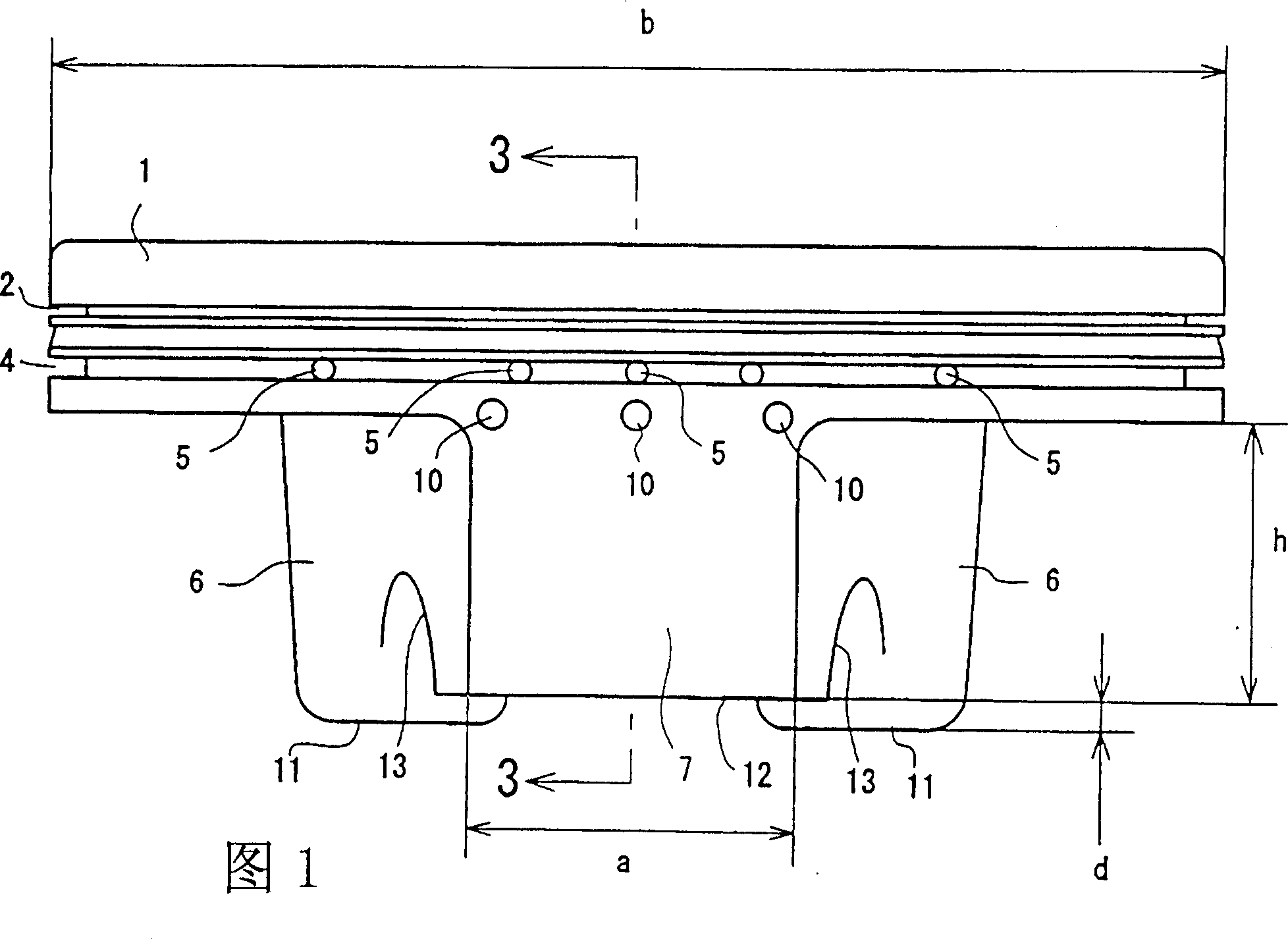

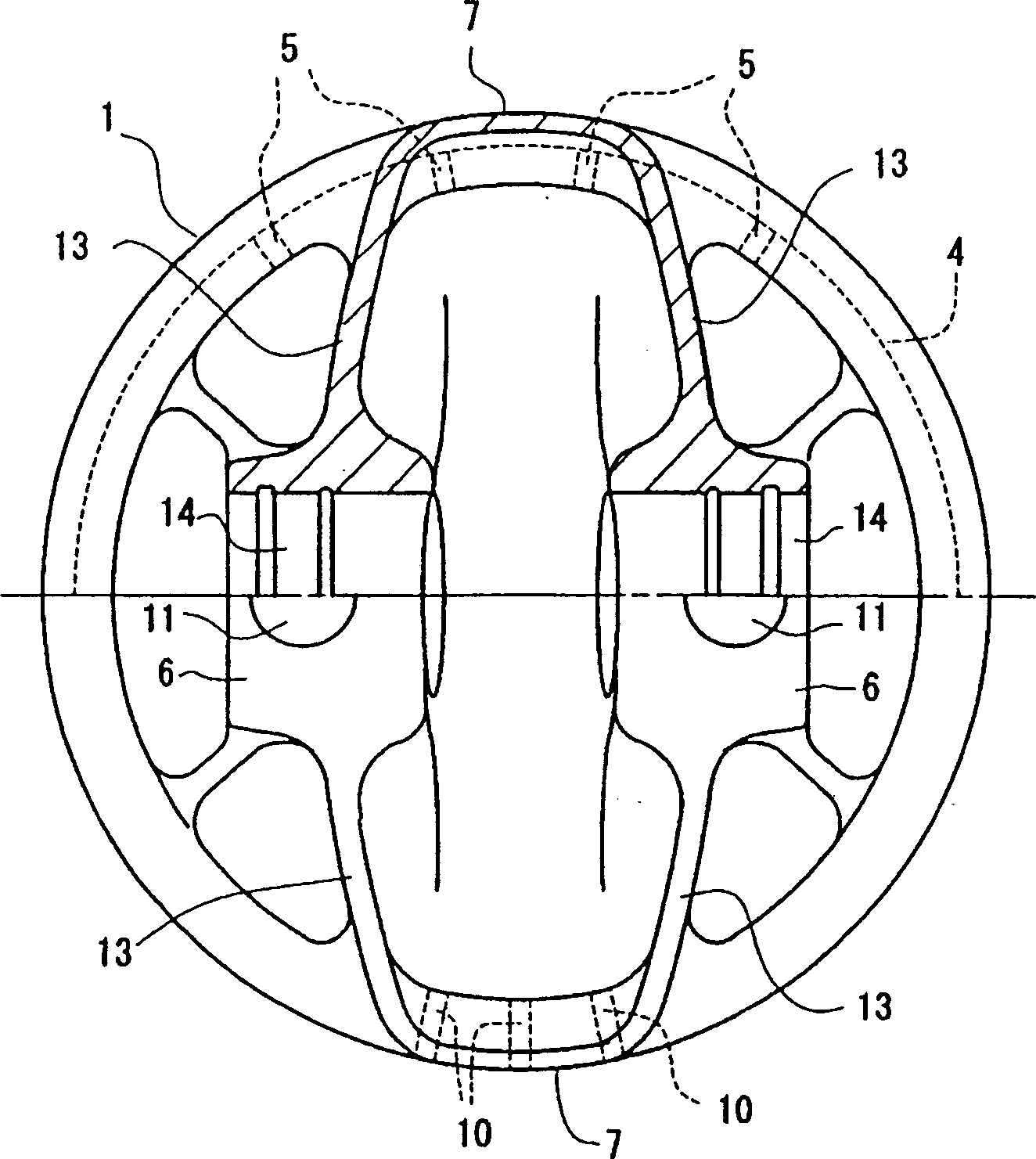

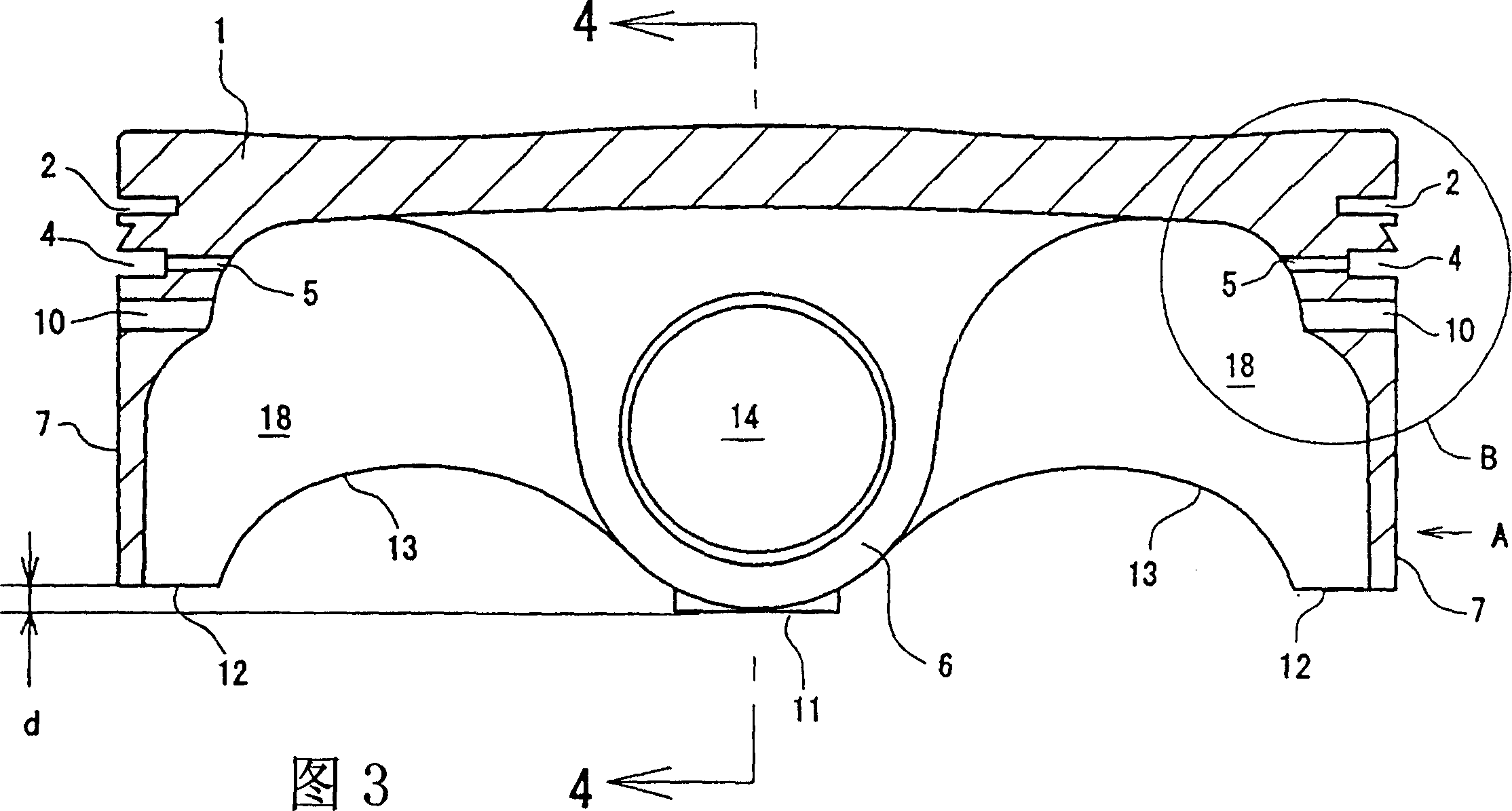

[0022] An embodiment will be described below with reference to the drawings. Fig. 1 is the front view (A arrow direction of Fig. 3) of the present embodiment piston, figure 2 It is a bottom view showing a half section from a piston pin seat to a skirt, and FIG. 3 is a cross-sectional view taken along line 3-3 in FIG. 1 . Figure 4 It is a sectional view of line 4-4 in FIG. 3 . Figure 5 It is an enlarged view of part B of FIG. 3 . Common symbols are used for parts common to the conventional example of FIG. 6 .

[0023] In FIG. 1, a first gas ring groove 2 is formed around the side surface of a crown 1, and an oil ring groove 4 is formed below it. On the bottom of the oil ring groove 4 , oil supply holes 5 are formed to penetrate inside and outside at appropriate intervals, and oil is supplied from the inner side of the piston to the surface side through the oil supply holes 5 . A pair of piston pin seat portions 6 and a skirt portion 7 are formed at the bottom of the crown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com